Académique Documents

Professionnel Documents

Culture Documents

Arc Welder Risk MG T Form

Transféré par

Mohd FikryTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Arc Welder Risk MG T Form

Transféré par

Mohd FikryDroits d'auteur :

Formats disponibles

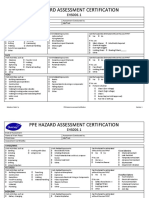

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: January 2012

Last Reviewed: August 2015

Page Number: 1 of 9

CENTRAL OFFICE USE ONLY

Next Review Date: August 2017

1. Hazard Management Details General

Make/Model No.:

Serial No.:

Work Location:

Plant/Equipment Item: ELECTRIC Arc WELDER

School:

Region:

Name of Person(s) Conducting Activity:

Date Conducted:

Description of Use:

An ARC welder is a machine used to

join two or more metals together.

It works by drawing upon a high voltage

electrical power source to create an arc

between an electrode and the base of a

substance (e.g. wrought iron or

aluminum).

This arc creates enough sustained high

heat temperatures to melt the metal at

the point of the arc allowing the metals

to fuse and create a weld.

Electrodes come in two different types.

They are either consumable or nonconsumable depending on if the

electrode is actually used up in the

welding process or is able to be reused.

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

Summary of Key Risks:

(refer to appropriate subsections):

Impact and cutting

Radiation

Radiation

Slips/trips/falls

Fire and explosion

Temperature

Other (gases and fumes)

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: January 2012

Page Number: 2 of 9

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

2. Documentation

Relevant Legislation/Standards

Is plant required to be registered?

Y/N

Y

N

Is a user license required?

Comments

AS 1674.1 Safety in welding and allied processes - Fire precautions

AS 1674.2 Safety in welding and allied processes - Electrical

AS 4024.1 Safety of machinery

Key reference material:

AS/NZS 3760: In service safety inspection and testing of electrical equipment

AS 60974.1 Arc welding equipment Welding power sources

AS 60974.11 Arc welding equipment Electrode holders

Plant Documentation

Are operators manuals accessible?

Y/N

Y

N

Comments

insert location

Is this a restricted use item?

(Insert restriction details)

Does this item require safe use

documents/test?

Safe use documents/test

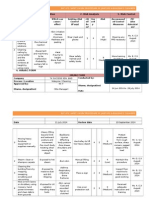

3. Hazard Identification

Hazards Inspected

ENTANGLEMENT

Can anyones hair, clothing, gloves, cleaning

brushes, tools, rags or other materials become

entangled with moving parts of the plant or

materials?

Risk Assessment

Cons

Like

Risk

Level

Y

Description of Risk

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

Control Measures

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: January 2012

Page Number: 3 of 9

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Hazards Inspected

Risk Assessment

Cons

Like

Risk

Level

IMPACT OR CUTTING INJURY

Can anyone be crushed/cut/struck etc. due to:

Material falling off the plant?

The plant tipping or rolling over?

Parts of the plant disintegrating or collapsing?

Uncontrolled/unexpected movement of

plant/load?

Lack of capacity to slow, stop or immobilise plant?

Contact with moving parts during testing,

inspection, operation, maintenance, cleaning

or repair?

Being thrown off or under the plant?

Contact with sharp or flying objects? (e.g.

work pieces being ejected)

The mobility of the plant?

Inappropriate parts and accessories being

used?

Other

Major

Moderat

e

Possibl

e

High

Possibl

e

Mediu

m

Description of Risk

Control Measures

Spitting metal may cause

burns/eye injury to

operator/bystanders.

Ensure appropriate screening is

in place to protect the

surrounding workspace.

Unexpected movement of the

plant (i.e. hoses getting

caught on an object) may

cause misdirection of torch.

Ensure inappropriate material is

not used in the welding process.

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

Ensure equipment is correctly

installed and regularly serviced

as per manufacturers service

and schedule instructions.

Ensure operator has been

trained in safe work practices

and appropriate PPE (e.g. eye

protection/welding mask,

gloves, apron is worn during

operation).

