Académique Documents

Professionnel Documents

Culture Documents

01 Ultrasonic Examination

Transféré par

dondon45Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

01 Ultrasonic Examination

Transféré par

dondon45Droits d'auteur :

Formats disponibles

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

1 of 17

STANDARD OPERATING PROCEDURE

FOR

ULTRASONIC EXAMINATION

Doc No :

RAN-SOP-NDT-01

Rev

01- 01- 2013

Date

SGS

IS

CDW

Prepared By

Reviewed By

Approved By

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

CONTENTS

1.0

SCOPE

2.0

APPLICABLE CODES

3.0

PERSONEL QUALIFICATION

4.0

SURFACE PREPARATION

5.0

GENERAL EXAMINATION

REQUIREMENTS

6.0

EQUIPMENT AND SUPPLIES

7.0

CALIBRATION

8.0

ACCEPTANCE CRETERIA

9.0

RELATED FORM OF SERVICE

REPORT

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

1 of 17

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

1.0

2.0

SCOPE

This procedure covers a system of

general conditions and specific

instructions as an aid to personnel

required to perform Ultrasonic

Examination to be applied to plate

and weld.

APPLICABLE CODES

ASME Boiler & Pressure Vessel

Code, Section V, Article 2, Latest

Edition & Addenda.

1.0

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

2 of 17

LINGKUP KERJA

Prosedur ini meliput suatu sistem yang

dikondisi secara

umum dan

instruksi

spesifik

sebagai suatu

panduan

ke

personil

sebagai

persyaratan

melaksanakan Pengujian Ultrasonik untuk

di- aplikasikan pada plat dan lasan

2.0

ACUAN STANDART

ASME Boiler & Pressure Vessel

Code, Section V, Article 2, Latest

Edition & Addenda.

AWS D 1.1,Structural Welding Code

Steel, 2008

AWS D 1.1,Structural Welding Code

Steel, 2008

ASME SECT I, Rule for contruction

of Power Boiler

ASME SECT I, Rule for contruction of

Power Boiler

ASME SECT VIII, Rule

contruction of Pressure Vessel

ASME

SECT

VIII,

Rule

contruction of Pressure Vessel

for

for

API 650, Welded Steel Tank Oil For

Storage

API 650, Welded Steel Tank Oil For

Storage

SNT - TC - 1A,ASNT recommended

practice

for

qualification

and

certification of

NDT Personnel,

2011 edition.

SNT - TC - 1A,ASNT recommended

practice

for

qualification

and

certification of

NDT Personnel,

2011 edition.

PT. Rekapenta Adi Nugraha Written

Practice Procedure No. RAN-QP01, which complies with SNT TC

1A.

PT. Rekapenta Adi Nugraha Written

Practice Procedure No. RAN-QP-01,

which complies with SNT TC 1A.

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

3.0

PERSONNEL QUALIFICATION

The Ultrasonic Examination shall be

performed

by

personnel

is

competent in the techniques of the

Ultrasonic Examination method for

which he is certified, including

making the examination

and

interpreting and evaluating the

results or as per PT. Rekapenta Adi

Nugraha which Written Practice No.

RAN-QP-01 of requirements.

3.0

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

3 of 17

Kualifikasi Personel

Pengujian

ultrasonik

harus

dilakukan

oleh

personil

yang

berkompeten didalam teknik penguji

an metode ultrasonik di mana ia

bersertifikat, mencakup melakukan

pengujian dan menginter pretasikan

dan mengevaluasi hasil sesuai

prosedure praktis tertulis PT.

Rekapenta Adi Nugraha No. RANQP-01 yang disyaratkan.

4.0

SURFACE PREPARATION

4.0

Persiapan Permukaan

4.1.

Base Metal

4.1

Base Metal

The base metal on each side of the

weld shall be free of weld spatter,

surface irregularrities, or foreign

matter that might interfere with the

examination.

4.2.

Weld Metals.

