Académique Documents

Professionnel Documents

Culture Documents

Graphical Method For Visualization of Machine's Downtime (Case Study of Scaling Machine)

Transféré par

HernánMaldonadoGámezTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Graphical Method For Visualization of Machine's Downtime (Case Study of Scaling Machine)

Transféré par

HernánMaldonadoGámezDroits d'auteur :

Formats disponibles

The 1st international workshop and congress on eMaintenance 2010, 22-24 June, Lule, Sweden

Graphical Method for Visualization of Machines Downtime

(Case study of Scaling Machine)

Andi R. Wijaya

Jan Lundberg

Uday Kumar

Mechanical & Industrial Engineering

Gadjah Mada University, Indonesia

Div. of Operation & Maintenance

Engineering, Lule University of

Technology, Sweden

Division of Operation and

Maintenance Engineering

Lule University of Technology

Lule, Sweden

+46 (920) 491748

Division of Operation and

Maintenance Engineering

Lule University of Technology

Lule, Sweden

+46 (920) 491826

Andi.Wijaya@ltu.se

Jan.Lundberg@ltu.se

Uday.Kumar@ltu.se

communication within the organization, Yates (1985) found that

the use of graphs as a managerial tool is one of the key success.

Purpose of this study is to develop a graphical method that can be

used as visual communication tool for maintenance engineering in

communicating to people with various backgrounds.

ABSTRACT

Visualization is the foundation for human to understand as human

think and create in a graphic world. By nature, maintenance

activity is a multi discipline approach, where maintenance

engineer should be able to convey their idea to people with

various backgrounds. In this situation, visualization is a powerful

mode; it can act as a bridge to eliminate the knowledge gap within

the group. Knight (2001) developed Jack-knife diagram for

visualizing total downtime and factors influencing the failure

(failure frequency and mean downtime) in a point estimation. As

failure data is a probabilistic in nature, it is important to look not

only point estimation but also interval estimation, so the precision

and uncertainty of estimation can be identified. This paper

proposes a way of visualizing total downtime and factors

influencing the failure (failure frequency and mean downtime) in

interval estimation. Case study from scaling machines is used for

illustration.

2. DATA VISUALIZATION

Data visualization is a process of converting raw numerical data

into graphical depiction of the data. The goal is to support

decision making through the use of properly designed graphical

representation of information. Verbal and numeric cues are

insufficient to trigger some insight into the specific nature of the

problem (Larkin and Simon, 1987). Presenting data in graphics

helps to break a mental block by providing a memory structure to

aid the decomposition of information in the problem (Lohse,

2001). Schmid (1954) has been summarized the advantage of

graphs as compared with textual and tabular forms as follow;

1.

Graphs are more effective in creating interest and in

appealing to the attention of the reader

2. Visual relationships, as portrayed by graphs, are more

clearly grasped and more easily remembered.

3. It saves time, since the essential meaning of large

masses data can be visualized at a glance

4. It can provide a comprehensive picture of a problem

that makes possible a more complete and betterbalanced understanding.

5. It can bring out hidden facts and relationships and can

stimulate analytical thinking and investigation.

This superiority of graphs over textual and tabular forms makes

graphs as major components in recent science reform documents

(Friel, Curcio and Bright, 2001).

Keywords

Graphical method, Jack-knife diagram, Interval estimation.

1. INTRODUCTION

A quote from Aristotle Now we have already discussed

imagination in the treatise On the Soul, and we concluded there

that thought is impossible without an image. It emphasizes that

visualization is the foundation for human to understand as human

think and create in a graphic world. Presenting data in visual form

(graphs, pictures and diagrams) can enhance data comprehension,

decision-making and communication of data information (Roth

and Bowen, 2003; Tory and Mller, 2004). The reason is due to

stimulation of cognitive processes (visual chunking, mental

imagery and parallel processing) and reduction in cognitive load

(Winn, 1994; Card et al, 1999).

In maintenance engineering, however, the development of the

graph for data visualization is not significantly developed. In most

publication related to maintenance, a classic Pareto diagram still

be utilized for presenting failure data despite of its deficiency (Lin

and Titmuss, 1995; Ashraf, et al, 1998; Hennessy, 2000; Platfoot,

2000; Kortelainen, et al, 2003; Das, 2005). Knight (2001) pointed

out three shortcomings of Pareto analysis in maintenance

engineering application. First, where an outcome is a product of

two factors, a Pareto diagram based on one factor alone cannot

determine which factor is dominant in contributing to the

problems. Second, by focusing on any one factor to the exclusion

of others, it may miss identifying individual events having high

time consumption, or those that may consume relatively little

By nature, maintenance activity is a multi discipline approach,

where maintenance engineer should be able to convey their idea

to people with various backgrounds. The key success in this type

of situation is relying on how to communicate. Communication is

only successful when both the sender and the receiver understand

the same information as a result of the communication. It is

widely accepted that visualization can improve the effectiveness

of the communication. It can act as a bridge to eliminate the

barrier of knowledge gap within the group. In a study on effective

99

ISBN 978-91-7439-120-6

The 1st international workshop and congress on eMaintenance 2010, 22-24 June, Lule, Sweden

much longer times. The shapes of the lognormal distribution for

different parameters are shown in figure 2.

