Académique Documents

Professionnel Documents

Culture Documents

Materials Report

Transféré par

Patrick GohCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Materials Report

Transféré par

Patrick GohDroits d'auteur :

Formats disponibles

Student ID: 9235733

Introduction:

This report discusses the mechanical performance of steel. In this two parts experiment we

examined the properties of heat treated steels and mechanical properties of steel over a

range of temperature. Steels are often heat treated to alter their properties in controlled

sequences, for specific engineering application. Heat treatment of steel uses phase

transformation to achieve certain properties by manipulating its carbon content. Heat

treatment begins with austenitisation which steels are heated to critical temperature and

cooled in different manners, which will result in different properties. Tensile test was carried

out to examine 4 080M46 steel coupons with different heat treatment conditions. In second

part of the experiment impact test was carried out on Grade 43a steel to study its toughness

over a range of temperature. Low carbon steel (bcc) is said to have ductile-to-brittle

transition temperature which can be critical in engineering application.

Experimental Methods:

Part 1- Heat Treatment of Steels

3 different types of cooling will be introduced. 3 out of 4 steel coupons will be treated by

annealing, oil-quenching, and water-quenching. The remaining coupon will undergoes

tensile test in as received condition as a reference. The 3 coupons are heated to 870 for 15

minutes. One is then set to furnace cooling and the other 2 are quenched in oil and water

respectively. Transferring of heated coupon to quenching liquid must be done quickly (1

sec). The 4 coupons will then undergo tensile test and 4 plots of load-displacement graph

are recorded. Continuous cooling transformation (CCT) diagram of the steel will be used to

determine its microstructure at room temperature.

Part 2- The Ductile to Brittle Transitions in Steels

Charpy impact test is used to study the toughness of the steel. Liquid nitrogen will be used

to lower the temperature of specimen while boiling water is used to rise the temperature.

The temperature of the specimen is recorded by using temperature probe before the impact

test is carried out. Value of impact energy absorbed by the specimen can be directly

recorded from the dial plate. By plotting the impact energy against temperature graph we

can determine the transition temperature of the specimen. Note that value of impact energy

recorded is in unit of ft-lb, and it can be converted to joules by the formula

1.35581795 =

The graph is expected to be a smooth curve.

MACE20037 Materials 2

Student ID: 9235733

Result:

Part 1- Heat Treatment of Steels

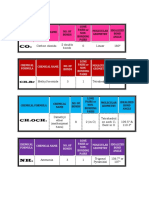

Type of heat

treatment

*Yield Stress

Ultimate Tensile

Elongation(mm)

%

/Proof Stress

Strength (MPa)

elongation

(MPa)

As received

457.570

716.197

7.750

0.0775

Annealed

258.627

431.708

26.333

0.2633

Oil quenched

397.887

587.481

10.419

0.1042

Water quenched

1094.190

1456.864

9.920

0.0992

*Yield stresses are determined by approximation because of the difficulty in obtaining at 0.2%

offset.

Part 2- The Ductile to Brittle Transitions in Steels

Temperature

()

-60

-40

-20

-0.5

10

20.5

24

30

46.7

55

10.2

11.5

14.2

40.7

37.3

67.8

83.4

208.8

188.5

229.1

Impact energy

(J)

Graph of impact energy (J) against temperature ().

MACE20037 Materials 2

Student ID: 9235733

Discussion:

Part 1- Heat Treatment of Steels

1. Based on Fe-FE3C diagram, it is required to heat the steel above 870 in order for

transformation into austenite phase. It is necessary to keep the temperature for

period of time for carbon diffusion to take place. This is to develop homogenous

austenite.

2. Martensite and bainite might have formed.

3. 400/hour=0.1/s. From the CCT diagram, pearlite formed.

4. Water quenched specimen has higher yield stress and is stronger than the oil

quenched specimen. The result was as expected as water quenched specimen

undergoes faster cooling rate that oil quenched specimen, which makes water

quenched specimen stronger. From the graph it can be seen that both quenched

specimens show a slight ductile behaviour, which we believe it could be a result of a

slow loading condition. Besides that, density of the material will not be ideally

identical at each length of the specimen and its impossible to be totally eliminated.

5. Oil quenched specimen has higher yield stress than annealed specimen. This is

because martensite is formed in oil quenched specimen, which makes the specimen

harder but brittle. Annealed specimen lost some of its strength but gained more

ductility.

