Académique Documents

Professionnel Documents

Culture Documents

Diesel Msds Report

Transféré par

Hanny DarmoocooCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Diesel Msds Report

Transféré par

Hanny DarmoocooDroits d'auteur :

Formats disponibles

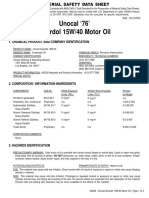

Material Safety Data Sheet

Page:

Infosafe No

LQ10L

Issue Date : May 2012

CS: 1.6.13

1 of

ISSUED by UNITEDPE

Product Name :DIESEL

1. IDENTIFICATION OF THE MATERIAL AND SUPPLIER

Product Name

DIESEL

Company Name

UNITED PETROLEUM PTY LTD

Address

Emergency Tel.

200 Hoddle Street Abbotsford

Vic 3067 Australia

1300 131 001

Telephone/Fax

Number

Recommended Use

Tel: (03)9413 1400

Fax: (03)9413 1401

Fuel for on-road diesel-powered engines.

Other Names

Name

Product Code

DIST.

HI FLOW DIESEL

ADO

AUTOMOTIVE GAS

2. HAZARDS IDENTIFICATION

Hazard

Classification

Risk Phrase(s)

Safety Phrase(s)

Signs and Symptoms

of Exposure

Safety Hazards

Environmental

Hazards

Other Information

HAZARDOUS SUBSTANCE.

NON-DANGEROUS GOODS.

Hazard classification according to the criteria of NOHSC.

Dangerous goods classification according to the Australia Dangerous Goods

Code.

R40 Limited evidence of a carcinogenic effect.

R51/53 Toxic to aquatic organisms, may cause long-term adverse effects in the

aquatic environment.

R65 Harmful: may cause lung damage if swallowed.

R66 Repeated exposure may cause skin dryness and cracking.

S2 Keep out of reach of children.

S36/37 Wear suitable protective clothing and gloves.

S61 Avoid release to the environment. Refer to special instructions/safety

data sheet.

S62 If swallowed, do not induce vomiting; seek medical advice immediately and

show this container or label.

If material enters lungs, signs and symptoms may include coughing, choking,

wheezing, difficulty in breathing, chest congestion, shortness of breath,

and/or fever. The onset of respiratory symptoms may be delayed for several

hours after exposure.

Defatting dermatitis signs and symptoms may include a burning sensation and/or

a dried/cracked appearance.

May ignite on surfaces at temperatures above auto-ignition temperature. Vapour

in the headspace of tanks and containers may ignite and explode at

temperatures exceeding autoignition temperature, where vapour concentrations

are within the flammability range. Not classified as flammable but will burn.

Electrostatic charges may be generated during pumping. Electrostatic discharge

may cause fire.

Toxic to aquatic organisms, may cause long-term adverse effects in the aquatic

environment.

This product is intended for use in closed systems only.

3. COMPOSITION/INFORMATION ON INGREDIENTS

Ingredients

Preparation

Description

Name

CAS

Proportion

Fuels, diesel, no.2

68476-34-6

100 %

Complex mixture of hydrocarbons consisting of paraffins, cycloparaffins,

aromatic and olefinic hydrocarbons with carbon numbers predominantly in the C9

to C25 range. May also contain several additives at <0.1% v/v each. May

contain cetane improver (Ethyl Hexyl Nitrate) at <0.2% v/v.

May contain catalytically cracked oils in which polycyclic aromatic compounds,

mainly 3-ring but some 4- to 6-ring species are present.

4. FIRST AID MEASURES

Print Date: 2/05/2012

CS: 1.6.13

Material Safety Data Sheet

Page:

Infosafe No

LQ10L

Issue Date : May 2012

CS: 1.6.13

2 of

ISSUED by UNITEDPE

Product Name :DIESEL

Inhalation

First Aid Facilities

Remove to fresh air. If rapid recovery does not occur, transport to nearest

medical facility for additional treatment.