average time but have the ability to cause operational

disturbances. Third, Pareto diagram is not useful for trending

comparisons across different time periods. To overcome these

shortcomings, Knight have developed Jack-knife diagram. In his

method, number of failure and mean downtime is plotted in a

logarithmic scatter plots. Plotting in logarithmic allow a constant

downtime to be appeared as a constant straight lines with uniform

negative gradient. It still reserves the basic information of Pareto

diagram (to highlight the most contributed downtime) and enables

identification of the dominant factors influencing the failure

(failure frequency and mean downtime). In his method, downtime

is presented as a single value (point estimation). In the last

decade, presenting data as point estimation is considered to be

insufficient (Altman et al, 2000; Curran-Everett, 2004; Council of

Science Editors, 2006). Presenting estimation should also be

accompanied by the precision and the uncertainty of the

estimation. As failure data is a probabilistic in nature, it is

essential to see also the reliability of an estimate (Gardner and

Altman, 2000). Two components might have same value of

downtime, but at a given confidence level their interval might

differ significantly. Thus it is important in visualizing failure data

to show not only point estimation but also the interval estimation,

so the precision of estimation and the uncertainty of the

estimation can be identified.

The probability density function of Weibull distribution is given

as

g ( y) =

y

exp ,

y>0

(1)

where > 0 is the shape parameter and > 0 is the scale

parameter of the distribution. The expected value, in this case is

Mean Time between Failure (MTBF), is given by

E (Y ) = y = + 1

(2)

3. INTERVAL ESTIMATION

In this study, interval estimation is determined by using the

assumption that failure times have Weibull distribution and the

repair times have lognormal distribution. It is well known that

failure times are often modeled with Weibull distribution

(Abernethy, 2000; Wiseman, 2001; Schroeder and Gibson, 2006).

About 85% - 95% of all failures data are adequately described

with Weibull distribution (Barringer, 2009). The reasons are that

Weibull distribution has the ability to provide reasonably accurate

failure analysis with small sample size and it has no specific

characteristics shape and depending upon the values of the

parameters it can adapt shape of many distributions (Abernethy,

2000). The shapes of the Weibull distribution for a different shape

parameter are shown in figure 1.

Figure 2. Lognormal Distribution

The probability density function of lognormal distribution is

given as

f ( x) =

1 ln( x) 2

exp

, x>0

2

x 2

(3)

where and are the mean and standard deviation of the

variables natural logarithm. The expected value, in this case is

Mean Time to Repair (MTTR), is given by

E ( X ) = x = exp + 2

2

(4)

Let the total life time of component defined as

Total time = DT + UT

(5)

where DT is downtime and UT is uptime, and MTTR and MTBF

is given by

Figure 1. Weibull Distribution

MTTR =

DT

m

(6)

MTBF =

UT

m

(7)

where m is number of failures.

It also known that lognormal distribution is widely used to model

repair times (Rausand and Hyland, 2004; Bovaird and Zagor,

2006; Schroeder and Gibson, 2006). About 85%-95% of all repair

times are adequately described by log normal distribution

(Barringer, 2009). The skewness of the lognormal distribution

with a long tails to the right fit to represent the repairment

situation. In a typical repairment situation, most of the repairs are

completed in a small time interval but in some cases it can take

For a given uptime, downtime can be formulated by using

equation (6) and (7) as

DT =

MTTR

UT ,

MTBF

(8)

Since the failure time distribution is Weibull and the repair time

distribution is lognormal, equation can be rewritten as

100

ISBN 978-91-7439-120-6

The 1st international workshop and congress on eMaintenance 2010, 22-24 June, Lule, Sweden

DT =

x

UT ,

y

where

(9)

X G = geometric mean of lognormal distribution

and interval estimation for downtime can be determined by

finding a confidence interval for X Y . The confidence

interval can be determined by an approximate method and an

exact method. In the approximate method, the confidence interval

is determined by establishing confidence intervals for x and y

to obtain an at least type confidence interval. In exact method,

the confidence interval for X Y is established simultaneously.

The exact confidence interval is more accurate than approximate

the confidence interval. Another advantage is that since the

confidence interval is solved simultaneously, the result can be

treated as a single dimension rather than two dimensions.

= p

X G

exp

2

a

1

m

1 + 1 2 y

i =1

X G

exp

2

UT < DT < b

1

m

1 + 1 2 y

i =1

UT

= time between failure

= standard deviation of time to repairs natural logarithm

= shape parameter of Weibull distribution

= constant for lower limit

= constant for upper limit

P[a < w < b] = g ( w) dw = p

(12)

The cumulative distribution function (cdf) of W for a given value

of b (the probability of the even that W is less than or equal to b)

can be computed as follow

(10)

n

G (b ) =

which implies a 100p% confidence interval for DT is

2

= scale parameter of Weibull distribution

To establish a 100p% confidence interval for DT, the value for a

and b has to be determined so that

By adopting procedure developed by Masters et al (1992), the

exact confidence interval for X Y is given by

2

2

X G

X G

exp

exp

2

x

2

P a

b

<

<

1

1

m

m

y

1 + 1 2 y i

+ 1 2 y i

i =1

i =1

2

( m) 2

exp 2

0 0

ln 2 z

1

n 1

wz (wz ) dz dw (13)

2

where

(11)

m = number of failures

n = number of repairs.

Tables of G(b) for selected values is presented in table 1.