Base metal pada setiap sisi lasan

harus terbebas spatter lasan,

ketidaksempurna an permukaan ,

atau bahan asing yang mungkin

mengganggu pengujian

4.2

Where the weld surface interferes

with the examination, the weld shall

be prepared as needed to permit

examination.

5.0.

GENERAL

REQUIREMENTS

EXAMINATION

5.1

Examination Coverage

The volume shall be examined by

moving the search unit over the

examination surface so as to scan

the entire examination volume. Each

pass of the search unit shall overlap

a minimum of 10% of the transducer

(piezo-electric element) dimension

perpendicular to the direction of the

scan.

Weld Metals

Di

mana

permukaan

lasan

mengganggu selama pengujian,

lasan harus dipersiapkan jika dibutuhkan untuk diijinkan pengujian.

5.0.

Persyaratan Pengujian

5.1.

Luasan yang diuji

Volume

harus diuji

dengan

menggerakkan

probe

diatas

permukaan

pengujian

supaya

meneliti

keseluruhan

volume

pengujian. Setiap probe harus

mempunyai overlap sedikitnya 10%

transducer ( piezo - electric element)

yang dimensinya tegak lurus dengan

arah dari pergerakan.

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

5.2.

Rate of Search Unit Movements.

5.2.

Recording Sensitivity Level

For both manual and mechanized

examination recording of indications

shall be made with respect to the

reference level

6.0.

EQUIPMENT AND SUPPLIES

6.1.

6.1.1

Ultrasonic Equipment

Frequency

This examination shall be conducted

with

a

pulse-echo

ultrasonic

instrument capable of generating

frequencies over the range of at

least 1 MHz to 5 MHz. Instruments.

operating at other frequencies may

be used if equal or better sensitivity

can

be

demonstrated

and

documented.

6.1.2

Screen Height Linearity

The ultrasonic instrument shall

provide linear vertical presentation

within +/- 5% of the full screen

height for 20% to 80% of the

calibrated screen height (base line to

maximum calibrated screen point

(s)). The procedure for evaluating

screen height linearity is provided in

ASME Sect. V Appendix I and shall

be performed at the beginning of

each period of extended use (or

every 3 months, whichever is less).

RAN-SOP-NDT-01

01-01-2013

Revision

Page

4 of 17

Kecepatan pergerakan probe

Tingkat pergerakan probe untuk

pengujian harus tidak boleh melebihi

6 inch/sec. Kecuali jika kalibrasi

dibuktikan

dengan

kecepatan

scanning.

The rate of search unit movement

for examination shall not exceed 6

inch/sec. Unless calibration is

verified at scanning speed.

5.3.

Document No

Date

5.3.

Pencatatan sensitivity level

Untuk keduanya manual dan

mekanisme record pengujian dari

indikasi harus dibuat ber- kenaan

dengan referensi level

6.0

PERALATAN DAN SUPLIES

6.1.

Peralatan Ultrasonik

6.1.1

Frekwensi

Pengujian ini harus dikondisikan

dengan

suatu

pulse-echo

instrumen ultrasonik yang mampu

dalam frekwensi pembangkit di atas

range sedikitnya 1 MHZ sampai 5

MHZ instrumen. Pengoperasian

pada

frekwensi lain

mungkin

digunakan jika sensitiviti lebih baik

atau sama dapat didemontrasikan

dan didokumentasikan

6.1.2

Tinggi layar Linear

Instrumen

ultrasonik

harus

menghasilkan presentasi vertikal

linier +/- 5% tinggi layar penuh

untuk 20% sampai 80% dari tinggi

layar yang dikalibrasi ( garis dasa r

ke titik layar maksimum kalibrasi (

s)). Prosedur untuk mengevaluasi

linearitas tinggi layar dipertunjukkan

dalam ASME Sect. V Apendix I dan

harus dilakukan pada awal setiap

periode penggunaan ( atau tiaptiap 3 bulan, yang mana

lebih

sedikit).

