Académique Documents

Professionnel Documents

Culture Documents

Fire Pumps

Transféré par

Khaleel0 évaluation0% ont trouvé ce document utile (0 vote)

36 vues2 pagespositive displacement pumps

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentpositive displacement pumps

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

36 vues2 pagesFire Pumps

Transféré par

Khaleelpositive displacement pumps

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

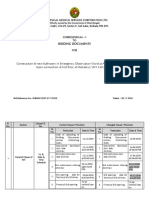

Installation of a fire pump is governed by section

27-946 of the citys administrative code. It requires

that additional water supply be provided for

standpipes in buildings over 300 feet high by one

or more manually-operated fire pumps. When a

fire pump is required to be installed, the pump

must be tested and pass inspection. This guide

offers tips for how to conduct a successful fire

pump test.

Every pump installation requires the following:

1.at least three 50 foot lengths of approved

2 1/2- inch rubber lined hose

2.three 2 1/2 x 1 1/8 nozzles

3.three spanner wrenches (stored in the pump

room or other convenient location) and

4.twelve washers

Signaling System

General requirements for fire

pump installation

In all buildings over 300 feet high there shall be a

telephone signaling system for fire department use

in operating the standpipe system.

Pump Room Guidelines

1.Location: the fire pump room shall be located at the entrance floor or below and shall

have access to street level by direct opening

to the street or by a 2-hour fire rated passageway or stairway.

2.Design: the room shall be of non-combustible construction with a 2-hour fire rating

and must be properly heated, lighted, ventilated, and drained. Horizontal fire pumps

must be located on a concrete foundation at

least 12 inches above the floor with (3) foot

clearance on all sides.

3.Prohibitions: no hazardous refrigerant, gas

pipe or gas-consuming device shall be located

in a fire pump room.

The power supply for a fire pump motor must be

taken from the street side of the house service

switch and must have a disconnect switch plainly

marked Fire Pump Power Supply.

Guidelines for automatic fire

pumps

An automatic fire pump may be used as the primary

water supply for standpipe and sprinkler systems in

buildings 300 feet or less in height or in the lower

300 feet, in higher buildings.

Automatic Fire Pump Capacity: Pump

capacity must be at least 500 GPM with a

minimum discharge pressure of 25 G.P.M and

a maximum of 500 G.P.M.

Pressure Relief Valve: Each automatic fire

pump shall have a 3-inch pressure relief valve

in its pump discharge, set to relieve below the

shut-off head of the pump but above the

required pressure at the highest hose valve.

Relief valve discharge with visual sight glass

may connect to the suction side of the pump

on the pump side of the suction valve.

Water supply guidelines

A manual fire pump is required in addition to the

primary water supply in all buildings over 300 feet

tall.

For both automatic and manual pumps, two

6-inch services from independent street mains

are required. Requirement for residential may

differ.

Capacity: Minimum standard is one 750

GMP pump or two 500 GMP pumps to discharge 50 psi plus friction above the normal

static pressure at the highest hose valve.

Pressure Relief Valve: A manually-operated fire pump shall have a 3-inch relief valve

for 500 GPM pumps and a 4 inch relief valve

for 750 GPM pumps. The relief valve shall not

be set more than 15 psi over the required

pressure at the highest hose outlet. The relief

valve discharge with visual sight glass may

connect back to the suction side of the pump

on the pump side of the suction valve.

Test Valve: Each manual fire pump shall

have a test valve in pump discharge that may

be connected to the discharge side of the relief

valve if it is piped back to the suction side of

the pump. A minimum of 3-inch test pipe is

required for 500 GPM pumps and 4 inch for

750 GPM pumps.

Manual Fire Pump Control: The first step

of the starter shall produce 100 psig at the

pump and each succeeding step increased by

50 psig up to the required pump pressure.

For automatic pumps, one 6-inch service and

a suction tank is permitted if valves at meter

and pump have tamper switches wired to an

approved central station of an operating fire

alarm company. In the event two separate

and distinct water mains are not available,

provide a suction tank with a 1/2 hour supply

at the rated capacity of the pump.

Power Supply

Guidelines for manual fire pumps

Equipment guidelines

Fire pumps at a glance

Tips for a successful fire pump

test

A fire pump test should be conducted only

after the hydrostatic test and walk through

inspection is completed.

Advance notice of inspection and test is

required.

You must have the approved and perforated

plans and the authorizing letter available.