Table 1. Factors for Computing Confidence Interval of Down Time

(Gray and Lewis, 1967)

101

ISBN 978-91-7439-120-6

The 1st international workshop and congress on eMaintenance 2010, 22-24 June, Lule, Sweden

where

4. CONFIDENCE JACK-KNIFE DIAGRAM

In this study, a new way of presenting failure data is developed

allowing a visualization of the downtime estimation that are

accompanied by the precision and the uncertainty of the

estimation at a given confidence level. As the proposed diagram is

developed based on the jack-knife diagram, hence it shall be

referred as a confidence jack-knife diagram.

TTRL = time to repair of limit (upper or lower)

DTL

= downtime of limit (upper or lower)

DTmean = mean downtime

and ordinate is determined as

mL =

A confidence Jack-knife diagram is presenting as log-log graph

(both the vertical and horizontal axis of a plot is scaled

logarithmically). The horizontal axis represent time to repair and

the vertical axis represent number of failures. Downtime is

determined by the multiplication of time to repair and number of

failures. As the diagram is presenting in log-log graph, a curve of

a constant downtime can be presented as a straight lines with

uniform negative gradient, see figure 3.

DTL

TTR L

(16)

The interval estimation is then established by connecting these

three points with a straight line, see figure 3.

5. APPLICATIONS AND EXAMPLES

To give an illustration on how to construct a confidence jackknife diagram and how it can be applied, two examples are given

bellow.

Example 1

In this example, confident Jack-knife diagram is used for

visualization of downtime that can be used as an aid for

prioritization of significant components. Data of unplanned

downtime for scaling machine is presented in table 2. Failures

data and repairs time data are sorted in ascending order. Confident

Jack-knife diagram is constructed for a given uptime of 8000 unit

time and a confidence interval of 90%. Step by step for plotting

component A on jack-knife diagram is providing as follow;

1.

Figure 3. Confidence Jack-knife Diagram

To establish confidence jack-knife diagram, three estimation

points should be determined. These three points are mean, upper

limit and lower limit of downtime. The mean downtime for a

given uptime is determined from equation (8), and the upper limit

and lower limit of downtime are determined from equation (11).

Prior calculation, level of confidence should be decided. The

choice for the level of confidence is somewhat arbitrary, in

practice values of 90%, 95% and 99% are often used (Snedecor

and Cochran, 1989).

gives 24.54.

Second step is determining the coordinates of the three

downtimes. For DTmean abscissa is MTTR (4.88) and ordinate

is calculated by equation (14), for UT = 8000 and MTBF =

942.09, then mmean = 8.49. Abscissa of DTUL and DTLL can be

determined by equation (15). For DTLL = 24.54, DTUL =

104.2, DTmean = 41.52 and MTTR = 4.88, then TTRUL = 7.4

and TTRUL = 3.5. Ordinates of DTUL and DTLL is determined

by equation (16) that gives mLL = 6.1 and mUL = 12.8.

3. Third step is establishing interval estimation by connecting

the three estimation points by a straight line.

Following similar procedure, the rest of component can be plotted

in the diagram. A diagram for components of scaling machine is

shown in figure 4.

2.

After the three estimation points are determined, the next step is

to determine their coordinates in the diagram. The coordinates for

the mean downtime, abscissa (time to repair) is MTTR and

ordinate (number of failures) is determined as

mmean =

UT

MTBF

(14)

For lower limit and upper limit of downtime, abscissa is provided

by equation below

TTRL = 10

[log

DTL log DTmean + log MTTR

First step is determining the downtimes (mean, upper and

lower limit). Mean downtime (DTmean) is calculated by

equation (8) and for uptime (UT) = 8000, MTBF = 942.09

and MTTR = 4.88, it gives 41.52. Upper and lower limit of

downtime is calculated by equation (11). Prior the

calculation of upper limit of downtime (DTUL), value for b

should be determined first. Since number of repairs (n) = 10,

and = 0.91, then n/2 = 12.12 and number of failures (m) =

9. From table 1, if n/2 = 10, G(b) = 0.95, and m = 9, then b

= 39.427. If n/2 = 15, G(b) = 0.95, and m = 9, then b =

36.897. By using linear interpolation, b is approximately

38.61. DTUL is calculated for b = 38.61, = 0.91, X G = e =

e1.17 = 3.23, = 0.83, and = 850.89 that gives 104.2.

Similar procedure applied for calculation of lower limit of

downtime (DTLL). From table 1, if n/2 = 10, G(b) = 0.05,

and m = 9, then b = 8.9081. If n/2 = 15, G(b) = 0.95, and m

= 9, then b = 9.4707. By using linear interpolation, b is

approximately 9.09. DTUL is calculated for b = 9.09, =

0.91, X G = e = e1.17 = 3.23, = 0.83, and = 850.89 that

(15)

102

ISBN 978-91-7439-120-6

The 1st international workshop and congress on eMaintenance 2010, 22-24 June, Lule, Sweden

Table 2.Failure data of scaling machine

information is needed especially for certain activities where the

decision should be based on three scenarios (optimistic, most

likely and pessimistic), eg. planning and budgeting of

maintenance activities.

In some cases, the maximum downtime is limited to certain value

and in this regards it is important to know how likely that the

downtime of components exceed that limit. Suppose that due to

the consequences of the failure, it is decided that limit for the

maximum downtime is 300 unit time and it is demanding that the

maximum probability of error is 5%. Then it can be seen from

figure 4 that component B, E and H at the confidence level of

95% will exceed the limit.