If swallowed, do not induce vomiting: transport to nearest medical facility

for additional treatment. If vomiting occurs spontaneously, keep head below

hips to prevent aspiration. If any of the following delayed signs and symptoms

appear within the next 6 hours, transport to the nearest medical facility:

fever greater than 101 F (37 C), shortness of breath, chest congestion or

continued coughing or wheezing.

Remove contaminated clothing. Immediately flush skin with large amounts of

water for at least 15 minutes, and follow by washing with soap and water if

available. If redness, swelling, pain and/or blisters occur, transport to the

nearest medical facility for additional treatment.

Flush eye with copious quantities of water. If persistent irritation occurs,

obtain medical attention.

Eye wash and normal washroom facilities.

Advice to Doctor

Treat symptomatically.

Other Information

For advice in an emergency, contact a Poisons Information Centre (Phone

Australia 13 1126) or a doctor at once.

Ingestion

Skin

Eye

5. FIRE FIGHTING MEASURES

Suitable

Extinguishing Media

Hazards from

Combustion

Products

Specific Hazards

Properties on

Heating & in case of

Fire

Unsuitable

Extinguishing Media

Foam, water spray or fog. Dry chemical powder, carbon dioxide, sand or earth

may be used for small fires only.

Hazardous combustion products may include: A complex mixture of airborne solid

and liquid particulates and gases (smoke). Carbon monoxide. Oxides of sulphur.

Unidentified organic and inorganic compounds. Carbon monoxide may be evolved

if incomplete combustion occurs.

Combustible liquid. Will burn under fire conditions. Will float and can be

reignited on surface water. Flammable vapours may be present even at

temperatures below the flash point.

Fire fighters should wear Self-Contained Breathing Apparatus (SCBA) operated

in positive pressure mode and full protective clothing to prevent exposure to

vapours or fumes. Water spray may be used to cool down heat-exposed

containers. Fight fire from safe location. This product should be prevented

from entering drains and watercourses.

Do not use water in a jet.

6. ACCIDENTAL RELEASE MEASURES

Emergency

Procedures

Wear appropriate personal protective equipment and clothing to prevent

exposure. Extinguish or remove all sources of ignition and stop leak if safe

to do so. Increase ventilation. Evacuate all unprotected personnel. If

possible contain the spill. Place inert absorbent, non-combustible material

onto spillage. Use clean non-sparking tools to collect the material and place

into suitable labelled containers for subsequent recycling or disposal.

Dispose of waste according to the applicable local and national regulations.

If contamination of sewers or waterways occurs inform the local water and

waste management authorities in accordance with local regulations.

7. HANDLING AND STORAGE

Handling and

Storage

Print Date: 2/05/2012

General Precautions:

Avoid breathing vapours or contact with material. Only use in well ventilated

areas. Wash thoroughly after handling. For guidance on selection of personal

protective equipment see Chapter 8 (Exposure controls/personal protection) of

this Material Safety Data Sheet. Use the information in this data sheet as

input to a risk assessment of local circumstances to help determine

appropriate controls for safe handling, storage and disposal of this material.

Air-dry contaminated clothing in a well-ventilated area before laundering.

Properly dispose of any contaminated rags or cleaning materials in order to

prevent fires. Prevent spillages.

Use local exhaust ventilation if there is risk of inhalation of vapours, mists

or aerosols. Never siphon by mouth.

Contaminated leather articles including shoes cannot be decontaminated and

should be destroyed to prevent reuse. For comprehensive advice on handling,

CS: 1.6.13

Material Safety Data Sheet

Page:

Infosafe No

LQ10L

Issue Date : May 2012

CS: 1.6.13

3 of

ISSUED by UNITEDPE

Product Name :DIESEL

Precautions for Safe

Handling

Conditions for Safe

Storage

Storage Regulations

Product Transfer

Recommended

Materials

Unsuitable Materials

Other Information

product transfer, storage and tank cleaning refer to the product supplier.

