Académique Documents

Professionnel Documents

Culture Documents

029 Hot Tap Procedure 0011

Transféré par

Fadlul Akbar HerfiantoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

029 Hot Tap Procedure 0011

Transféré par

Fadlul Akbar HerfiantoDroits d'auteur :

Formats disponibles

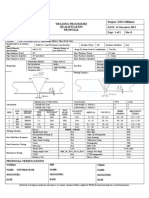

BASF Corporation

Title: HOT TAP PROCEDURE

Individual Unit

Procedure

Function: Safety

No.: BCF 020.029

Page: 1 of 5

Freeport Site

Reviewed: New

Effective: 11/07/00 Supersedes: SS #29

Preparer:

Owner:

Approver:

Site Safety Representative

Manager, Environ, Health & Safety

VP and Gen. Mgr.,

Freeport

1.

PURPOSE

This procedure and attached work instructions provide guidelines and requirements for

the use of hot tap procedures. The use of hot tap procedures is to be limited to jobs that

cannot be accomplished using standard procedures without incurring a major safety,

economic or production impact. API 2201 serves as the basis for this procedure.

2.

DEFINITIONS

2.1.

*Hot Tap

The method of attaching connections or accessories onto a vessel or process line

that is in service. This includes not only the attachment of any external device

made by welding but also all penetrations into the process.

2.2.

Hot Tap Permit

A stepped checklist for the request, approval and procedures for performing

welding and hot tap operations. See BCF020.029 WI.

2.3.

*Post Weld Heat Treatment (PWHT)

Heating a vessel, pipe or structure to a sufficient temperature to relieve the

residual stresses which are the result of mechanical treatment or welding.

3.

SCOPE

This procedure and attached work instructions apply to BASF Corporations Freeport Site

(BCF).

4.

PROCEDURE

4.1.

General

Hot taps shall not be performed on vessels containing flammable liquids while

the liquid is being pumped out of the vessel. Pumps/valving must be

shutdown/closed and red tagged.

Hot taps upstream of rotating/reciprocating equipment, or control/isolation

valves, must be protected from cuttings by filters, screens or traps.

A thickness test and visual inspection must be conducted in the immediate

area and extending out a minimum of 12 inches, or the diameter of the line,

whichever is larger.

Note: If the thickness is less than the original thickness, or is less than 3/16

inches, an engineering evaluation must be done to determine if it is safe to

make a hot tap.

BASF Corporation

Title: HOT TAP PROCEDURE

Individual Unit

Procedure

Function: Safety

No.: BCF 020.029

Freeport Site

Reviewed: 11/99

Page: 2 of 5

Effective: 11/07/00 Supersedes:

SS #29

The TES Pressure Vessels Group shall evaluate and determine if a reinforcing

pad is required. The PV Group will provide a sketch showing fabrication

details for the attachment.

The hot tap location must be:

More than 18 inches from all flanges or threaded connections,

More than 3 inches from a welded seam.

Note: Proposed hot taps which do not meet these requirements may be

approved by the TES PV Group if an engineering analysis of the vessel,

piping design, operating conditions and the taps location is performed.

When welding the hot tap nozzle onto a line that contains flammable materials,

the flow in the line for a liquid or gas process must be at least 1.3 feet per

second, as a minimum.

Note: Excessive flow rates will increase the cooling rate at the weld site and

could increase the risk of weld cracking.

4.2.

When welding on a vessel containing liquid, the level must be at least 3 feet

above the location of the hot tap.

The oxygen content within the vessel or equipment must be less than 1%.

Prohibited Hot Taps

Hot taps on equipment in the below services shall not be done:

Vapor/air or vapor/oxygen mixtures near or within their flammable explosive

range.

Peroxides, chlorine, or other chemicals likely to violently decompose or

become hazardous from the heat of welding.

Unsaturated hydrocarbons (such as ethylene) that may experience exothermic

decomposition due to the high temperatures created by welding.