Since in the confidence Jack-knife diagram, the downtime is

presenting as a function of time to repair and number of failures it

also visualizes the reliability and maintainability issues. It shows

which components that need to be improved their reliability

or/and maintainability. In figure 4, it shows that the high

downtimes of component B, F, E and C are mainly due to the

reliability problem (high value for the number of failures), while

the high downtime of component H is mainly due to

maintainability problem (high value for the time to repairs).

Suppose the smoothness (uninterrupted) of the operation is taken

into consideration in the prioritization of significant components.

For the similar value of downtime, a high frequent of interruption

with a short duration is less favor than a low frequent of

interruption with a long duration. Then it can be seen in the figure

4 that in comparing the components of F, E and H, which have

approximately equal mean downtime, a higher priority should be

given to components F and E than component H.

Figure 4. Confidence Jack-knife diagram for components of

scaling machine

From figure 4, it can be observed that presenting in interval

estimation provides better insight into the hidden fact of the data

than presenting in point estimation. For example in the

prioritization of significant components based on downtime, it

visualize that two different orders of the rank can be constructed.

The order of significant components based on the mean

estimation (likelihood) and lower limit estimation (best scenario)

is B, E, F, C, H, A, G, D, while based on the upper limit

estimation (worst scenario) is B, H, E, C, F, A, G, D. This kind of

Example 2.

In this example, confidence Jack-knife diagram is used to

visualize the effectiveness of design alternatives in reducing

103

ISBN 978-91-7439-120-6

The 1st international workshop and congress on eMaintenance 2010, 22-24 June, Lule, Sweden

downtime. In practice, strategy of redesign for reducing downtime

can be classified into three strategies, they are;

a.

Design out Maintenance (DOM), in this strategy, aim is to

improve reliability of the product so the number of failures

are reduced but the time to repairs are remain constant,

b. Design for Maintenance (DFM), in this strategy, aim is to

improve maintainability (how ease to maintain) of the

product so the time to repairs are reduced but the number of

failures are remain constant,

c. Combination of DOM and DFM, in this strategy, aim is to

improve both maintainability and reliability of the product.

To give an illustration, a set of artificial data is generated

portraying a typical design improvement scenario. Distribution

fitting of failures data of mechanical component shows that time

to fail fit to Weibull distribution with = 2.0, = 565.5 and

MTBF = 501.1 and time to repair fit to lognormal distribution

with = 3.05, = 0.47 and MTTR = 23.57. For an uptime of

11000 unit time, it gives a mean downtime of 517.4 unit times. To

reduce downtime, five alternative designs have been developed.

The first two designs (design A and B) adopted DOM strategy,

thus attempt is to increase MTBF by keeping a constant MTTR.

The second two designs (design D and E) adopted DFM strategy,

thus attempt is to reduce MTTR by keeping a constant MTBF.

The third design (design C) adopted a combination of DOM and

DFM strategy. Trial test have been conducted to evaluate the

effectiveness of the alternative designs in reducing downtime.

Results of the trial test (given in ascending order) are shown in

table 3.

Figure 5. Confidence Jack-knife diagram of design

alternatives

From figure 5, it shows that though the five design alternatives

have an equal mean downtime but their 95% confidence interval

are varied significantly. In case of lower limit (best scenario), a

discrepancy of approximately 40 unit times is observed, while in

case of upper limit (worst scenario), a discrepancy of

approximately 200 unit time is observed.

Table 3. Results of trial test of design alternatives

By just considering the downtime, design B might be the best

alternative, as it has the lower value of the downtime at the worst

scenario. However the stability of the strategies (DOM or/and

DFM) should also be taken into consideration. It can be observed

from figure 3 that in comparison of DOM and DFM strategies, the

downtime in case of DFM is more sensitive to distribution

parameters than in case of DOM. Changing the lognormal

distribution parameters from = 2.5, = 0.86 (design A) to =

2.8, = 0.36 (design B), will alter the downtime up to

approximately 200 unit times. While changing the Weibull

distribution parameters from = 2.0, = 757.6 (design E) to =

6.7, = 719.4 (design D) will alter the downtime by

approximately 40 unit time. Thus in this particular case, strategy

of DOM gives better stability than strategy of DFM. These kind

of information are needed in the decision making process and the

confident jack-knife diagram can be used as an aid in visualizing

alternative designs improvement.

From the table 3, it can be calculated that all five alternatives

designs have an equal ratio of MTTR/MTBF, approximately

0.035. It indicates that all design alternatives have an equal mean

downtime. For an uptime of 11000 unit times, it gives a mean

downtime of approximately 386.5 unit times which is lower than

the current design (517.4 unit times). A question arise is which

design alternative should be employed. Confidence Jack-knife

diagram is used to visualize the effectiveness of the five design

alternatives. Following similar procedure as example 1, the

diagram is constructed, as shown in figure 5.

6. Conclusions

A new way of presenting failure data is developed, allowing a

visualization of the downtime estimation and the precision and the

uncertainty of the estimation at a given confidence level and

factors influencing the failure. Presenting failure data in this new

diagram provides better insight into the hidden fact of the data. It

can be used as a visual communication tool for maintenance

engineering in communicating failure data to people with various

backgrounds.