Maintenance and Fuelling Activities - Avoid inhalation of vapours and contact

with skin.

Avoid inhaling vapour and/or mists. Avoid prolonged or repeated contact with

skin. When using do not eat or drink. Extinguish any naked flames. Do not

smoke. Remove ignition sources. Avoid sparks. Earth all equipment.

Electrostatic charges may be generated during pumping. Electrostatic discharge

may cause fire. The vapour is heavier than air, spreads along the ground and

distant ignition is possible.

Drum and small container storage: Drums should be stacked to a maximum of 3

high. Use properly labelled and closeable containers. Tank storage: Tanks must

be specifically designed for use with this product. Bulk storage tanks should

be diked (bunded). Locate tanks away from heat and other sources of ignition.

Must be stored in a diked (bunded) well-ventilated area, away from sunlight,

ignition sources and other sources of heat. Vapours from tanks should not be

released to atmosphere. Breathing losses during storage should be controlled

by a suitable vapour treatment system. The vapour is heavier than air. Beware

of accumulation in pits and confined spaces. Keep in a bunded area with a

sealed (low permeability) floor, to provide containment against spillage.

Prevent ingress of water.

For information on the design of the storeroom, reference should be made to

Australian Standard AS1940 - The storage and handling of flammable and

combustible liquids and AS/NZS 4452:1997 The storage and handling of toxic

substances. Reference should also be made to all applicable local and national

regulations.

Classified as a C1 (COMBUSTIBLE LIQUID) for the purpose of storage and

handling, in accordance with the requirements of AS 1940. Refer to State

Regulations for storage and transport requirements. AS 1940:2004 The storage

and handling of flammable and combustible liquids.

Avoid splash filling. Wait 2 minutes after tank filling (for tanks such as

those on road tanker vehicles) before opening hatches or manholes. Wait 30

minutes after tank filling (for large storage tanks) before opening hatches or

manholes. Keep containers closed when not in use. Do not use compressed air

for filling, discharging or handling. Contamination resulting from product

transfer may give rise to light hydrocarbon vapour in the headspace of tanks

that have previously contained gasoline. This vapour may explode if there is a

source of ignition. Partly filled containers present a greater hazard than

those that are full, therefore handling, transfer and sampling activities need

special care.

For containers, or container linings use mild steel, stainless steel.

Aluminium may also be used for applications where it does not present an

unnecessary fire hazard. Examples of suitable materials are: high density

polyethylene (HDPE) and Viton (FKM), which have been specifically tested for

compatibility with this product. For container linings, use amine-adduct cured

epoxy paint. For seals and gaskets use: graphite, PTFE, Viton A, Viton B.

Some synthetic materials may be unsuitable for containers or container linings

depending on the material specification and intended use. Examples of

materials to avoid are: natural rubber (NR), nitrile rubber (NBR), ethylene

propylene rubber (EPDM), polymethyl methacrylate (PMMA), polystyrene,

polyvinyl chloride (PVC), polyisobutylene.; However, some may be suitable for

glove materials.

Ensure that all local regulations regarding handling and storage facilities

are followed.

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

National Exposure

Standards

National Occupational Health And Safety Commission (NOHSC), Australia Exposure

Standards:

Substance

Naphthalene

Oil mist,

mineral

TWA

mg/m

52

5 (mist)

ppm

10

-

STEL

ppm

15

-

NOTICES

mg/m

79

-

TWA (Time Weighted Average): The average airborne concentration of a

Print Date: 2/05/2012

CS: 1.6.13

Material Safety Data Sheet

Page:

Infosafe No

LQ10L

Issue Date : May 2012

CS: 1.6.13

4 of

ISSUED by UNITEDPE

Product Name :DIESEL

particular substance when calculated over a normal eight-hour working day, for

a five-day week.

STEL (Short Term Exposure Limit): The average airborne concentration over a 15

minute period which should not be exceeded at any time during a normal

eight-hour workday.