6. Relative toughness: Annealed > water quenched > as received > oil quenched. Note

that area under the graph for annealed and water quenched are almost similar. As

mentioned above, water quenched doesnt show high brittleness as expected,

possibly due to slow loading. As received specimen has high toughness than oil

quenched specimen because latter one shows less ductility. We emphasise on the

definition of toughness as the ability of a material to absorb energy before fracture,

which means it must be strong and ductile.

7. The quenched specimen should undergo tempering. Tempering is a controlled

heating process where material is heated to temperature below austenitisation

temperature but high enough for diffusion to occur and allows fine distribution of

Fe3C precipitates. This will partially restore the ductility of the material and makes it

tougher.

Part 2- The Ductile to Brittle Transitions in Steels

1. No. A more precise temperature measurement will be required by identify the

warming curve of the specimen. 10 set of values cannot clearly differentiate the

lower shelf and upper shelf temperatures. Friction between pendulum and its

support is not accounted for which doesnt contribute to toughness of material.

2. 28. Temperature before the start of the test was assumed to be the

instantaneous temperature of the specimen right before impact. Heat loss, air

resistance, and friction from dragging pointer and support are negligible. We

also assumed the properties of the specimen are uniform throughout the length.

The plot is assumed to be reliable.

MACE20037 Materials 2

Student ID: 9235733

3. Lower shelf and upper shelf temperature were not clearly identified. At each

temperature, only one experiment was carried out. Surrounding temperature was

not considered as it might not be the same when the machine is calibrated.

Instantaneous temperature during the cutting moment cannot be determined. Point

of contact might not be at the tip of the notch (thinness part of the specimen).

4. No. Based on the plot -20 is below the ductile to brittle transition temperature

(DBTT). The steel is dominated by brittle behaviour.

Conclusion:

This experiment helps me to a better understanding of heat treated steel and influence of

temperature on the toughness of steel. Generally martensite phase harden the steel but is

prone to brittle failure. This can be overcome by tempering the steel. Annealed steel has

better ductility but it has low yield stress. CCT diagram can be used to determine the

properties of a heat treated steel. Toughness is defined as the ability to absorb energy

before fracture. Steel shows a ductile to brittle transition temperature which could be vital

in engineering application. Below the DBTT, the steel shows brittle behaviour and can only

absorbs small amount of energy before fracture.

MACE20037 Materials 2

Vous aimerez peut-être aussi

- PDFDocument4 pagesPDFPatrick GohPas encore d'évaluation

- 14 SubjectbibliographytextbooksDocument3 pages14 SubjectbibliographytextbooksPatrick GohPas encore d'évaluation

- Basics of Iron and Steel MakingDocument4 pagesBasics of Iron and Steel MakingsanbajajPas encore d'évaluation

- Penang MapDocument2 pagesPenang MapYusri BidinPas encore d'évaluation

- Penang MapDocument2 pagesPenang MapYusri BidinPas encore d'évaluation

- Ice Handout2Document17 pagesIce Handout2Camilo Jose100% (2)

- HEVO Role Description 2015-16Document1 pageHEVO Role Description 2015-16Patrick GohPas encore d'évaluation

- Goh Nam Dynamics Lab Coursework 2014-2015Document7 pagesGoh Nam Dynamics Lab Coursework 2014-2015Patrick GohPas encore d'évaluation

- Ace Ahead Chemistry (CD-Rom) 1st (17.2.11)Document17 pagesAce Ahead Chemistry (CD-Rom) 1st (17.2.11)helenxiaochingPas encore d'évaluation

- Manufacturing Engineering 2Document4 pagesManufacturing Engineering 2Patrick GohPas encore d'évaluation

- Applied Thermo Engine Test Error SourcesDocument2 pagesApplied Thermo Engine Test Error SourcesPatrick GohPas encore d'évaluation

- Ace Ahead .Physics Vol 1. Student. Practical GuideDocument18 pagesAce Ahead .Physics Vol 1. Student. Practical GuideKee N. KeePas encore d'évaluation

- Astronomical TelescopeDocument4 pagesAstronomical TelescopePatrick GohPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hollosep Trial in SpainDocument10 pagesHollosep Trial in SpainGandrig F VendrisPas encore d'évaluation

- Physical Mechanism of Sono-Fenton ProcesDocument11 pagesPhysical Mechanism of Sono-Fenton ProcesDebanjan DuttaPas encore d'évaluation

- Gwf-Int 01 2011 ArtikelDocument12 pagesGwf-Int 01 2011 ArtikelPetra Margot PedrazaPas encore d'évaluation

