Académique Documents

Professionnel Documents

Culture Documents

706096

Transféré par

Peter Jean-jacquesCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

706096

Transféré par

Peter Jean-jacquesDroits d'auteur :

Formats disponibles

Rolling Grilles

Practical Design

Applications

+

+

+

+

+

+

+

+

Mall Storefronts

Behind Storefront Glass

School Corridors

Service Window Openings

Healthcare

Airports / Transportation

Hospitality / Public Space

Parking Garage Vehicular

Access Control

Benefits

Available Options

+ Cornell can manufacture and ship most

standard grilles in one to two weeks.

+ Size Flexibility - each unit is built to exact

opening size requirements.

+ Compact Storage - curtain stores in an

overhead coil that is totally supported by

extensions of the side guides.

+ Durability - commercial duty design.

+ Maintenance - little to none.

+ Repairs - job records are retained and

parts are readily available.

+ Hoods and fascias

+ Cylinder locks with or without

an interior thumbturn

+ Bottom bar sensing edge for

motorized units

+ Operator covers for exterior

mounted units or exposed

operators below 8-0 high

+ Emergency manual release system

+ Motor mounted interlock device

VisionAire

Model ESG10

Open air design allows free

circulation of air and full

visual access of the area

being protected. Curtain

constructed of 5/16 diameter solid

aluminum rods of alloy 5056 H32

(stainless or galvanized optional) at 2 on

center supported by vertical chains formed

of eyeletted aluminum (stainless optional)

spaced at 9 apart. For added security, the

chains may be specified to be spaced at 6

or 3 apart.

VisionAire

Model ESG12

Alternative open air design

in a Brick Pattern

configuration that provides

superior durability in high

cycle applications. Curtain constructed of

horizontal 5/16 diameter solid aluminum

rods of alloy 5056 H32 at 2 centers.

Rods supported by heavy duty aluminum

links, held in a staggered position by tube

spacers throughout the entire curtain

assembly. Can also be used in any opening

if a brick pattern configuration is desired.

VistaGard

Model ESG11

Grilles glazed with G.E.

Lexan (or equal) panels in

the curtain design. Panel

modules are clear 12 x 3,

1/8 thick flame-retardant polycarbonate

material that provides additional

protection from theft of small articles

through the curtain and creates a barrier

against refuse, odors and smoke. Panels

are secured by bronze color molded nylon

links attached to 5/16 diameter solid

aluminum horizontal rods of alloy 5056 H32.

Rolling Grille Components

Brackets

Minimum 3/16 steel plates bolt

to guide supporting member

and support counter balance

shaft and curtain.

Standard Material & Finish:

steel, with SpectraShield

powder coating 30-7192 gray

Counterbalance Shaft

4-1/2 minimum diameter outer

shaft and 1-1/4 minimum inner shaft.

This assembly supports the curtain and

contains counter-balance torsion springs for

assisting operation.

Standard Material: steel

Optional Hood

& Fascia

(not normally provided when

unit is concealed above a ceiling)

Protective sheet metal enclosure

for the curtain.

Standard Material & Finishes: ASTM A 653

GalvaNex coating system, light gray enamel top coat or

aluminumin mill, clear and color anodized or 300 series

stainless steel with a #4 finish

Guides

Extruded aluminum

sections equipped

with polypropylene

pile runners and

mounting member.

Support the entire

weight of the unit.

Standard Material

& Finish: mill finish

aluminum

Optional Finishes:

clear and color

anodized aluminum

Bottom Bar

2 x 3 1/2 heavy duty

extruded aluminum

tubular section that

houses optional locking

mechanisms. For widths

greater than 27-4, the bottom

bar is reinforced with 3 x 2 x 3/16

aluminum angle(s).

Standard Material & Finish: mill finish

aluminum

Optional Material: stainless steel angles

Curtain

A series of: straight pattern horizontal rods and

chains OR horizontal rods and tube spacers with

vertical links in a brick pattern OR rods with

glazed polycarbonate panels between molded

nylon links. See complete curtain description on

front page.

Standard Material & Finish: mill finish aluminum

Optional Materials: stainless or galvanized steel

(VisionAire ESG10 and VistaGard only)

Operation

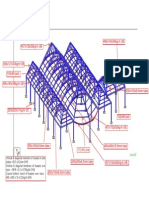

Self-Supporting Installation Option

Push-up operation shown. Hand crank, chain and

motors are available. Grilles operate by rotating

the shaft gear end. The opposite end of shaft

applies spring tension and is equipped with a

spring adjusting wheel.