An authorized fire pump company representative must be on site at the time of the test.

All pump and control panel wiring should be

complete before the test is conducted.

BUILD

UILDIN

IN

Fifty feet of approved 2 1/2-inch rubber lined

hose with 1 1/8-inch nozzle shall be connected to the highest 2 1/2-inch hose outlet valve

for each 250 GPM of rated pump capacity.

At the top of the highest riser, there shall be

provided above the main roof level, a 3-way

manifold equipped with three 2-1/2 inch hose

valves with hose valve caps.

Hose nozzle shall discharge at or above highest hose outlet, or through a manifold.

Pitot tube gauge readings shall be taken at

each nozzle to determine required pump

capacity.

Note: 46 pitot gauge reading from one nozzle

is equal to 254 GPM (1 1/8-inch nozzle).

Check all controls for good working order. No

valves in the line leading to controls.

For manual fire pumps, suction and discharge

pressures shall be recorded for each step of

pump speed. The pump R.P.M. electrical current and voltage readings shall be recorded

with specific discharge pressure for each supply condition.

When pumps are supplied by two services,

the test shall be conducted from each service,

independent of each other, and in addition,

with both services supplying the pump.

Reminder:

No Schedule B amendment is required for

minor variations in fixture count.

Details are available on-line at

www.nyc.gov/buildings

Go to resources link and then PIPES.

Does not apply to Gas (PL), Sprinkler (SP or PL),

Medical (PL), or Standpipe (SD)

Call 311 to:

Report illegal construction work

Reach DOB Program Units or Borough Offices

New York City Department of Buildings

Executive Offices / 212-566-5000

280 Broadway, New York, NY 10007

Manhattan Borough Office / 212-566-0042

280 Broadway, New York, NY 10007

Bronx Borough Office / 718-579-6920

1932 Arthur Avenue, Bronx, NY 10457

Brooklyn Borough Office / 718-802-3675

210 Joralemon Street, Brooklyn, NY 11202

Queens Borough Office / 718-286-0600

120-55 Queens Boulevard, Kew Gardens, NY 11424

Staten Island Borough Office / 718-816-2300

10 Richmond Terrace, Borough Hall, Staten Island, NY 10301

For comprehensive information about DOB, to check

the status of a filing on the Building Information

System (BIS), and to download plan/work approval

forms and the Building Code, visit NYC.gov/buildings

BUILD

UILDIN

ING

GS

NYC

Pump test guidelines

Department of Investigation (DOI) / 212-825-3330

80 Maiden Lane, New York, NY 10038

Call 311 for non-emergency complaints or information for

Building Department services.

Use 911 only for life threatening emergencies.

Visit NYC.gov/buildings to:

Access comprehensive information about DOB

Check the status of a filing on the Building Information

System (BIS)

Download plan/work approval forms and the Building Code

Mission

The NYC Department of Buildings ensures the safe and lawful

use of buildings and properties by enforcing the Building

Code and Zoning Resolution. We facilitate development with

integrity, efficiency and professionalism.

Michael R. Bloomberg, MAYOR

Patricia J. Lancaster, FAIA, COMMISSIONER

P

about

Fire Suppression

Work: The Guide

to Fire Pump

Installation and

Testing

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Kasambahay ContractDocument4 pagesKasambahay ContractRomeo LimPas encore d'évaluation

- Durable Power of Attorney FormDocument6 pagesDurable Power of Attorney Formpowerofattorney100% (5)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- World of Warcraft RPG: Lands of Mystery Web ExtrasDocument5 pagesWorld of Warcraft RPG: Lands of Mystery Web ExtrasJacob Bos75% (4)

- Letter To SuperVDOE Loudoun County Super RemovalDocument149 pagesLetter To SuperVDOE Loudoun County Super RemovalABC7NewsPas encore d'évaluation

- Fire Flow Requirements For Buildings Using ISO MethodDocument3 pagesFire Flow Requirements For Buildings Using ISO MethodKhaleelPas encore d'évaluation

- Engineering Data: Iso 9001 Certified CompanyDocument32 pagesEngineering Data: Iso 9001 Certified CompanyKhaleelPas encore d'évaluation

- Fet - 2012 NotificationDocument1 pageFet - 2012 NotificationKhaleelPas encore d'évaluation

- Comp EnggDocument18 pagesComp EnggKhaleelPas encore d'évaluation

- Fundamentals of Building Piping SystemsDocument5 pagesFundamentals of Building Piping SystemsKhaleelPas encore d'évaluation