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: January 2012

Page Number: 4 of 9

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Risk Assessment

Cons

Like

Risk

Level

Hazards Inspected

SHEARING

Can anyones body parts be sheared between

two parts of plant, or between a part of the plant

and a work piece or structure?

PRESSURISED CONTENT

Can anyone come into contact with fluids or

gases under high pressure, due to plant failure or

misuse of the plant?

ELECTRICITY

Can anyone be injured or burnt due to:

Live electrical conductors? (e.g. exposed wires)

Working in close proximity to electrical

conductors?

Access to electricity?

Damaged or poorly maintained electrical

leads, cables or switches?

Water near electrical equipment?

Lack of isolation procedures?

Other

Major

Unlikel

y

Mediu

m

Major

Unlikel

y

Mediu

m

Major

Unlikel

y

Mediu

m

Major

Unlikel

y

Mediu

m

Description of Risk

Potential for the welder to

receive a shock by

simultaneously touching the

electrode and work piece

poses an electrical hazard.

Damaged or frayed electrical

leads pose an electrical

hazard.

Electrical leads that have not

been tested and tagged as

specified in AS 3760 pose an

electrical hazard.

An electrode holder that is

not fully insulated (damaged

or worn) poses an electrical

hazard.

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

Control Measures

Operator to wear appropriate

clothing and PPE while welding.

Ensure welder is be set to an

appropriate voltage.

Where possible provide rubber

insulating matting.

Operator to check for damaged

electrical cords prior to use.

Avoid welding in wet areas or

welding in wet or damp clothing

Ensure equipment is regularly

serviced, tested and tagged and

appropriate isolation procedures

(e.g. lock out tags) are in place.

Operator to check for wear or

damage to electrode holder

prior to use.

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: January 2012

Page Number: 5 of 9

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Hazards Inspected

Risk Assessment

Cons

Like

Risk

Level

Description of Risk

Control Measures

Risk Assessment

Cons

Like

Risk

Level

Description of Risk

Control Measures

ERGONOMICS

Can anyone be injured due to:

Poorly designed workstation?

Repetitive body movement?

Constrained body posture or the need for

excessive effort?

Design deficiency causing psychological

stress?

Inadequate or poorly placed lighting?

Does the plant impact on the surrounding

workplace and create potential hazards?

(Consider safe access and egress from plant,

workflow and design of the workplace)

Is the location of the plant inappropriate?

(Consider potential effects due to

environmental conditions and terrain)

Other

Hazards Inspected

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: January 2012

Page Number: 6 of 9

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Hazards Inspected

RADIATION

Can anyone using the plant, or in the vicinity of

the plant suffer injury or illness due to exposure to

radiation in the form of any of the following:

infra-red radiation

ultra violet light

microwaves

NOISE

Can anyone using the plant, or in the vicinity of

the plant, suffer injury due to exposure to noise?

VIBRATION

Can anyone be injured or suffer ill-health from

exposure to vibration?

FRICTION

Can anyone be burnt due to contact with moving

parts, materials or surfaces of the plant?

SUFFOCATION

Can anyone be suffocated due to lack of oxygen,

or atmospheric contamination?

CONDITION

Is a hazard likely due to the age and condition of

the plant? (Consider how hard the machine has

been worked, and whether it is used constantly or

rarely).

Can anyone be injured as a result of the plant

not serviced appropriately and/or maintained

in line with manufacturers recommendations?

Risk Assessment

Moderat Possibl Mediu

e

e

m

Description of Risk

UV light generated by the

welding process can cause

inflammation of the cornea

otherwise known as welders

flash.

Control Measures

Ensure operator/observers are

wearing appropriate eye wear

(e.g. welders mask). Include in

safe work procedures.

Ensure appropriate screening is

in place to protect the

surrounding work areas. Include

in safe work procedures.

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: January 2012

Page Number: 7 of 9

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Hazards Inspected

SLIPS/TRIPS/FALLS

Can anyone using the plant, or in the vicinity of

the plant, slip, trip or fall due to:

Uneven, slippery or steep work surfaces?