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

6.1.2. Amplitude Control Linearity

The ultrasonic instrument shall

utilize an amplitude control accurate

over its useful range to +/- 20% of

the nominal amplitude ratio, to allow

measurement of indications beyond

the linear range of the vertical

display on the screen. The

procedure for evaluating amplitude

control linearity is given in Appendix

II of ASME Sect. V and shall be

performed at the beginning of each

period of extended use (or every 3

months, whichever is less).

6.2

6.3

Frequency

Examination shall be performed at a

nominal frequency 2.25 MHz unless

variables

such as

production

material grain structure require the

use of other frequencies to assure

adequate penetration or better

resolution.

Couplant

Starch or other water based

cellulose paste couplant shall be

used. Same couplant shall be used

in calibration and testing. Proprietary

brand couplant may also be used.

Sono 600 shall be used for hot

temperature inspection ( 315 C max

for short term scanning and 260 C

max for long term scanning)

6.1.2

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

5 of 17

Amplitudo linear control

Instrumen

ultrasonik

harus

menggunakan

suatu

amplitudo

kontrol

untuk mengendalikan

akurasi lebih penggunaan range

+/20%

dari

perbandingan

amplitudo

nominal,

diijinkan

pengukuran indikasi di luar jangkau

linear yang di- pertunjukan vertikal

pada

layar.

Prosedur

untuk

mengevaluasi

kontrol

linearitas

amplitudo

disampaikan

dalam

Apendix II ASME Sect.V dan akan

dilakukan pada

awal periode

penggunaan ( atau tiap-tiap 3 bulan,

yang mana h lebih sedikit).

6.2

Frekwensi

Pengujian harus dilakukan pada

frekwensi nominal 2.25 MHZ kecuali

jika variabel seperti struktur butir

material

produk

diperlukan

penggunaan frekwensi yang lain

untuk meyakinkan penetrasi cukup

atau resolusi lebih baik.

6.3

Kuplan

Coplant

mendasarkan

bahan

selulose pasta

coplant

harus

digunakan. Couplant sama harus

digunakan didalam pengujian dan

kalibrasi.

merek

kepemilikan

couplant boleh juga diguna kan.

Sono 600 harus digunakan untuk

pemeriksaan pada suhu panas (

315 C max untuk cepat- syarat

Scanning dan 260 C max untuk

lama syarat scanning

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

6 of 17

7.0.

CALIBRATION

7.0.

KALIBRASI

7.1.

DETERMINATION

OF

ENTRY

POINT OF ANGLE BEAM SEARCH

UNIT.

7.1

MENENTUKAN

INDEK POINT

SUDUT

LETAK

TITIK

DARI PROBE

a. Place the search unit in position

D on the VI Block (See Fig. 1).

a. Tempatkan probe dalam posisi D

pada VI Blok ( Lihat Gambar. 1).

b. Move the search unit until the

signal from the radius is

maximized. The point on the

search unit which aligns with the

line on the calibration block is

the point of the entry point.

b. Gerakkan probe sampai signal

dari radius maksimal. Titik point

probe

yang mana

segaris

dengan garis pada blok kalibrasi

adalah titik dari titik point.

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

7 of 17

7.2.

DETERMINATION OF THE ANGLE

BEAM SEARCH UNIT

7.2

MENENTUKAN

SUDUT

a.

Place the search unit in position B or

C ( depending on the angle of

search unit ) on the VI Block, ( See

Fig. 1 ).

a.

Tempatkan probe di posisi B atau C

(tergantung pada sudut probe) pada

VI Blok,(lihat gambar. 1).

b.

Maksimalkan

signal

dengan

menggerakkan probe kedepan dan

kebelakang. Ketika signal maksimal,

sudut bisa terukur menggunakan

index

probe dan gores

garis

referensi pada block atau secara

phisik tergambar garis pensil pada

blok

dan

mengukur

dengan

protactor.

c.

Toleransi sudut pengukuran harus

2 o.

7.3.

MENENTUKAN

HORISONTAL

a.