Many grille installations utilize structural steel tubes for support,

which allows for installation prior to the walls and ceiling being

built. The tubes are factory prepared for the attachment of all

grille components. Tubes are attached to the floor slab below

and the joists above, thereby becoming self-supporting.

Mounting & Clearances

Between Jambs

Self-Supporting

Mounts to structural tubes

that are attached to the floor

slab and braced to the

structure above.

Between Jambs

Conventional

Mounts within the opening,

fascia (front hood closure

piece) required.

Face of Wall

Maintains clearance of full

opening, minimal exposed

components.

Special Feature Options

+ Manual Release System for

use with motorized grilles to

meet building code exit

requirements. Wall mounted

pull handle disengages the

motor allowing grille to

partially open for egress.

+ Motor Mounted Interlock an overload sensing device that

prevents damage if motor operation is

attempted when the grille is locked.

Field wired guide mounted interlocks are

no longer necessary.

+ EZ Lift Package - extends manual pushup operation by about 33%. Push-up

VisionAire aluminum grilles are available

up to 22 wide by 10 high.

Special Applications

+ High Cycle Construction - for grilles that

will cycle more than 5 times per day,

such as parking garages and sally port

openings, Cornell recommends Model

ESG12 brick pattern configuration. An

alternative construction is Cornells

SentryGate grille.

+ High Cycle Springs - heavy duty springs

manufactured to withstand cycles of

50,000 or 100,000.

+ Combination Doors - combines two

different curtains on the same opening.

Typically an insulated door is used in

conjunction with either an open design

rolling grille or a ScreenGard door.

+ Fixed Panels - grille curtain can be

mounted in a fixed frame assembly to

be installed near a rolling grille curtain

or separately.

+ Sloping or Irregular Sills - special

bottom bar designs meet odd floor

conditions including slopes, curbs or rails.

+ Removable Guide Mullions - used for

extra wide openings that require full

access on a limited basis.

Optional Finishes

+ Aluminum in clear or color anodized

+ Stainless steel, 300 series #4 finish

(VisionAire ESG10 and VistaGard only)

+ Hot-dip galvanized steel rods (VisionAire

ESG10 and VistaGard only)

+ Powder coat finish on perimeter

components in selected color (not

available on curtains)

An ISO 9001:2000 Registered Company

Crestwood Industrial Park

Mountaintop, PA 18707

TEL 800.233.8366 FAX 800.526.0841

Architect and Design Support: Ext. 551

Website: www.cornelliron.com

Email: ADS@cornelliron.com

Rev. 2.007 Cornell Iron Works

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Sports Field DrainageDocument3 pagesSports Field DrainagePeter Jean-jacquesPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Design of Custom ElementsDocument5 pagesDesign of Custom ElementsPeter Jean-jacquesPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Keyboard ShortcutsDocument2 pagesKeyboard ShortcutsUmt KcPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Soil PenetrometerDocument4 pagesSoil PenetrometerPeter Jean-jacquesPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Equipment: Method of Assessment:: Block Extraction and ExaminationDocument2 pagesEquipment: Method of Assessment:: Block Extraction and ExaminationPeter Jean-jacquesPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Argos Usa - Cements For MasonryDocument39 pagesArgos Usa - Cements For MasonryPeter Jean-jacques0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Steel Sheet Piling SpecificationDocument5 pagesSteel Sheet Piling SpecificationPeter Jean-jacquesPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- RICS Standard Form For Consultants AppointmentDocument39 pagesRICS Standard Form For Consultants AppointmentPeter Jean-jacquesPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Weep Hole Part Elevation Section: Drawn: Checked: Approved: Date: CAW 5/9/2011Document1 pageWeep Hole Part Elevation Section: Drawn: Checked: Approved: Date: CAW 5/9/2011Peter Jean-jacquesPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Approach Slab DetailsDocument2 pagesApproach Slab DetailsPeter Jean-jacquesPas encore d'évaluation

- Cathedral Roof Truss StructureDocument1 pageCathedral Roof Truss StructurePeter Jean-jacquesPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Metal Spiral Stairs Install ManualDocument36 pagesMetal Spiral Stairs Install ManualPeter Jean-jacquesPas encore d'évaluation

- f' f φ = 29° γ = 120 pcf: AssumptionsDocument3 pagesf' f φ = 29° γ = 120 pcf: AssumptionsPeter Jean-jacquesPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Azure Essentials: Module 5: Azure Cost Management and Service Level AgreementsDocument9 pagesAzure Essentials: Module 5: Azure Cost Management and Service Level Agreementsrajagopalan19Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Prednisolone Versus Dexamethasone For Croup: A Randomized Controlled TrialDocument11 pagesPrednisolone Versus Dexamethasone For Croup: A Randomized Controlled TrialA Joel ZjPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Inverter ProjectDocument19 pagesInverter ProjectRavi Sharma100% (1)