Poor housekeeping, e.g. spillage in the vicinity?

Obstacles being placed in the vicinity of the

plant?

Inappropriate or poorly maintained floor or

walking surfaces (i.e. lack of a slip-resistant

surface, unprotected holes, penetrations or

gaps?)

If operating or maintaining plant at height can

anyone slip, trip or fall due to:

Use of work platforms, stairs or ladders?

Lack of guardrails or other suitable edge

protection?

Other

Risk Assessment

Cons

Like

Risk

Level

Hazards Inspected

FIRE AND EXPLOSION

Can anyone be injured by fire?

Minor

Minor

Possibl

e

Mediu

m

Possibl

e

Mediu

m

Risk Assessment

Cons

Like

Risk

Level

Y

Moderat

e

Possibl

e

Mediu

m

Description of Risk

Control Measures

Poor housekeeping practices

allowing the build-up of

waste materials or failure to

immediately clean up spills

could result in a slip hazard.

Ensure appropriate cleaning

and housekeeping practices are

maintained to minimise the risk

of a slip, trip or fall.

Inappropriate placement of

objects (e.g. spare materials,

electric cords, bags etc) in

the immediate vicinity of the

plant equipment may result in

a trip hazard.

Description of Risk

Electrodes, hot metal,

spitting metal and sparks

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

Control Measures

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: January 2012

Page Number: 8 of 9

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Hazards Inspected

Can anyone be injured by explosion of

gases, vapours, liquids, dusts, or other

substances?

Risk Assessment

Description of Risk

may become an ignition

source if flammable material

is in the immediate vicinity

(e.g. wood dust, rags etc).

Control Measures

Ensure good housekeeping

practices are maintained around

the arc welder.

Allow hot metal to cool prior to

handling.

Provide a fire spotter when work

is being carried out.

Ensure appropriate fire

extinguishers are available and

accessible at all times. Provide

instruction to employees and

students on how to use fire

equipment.

TEMPERATURE/MOISTURE

Can anyone come into contact with objects at

high or low temperatures?

Can anyone suffer ill-health due to exposure

to high or low temperatures?

Can anyone be injured or suffer ill-health due

to exposure to moisture?

Moderat

e

Possibl

e

Mediu

m

Hot electrodes, hot metal,

spitting metal and sparks

may come into contact with a

person.

Ensure appropriate PPE (e.g.

gloves, apron and welding

mask) is worn whilst operating

the arc welder.

Allow hot metal to cool prior to

handling.

Ensure appropriate fire fighting

equipment/systems are in

place.

OTHER

Can anyone be injured or suffer ill-health from

exposure to:

Ensure work area is

appropriately ventilated when in

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

No: DET ESWB-10-2-2

Authorised By: Manager ESWB

Title: Plant and Equipment Risk Management Form

Issue Date: January 2012

Page Number: 9 of 9

CENTRAL OFFICE USE ONLY

Last Reviewed: August 2015

Next Review Date: August 2017

Hazards Inspected

Chemicals?

Toxic gases or vapours?

Fumes/Dusts?

Other? (please specify)

Risk Assessment

Y

Moderat

e

Moderat

e

Possibl

e

Possibl

e

Mediu

m

Mediu

m

Description of Risk

Fumes and gases produce

during arc welding may be

hazardous to health.

4. Risk Assessment Signoff

Authorised By:

Signature:

THIS DOCUMENT IS UNCONTROLLED WHEN PRINTED

Date:

Control Measures

operation (e.g. exhaust

extraction).