Biological Limit

Values

Engineering

Controls

Respiratory

Protection

Eye Protection

Hand Protection

Body Protection

Additional Information: In the absence of a national exposure limit, the

American Conference of Governmental Industrial Hygienists (ACGIH) recommends

the following values for Diesel Fuel: TWA - 100 mg/m Critical effects based

on Skin and Irritation.

No biological limit available.

Provide sufficient ventilation to keep airborne levels below the exposure

limits. Where vapours or mists are generated, particularly in enclosed areas,

and natural ventilation is inadequate, a flameproof exhaust ventilation system

is required. Refer to AS 1940 - The storage and handling of flammable and

combustible liquids and AS/NZS 60079.10.1:2009 Explosive atmospheres Classification of areas - Explosive gas atmospheres, for further information

concerning ventilation requirements.

If engineering controls are not effective in controlling airborne exposure

then an approved respirator with a replaceable organic vapour filter should be

used. Reference should be made to Australian/New Zealand Standards AS/NZS

1715, Selection, Use and Maintenance of Respiratory Protective Devices; and

AS/NZS 1716, Respiratory Protective Devices, in order to make any necessary

changes for individual circumstances.

Safety glasses with side shields or chemical goggles should be worn. Final

choice of appropriate eye/face protection will vary according to individual

circumstances. Eye protection devices should conform with Australian/New

Zealand Standard AS/NZS 1337 - Eye Protectors for Industrial Applications.

Wear gloves of impervious material such as nitrile. Final choice of

appropriate gloves will vary according to individual circumstances i.e.

methods of handling or according to risk assessments undertaken. Reference

should be made to AS/NZS 2161.1: Occupational protective gloves - Selection,

use and maintenance.

Suitable protective work wear, e.g. cotton overalls buttoned at neck and wrist

is recommended. Chemical resistant apron is recommended where large quantities

are handled.

9. PHYSICAL AND CHEMICAL PROPERTIES

Appearance

Yellow. Pale straw. Colourless. Liquid.

Odour

May contain a reodorant

Melting Point

Not available

Freezing Point

Not available

Boiling Point

170 - 390 C

Solubility in Water

Not available

pH Value

Not available

Vapour Pressure

< 1 hPa at 20 C

Vapour Density

(Air=1)

Octanol/Water

Partition Coefficient

Density

Not available

Flash Point

63 C (estimated)

Flammability

Combustible liquid

Auto-Ignition

Temperature

> 220 C

Print Date: 2/05/2012

3 - 6

Typical 0.84 g/cm at 15 C

CS: 1.6.13

Material Safety Data Sheet

Page:

Infosafe No

LQ10L

Issue Date : May 2012

CS: 1.6.13

5 of

ISSUED by UNITEDPE

Product Name :DIESEL

Flammable Limits Lower

Flammable Limits Upper

Kinematic Viscosity

1 %(V)

6 %(V)

2 - 4.5 mm/s at 40 C

10. STABILITY AND REACTIVITY

Chemical Stability

Stable under normal conditions of storage and handling.

Conditions to Avoid

Avoid heat, sparks, open flames and other ignition sources.

Incompatible

Materials

Hazardous

Decomposition

Products

Strong oxidising agents.

Hazardous

Polymerization

Hazardous decomposition products are not expected to form during normal

storage.

Thermal decomposition is highly dependent on conditions. A complex mixture of

airborne solids, liquids and gases, including carbon monoxide, carbon dioxide

and other organic compounds will be evolved when this material undergoes

combustion or thermal or oxidative degradation.

Will not occur.

11. TOXICOLOGICAL INFORMATION

Toxicology

Information

Inhalation

Ingestion

Skin

Eye

Mutagenicity

Carcinogenicity

Information given is based on product data, a knowledge of the components and

the toxicology of similar products:

LD50 (Oral, Rat): >2,000 mg/kg

LD50 (Dermal, Rabbit): >2,000 mg/kg

LC50 (Inhalation, Rat): >5 mg/L/4h

High concentrations may cause central nervous system depression resulting in

headaches, dizziness and nausea; continued inhalation may result in

unconsciousness and/or death.