104

ISBN 978-91-7439-120-6

The 1st international workshop and congress on eMaintenance 2010, 22-24 June, Lule, Sweden

Policy, TAPPI Journal, Vol.2 No. 8, pp. 8 12, available

at:

http://www.softmagic.fi/Contents/referenssit/82993803AUG

08.pdf (accessed 20 January 2010)

7. References

[1] Abernethy, R.B. (2000). The New Weibull Handbook, Gulf

Publisher Co., Houston

[2] Altman, D.G., Machin, D., Bryant, T.N. and Gardner, M.J.

(2000). Statistics with Confidence, BMJ Books, Bristol, UK

[16] Larkin, J.H. and Simon, H.A. (1987). Why a Diagram is

(Sometimes) Worth Ten Thousand Words, Cognitive

Science, Vol. 11, pp. 65 99

[3] Ashraf W.L, Richard, F.O. and Glyn, B.W. (1998). An

Effective Maintenance System Using the Analytic Hierarchy

Process, Integrated Manufacturing Systems, Vol. 9 No. 2,

pp. 87 98

[17] Lin, T. and Titmuss, D. (1995). Critical Component

Reliability and Preventive Maintenance Improvement to

Reduce Machine Downtime, Computers & Industrial

Engineering, Vol. 29 Issues 1-4, pp. 21 23

[4] Barringer, H.P. (2009). Which Reliability Tool Should I

Use?, available at:

http://www.reliabilityweb.com/art07/reliability_tools.htm

(accessed 20 January 2010).

[18] Lohse, G.L. (2001). Models of Graphical Perception, in

Karwowski, W. (Ed), International Encyclopedia of

Ergonomics and Human Factors, Taylor and Francis,

London.

[5] Bovaird, R.L. and Zagor, H.L. (2006). Lognormal

Distribution and Maintainability in Support Systems

Research, Naval Research Logistics Quarterly, Vol. 8 No.

4, pp. 343 356

[19] Masters, B.N., Lewis, T.O. and Kolarik, W.J. (1992). A

Confidence Interval for the Availability Ratio for System

with Weibull Operating Time and Lognormal Repair Time,

Microelectron Reliability, Vol. 32 No. 1, pp. 89 99.

Platfoot, R.A. (2000). Improving Return from

Maintenance, Proceedings of the IIR Maintenance

Management 2000, April 2000, Aukland, New Zealand,

available at:

http://www.covaris.com.au/papers/Improving%20Return%20

from%20Maintenance.pdf (accessed 20 January 2010)

[6] Card, S.K., Mackinlay, J.D. and Schneiderman, B. (1999).

Reading in Information Visualization: Using Vision to Think,

Morgan Kaufmann Publishers Inc., San Francisco

[7] Council of Science Editors, Style Manual Subcommittee,

(2006). Scientific Style and Format: the CSE Manual for

Authors, Editors, and Publishers, 7th ed., Rockefeller Univ.

Press, Reston, Virginia, USA

[20] Rausand, M. and Hyland, A. (2004). System Reliability

Theory: Models, Statistical Methods, and Applications, John

Wiley and Sons Inc., New Jersey

[8] Curran-Everett D. and Benos, D.J. (2004). Guidelines for

Reporting Statistics in Journals Published by the American

Physiological Society, American Journal of Physiology

Endocrinology and Metabolism, Vol. 287, pp. E189 E191

[21] Roth, W.M. and Bowen, G.M. (2003). When are Graphs

Worth Ten Thousand Words? An Expert-expert Study,

Cognition and Instruction, Vol. 21, pp. 429 473

[9] Das, P. (2005). Improving the Maintenance System of

Tippers A Case Study, Economic Quality Control, Vol.

20 No. 1, pp. 51 67

[22] Schmid, C.F. (1954). Handbook of Graphic Presentation,

Ronald Press Co., New York

[10] Friel, S.N., Curcio, F.R. and Bright, G.W. (2001). Making

Sense of Graphs: Critical Factors Influencing

Comprehension and Instructional Implications, Journal for

Research in Mathematics Education, Vol. 32, pp. 124 158

[23] Schroeder, B. and Gibson, G. (2005). A Large-scale Study

of Failures in High-performance-computing Systems,

Supercedes Carnegie Mellon University Parallel Data Lab

Technical Report, CMU-PDL-05-112, Carnegie Mellon

University, available at: http://www.pdl.cmu.edu/PDLFTP/stray/CMU-PDL-05-112.pdf (accessed 20 January

2010)

[11] Gardner, M.J. and Altman, D.G. (2000). Estimating with

Confidence, in Altman, D.G., Machin, D., Bryant, T.N. and

Gardner, M.J. (eds.), Statistics with Confidence, BMJ Books,

London

[24] Snedecor, G.W. and Cochran, W.G. (1989). Statistical

Methods, 8th Edition, Iowa State University Press., Iowa

[12] Gray, H.L. and Lewis, T.O. (1967). A Confidence Interval

for the Availability Ratio, Technometrics, Vol. 9 No. 3, pp.

465 471.

