Académique Documents

Professionnel Documents

Culture Documents

Fluid Mechanics - Intro - Hydropower Systems

Transféré par

Oyedotun TundeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Fluid Mechanics - Intro - Hydropower Systems

Transféré par

Oyedotun TundeDroits d'auteur :

Formats disponibles

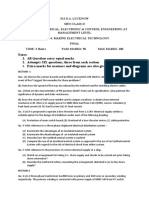

[ENGR.SOJOBI, A.O.

AMASCE,GMICE]

April 28, 2014

GEC223: FLUID MECHANICS

MODULE 4: HYDROPOWER SYSTEMS

DEPARTMENT OF CIVIL ENGINEERING, LANDMARK UNIVERSITY, KWARA STATE,

NIGERIA

Course Objectives/Goals

1. Teach students the basic concepts and theories governing fluid in motion and

at rest.

2. Teach students frictional effects and losses in pipe and duct flow.

3. Make students understand the practical uses of dimensional analysis in

hydraulic engineering.

4. Familiarize students with principles of construction and operation of selected

hydraulic machinery

5. Make students appreciate the use of hydropower systems, governing

equations and operations.

HYDROPOWER SYTEMS

Hydropower is the power generated by utilizing the hydraulic energy of water. The

worlds exploitable hydropower potential is approximately 2724MKW. The present

installed capacity is approximately 200MKW which is about 9% of exploitable

hydropower potential. It has the advantages of operational flexibility and

spectacular operational flexibility.

Hydropower system utilizes hydraulic turbines which converts hydraulic energy of

water into mechanical energy. This is made possible by a change in moment of

momentum between turbine entrance and exit producing a torque on the turbine

runner causing it to rotate. As the turbine runner rotates, the turbine main shaft

rotates. Likewise, since the generator shaft is coupled to the turbine main shaft, the

generator shaft rotates which ensures the rotation of the generator, which produces

electrical power.

ADVANTAGES OF HYDROPOWER PLANTS

1.

2.

3.

4.

Large untapped potential at abundant sites.

Cheapest among new renewable sources of energy.

Highly reliable

Maintenance and operation charges are very low.

1

[ENGR.SOJOBI, A.O.AMASCE,GMICE]

April 28, 2014

5. Running cost of the plant is low.

6. Plant efficiency does not change with age.

7. High efficiency between 85% - 95%.

8. Less supervising staff is required.

9. Less pollution.

10.

Long project life between 100-125 years

11.

Capability of multiple uses such as irrigation and flood control.

12.

Machines used in hydro-electric plants are more robust and run at low

speeds between 300-400r.p.m.

13.

No fuel charges

14.

Minimum transmission and distribution losses.

DISADVANTAGES OF HYDROPOWER PLANTS

1.

2.

3.

4.

Initial cost of the plant is very high.

Long gestation period between project initiation and implementation.

Require long transmission lines which generate some losses.

Highly dependent on quantity of available water.

MAJOR OBSTACLES TO UTILIZATION OF HYDROPOWER RESOURCES

1. Large investments

2. Long gestation period

3. Increased cost of power transmission

LOCATION OF HYDROPOWER PLANTS

1. Rivers

2. Canals and river falls

3. Seas/ocean

FACTORS TO CONSIDER IN LOCATION OF HYDROPOWER PLANTS

1.

2.

3.

4.

5.

6.

7.

8.

Site data assessment

Hydropower design and engineering

Economic feasibility analysis and finance services

Procurement of land and site development

Civil and electrical works associated with hydropower systems

Complete infrastructure for development of hydropower system

Establishment of sub-stations

Operation and maintenance

COMPONENTS OF HYDROPOWER SYSTEM AND THEIR AVERAGE LIVES

S/

COMPONENT

AVERAGE LIFE

2

[ENGR.SOJOBI, A.O.AMASCE,GMICE]

N

1

2

3

Reservoirs

Dams

(i) Earthen, concrete

(ii)Loose rock

Waterways

(i) Canals, tunnels

(ii) Penstocks

(a) Steel

(b) Concrete

Power house and equipment

(i) Building

(ii) Generators

(iii) Transformers

(iv) Turbines (hydraulic)

(v) Pumps

70-80

150

60

50-100

40-50

25-50

35-50

25

30

5

20-25

HYDROPLANT CONTROLS

1.

2.

3.

4.

5.