Harmful-may cause lung damage if swallowed. Small amounts of liquid aspirated

into the respiratory system during ingestion or from vomiting may cause severe

pulmonary injury that may lead to death. May cause irritation to the mouth,

throat, esophagus and stomach with symptoms of nausea, abdominal discomfort,

vomiting and diarrhoea.

May cause moderate skin irritation. Prolonged/repeated contact may cause

defatting of the skin which can lead to dermatitis.

May be irritating to eyes. The symptoms may include redness, itching and

tearing.

In-vitro mutagenicity studies show that mutagenic activity is related to 4-6

ring polycyclic aromatic content.

Limited evidence of carcinogenic effect. Repeated skin contact has resulted in

irritation and skin cancer in animals.

This substance is classified as a Category 3 Carcinogen according to National

Occupational Health and Safety Commission (NOHSC). That is, there is some

evidence from appropriate animal studies that human exposure to this substance

may result in the development of cancer, but this evidence is insufficient to

place the substance in Category 2. Category 3 Carcinogens are substances that

cause concern for humans owing to possible carcinogenic effects.

12. ECOLOGICAL INFORMATION

Ecological

Information

Ecotoxicity

Persistence /

Degradability

Print Date: 2/05/2012

Information given is based on a knowledge of the components and the

ecotoxicology of similar products. Fuels are typically made from blending

several refinery streams. Ecotoxicological studies have been carried out on a

variety of hydrocarbon blends and streams but not those containing additives.

Acute Toxicity: Toxic:LL/EL/IL50 1-10 mg/l(to aquatic organisms)(LL/EL50

expressed as the nominal amount of product required to prepare aqueous test

extract).

Toxic to aquatic organisms, may cause long-term adverse effects in the aquatic

environment.

Major constituents are inherently biodegradable. The volatile constituents

will oxidize rapidly by photochemical reactions in air.

CS: 1.6.13

Material Safety Data Sheet

Page:

Infosafe No

LQ10L

Issue Date : May 2012

CS: 1.6.13

6 of

ISSUED by UNITEDPE

Product Name :DIESEL

Mobility

Bioaccumulative

Potential

Other Adverse

Effects

Floats on water. Partly evaporates from water or soil surfaces, but a

significant proportion will remain after one day. Large volumes may penetrate

soil and could contaminate groundwater. Contains volatile constituents.

Contains constituents with the potential to bioaccumulate.

Films formed on water may affect oxygen transfer and damage organisms.

13. DISPOSAL CONSIDERATIONS

Disposal

Considerations

Product Disposal

Container Disposal

Local Legislation

The disposal of the spilled or waste material must be done in accordance with

applicable local and national regulations.

Recover or recycle if possible. It is the responsibility of the waste

generator to determine the toxicity and physical properties of the material

generated to determine the proper waste classification and disposal methods in

compliance with applicable regulations. Do not dispose into the environment,

in drains or in water courses. Do not dispose of tank water bottoms by

allowing them to drain into the ground. This will result in soil and

groundwater contamination. Waste arising from a spillage or tank cleaning

should be disposed of in accordance with prevailing regulations, preferably to

a recognised collector or contractor. The competence of the collector or

contractor should be established beforehand.

Send to drum recoverer or metal reclaimer. Drain container thoroughly. After

draining, vent in a safe place away from sparks and fire. Residues may cause

an explosion hazard if heated above the flash point. Do not puncture, cut or

weld uncleaned drums. Do not pollute the soil, water or environment with the

waste container. Comply with any local recovery or waste disposal regulations.

Disposal should be in accordance with applicable regional, national, and local

laws and regulations. Local regulations may be more stringent than regional or

national requirements and must be complied with.