[25] Tory, M. and Mller, T. (2004). Human Factors in

Visualization Research, IEEE Transactions on Visualization

and Computer Graphics, Vol. 10, pp. 72 84

[13] Hennessy, C., Freerks, F., Campbell, J.E. and Thompson,

B.M. (2000). Automated analysis of failure event data,

Proceeding of the Modeling and Analysis of Semiconductor

Manufacturing Conference, Tempe, Arizona, March 27,

2000, available at:

http://www.osti.gov/bridge/purl.cover.jsp?purl=/752663aq6kj7/webviewable/ (accessed 20 January 2010)

[26] Winn, W.D. (1994). Contributions of Perceptual and

Cognitive Processes to the Comprehension of Graphics, in

Schnotz, W. and Kulhavy, R. (Eds.), Comprehension of

Graphics, Elsevier, Amsterdam

[14] Knights, P. (2001). Rethinking Pareto Analysis:

Maintenance Applications of Logarithmic Scatterplots,

Journal of Quality in Maintenance Engineering, Vol. 7 No.

4, pp. 252 263

[27] Wiseman, M. (2001). Reliability Management and

Maintenance Optimization: Basic Statistics and Economics,

in Campbell, J.D and Jardine, A.K.S. (Eds), Maintenance

Excellence: Optimizing Equipment Life-Cycle Decisions,

Marcel Dekker Inc., New York

[15] Kortelainen, H., Kupila, K., Silenius, S. and Pivike, A.

(2003). Data for Better Maintenance Plans and Investments

[28] Yates, J. (1985). Graphs as a Managerial Tool: A Case

Study of Du Pont's Use of Graphs in the Early Twentieth

105

ISBN 978-91-7439-120-6

The 1st international workshop and congress on eMaintenance 2010, 22-24 June, Lule, Sweden

Century, Journal of Business Communication, Vol. 22 No.

1, pp. 5 33

106

ISBN 978-91-7439-120-6

Vous aimerez peut-être aussi

- Ellison - 2001 - Exploratory Data Analysis and Graphical DisplayDocument26 pagesEllison - 2001 - Exploratory Data Analysis and Graphical DisplayThyago NavesPas encore d'évaluation

- Croissant y Millo, Panel Data EconometricsDocument52 pagesCroissant y Millo, Panel Data EconometricsAgustín Cugno100% (1)

- Panel Data Econometrics in R: The PLM Package: Yves Croissant Giovanni MilloDocument51 pagesPanel Data Econometrics in R: The PLM Package: Yves Croissant Giovanni MilloLidiya KhadjibayevaPas encore d'évaluation

- Tracking with Particle Filter for High-dimensional Observation and State SpacesD'EverandTracking with Particle Filter for High-dimensional Observation and State SpacesPas encore d'évaluation

- Cob 2021 2133Document8 pagesCob 2021 2133Andre MirandaPas encore d'évaluation

- Integer Optimization and its Computation in Emergency ManagementD'EverandInteger Optimization and its Computation in Emergency ManagementPas encore d'évaluation

- MEME19403 Data Analytics and Visualization: Module Three: Visualization With DashboardDocument51 pagesMEME19403 Data Analytics and Visualization: Module Three: Visualization With DashboardFucKerWengiePas encore d'évaluation

- 2015 - Svetunkov, Kourentzes - M P RA Complex Exponential Smoothing Complex Exponential Smoothing - UnknownDocument41 pages2015 - Svetunkov, Kourentzes - M P RA Complex Exponential Smoothing Complex Exponential Smoothing - UnknownalPas encore d'évaluation

- A Decision Tree For Weather Prediction: Elia Georgiana PetreDocument7 pagesA Decision Tree For Weather Prediction: Elia Georgiana PetreCatalin CrisanPas encore d'évaluation

- Panel Data Analysis Using STATA 13Document17 pagesPanel Data Analysis Using STATA 13Sardar AftabPas encore d'évaluation

- 多维数据可视化技术Document11 pages多维数据可视化技术WUYUEPas encore d'évaluation

- An Elementary Introduction To Information GeometryDocument61 pagesAn Elementary Introduction To Information GeometryMiguel OrrilloPas encore d'évaluation

- Modeling Visual Reasoning On Graph Using Qualitative InterpretationDocument8 pagesModeling Visual Reasoning On Graph Using Qualitative Interpretationshilpi_sweetPas encore d'évaluation

- SSRN Id3981160Document44 pagesSSRN Id3981160hetalpatel259Pas encore d'évaluation

- Customer Churn in Mobile Markets: A Comparison of TechniquesDocument14 pagesCustomer Churn in Mobile Markets: A Comparison of TechniquesShreya ShahPas encore d'évaluation

- Panel Data Slides - 230919 - 160722Document92 pagesPanel Data Slides - 230919 - 160722davPas encore d'évaluation

- Balazsi-Matyas: The Estimation of Multi-Dimensional FixedEffects Panel Data ModelsDocument38 pagesBalazsi-Matyas: The Estimation of Multi-Dimensional FixedEffects Panel Data Modelsrapporter.netPas encore d'évaluation

- Makro EkonomiDocument22 pagesMakro EkonomiYinS3llyPas encore d'évaluation

- Fuzzy AHPDocument17 pagesFuzzy AHPmsdpardisPas encore d'évaluation

- Vorlage Bachelor Thesis Word 2010Document8 pagesVorlage Bachelor Thesis Word 2010bsqbr7px100% (2)

- SPE 127761 Probabilistic Modeling For Decision Support in Integrated OperationsDocument13 pagesSPE 127761 Probabilistic Modeling For Decision Support in Integrated OperationsmhdstatPas encore d'évaluation

- 3.2 Stockton, Accord ESL - Allocation UncertaintyDocument32 pages3.2 Stockton, Accord ESL - Allocation UncertaintyAdilbekMursaliyevPas encore d'évaluation