- High Pressure Processing of Food - Principles, Technology and ApplicationsDocument758 pagesHigh Pressure Processing of Food - Principles, Technology and ApplicationsEduardo Estrada100% (1)

- ENG 110-Task 4 (Unintended Messages)Document2 pagesENG 110-Task 4 (Unintended Messages)Erika Noreen Dela RosaPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Risk Management Policy StatementDocument13 pagesRisk Management Policy StatementRatnakumar ManivannanPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- PCC 2 What Is PCC 2 and Article of Leak Box On Stream RepairGregDocument12 pagesPCC 2 What Is PCC 2 and Article of Leak Box On Stream RepairGregArif Nur AzizPas encore d'évaluation

- Me22 M1a1Document2 pagesMe22 M1a1Jihoo JungPas encore d'évaluation

- PackageDocument3 pagesPackagegvspavan67% (3)

- CGG Book 1Document34 pagesCGG Book 1api-245318709Pas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Quick Guide To Cardiopulmonary Care 4th EditionDocument185 pagesQuick Guide To Cardiopulmonary Care 4th EditionLorenzo Romero AlbarranPas encore d'évaluation

- Treeleaf Basic Zazen InstructionsDocument16 pagesTreeleaf Basic Zazen InstructionsFaisal sarhiPas encore d'évaluation

- Standard Practice For Magnetic Particle Testing For AerospaceDocument16 pagesStandard Practice For Magnetic Particle Testing For AerospaceSaul RuizPas encore d'évaluation

- Nomenclature Practice ProblemsDocument4 pagesNomenclature Practice ProblemsMax DavidsonPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- TDS-PE-102-UB5502H (Provisional) 2019Document2 pagesTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraPas encore d'évaluation

- The Zombie in The Brain and The Woman Who Died LaughingDocument40 pagesThe Zombie in The Brain and The Woman Who Died Laughingcory_ruda100% (1)

- Ocean StarDocument36 pagesOcean Starrobertshepard1967Pas encore d'évaluation

- Wel-Come: Heat Treatment Process (TTT, CCT & CCR)Document14 pagesWel-Come: Heat Treatment Process (TTT, CCT & CCR)atulkumargaur26Pas encore d'évaluation

- 3.0.2 3.0.2 Thermax Inc.: Pressure Building Ambient Vaporizers For Bulk Storage TanksDocument2 pages3.0.2 3.0.2 Thermax Inc.: Pressure Building Ambient Vaporizers For Bulk Storage TanksSiDdu KalashettiPas encore d'évaluation

- 2nd Year HEROES SUMMARIESDocument4 pages2nd Year HEROES SUMMARIESMustafa NizamiPas encore d'évaluation

- TMP DEDADocument8 pagesTMP DEDAFrontiersPas encore d'évaluation

- Guide For Visual Inspection of Structural Concrete Building ComponentsDocument76 pagesGuide For Visual Inspection of Structural Concrete Building ComponentsMazin AlwashPas encore d'évaluation

- 2016 Liberal Policy ResolutionsDocument86 pages2016 Liberal Policy ResolutionsCPAC TVPas encore d'évaluation

- Biecco Lawrie Ece Gec Reyrolle Burn Jyoti SwitchgearDocument18 pagesBiecco Lawrie Ece Gec Reyrolle Burn Jyoti SwitchgearSharafat AliPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Chrono Biology SeminarDocument39 pagesChrono Biology SeminarSurabhi VishnoiPas encore d'évaluation

- Real Time EvaluationDocument3 pagesReal Time Evaluationأيوب علاءPas encore d'évaluation

- Bradycardia AlgorithmDocument1 pageBradycardia AlgorithmGideon BahulePas encore d'évaluation

- PsychodramaDocument5 pagesPsychodramaAkhila R KrishnaPas encore d'évaluation

- X-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteDocument2 pagesX-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteAmr RagabPas encore d'évaluation

- Research Article Effects of PH On The Shape of Alginate Particles and Its Release BehaviorDocument10 pagesResearch Article Effects of PH On The Shape of Alginate Particles and Its Release BehaviorAmalia HanifaPas encore d'évaluation

- House Rules: How to Decorate for Every Home, Style, and BudgetD'EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetPas encore d'évaluation