Hydraulic controls

Machine controls-starting and stopping

Machine controls-loading and frequency

Voltage control of generator and system

Machine protection

COST CONSIDERATIONS FOR HYDROPOWER PLANT

1.

2.

3.

4.

5.

6.

7.

Cost

Cost

Cost

Cost

Cost

Cost

Cost

of

of

of

of

of

of

of

land

highway required for the construction work

construction

engineering supervision of project

building

equipment

equipment used for power transmission

CLASSIFICATION OF HYDROPOWER PLANTS

A. Based on storage characteristics

1. Run-of river plants

2. Storage/reservoir plants

3. Pumped-storage plants

4. Tidal plants

B. Based on load characteristics

3

April 28, 2014

[ENGR.SOJOBI, A.O.AMASCE,GMICE]

April 28, 2014

1. Base-load plant

2. Peak-load plant

C. Based on head

1. Low-head plants

2. Medium-head plants

3. High-head plants

D. Based on plant capacity

1. Micro-capacity plants

2. Medium-capacity plants

3. High-capacity plants

4. Super-capacity plants

E. Base on type of fall

1. Concentrated fall plant

2. Divided fall plant

A. STORAGE CLASSIFICATION

(1)RUN-OF-RIVER PLANTS

These are located on perennial rivers with adequate water discharges all

seasons. It makes use of pondage created upstream using weirs to store

water which are utilized during off-peak hours.

(2) STORAGE PLANTS

These are constructed on non-perennial rivers. They utilize large reservoirs

which are created by dams constructed the river. The reservoir carries over

storage from rainy season to dry season.

(3) PUMPED-STORAGE PLANTS: The water used in generating electrical power

is pumped back. They generate power only during peak-load period. Pumps

are run with secondary power available from some other plants in the system.

They provide additional capacity to meet peak demand.

(4) TIDAL PLANTS

They utilize high tides at sea for generation of power. They are used where

tidal range is high e.g. at La Rance power plant in France where tidal range is

approximately 1m.

B. LOAD CLASSIFICATION

1. BASE-LOAD PLANTS-Takes care of base load of the power system

2. PEAK-LOAD PLANT- Takes care of peak load of the power system

4

[ENGR.SOJOBI, A.O.AMASCE,GMICE]

April 28, 2014

C. HEAD CLASSIFICATION

1. LOWER-HEAD PLANT- Operating head between 0-30m e.g. run-of-river plant

and Kaplan turbines usually used.

2. MEDIUM-HEAD PLANT- Operating head between 30-250m. e.g. Francis

turbine, which could either be low-range of medium head or high-range of

medium-head.

3. HIGH-HEAD PLANT-Operating head greater than 250. The power plant is

located at the toe of the dam. Storage plants are usually used. Examples

include pelton turbines, axial flow and mixed-flow turbines.

D. PLANT-CAPACITY CLASSIFICATION

1. Micro-capacity plants-Capacity <5MW

2. Medium-capacity plants- Capacity between 5MW-100MW

3. High-capacity plants- Capacity between 101MW-1000MW

4. Super-capacity plants- Capacity >1000MW

E. FALL CLASSIFICATION

1. Concentrated-fall plant- Power house located close to dam or weir to utilize

entire head created.

2. Divided-fall plants- Located at considerable distance from the dam or weir

on the downstream utilizing steep fall available in the ground surface.

GENERAL ARRANGEMENTS OF A HYDROPOWER PLANT

1. DAM OR WEIR: Dam is constructed across a river to create storage on its

upstream for storage plants. Weir is constructed across a river to raise the

water level.

2. INTAKES: Constructed to draw water stored in the reservoir. It has control

gates and trash racks.

3. CONVEYANCE SYSTEM: Carries water from the reservoir to the power house. It

may include canals, pipes, penstocks or tunnels.

5

[ENGR.SOJOBI, A.O.AMASCE,GMICE]

April 28, 2014

4. FOREBAYS: This enlarged body of water just upstream of intake. It is also a

pond formed upstream of penstocks. It is required only when conveyance

system has channel flow.

5. SURGE TANK: It is used to reduce the water hammer effect at the upstream of

the power house due to the use of very high pressure conduit called penstock.

6. POWER HOUSE: A building for housing the equipment required for power

generation such as turbines and generators.