- (IJCT-V2I1P13) Author: Mr. Roshan P. Helonde, Prof. M.R. JoshiDocument5 pages(IJCT-V2I1P13) Author: Mr. Roshan P. Helonde, Prof. M.R. JoshiIjctJournalsPas encore d'évaluation

- Ijdkp 030207Document12 pagesIjdkp 030207Lewis TorresPas encore d'évaluation

- PLMDocument51 pagesPLMBruno André NunesPas encore d'évaluation

- Modelling Dynamic Patterns Using Mobile DataDocument6 pagesModelling Dynamic Patterns Using Mobile DataCS & ITPas encore d'évaluation

- An Optimal Control Approach For The Registration of Image Time-SeriesDocument8 pagesAn Optimal Control Approach For The Registration of Image Time-SeriesmarcniethammerPas encore d'évaluation

- Impact of Graphs and Network in Minimizing Project and Product CostDocument6 pagesImpact of Graphs and Network in Minimizing Project and Product CostThe IjbmtPas encore d'évaluation

- How Is Machin Learning Useful For Macroeconomic ForecastingDocument52 pagesHow Is Machin Learning Useful For Macroeconomic ForecastingSofien HaddadPas encore d'évaluation

- Fuzzy Multiple Objective Programming Techniques in Modeling Forest PlanningDocument6 pagesFuzzy Multiple Objective Programming Techniques in Modeling Forest PlanningpunxkokoPas encore d'évaluation

- Descriptive AnalyticsDocument15 pagesDescriptive AnalyticsVishnu PPas encore d'évaluation

- Steganography Based On Contour Let TransformDocument6 pagesSteganography Based On Contour Let TransformAneesh NpPas encore d'évaluation

- Decision-Making Management: A Tutorial and ApplicationsD'EverandDecision-Making Management: A Tutorial and ApplicationsPas encore d'évaluation

- Evaluation of Approximate Rank-Order Clustering Using Matthews Correlation CoefficientDocument8 pagesEvaluation of Approximate Rank-Order Clustering Using Matthews Correlation Coefficientiraoui jamal (Ebay)Pas encore d'évaluation

- Visualization PipelineDocument41 pagesVisualization PipelineAlruAlmu BandarPas encore d'évaluation

- Solutions: Attempt All QuestionsDocument2 pagesSolutions: Attempt All QuestionsROHIT JAISWALPas encore d'évaluation

- An Elementary Introduction To Information GeometryDocument56 pagesAn Elementary Introduction To Information GeometryRuigang WangPas encore d'évaluation

- Thesis Master of ScienceDocument8 pagesThesis Master of ScienceAngelina Johnson100% (2)

- Bin-Summarise-Smooth: A Framework For Visualising Large DataDocument9 pagesBin-Summarise-Smooth: A Framework For Visualising Large DataDarfElfDrizztPas encore d'évaluation

- A Face Recognition Scheme Based On Principle Component Analysis and Wavelet DecompositionDocument5 pagesA Face Recognition Scheme Based On Principle Component Analysis and Wavelet DecompositionInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- A Study of Personality Influence in Building Work Life Balance Using Fuzzy Relation Mapping (FRM)Document6 pagesA Study of Personality Influence in Building Work Life Balance Using Fuzzy Relation Mapping (FRM)IIR indiaPas encore d'évaluation

- N-Beats: N: Eural Basis Expansion Analysis For Interpretable Time Series ForecastingDocument31 pagesN-Beats: N: Eural Basis Expansion Analysis For Interpretable Time Series ForecastingJeydson LPas encore d'évaluation

- Cosc2753 A1 MCDocument8 pagesCosc2753 A1 MCHuy NguyenPas encore d'évaluation

- The Graphical Analysis For Maintenance Management Method: A Quantitative Graphical Analysis To Support Maintenance Management Decision MakingDocument11 pagesThe Graphical Analysis For Maintenance Management Method: A Quantitative Graphical Analysis To Support Maintenance Management Decision MakingMitchel HerreraPas encore d'évaluation

- Ijdkp 030205Document18 pagesIjdkp 030205Lewis TorresPas encore d'évaluation

- Remarks On Monte Carlo Method in Simulation of Financial Problems - Final2Document9 pagesRemarks On Monte Carlo Method in Simulation of Financial Problems - Final2Oyelami Benjamin OyediranPas encore d'évaluation

- Descriptive Stat1Document24 pagesDescriptive Stat1Zia AhmadPas encore d'évaluation

- BSc. AC-Sem IVDocument19 pagesBSc. AC-Sem IVNisarg ChauhanPas encore d'évaluation

- Econometrica, Vol. 71, No. 2 (March, 2003), 483-549Document67 pagesEconometrica, Vol. 71, No. 2 (March, 2003), 483-549Daryl GoldingPas encore d'évaluation

- Multi-Step-Ahead Prediction With Neural NetworksDocument12 pagesMulti-Step-Ahead Prediction With Neural NetworksDinibel PérezPas encore d'évaluation

- Challenges in Computational TopologyDocument20 pagesChallenges in Computational TopologyMohamed SolimanPas encore d'évaluation

- Using The Analytic Hierarchy Process For Choosing A Best SmartphoneDocument13 pagesUsing The Analytic Hierarchy Process For Choosing A Best SmartphoneKosara ZivgovicPas encore d'évaluation