Vous aimerez peut-être aussi

- Yellow Book Within Words PatternsDocument54 pagesYellow Book Within Words Patternsapi-269897268Pas encore d'évaluation

- Hajj and Umrah Step by StepfDocument12 pagesHajj and Umrah Step by StepfMohiddin MohammadPas encore d'évaluation

- Manual Handling ChartDocument20 pagesManual Handling ChartTatak Bay Ahmed100% (1)

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathPas encore d'évaluation

- Risk Assessment ActivityDocument5 pagesRisk Assessment ActivityHarthwell CapistranoPas encore d'évaluation

- HAZARDS AND RISKS EXPLAINEDDocument20 pagesHAZARDS AND RISKS EXPLAINEDJhunrey ObnialaPas encore d'évaluation

- Chisels Risk AssessmentDocument1 pageChisels Risk AssessmentTawfik Mohamed Abu Zaid100% (1)

- JHA for Hill Cutting Activities at Port of SalalahDocument8 pagesJHA for Hill Cutting Activities at Port of SalalahSreekumarPas encore d'évaluation

- Sample-Risk Assessment & Safe Work Method StatementDocument4 pagesSample-Risk Assessment & Safe Work Method StatementioanchiPas encore d'évaluation

- National Safety Week Program AgendaDocument3 pagesNational Safety Week Program AgendaDJadee Anuppur AmlaiPas encore d'évaluation

- Measuring health and safety performanceDocument31 pagesMeasuring health and safety performancesohaibPas encore d'évaluation

- Ppe Hazard AssessmentDocument4 pagesPpe Hazard AssessmentNeha PatelPas encore d'évaluation

- Fight On! - Issue #007Document90 pagesFight On! - Issue #007gilgoos100% (3)

- Procedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresDocument10 pagesProcedure For Identification of Environmental Aspects, Hazards, Evaluation of Impacts, Risks and Determination of Control MeasuresradhouanePas encore d'évaluation

- PR 15 Hira Procedure Bim& Tim r1Document17 pagesPR 15 Hira Procedure Bim& Tim r1Purna Chandra BaruaPas encore d'évaluation

- HIRAC - Work - at - Height - Template PDFDocument8 pagesHIRAC - Work - at - Height - Template PDFRohma Desi ThirtasariPas encore d'évaluation

- Grammer TestDocument28 pagesGrammer TestAruran Arulanantham100% (2)

- Autoclaves - Generic Assessment - L Use of AutoclavesDocument1 pageAutoclaves - Generic Assessment - L Use of AutoclavesaKureishiPas encore d'évaluation

- PC200-8M0 OmmDocument397 pagesPC200-8M0 Ommwawan wardianto100% (4)

- Comprehensive Preparedness ManualDocument403 pagesComprehensive Preparedness Manual151177yeshua100% (2)

- Unsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentDocument5 pagesUnsafe Act, Unsafe Condition, Nearmiss & IncidentaccidentTayyab Hasnain Saadat JanjuaPas encore d'évaluation

- Phrasal Verbs CAEDocument17 pagesPhrasal Verbs CAEmarsorianobeb100% (11)

- Toolbox Safety EssentialsDocument8 pagesToolbox Safety Essentialsbeng acostaPas encore d'évaluation

- JSA ScaffoldingDocument2 pagesJSA Scaffoldingmyco samPas encore d'évaluation

- The Little FoxDocument6 pagesThe Little Foxvaytiare.lopez1100% (3)

- How To Make Your Own Knives - Jim Mayes (S)Document185 pagesHow To Make Your Own Knives - Jim Mayes (S)karnizsdjuro83% (12)

- Shazia's Unique Story Tests Her FaithfulnessDocument71 pagesShazia's Unique Story Tests Her FaithfulnessSaba Ali80% (5)

- Maintenance of Hand and Power Tools Procedure (VET)Document6 pagesMaintenance of Hand and Power Tools Procedure (VET)taufikPas encore d'évaluation

- Candidate's observation sheet identifies health and safety risksDocument8 pagesCandidate's observation sheet identifies health and safety risksMarya HasniPas encore d'évaluation

- 28.1.1 Mobile Equipment Inspection ChecklistDocument1 page28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemPas encore d'évaluation

- Personal Protective Equipment PPEDocument34 pagesPersonal Protective Equipment PPEKaren Dela TorrePas encore d'évaluation

- ESH Compliance Check List: Noise ControlDocument1 pageESH Compliance Check List: Noise ControlRichard BaileyPas encore d'évaluation

- Job Safety Assessment (Jsa)Document19 pagesJob Safety Assessment (Jsa)Saravanan Sara0% (1)