Caustics, amines, and acids (such as H. F. acid) if the concentrations and

operating temperatures are such that the fabrication specifications require post

weld heat treatment (stress relieving).

Oxygen

Oxygen enriched atmospheres.

Note: The amount of oxygen needed for an enriched atmosphere varies with

each products flammable limits.

Compressed air, unless known to be free of flammables and combustibles,

such as lubricating oil residues.

BASF Corporation

Title: HOT TAP PROCEDURE

Individual Unit

Procedure

Function: Safety

No.: BCF 020.029

Freeport Site

Reviewed: 11/99

5.

Page: 3 of 5

Effective: 11/07/00 Supersedes:

SS #29

Lines or equipment in any service where post weld heat treatment is required.

Lines or equipment that are clad or lined.

4.3.

Restricted Hot Taps

Welding or hot tapping on piping or equipment in vacuum service

(< atmospheric pressure) must have an engineering evaluation, and approval,

from the TES Pressure Vessels Group.

Welding or hot tapping on piping or equipment in hydrogen service must have

an engineering review, and approval, by a competent person (as determined

by the TES Group).

4.4.

*Training

Safe Work Permit and Hot Tap Permit writers shall be trained in the

requirements of this procedure and attached work instructions.

Training shall be done upon eligibility to write said permits, when changes to

the procedure(s) are made, or every three years as a minimum.

4.5

*Documentation

A record of training shall be kept in the employees training file.

The record should reflect the following:

Date of training

Instructor

RESPONSIBILITIES

5.1.

Managers

Review/approve hot tap requests.

Designate, in writing, qualified BASF personnel who are trained/authorized to

write and issue hot tap permits.

Audit hot tap permit system for compliance to requirements.

*Ensure unit/department personnel are trained in the requirements of this

procedure and attached work instructions.

5.2.

TES Mechanical Group, a.k.a., Pressure Vessel Group (TES MG)

Review hot tap permit requests.

Provide guidance/assistance to BASF Requestor and/or Representative in

acquiring thickness tests and performing visual inspections of the hot tap site.

BASF Corporation

Title: HOT TAP PROCEDURE

Individual Unit

Procedure

Function: Safety

No.: BCF 020.029

Freeport Site

Reviewed: 11/99

Page: 4 of 5

Effective: 11/07/00 Supersedes:

SS #29

Provide welding procedures/drawings and/or additional requirements i.e.,

reinforcement pads, flow and pressure requirements, etc.

Provide/assign restricted hot tap permit evaluations.

Approve hot tap permit requests.

5.3.

BASF Requestor

Fill in section "A" of the permit and submit to owning manager.

5.4.

BASF Representative

Coordinate hot tap job assignment and ensure that all necessary signatures

are obtained as the job progresses from step to step.

Verify procedural calculations and monitor job to ensure all required

procedures are followed.

Issue the Hot Tap Permit to the Hot Tap Technician (HTT).

Maintain original hot tap permit until the work is complete.

*Ensure that the control room is notified at the beginning of the welding step

and at the beginning of the hot tap step.

*Advise DOT of pending hot tap procedures for scheduling/preparation

purposes.

*Train in the requirements of this procedure and attached work instructions.

5.5.

DOT Leader

Coordinate with BASF Representative and Team to prepare necessary

procedures, emergency plans and address requirements for hot tap work, i.e.,

flows, temperatures, levels, communications, stand-by personnel, etc.

Review and sign section "B" and "C" when required to, ascertain that

requirements of hot tap permit have been met and that approval is given.

Notify team when hot tap welding and drilling activities are in progress.

*Train designated personnel in the requirements of this procedure and

attached work instructions.

5.6.

Hot Tap Technician (HTT)

Provide copy of hot tap rigs depth measurements, cutting distance calculations

to BASF Representative.

Verify with BASF Representative that there is sufficient room at the hot tap site

to safely operate the hot tap rig.