7. TAIL RACE: This is a channel in which water after passing through the turbines

is discharged.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Real Property Asset ManagementDocument43 pagesReal Property Asset ManagementOyedotun TundePas encore d'évaluation

- Minerals and Rocks Lecture NotesDocument22 pagesMinerals and Rocks Lecture NotesOyedotun Tunde67% (3)

- Coal Mill SafetyDocument17 pagesCoal Mill SafetyPaulo VidasPas encore d'évaluation

- Technical Study of Electric Vehicles and Charging InfrastructureDocument455 pagesTechnical Study of Electric Vehicles and Charging InfrastructureRudra BarotPas encore d'évaluation

- United A319-A320 Circuit Breaker Panels GuideDocument52 pagesUnited A319-A320 Circuit Breaker Panels GuideBELISARIO83% (6)

- Coal Mill & Fan PerformanceDocument52 pagesCoal Mill & Fan PerformanceManohar TatwawadiPas encore d'évaluation

- TESTINGDocument7 pagesTESTINGSoner Kulte100% (1)

- Electric Power TransmissionDocument6 pagesElectric Power TransmissionLimuel John Vera CruzPas encore d'évaluation

- Metal - Complexation - Part 2Document29 pagesMetal - Complexation - Part 2Oyedotun TundePas encore d'évaluation

- Introduction To Project ManagementDocument89 pagesIntroduction To Project ManagementOyedotun TundePas encore d'évaluation

- Lecture 3 Introduction To Spatial Data AnalysisDocument19 pagesLecture 3 Introduction To Spatial Data AnalysisOyedotun TundePas encore d'évaluation

- Chinasajonathan@Yahoo Com1441756912Document5 pagesChinasajonathan@Yahoo Com1441756912Oyedotun TundePas encore d'évaluation

- Introduction to Engineering Geology StratigraphyDocument7 pagesIntroduction to Engineering Geology StratigraphyOyedotun Tunde100% (3)

- Internal Earth Processes Lecture NotesDocument20 pagesInternal Earth Processes Lecture NotesOyedotun Tunde50% (2)

- 419 Chap 1Document5 pages419 Chap 1Oyedotun TundePas encore d'évaluation

- Structure of The Earth (Main)Document8 pagesStructure of The Earth (Main)Oyedotun TundePas encore d'évaluation

- Vocabularies Used by Top English Speakers in NigeriaDocument1 pageVocabularies Used by Top English Speakers in NigeriaOyedotun TundePas encore d'évaluation

- LandformsDocument2 pagesLandformsOyedotun TundePas encore d'évaluation

- Weathering, Erosion and Sedimentation Lecture NotesDocument28 pagesWeathering, Erosion and Sedimentation Lecture NotesOyedotun TundePas encore d'évaluation

- Sampling TechniqueDocument8 pagesSampling TechniqueAditya GangradePas encore d'évaluation

- CVE312 Fluid Mechanics II Pressure and StabilityDocument28 pagesCVE312 Fluid Mechanics II Pressure and StabilityOyedotun TundePas encore d'évaluation

- Ijais12 450577Document8 pagesIjais12 450577Oyedotun TundePas encore d'évaluation

- TransducersDocument18 pagesTransducersOyedotun TundePas encore d'évaluation

- CVE312 Fluid Mechanics II New NOTEDocument28 pagesCVE312 Fluid Mechanics II New NOTEOyedotun TundePas encore d'évaluation

- WTRF5Document4 pagesWTRF5mostafaaboali6569Pas encore d'évaluation

- Labs Report E.I.EDocument9 pagesLabs Report E.I.EOyedotun TundePas encore d'évaluation

- EWB TutorialDocument18 pagesEWB TutorialXereal SuarezPas encore d'évaluation

- Two Wires Appliances Such As IronDocument1 pageTwo Wires Appliances Such As IronOyedotun TundePas encore d'évaluation

- Module 2 Original 227Document44 pagesModule 2 Original 227Oyedotun TundePas encore d'évaluation

- Concrete - Supp Lab ManualDocument7 pagesConcrete - Supp Lab ManualFatmah El WardagyPas encore d'évaluation

- Transformers Guide: Everything You Need to KnowDocument10 pagesTransformers Guide: Everything You Need to KnowOyedotun TundePas encore d'évaluation

- Rivalain EtalDocument14 pagesRivalain EtalOyedotun TundePas encore d'évaluation

- Module 2 Original 227Document44 pagesModule 2 Original 227Oyedotun TundePas encore d'évaluation

- Electrical Measurement InstrumentationDocument19 pagesElectrical Measurement InstrumentationOyedotun TundePas encore d'évaluation