- Engineering ToolboxDocument7 pagesEngineering Toolboxasgart02Pas encore d'évaluation

- OVERALL SuperceededDocument1 pageOVERALL SuperceededKhaleelPas encore d'évaluation

- Ceniza V Neri 3Document5 pagesCeniza V Neri 3Michael Kevin MangaoPas encore d'évaluation

- Corporative Act 1992Document11 pagesCorporative Act 1992Nirmal ShresthaPas encore d'évaluation

- Parental / Guardian Consent: Bernardo D. Carpio National High School Senior High SchoolDocument1 pageParental / Guardian Consent: Bernardo D. Carpio National High School Senior High SchoolJean Marie PatalinghogPas encore d'évaluation

- Notice: Pollution Control Consent Judgments: Cambridge-Lee Industries, LLC, Et Al.Document2 pagesNotice: Pollution Control Consent Judgments: Cambridge-Lee Industries, LLC, Et Al.Justia.comPas encore d'évaluation

- The Asylum CaseDocument5 pagesThe Asylum CaseGrande MaisonPas encore d'évaluation

- LLB Syllbus of Mgsu University BikanerDocument64 pagesLLB Syllbus of Mgsu University BikanerAnupama UniyalPas encore d'évaluation

- Problem Areas in Legal Ethics Case List of Atty. DechavezDocument9 pagesProblem Areas in Legal Ethics Case List of Atty. DechavezMaria RumusudPas encore d'évaluation

- West Bengal Medical Services Corporation Ltd. Swasthya Sathi, GN-29, Sector-V, Salt Lake, Kolkata-700 091Document2 pagesWest Bengal Medical Services Corporation Ltd. Swasthya Sathi, GN-29, Sector-V, Salt Lake, Kolkata-700 091kuntal dasPas encore d'évaluation

- Coaching AgreementDocument4 pagesCoaching AgreementShalinei.CPas encore d'évaluation

- Rule 9 GillianDocument4 pagesRule 9 GillianGillian Caye Geniza BrionesPas encore d'évaluation

- Partnership Case Digest CompilationDocument12 pagesPartnership Case Digest CompilationTonifranz Sareno50% (4)

- Rule: Ports and Waterways Safety Regulated Navigation Areas, Safety Zones, Security Zones, Etc.: Lake Michigan Captain of The Port Zone, MIDocument2 pagesRule: Ports and Waterways Safety Regulated Navigation Areas, Safety Zones, Security Zones, Etc.: Lake Michigan Captain of The Port Zone, MIJustia.comPas encore d'évaluation

- Maharashtra Registration Rules, 1961 V1Document31 pagesMaharashtra Registration Rules, 1961 V1kishorawacharPas encore d'évaluation

- Trusts ReviewerDocument6 pagesTrusts ReviewerRuth Hazel Galang100% (1)

- Convertible Loan Agreement Template: How To Use This TemplateDocument11 pagesConvertible Loan Agreement Template: How To Use This TemplateGaos FakhryPas encore d'évaluation

- MAPP V. OhioDocument32 pagesMAPP V. OhioGraden NapierPas encore d'évaluation

- CCTV Installation GuidelinesDocument13 pagesCCTV Installation GuidelinesdgrsriPas encore d'évaluation

- Cortez v. CortezDocument9 pagesCortez v. CortezArjay ElnasPas encore d'évaluation

- Conditions & WaranteeDocument2 pagesConditions & WaranteePraveen PanwarPas encore d'évaluation

- G & S TransportDocument5 pagesG & S TransportGlenn FloresPas encore d'évaluation

- State of Punjab Vs Assocaited Hotels of IndiaDocument9 pagesState of Punjab Vs Assocaited Hotels of IndiasauravchopraPas encore d'évaluation

- Global Office Occupiers Guide 2011Document254 pagesGlobal Office Occupiers Guide 2011David MegoPas encore d'évaluation

- Seth JudgmentDocument8 pagesSeth Judgmentshilpasingh1297Pas encore d'évaluation

- TVA V HILL Case BriefDocument5 pagesTVA V HILL Case Briefsamantha koferPas encore d'évaluation

- Accountability of The Supreme Court Judges of Bangladesh: A Legal AnalysisDocument7 pagesAccountability of The Supreme Court Judges of Bangladesh: A Legal AnalysisIjahss JournalPas encore d'évaluation