Adhere to the requirements of this procedure, work instructions, permit and

API's recommended practice 2201 (Hot Taps).

Verify applicable questions in section "C" and sign the hot tap permit before

beginning the tapping procedure.

BASF Corporation

Title: HOT TAP PROCEDURE

Individual Unit

Procedure

Function: Safety

No.: BCF 020.029

Freeport Site

Reviewed: 11/99

6.

Page: 5 of 5

Effective: 11/07/00 Supersedes:

SS #29

Verify applicable questions in section "D" and sign the hot tap permit before

removing the hot tap rig.

*RELATED DOCUMENTS

API Recommended Practice 2201

BCF020.023 Hot Work

BCF020.029WI Hot Tap Permit

BCF020.001 Safe Work Procedure

BCF020.029WI

Hot Tap Permit

Vous aimerez peut-être aussi

- LicencesDocument5 pagesLicencesstopnaggingmePas encore d'évaluation

- Hot Tap CalculationDocument20 pagesHot Tap CalculationVetti Payan100% (6)

- Orifice Flange Guide - Daniel FlowDocument45 pagesOrifice Flange Guide - Daniel FlowSammyPas encore d'évaluation

- Calculus HandbookDocument198 pagesCalculus HandbookMuneeb Sami100% (1)

- Hot Tap ProcedDocument4 pagesHot Tap Procedvijimurugan2003100% (1)

- GRP Procedure PDFDocument42 pagesGRP Procedure PDFJITHIN KRISHNAN MPas encore d'évaluation

- BAB III EPCI of KP 47 Pipeline Permanent RepairDocument8 pagesBAB III EPCI of KP 47 Pipeline Permanent Repairsuwindisaragih100% (1)

- 62-P-90Rev A Method Statement For Oxygen Line FabricationDocument13 pages62-P-90Rev A Method Statement For Oxygen Line FabricationAsadAliAliPas encore d'évaluation

- BOLT Torquing ReportDocument4 pagesBOLT Torquing ReportSumith Kumar S MPas encore d'évaluation

- Specification FOR Carbon Steel Seamless Linepipe For Submarine Pipelines (Sour Service)Document27 pagesSpecification FOR Carbon Steel Seamless Linepipe For Submarine Pipelines (Sour Service)GomathyselviPas encore d'évaluation

- Hot Tap ProcedureDocument21 pagesHot Tap ProcedureImanuel Sitepu100% (1)

- Orifice FlangesDocument4 pagesOrifice FlangesdediekosPas encore d'évaluation

- Pressure Test Certificate PDFDocument1 pagePressure Test Certificate PDFMarkLouiseSumugatOlandresPas encore d'évaluation

- Internal Cleaning of PipingDocument14 pagesInternal Cleaning of PipingMcmiltondmordomPas encore d'évaluation

- Hot TapDocument4 pagesHot TapmiteshPas encore d'évaluation

- 760C Tapping MachineDocument6 pages760C Tapping MachineTunjung Wicaksana RanukusumaPas encore d'évaluation

- Procedure Welding Part 2Document14 pagesProcedure Welding Part 2mohammadPas encore d'évaluation

- Work Instruction FOR: Tensile TestDocument4 pagesWork Instruction FOR: Tensile TestmahendraPas encore d'évaluation

- 583-9738 Procedure For Piping 00Document22 pages583-9738 Procedure For Piping 00sivaramPas encore d'évaluation

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDocument1 pageWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiPas encore d'évaluation

- B 84567 SB PP0 DRT ST 60 0003 - 2 - AOC - Existing Fuel Gas System Adequacy CheckDocument41 pagesB 84567 SB PP0 DRT ST 60 0003 - 2 - AOC - Existing Fuel Gas System Adequacy CheckFadlul Akbar Herfianto100% (1)

- Lateritic NickelDocument27 pagesLateritic NickelRAVI1972100% (2)