14. TRANSPORT INFORMATION

Transport

Information

Not classified as Dangerous Goods according to the Australian Code for the

Transport of Dangerous Goods by Road and Rail. (7th edition)

Note: Not classified under ADG 07 regulations as special provision AU 02

applies.

IMDG:

Identification number: UN 3082

Proper shipping name: ENVIRONMENTALLY HAZARDOUS SUBSTANCE, LIQUID, N.O.S.

Technical name: (Gas oil - unspecified)

Class / Division: 9

Packing group: III

IMDG Marine

Pollutant (MP)

IATA (Country variations may apply):

UN No.: 3082

Proper shipping name: Environmentally hazardous substance, liquid, n.o.s.

Technical name: (Gas oil - unspecified)

Class / Division: 9

Packing group: III

Yes

15. REGULATORY INFORMATION

Poisons Schedule

Classified as Hazardous according to criteria of National Occupational Health

& Safety Commission (NOHSC), Australia.

Not classified as a Scheduled Poison according to the Standard for the Uniform

Scheduling of Medicines and Poisons (SUSMP).

Not Scheduled

Hazard Category

Harmful,Dangerous for the environment

AICS (Australia)

All components are listed or exempt.

Regulatory

Information

16. OTHER INFORMATION

Print Date: 2/05/2012

CS: 1.6.13

Material Safety Data Sheet

Page:

Infosafe No

LQ10L

Issue Date : May 2012

CS: 1.6.13

7 of

ISSUED by UNITEDPE

Product Name :DIESEL

Date of preparation

or last revision of

MSDS

MSDS Created: May 2012

...End Of MSDS...

Copyright ACOHS Pty Ltd

Copyright in the source code of the HTML, PDF, XML, XFO and any other electronic files rendered by an Infosafe system for Infosafe MSDS displayed is the intellectual

property of Acohs Pty Ltd.

Copyright in the layout, presentation and appearance of each Infosafe MSDS displayed is the intellectual property of Acohs Pty Ltd.

The compilation of MSDS's displayed is the intellectual property of Acohs Pty Ltd.

Copying of any MSDS displayed is permitted for personal use only and otherwise is not permitted. In particular the MSDS's displayed cannot be copied for the purpose of

sale or licence or for inclusion as part of a collection of MSDS without the express written consent of Acohs Pty Ltd.

Print Date: 2/05/2012

CS: 1.6.13

Vous aimerez peut-être aussi

- Msds DieselDocument10 pagesMsds DieselrajeshkunuPas encore d'évaluation

- Diesel Fuel MsdsDocument10 pagesDiesel Fuel Msdsrongo84Pas encore d'évaluation

- Msds F34avturfsiiDocument10 pagesMsds F34avturfsiiAyat TullahPas encore d'évaluation

- Msds EthanolDocument11 pagesMsds EthanolAsih MiniartiPas encore d'évaluation

- SAFETY - Data Sheet For PetrolDocument13 pagesSAFETY - Data Sheet For Petroluday_khandavilliPas encore d'évaluation

- MSDS - Diesel (Shell)Document18 pagesMSDS - Diesel (Shell)udin0% (3)

- Sasol LV3Document8 pagesSasol LV3Dave CPas encore d'évaluation

- Shell - LPG - Jan 2010Document8 pagesShell - LPG - Jan 2010slvmr_estrada1259Pas encore d'évaluation

- Hfo Msds ShellDocument9 pagesHfo Msds ShellLiam MoylanPas encore d'évaluation

- Safety Data Sheet - Petroleum CokeDocument7 pagesSafety Data Sheet - Petroleum CokeStephen BoylePas encore d'évaluation

- Hypogear 80W-90 - BP Australia Pty LTDDocument5 pagesHypogear 80W-90 - BP Australia Pty LTDBiju_PottayilPas encore d'évaluation