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerPas encore d'évaluation

- Nebosh IGC 3 Observation Sheet 00218445 FinalDocument13 pagesNebosh IGC 3 Observation Sheet 00218445 FinalNahaz HydrosePas encore d'évaluation

- Welding PPE GuideDocument9 pagesWelding PPE Guidecyrelle rose jumentoPas encore d'évaluation

- 01-Ppe Eng PDFDocument17 pages01-Ppe Eng PDFZaki AdamouPas encore d'évaluation

- Technical Drilling SafetyDocument4 pagesTechnical Drilling SafetyjihadspiritPas encore d'évaluation

- Safe Hoisting and Rigging ProceduresDocument3 pagesSafe Hoisting and Rigging ProceduresAditya Raj MishraPas encore d'évaluation

- RA Arc, Welding 150310Document4 pagesRA Arc, Welding 150310Mohd FikryPas encore d'évaluation

- Red by W. Somerset MaughamDocument15 pagesRed by W. Somerset MaughamMasha Shapurko100% (1)

- Clothes and Accessories Vocabulary Esl Picture Dictionary Worksheets For Kids PDFDocument6 pagesClothes and Accessories Vocabulary Esl Picture Dictionary Worksheets For Kids PDFgilca.monicaluizaPas encore d'évaluation

- Safety & Health ProgramDocument2 pagesSafety & Health ProgramD.k. PathakPas encore d'évaluation

- TSTI FormDocument2 pagesTSTI FormJinu ThomasPas encore d'évaluation

- JSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedDocument13 pagesJSA For Refurbishing and Repainting 23oct2017 (Woqod LPG Plant) UpdatedJoseph PerezPas encore d'évaluation

- MSDS - Asada Threading Oiil Red - ENDocument7 pagesMSDS - Asada Threading Oiil Red - ENnghiaPas encore d'évaluation

- Building De-Dusting JSADocument3 pagesBuilding De-Dusting JSAJayesh J PillaiPas encore d'évaluation

- HIRA in Process Safety PDFDocument16 pagesHIRA in Process Safety PDFAlvin AlfiyansyahPas encore d'évaluation

- JHA # 009 - Hot WorkDocument7 pagesJHA # 009 - Hot WorkkumarPas encore d'évaluation

- EVT471Document3 pagesEVT471Nurul AqielaPas encore d'évaluation

- Generic Mechanical Workshop Risk AssessmentDocument6 pagesGeneric Mechanical Workshop Risk AssessmentMohammad Abubakar SiddiqPas encore d'évaluation

- BP Safety AlertDocument2 pagesBP Safety AlertRikza AhmadPas encore d'évaluation

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaPas encore d'évaluation

- 2 Consequence Management ProcedureDocument10 pages2 Consequence Management ProcedureriyazaliPas encore d'évaluation

- Risk Assessment (Park Bench)Document2 pagesRisk Assessment (Park Bench)BaileyPas encore d'évaluation

- HSE-201-PR - Form 1 - Toolbox Meeting FormDocument1 pageHSE-201-PR - Form 1 - Toolbox Meeting FormCobbinah MarkPas encore d'évaluation

- Fire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopDocument37 pagesFire Extinguisher Training: Instructor: SGT Michael Chism Bco204 Elm ShopTimmy CheongPas encore d'évaluation

- F-Sp-Hse06-01 Rev 03 Hira NewDocument14 pagesF-Sp-Hse06-01 Rev 03 Hira Newvishal bailurPas encore d'évaluation

- Unloading of EWPs From ContainersDocument10 pagesUnloading of EWPs From ContainersPirashanth SathananthanPas encore d'évaluation

- Trade Area: Construction Industry-PaintingDocument3 pagesTrade Area: Construction Industry-PaintingRam-tech Jackolito FernandezPas encore d'évaluation

- Qcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEDocument75 pagesQcs 2010 Section 11 Part 1.7 Regulatory Document - FIRE and FLAMMABLEbryanpastor106100% (1)