- Lab Report No 8Document11 pagesLab Report No 8Mansoob BukhariPas encore d'évaluation

- IEM PI A401 - ANNEXE - Design & Site ExperienceDocument5 pagesIEM PI A401 - ANNEXE - Design & Site ExperienceapiplajengilaPas encore d'évaluation

- Epo-Tek 353ND: Technical Data SheetDocument2 pagesEpo-Tek 353ND: Technical Data SheetJamesPas encore d'évaluation

- Bonite Bonite LDDocument2 pagesBonite Bonite LDManoj ChitrePas encore d'évaluation

- Metal Ions in Biological SystemsDocument10 pagesMetal Ions in Biological SystemsFurkan Mat SallehPas encore d'évaluation

- DubniumDocument8 pagesDubniumKevinPas encore d'évaluation

- Porosity and Wear Resistance of Flame Sprayed TungstenDocument7 pagesPorosity and Wear Resistance of Flame Sprayed Tungstenlacoste11111Pas encore d'évaluation

- Bioorganic & Medicinal Chemistry LettersDocument3 pagesBioorganic & Medicinal Chemistry LetterschemikanthPas encore d'évaluation

- Types of Thermodynamic ProcessesDocument10 pagesTypes of Thermodynamic ProcessesChandana SamalaPas encore d'évaluation

- Molecular Geometry ChartDocument3 pagesMolecular Geometry ChartJoyci CauilanPas encore d'évaluation

- Lab 2 (Topic 9)Document4 pagesLab 2 (Topic 9)diva nathanPas encore d'évaluation

- Pentens Industrial Flooring Solution NewDocument32 pagesPentens Industrial Flooring Solution Newウィリアムズ アンディPas encore d'évaluation

- Hindi Physics, Chemistry and Biology Notes for Pre-Medical ExamDocument37 pagesHindi Physics, Chemistry and Biology Notes for Pre-Medical ExamAnuz MominPas encore d'évaluation

- SARA PEREZ TRUJILLO - Molecules and Bonds 7BDocument4 pagesSARA PEREZ TRUJILLO - Molecules and Bonds 7BApuestas JulanoPas encore d'évaluation

- 13X 30403 A CertificateDocument4 pages13X 30403 A CertificatePhạm DươngPas encore d'évaluation

- Determination of Total Lipids As Fatty Acid Methyl Esters (FAME) by in Situ TransesterificationDocument16 pagesDetermination of Total Lipids As Fatty Acid Methyl Esters (FAME) by in Situ TransesterificationpeterPas encore d'évaluation

- Latihan Uas CH 4-6Document16 pagesLatihan Uas CH 4-6rizkaPas encore d'évaluation

- Bruker Almanac 2011Document205 pagesBruker Almanac 2011Sandi WijayaPas encore d'évaluation

- Thermodynamics Chapter 1 ReviewDocument20 pagesThermodynamics Chapter 1 ReviewReinzo GallegoPas encore d'évaluation

- eAuditNet Proficency Testing (PT) Providers 312019Document2 pageseAuditNet Proficency Testing (PT) Providers 312019viverefelicePas encore d'évaluation

- Thermochemistry: Practice Questions For H2 Chemistry Remedial ClassesDocument7 pagesThermochemistry: Practice Questions For H2 Chemistry Remedial ClassesTimPas encore d'évaluation

- Retrowrap Materials Performance FactsDocument2 pagesRetrowrap Materials Performance FactsMPas encore d'évaluation

- ADSORPTION vs ABSORPTIONDocument19 pagesADSORPTION vs ABSORPTIONنور الهدىPas encore d'évaluation

- Syl-Off: Solvent-Based, Platinum-Catalyzed Silicone Release Coatings From Dow CorningDocument12 pagesSyl-Off: Solvent-Based, Platinum-Catalyzed Silicone Release Coatings From Dow CorningAndrea GrajalesPas encore d'évaluation

- Science Experiments 4th GradeDocument8 pagesScience Experiments 4th GradeNarayanPas encore d'évaluation

- Amanda Barnard: Amanda Susan Barnard (Born 31 December 1971) Is An AustralianDocument3 pagesAmanda Barnard: Amanda Susan Barnard (Born 31 December 1971) Is An AustralianstfPas encore d'évaluation

- Service - FL - en Cranex Tome SoredexDocument432 pagesService - FL - en Cranex Tome Soredexdr.sherifbisharaPas encore d'évaluation