- Material Safety Data Sheet: Section 1: Product IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1: Product Identificationcvolkan1Pas encore d'évaluation

- LEHDER Environmental Services LimitedDocument8 pagesLEHDER Environmental Services LimitedAnonymous oQKQLFPas encore d'évaluation

- Handigas - BOCDocument4 pagesHandigas - BOCBiju_PottayilPas encore d'évaluation

- 1 Thinner MSDSDocument10 pages1 Thinner MSDSLovePas encore d'évaluation

- MSDS EthanolDocument13 pagesMSDS EthanolShahida Norizan100% (1)

- Pep Set Al5995 CatalystDocument11 pagesPep Set Al5995 CatalystfeelingzudoPas encore d'évaluation

- MSDS 15W40Document4 pagesMSDS 15W40Sukhjeet SinghPas encore d'évaluation

- MSDS: Iso-OctenesDocument7 pagesMSDS: Iso-OctenesHeavenL77Pas encore d'évaluation

- MSDS - PetrolDocument10 pagesMSDS - PetrolManeesh MenonPas encore d'évaluation

- Ficha de Datos de Seguridad Bitzer-BSE-170-OilDocument7 pagesFicha de Datos de Seguridad Bitzer-BSE-170-OilMONTAJES IND VELANDIAPas encore d'évaluation

- Aeroshell Fluid 41Document7 pagesAeroshell Fluid 41임희훈Pas encore d'évaluation

- Alexia Ls - MsdsDocument7 pagesAlexia Ls - MsdsBeryl FernandesPas encore d'évaluation

- Safety Matches PDFDocument4 pagesSafety Matches PDFBorislav MalinovićPas encore d'évaluation

- MsdsbiodieselDocument10 pagesMsdsbiodieselHafid AlwanPas encore d'évaluation

- Material Data Safety Sheet Jet A1 ShellDocument10 pagesMaterial Data Safety Sheet Jet A1 ShellAdnan Haji HarbiPas encore d'évaluation

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthPas encore d'évaluation

- Ms Ds BiodieselDocument10 pagesMs Ds BiodieselOsckar DezPas encore d'évaluation

- Msds LcoDocument9 pagesMsds LcoDeshanPas encore d'évaluation

- Shell Alvania Grease RL 3Document7 pagesShell Alvania Grease RL 3Alberto PerezPas encore d'évaluation

- Kerosene MSDSDocument4 pagesKerosene MSDSvinay1999Pas encore d'évaluation

- TCP MsdsDocument11 pagesTCP MsdsSkySupplyUSAPas encore d'évaluation

- Isopar HDocument11 pagesIsopar Hwaxim26322Pas encore d'évaluation

- Engine Oil MSDSDocument7 pagesEngine Oil MSDSSantos RexPas encore d'évaluation

- 105 - KeroseneDocument13 pages105 - Keroseneloveanbu24Pas encore d'évaluation

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthPas encore d'évaluation

- Fleetguard DCA-4 Liquid - CumminsDocument12 pagesFleetguard DCA-4 Liquid - CumminsYasser JaviPas encore d'évaluation

- It Xylene MsdsDocument8 pagesIt Xylene MsdsHendriyana StPas encore d'évaluation

- Kerosene PDFDocument9 pagesKerosene PDFishnafathonahPas encore d'évaluation

- SDS - Bengalac Aluminium - English (Uk) - Dubai-Start ScribdDocument5 pagesSDS - Bengalac Aluminium - English (Uk) - Dubai-Start ScribdBalasubramanian AnanthPas encore d'évaluation

- Hogans Aersol Touchup Paint MSDSDocument5 pagesHogans Aersol Touchup Paint MSDSBiju_PottayilPas encore d'évaluation

- Safety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingDocument4 pagesSafety Data Sheet: 1. Identification of The Substance/preparation and of The Company/undertakingBalasubramanian AnanthPas encore d'évaluation