- Module 1 Gec 227Document22 pagesModule 1 Gec 227Oyedotun TundePas encore d'évaluation

- SWT 16Document2 pagesSWT 16Santhu MeprathuPas encore d'évaluation

- Model To Measure Energy in A Fuel: ExperimentDocument1 pageModel To Measure Energy in A Fuel: ExperimentNkemzi Elias NzetengenlePas encore d'évaluation

- Paper 4 Marine Electrical TechnologyDocument2 pagesPaper 4 Marine Electrical TechnologysuveshPas encore d'évaluation

- Contor Electronic Monofazat de Energie Electrică: Caracteristici TehniceDocument2 pagesContor Electronic Monofazat de Energie Electrică: Caracteristici TehniceSergiu Silviu SfetcuPas encore d'évaluation

- Carrier floor mounted inverter and fixed speed air conditioners performance and specsDocument2 pagesCarrier floor mounted inverter and fixed speed air conditioners performance and specsArthur DeiparinePas encore d'évaluation

- Laporan Gangguan Engine 2 AVR Diode Protection TripDocument3 pagesLaporan Gangguan Engine 2 AVR Diode Protection TripGIDEON SEBASTIAN TODING TIRANDAPas encore d'évaluation

- Inverter Selection GuideDocument8 pagesInverter Selection GuideboisPas encore d'évaluation

- Pamilacan IslandDocument4 pagesPamilacan IslandRogen QuibolPas encore d'évaluation

- William 2019 IOP Conf. Ser. Earth Environ. Sci. 397 012006Document17 pagesWilliam 2019 IOP Conf. Ser. Earth Environ. Sci. 397 012006mrccahmedPas encore d'évaluation

- ABB HVAC Webinars - Power Quality in Buildings 26082020Document31 pagesABB HVAC Webinars - Power Quality in Buildings 26082020dave chaudhuryPas encore d'évaluation

- TSI Nova 48 230 Data Sheet V10Document2 pagesTSI Nova 48 230 Data Sheet V10ThanosEleftheroudisPas encore d'évaluation

- 0530 DWG BSC 40 007 - Grounding - Rev02Document1 page0530 DWG BSC 40 007 - Grounding - Rev02Luis Marín DíazPas encore d'évaluation

- Solved American Bakeries Had A Fleet of Over 3 000 Delivery Trucks PDFDocument1 pageSolved American Bakeries Had A Fleet of Over 3 000 Delivery Trucks PDFAnbu jaromiaPas encore d'évaluation

- Ansaldo-Original Service Provider BrochureDocument4 pagesAnsaldo-Original Service Provider BrochureaniekanPas encore d'évaluation

- Work Energy TheoremDocument12 pagesWork Energy TheoremJother AmutanPas encore d'évaluation

- 03 Lm2500 CourseDocument86 pages03 Lm2500 CourseSerg MarushkoPas encore d'évaluation

- Print Version - Ansi (Ieee) Protective Device NumberingDocument5 pagesPrint Version - Ansi (Ieee) Protective Device NumberingParichay GuptoPas encore d'évaluation

- Buy APC 0.6-84 (KVA-VAH) Interactive UPS Online - GeMDocument4 pagesBuy APC 0.6-84 (KVA-VAH) Interactive UPS Online - GeMArun Chand C VPas encore d'évaluation

- 10 Turn-Motorized Potentiometer Drive 10 Gang-MotorpotentiometerantriebDocument9 pages10 Turn-Motorized Potentiometer Drive 10 Gang-Motorpotentiometerantriebmiguel-Pas encore d'évaluation

- (DBBV) Reference ListDocument13 pages(DBBV) Reference ListCassy AbulenciaPas encore d'évaluation

- 001-Annex 01 Preliminary Project Time ScheduleDocument2 pages001-Annex 01 Preliminary Project Time ScheduleCharu ChhabraPas encore d'évaluation

- Principle of Operation of RCCBDocument5 pagesPrinciple of Operation of RCCBchamara kumarasinghePas encore d'évaluation

- Daikin AlthermaDocument48 pagesDaikin AlthermaDaniel MilosevskiPas encore d'évaluation

- Surge Protection For LiftsDocument8 pagesSurge Protection For LiftsSándor BarabásPas encore d'évaluation

- COMPAIR Portable CompressorDocument14 pagesCOMPAIR Portable CompressorNova HeryPas encore d'évaluation