- A Proposed Churn Prediction Model: Essam Shaaban, Yehia Helmy, Ayman Khedr, Mona NasrDocument5 pagesA Proposed Churn Prediction Model: Essam Shaaban, Yehia Helmy, Ayman Khedr, Mona NasrManjunathPas encore d'évaluation

- Robust Computer VisionDocument7 pagesRobust Computer Visionjuan perezPas encore d'évaluation

- A Versatile Workflow For Linear Modelling in RDocument15 pagesA Versatile Workflow For Linear Modelling in RJhon RengifoPas encore d'évaluation

- Algorithmic Trading Strategy, Based On GARCH (1, 1) Volatility and Volume Weighted Average Price of AssetDocument6 pagesAlgorithmic Trading Strategy, Based On GARCH (1, 1) Volatility and Volume Weighted Average Price of AssetInternational Organization of Scientific Research (IOSR)Pas encore d'évaluation

- If You NeedDocument5 pagesIf You NeedAlexPas encore d'évaluation

- Altair's Student Guides - CAE and Design Optimization - AdvancedDocument70 pagesAltair's Student Guides - CAE and Design Optimization - AdvancedKFourMetrics100% (11)

- Rain Fading in Microwave NetworksDocument10 pagesRain Fading in Microwave NetworksAviat Networks100% (1)

- 888Document12 pages888Phillip RamirezPas encore d'évaluation

- Resume For Internship Engineering ObjectiveDocument6 pagesResume For Internship Engineering Objectivevepybakek1t3100% (2)

- Ed0016 Design Change Management DCN and VerianceDocument8 pagesEd0016 Design Change Management DCN and Verianceshiviitd02100% (1)

- CM20160614 29510 52017 PDFDocument32 pagesCM20160614 29510 52017 PDFRicardo Sanzana0% (1)

- Chapter 2 4.tqmDocument26 pagesChapter 2 4.tqmJudy Ann LuzPas encore d'évaluation

- Self Driving Car (PowerPoint)Document29 pagesSelf Driving Car (PowerPoint)immi19890% (1)

- Odule: Pavement Management Systems OverviewDocument29 pagesOdule: Pavement Management Systems Overviewharish babu aluruPas encore d'évaluation

- Reliability Prediction MethodsDocument12 pagesReliability Prediction MethodsJEINNER CASTRO CASTROPas encore d'évaluation

- 4100 C P&H - Catalogue PDFDocument8 pages4100 C P&H - Catalogue PDFsuturPas encore d'évaluation

- Workshop On RCM, Jan 2020Document4 pagesWorkshop On RCM, Jan 2020Naga ChaitanyaPas encore d'évaluation

- Key Indicators of Reverse Logistics For Dairy IndustryDocument3 pagesKey Indicators of Reverse Logistics For Dairy IndustryViprasPas encore d'évaluation

- INCOSE Benefits Limitations of Current Techniques For Measuring System ReadinessDocument36 pagesINCOSE Benefits Limitations of Current Techniques For Measuring System ReadinesslcatarinoPas encore d'évaluation

- Importance of QualityDocument10 pagesImportance of QualityjaveljamaicaPas encore d'évaluation

- Integrating The SIME Method With Standard Time Domain Simulation Software To Search For Transient Stability LimitsDocument7 pagesIntegrating The SIME Method With Standard Time Domain Simulation Software To Search For Transient Stability LimitsKhumraj PunPas encore d'évaluation

- Failure Analysis of Mechanical Components PDFDocument2 pagesFailure Analysis of Mechanical Components PDFJenny67% (3)

- DE100 Operation Guide 3rd EditionDocument188 pagesDE100 Operation Guide 3rd EditionVladimir VichevPas encore d'évaluation

- O G Power Dist Application GuideDocument24 pagesO G Power Dist Application GuidePatran ValentinPas encore d'évaluation

- Senjata DDtankDocument1 pageSenjata DDtankFast MuzakiPas encore d'évaluation

- BIW Products and Services (4 - 13 - 17)Document13 pagesBIW Products and Services (4 - 13 - 17)lapinPas encore d'évaluation

- MTBFDocument4 pagesMTBFJulio CRPas encore d'évaluation

- Reliability Old SyllabusDocument2 pagesReliability Old SyllabuscivaasPas encore d'évaluation

- L&T Hydrocarbon Engineering Limited (LTHE) : A Wholly Owned Subsidiary of Larsen & Toubro LimitedDocument29 pagesL&T Hydrocarbon Engineering Limited (LTHE) : A Wholly Owned Subsidiary of Larsen & Toubro LimitedJaveria NazPas encore d'évaluation

- AviaciónDocument27 pagesAviaciónRogelio CastroPas encore d'évaluation

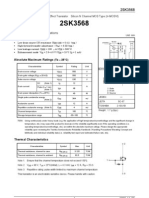

- 2 SK 3568Document6 pages2 SK 3568Angel De Dios RosoPas encore d'évaluation

- Subcontractor SOWDocument3 pagesSubcontractor SOWMaria MarquezPas encore d'évaluation

- Change Information - cs-29 Amendment 11Document55 pagesChange Information - cs-29 Amendment 11Алексей КривегаPas encore d'évaluation

- Quality Assurance, or QA For Short, Is The Set of Planned and Systematic ActionsDocument24 pagesQuality Assurance, or QA For Short, Is The Set of Planned and Systematic Actions0921py100% (1)