- Flash Point Int Green DieselDocument8 pagesFlash Point Int Green DieselAnggya AnggyPas encore d'évaluation

- MSDS SMF Lead Acid BatteryDocument9 pagesMSDS SMF Lead Acid BatteryebbasinghPas encore d'évaluation

- Material Safety Data Sheet: Natural GasDocument5 pagesMaterial Safety Data Sheet: Natural Gasprasad5034Pas encore d'évaluation

- MSDS Jotun-BaltoflakeDocument6 pagesMSDS Jotun-Baltoflakerezza182Pas encore d'évaluation

- Turbo Oil T 68Document7 pagesTurbo Oil T 68Akbar RoSyidPas encore d'évaluation

- MSDS Jet A-1Document6 pagesMSDS Jet A-1jimeshchandranPas encore d'évaluation

- Corena S2 P100Document7 pagesCorena S2 P100Beryl FernandesPas encore d'évaluation

- Ethyl Ether: 1. Chemical Product and Company IdentificationDocument7 pagesEthyl Ether: 1. Chemical Product and Company IdentificationiwansaputratekimPas encore d'évaluation

- MSDS Cane MolassesDocument4 pagesMSDS Cane MolassesTaufik NurazizPas encore d'évaluation

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesD'EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesPas encore d'évaluation

- After a Disaster: Information to Help You and Your Family RecoverD'EverandAfter a Disaster: Information to Help You and Your Family RecoverPas encore d'évaluation

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesD'EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Workplace Vocabulary for Esl Students: With Exercises and TestsD'EverandWorkplace Vocabulary for Esl Students: With Exercises and TestsPas encore d'évaluation

- Improvised Munitions Handbook – Learn How to Make Explosive Devices & Weapons from Scratch (Warfare Skills Series): Illustrated & With Clear InstructionsD'EverandImprovised Munitions Handbook – Learn How to Make Explosive Devices & Weapons from Scratch (Warfare Skills Series): Illustrated & With Clear InstructionsÉvaluation : 3.5 sur 5 étoiles3.5/5 (7)

- Msds of OxygenDocument7 pagesMsds of OxygensahilchemPas encore d'évaluation

- MSDS Natural GasDocument5 pagesMSDS Natural GasRadhakrishna MadabhushiPas encore d'évaluation

- Metric and US Conversion FormulasDocument2 pagesMetric and US Conversion FormulassahilchemPas encore d'évaluation

- Msds ChlorineDocument9 pagesMsds ChlorinesahilchemPas encore d'évaluation

- Msds Ldpe en UsDocument3 pagesMsds Ldpe en UssahilchemPas encore d'évaluation

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationsahilchemPas encore d'évaluation

- Material Safety Data Sheet 1.: Chemical Product & Manufacturer'S DetailsDocument0 pageMaterial Safety Data Sheet 1.: Chemical Product & Manufacturer'S DetailssahilchemPas encore d'évaluation

- Sinha LechatelierprinDocument9 pagesSinha LechatelierprinsahilchemPas encore d'évaluation

- MSDS - Sulphur 90%: Section 1. Product InformationDocument3 pagesMSDS - Sulphur 90%: Section 1. Product InformationsahilchemPas encore d'évaluation

- Material Safety Data Sheet Mixed Xylene: 1. Product and Company IdentificationDocument7 pagesMaterial Safety Data Sheet Mixed Xylene: 1. Product and Company IdentificationsahilchemPas encore d'évaluation

- Material Safety Data Sheet: 1. Identification of The Substance/Preparation and The Company/UndertakingDocument7 pagesMaterial Safety Data Sheet: 1. Identification of The Substance/Preparation and The Company/UndertakingsahilchemPas encore d'évaluation

- L7 8Document44 pagesL7 8huyphuca2Pas encore d'évaluation

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping IndustrysahilchemPas encore d'évaluation

- Material and Energy BalanceDocument26 pagesMaterial and Energy Balancezest321Pas encore d'évaluation