- Method Statement Pipeline - Iccp InstallationDocument10 pagesMethod Statement Pipeline - Iccp InstallationSumer LandPas encore d'évaluation

- WE1884 - ITP For Shop Fab. of Header Coils-120813Document4 pagesWE1884 - ITP For Shop Fab. of Header Coils-120813imran100% (1)

- Materials System SpecificationDocument14 pagesMaterials System Specificationnadeem shaikhPas encore d'évaluation

- Participant Observation: Qualitative Research Methods: A Data Collector's Field GuideDocument17 pagesParticipant Observation: Qualitative Research Methods: A Data Collector's Field GuideMarta CabreraPas encore d'évaluation

- BGEP-JPKE-P133-PAXX-PL-08-142-0015-D (1) March 11Document48 pagesBGEP-JPKE-P133-PAXX-PL-08-142-0015-D (1) March 11Gururaj P KundapurPas encore d'évaluation

- W SER 0502 AD Manual Flange Torque TighteningDocument8 pagesW SER 0502 AD Manual Flange Torque TighteningAnonymous IJBjI0Pas encore d'évaluation

- Welding Procedures and Welding Qualiy Control For PipingDocument17 pagesWelding Procedures and Welding Qualiy Control For PipingImam BuchairiPas encore d'évaluation

- Re-Welding, Expansion & HT ProcedureDocument6 pagesRe-Welding, Expansion & HT Proceduresuria qaqcPas encore d'évaluation

- 5.1 Vendor Quality PlanDocument52 pages5.1 Vendor Quality PlanPanneer SelvamPas encore d'évaluation

- 002 016 1 PDFDocument15 pages002 016 1 PDFaepriyadiPas encore d'évaluation

- Intsallation of Hot Tap FittingsSAEP0311Document25 pagesIntsallation of Hot Tap FittingsSAEP0311Ehab SaadPas encore d'évaluation

- Tank Field Inspection and Test ProcedureDocument29 pagesTank Field Inspection and Test ProcedureFadlul Akbar Herfianto100% (2)

- Ch06 Allocating Resources To The ProjectDocument55 pagesCh06 Allocating Resources To The ProjectJosh ChamaPas encore d'évaluation

- Hot TappingDocument15 pagesHot Tappingghkashyap150% (2)

- Psp-Koti-19 - Hot Tapping Procedure - Rev 0Document14 pagesPsp-Koti-19 - Hot Tapping Procedure - Rev 0cheehoong82Pas encore d'évaluation

- 1 Hot Tap MKSR Dec 2018 003Document137 pages1 Hot Tap MKSR Dec 2018 003Billy KurniawanPas encore d'évaluation

- Material Conversion TableDocument1 pageMaterial Conversion TableravikumarangPas encore d'évaluation

- Participate in Safe Food Handling Practices SITXFSA002 - PowerpointDocument71 pagesParticipate in Safe Food Handling Practices SITXFSA002 - PowerpointJuan Diego Pulgarín Henao100% (2)

- A-Method Statement Painting and Touch-Up Painting For Furnace-CDocument20 pagesA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngPas encore d'évaluation

- Hot TapDocument13 pagesHot TapMSPas encore d'évaluation

- Hot Tap ProcedureDocument6 pagesHot Tap ProcedureNatarajan MurugesanPas encore d'évaluation

- Method Statement: Hot TapDocument43 pagesMethod Statement: Hot TapJaldeep GiniyaPas encore d'évaluation

- S.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5Document7 pagesS.O.P For Hydro-Test: Ipcl-Gandhar Complex WI/GC-C&I/6.3/001 GC Maintenance Manual Hydro Test OF5கோகுல் இராPas encore d'évaluation

- ITP For Pipeline Repair Works - by Using Belzona Superwrap IIDocument4 pagesITP For Pipeline Repair Works - by Using Belzona Superwrap IIAhmedPas encore d'évaluation