- PPE Disposal SOPDocument2 pagesPPE Disposal SOPAmit MakwanaPas encore d'évaluation

- Ev02 - Brief Program For New Work at Height CampaignDocument2 pagesEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanPas encore d'évaluation

- Part 3 ObservationsDocument7 pagesPart 3 ObservationsAmjadPas encore d'évaluation

- Ra1 - General Risk Assessment Form 2015Document3 pagesRa1 - General Risk Assessment Form 2015api-349297013Pas encore d'évaluation

- HIRAC Work at HeightDocument7 pagesHIRAC Work at HeightMitchRappPas encore d'évaluation

- RFSSB-EHS-P-004 HIRARC Procedure PDFDocument4 pagesRFSSB-EHS-P-004 HIRARC Procedure PDFNajman HamdiPas encore d'évaluation

- Ppe Training Record: Department Occupation Type of Ppe Make/Model Name InitialsDocument3 pagesPpe Training Record: Department Occupation Type of Ppe Make/Model Name Initialsvlad100% (1)

- JsaDocument10 pagesJsaTanzeel LiaqatPas encore d'évaluation

- Risk Assessment Record for BPGIC TerminalDocument4 pagesRisk Assessment Record for BPGIC TerminalAbdul HadiPas encore d'évaluation

- Class Prophecy A Dream Is A Picture of RealityDocument6 pagesClass Prophecy A Dream Is A Picture of RealityLiane DegenerszPas encore d'évaluation

- Vocabulary Worksheets: ContentsDocument27 pagesVocabulary Worksheets: ContentsgloriaPas encore d'évaluation

- Anna University NO Dues Form 2018Document2 pagesAnna University NO Dues Form 2018HarishPratabhccPas encore d'évaluation

- Highly Chemical Resistant Epoxy CoatingDocument2 pagesHighly Chemical Resistant Epoxy Coatingsudhialakkal0% (1)

- Peculiar Personal Problems of Men and Women by Sheikh Ashraf Ali Thanvi (R.a)Document23 pagesPeculiar Personal Problems of Men and Women by Sheikh Ashraf Ali Thanvi (R.a)MUSALMAN BHAIPas encore d'évaluation

- CE Delft - The Environmental Impact of Mink Fur ProductionDocument81 pagesCE Delft - The Environmental Impact of Mink Fur ProductionAnion SlanderPas encore d'évaluation

- Family Members and Activities in SpanishDocument13 pagesFamily Members and Activities in SpanishFlor DisantiPas encore d'évaluation

- 2014 HSC English p1 STD AdvDocument12 pages2014 HSC English p1 STD Advapi-294354534Pas encore d'évaluation

- Cal Year IndexDocument36 pagesCal Year IndexKA25 ConsultantPas encore d'évaluation

- A Bride For Me Before A Bride For You!Document2 pagesA Bride For Me Before A Bride For You!Morgan SquibbPas encore d'évaluation

- Swimming LessonDocument5 pagesSwimming LessonBUNTA, NASRAIDAPas encore d'évaluation

- Dragonborn Sorcerer 1: Character NameDocument1 pageDragonborn Sorcerer 1: Character NameWill SmithPas encore d'évaluation

- Hoover F5411 Steam Vac Jr.Document8 pagesHoover F5411 Steam Vac Jr.Jeffrey A BradleyPas encore d'évaluation

- #34 SHIRLEY F. TORRES v. IMELDA PEREZ, GR No. 188225, 2012-11-28Document3 pages#34 SHIRLEY F. TORRES v. IMELDA PEREZ, GR No. 188225, 2012-11-28Denise DianePas encore d'évaluation

- Daraz MPL Product ResearchDocument15 pagesDaraz MPL Product ResearchAsad KhanPas encore d'évaluation

- This Burns My Heart by Samuel ParkDocument30 pagesThis Burns My Heart by Samuel ParkSimon and SchusterPas encore d'évaluation

- Wearing A Face Mask For COVID-19Document2 pagesWearing A Face Mask For COVID-19AsadUllah NiaziPas encore d'évaluation