- ITP Expoxy Bonded Pipeline TripatraDocument16 pagesITP Expoxy Bonded Pipeline TripatraparwotoPas encore d'évaluation

- Procedure For Field Joint CoatingDocument10 pagesProcedure For Field Joint CoatingM Waqas HabibPas encore d'évaluation

- Pygas SpecDocument1 pagePygas SpecFadlul Akbar HerfiantoPas encore d'évaluation

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDocument26 pagesNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosPas encore d'évaluation

- Piping Daily Fit Up Quality Control and Inspection Report FormDocument1 pagePiping Daily Fit Up Quality Control and Inspection Report FormMd Shariful IslamPas encore d'évaluation

- Doc. No Revision No Revision DateDocument6 pagesDoc. No Revision No Revision DateShyam SinghPas encore d'évaluation

- A-Qac-Pro-730-38930 Rev ADocument10 pagesA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiPas encore d'évaluation

- 2009 LineMaster ScheduleDocument5 pages2009 LineMaster Scheduleantonio gutierrez100% (1)

- MS For HDPE Pipes Laying ActivityDocument7 pagesMS For HDPE Pipes Laying ActivityJust Do LovePas encore d'évaluation

- TP-01Hydrostatic Test Cover SheetDocument4 pagesTP-01Hydrostatic Test Cover SheetAnonymous GaMb5H52100% (1)

- Att 1 - FPI CFP Training Procedure Rev. 0Document11 pagesAtt 1 - FPI CFP Training Procedure Rev. 0miteshPas encore d'évaluation

- Hydro Test ReportDocument2 pagesHydro Test ReportAnonymous a8oga83Pas encore d'évaluation

- WPS Sa 517Document2 pagesWPS Sa 517DHANANNJAI SINGH -Pas encore d'évaluation

- Asme Sec Ix IntroDocument24 pagesAsme Sec Ix IntroTim Joseph AlvaroPas encore d'évaluation

- JK Pipeline Welding & Installation Traceability Procedure CoDocument1 pageJK Pipeline Welding & Installation Traceability Procedure Cogst ajahPas encore d'évaluation

- Technical Proposal Descaling Removal Pulai - A (2013 ASD)Document22 pagesTechnical Proposal Descaling Removal Pulai - A (2013 ASD)hash117Pas encore d'évaluation

- INS T 004, Tol - OvalityDocument4 pagesINS T 004, Tol - OvalityDeepakPas encore d'évaluation

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickPas encore d'évaluation

- Oman-India Fertilizer Project OIFDocument24 pagesOman-India Fertilizer Project OIFBassam Dahham83% (6)

- Materials System SpecificationDocument15 pagesMaterials System SpecificationAwais CheemaPas encore d'évaluation

- Shop ItpDocument4 pagesShop ItpRanu JanuarPas encore d'évaluation

- Snoop Leak Test LiquidDocument6 pagesSnoop Leak Test Liquidaldi_crisPas encore d'évaluation

- PWHT Procedure Rev.1Document14 pagesPWHT Procedure Rev.1Agni DuttaPas encore d'évaluation

- Tecumseh Guidelines For Utilization of R404A and R507Document7 pagesTecumseh Guidelines For Utilization of R404A and R507Fadlul Akbar HerfiantoPas encore d'évaluation

- Agh IGEM-SR-16 Edition 2Document10 pagesAgh IGEM-SR-16 Edition 2Fadlul Akbar HerfiantoPas encore d'évaluation

- Sket Pump House ModelDocument1 pageSket Pump House ModelFadlul Akbar HerfiantoPas encore d'évaluation

- MSDS MolassesV2Document3 pagesMSDS MolassesV2Fadlul Akbar HerfiantoPas encore d'évaluation

- Book 1 GaegaegeagDocument2 pagesBook 1 GaegaegeagFadlul Akbar HerfiantoPas encore d'évaluation

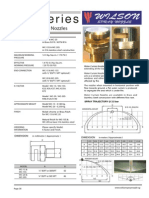

- WC Series: Water Curtain NozzlesDocument1 pageWC Series: Water Curtain NozzlesFadlul Akbar HerfiantoPas encore d'évaluation

- BECIL Registration Portal: How To ApplyDocument2 pagesBECIL Registration Portal: How To ApplySoul BeatsPas encore d'évaluation

- Public Access - The GauntletDocument1 pagePublic Access - The GauntletTesting0% (2)

- Student Exploration: Digestive System: Food Inio Simple Nutrien/oDocument9 pagesStudent Exploration: Digestive System: Food Inio Simple Nutrien/oAshantiPas encore d'évaluation

- Avid Final ProjectDocument2 pagesAvid Final Projectapi-286463817Pas encore d'évaluation

- Footing - f1 - f2 - Da RC StructureDocument42 pagesFooting - f1 - f2 - Da RC StructureFrederickV.VelascoPas encore d'évaluation

- Understanding The Marshall AttackDocument6 pagesUnderstanding The Marshall Attacks.for.saad8176Pas encore d'évaluation

- MCQs - Chapters 31 - 32Document9 pagesMCQs - Chapters 31 - 32Lâm Tú HânPas encore d'évaluation

- Baxter - Heraeus Megafuge 1,2 - User ManualDocument13 pagesBaxter - Heraeus Megafuge 1,2 - User ManualMarcos ZanelliPas encore d'évaluation

- Health and Safety For The Meat Industry: Guidance NotesDocument198 pagesHealth and Safety For The Meat Industry: Guidance NotesPredrag AndjelkovicPas encore d'évaluation

- Personal Finance Kapoor 11th Edition Solutions ManualDocument26 pagesPersonal Finance Kapoor 11th Edition Solutions Manualsiennamurielhlhk100% (28)

- Amp DC, OaDocument4 pagesAmp DC, OaFantastic KiaPas encore d'évaluation

- UntitledDocument13 pagesUntitledTestPas encore d'évaluation

- Agile ModelingDocument15 pagesAgile Modelingprasad19845Pas encore d'évaluation

- Advent Wreath Lesson PlanDocument2 pagesAdvent Wreath Lesson Planapi-359764398100% (1)

- Antibiotics MCQsDocument4 pagesAntibiotics MCQsPh Israa KadhimPas encore d'évaluation

- AstmDocument5 pagesAstmyanurarzaqaPas encore d'évaluation

- Ac1025 Exc16 (1) .PDFTTTTTTTTTTTTTTTTTTTDocument50 pagesAc1025 Exc16 (1) .PDFTTTTTTTTTTTTTTTTTTTHung Faat ChengPas encore d'évaluation

- CV ChristianDocument2 pagesCV ChristianAlya ForeferPas encore d'évaluation

- Migne. Patrologiae Cursus Completus: Series Latina. 1800. Volume 51.Document516 pagesMigne. Patrologiae Cursus Completus: Series Latina. 1800. Volume 51.Patrologia Latina, Graeca et OrientalisPas encore d'évaluation

- Nutrition Great Foods For Getting Vitamins A To K in Your DietDocument1 pageNutrition Great Foods For Getting Vitamins A To K in Your DietDhruv DuaPas encore d'évaluation

- Formal Letter LPDocument2 pagesFormal Letter LPLow Eng Han100% (1)

- TW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Document3 pagesTW BT 01 - Barstock Threaded Type Thermowell (Straight) : TWBT - 01Anonymous edvYngPas encore d'évaluation

- The International Poker RulesDocument2 pagesThe International Poker RulesOutontheBubblePas encore d'évaluation

- Journal of Atmospheric Science Research - Vol.5, Iss.4 October 2022Document54 pagesJournal of Atmospheric Science Research - Vol.5, Iss.4 October 2022Bilingual PublishingPas encore d'évaluation