Tempatkan probe normal dalam

posisi E& G pada VI blok( lihat

gambar 1)

Bawa berurutan dinding belakang

echo, pada gilirannya, Kira-kira

tingginya sama ( e.g. 80% tinggi

layar penuh). Tepi dari tiap echo

perlu berbaris

dengan perkiraan

garis yang sesuai. catat setiap

penyimpangan, dan ukur kira-kira

separuh tingginya layar penuh.

b.

Maximize the signal by moving the

search unit backward and forward.

When the signal is maximized, the

beam angle can be measured using

the search unit Index and Engraved

reference lines on the block or

physically drawing in pencil line on

block and measuring with protactor.

c.

The tolerance of Beam

measurement shall be 2.

7.3.

DETERMINATION

HORIZONTAL LINEARITY

a.

Place the straight beam search unit

in position E & G on the VI block (

see fig. 1 )

Angle

OF

b.

b.

c.

d.

Bring successive back wall echoes,

in turn, to A approximately the same

height (e.g. 80% full screen height).

The leading edge of each echo

should line up with the appropriate

graticule line. Record any deviation,

and measured at approximately half

full screen height.

For range less than 255 mm ( 10 in.

), place the search unit in position G,

and for greater than 255 mm ( 10 in.

), place the search unit in position E.

The deviation of the base linearity

shall not exceed 2% of full time

base range.

NILAI

PROBE

LINEAR

c.

Untuk range kurang dari 255 mm

(10 in) , tempatkan probe pada

posisi G, dan untuk lebih besar

dari 255 mm (10 in), tempatkan

probe pada posisi E.

d.

Penyimpangan dari dasar linearitas

tidak boleh melebihi 2%

dasar

range full time.

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

8 of 17

7.4.

MENENTUKAN RESOLUSI PROBE

NORMAL

a.

Tempatkan probe dalam posisi F

pada VI blok ( Lihat gambar. 1).

b.

Tiga signal dari 85 mm, 91 mm dan

100

mm

permukaan

perlu

ditampilkan dengan jelas.

7.5

MENENTUKAN RESOLUSI PROBE

SUDUT

Place the search unit in position H &

I on IOW Beam Profile Block ( See

Fig. 2 )

a.

Tempatkan probe dalam posisi H

dan I pada IOW profil blok ( Lihat

gambar. 2).

The signals from three of the side

drilled holes should be clearly

resolved on the CRT at one time.

b.

Signal sebanyak tiga dari sisi

lubang

perlu

dengan

jelas

dipisahkan pada CRT pada satu

waktu.

7.4.

DETERMINATION

OF

THE

RESOLUTION OF

STRAIGHT

BEAM SEARCH UNIT.

a.

Place the search unit in position F

on the VI block (See Fig. 1).

b.

Three signals from the 85 mm, 91

mm and 100 mm surfaces should be

clearly displayed.

7.5.

DETERMINATION

OF

THE

RESOLUTION OF ANGLE BEAM

SEARCH UNIT.

a.

b.

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

7.6.

DETERMINATION

OF

BEAM

SPREAD IN THE VERTICAL LINE

a.

Place the search unit on surface A

and B in the IOW profile block ( See

Fig. 3 ).

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

9 of 17

7.6.

MENENTUKAN BEAM SPREAD

a.

Tempatkan probe pada permukaan

A dan B di dalam IOW profil blok(

Lihat gambar. 3).

Fig.3

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

10 of 17

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

The reading Y ( forward position ) is

laid off behind the beam axis and the

backward shift X in front of it. Figure

4d shows the complete profile with

target.

Revision

Page

11 of 17

Ketika titik point posisinya maju ,

tepi

dari

lubang

target

menginterupsi lebih rendah pada

batas 20 dB referensi permukaan,

dan vise versa ketika probe

kebanyakan posisi . Posisi maju

dan posisi mundur pada titik point

probe juga ditandai pada block.

When the entry point in its forward

position, the edge of the target hole

intercepts the lower on rear

boundary of the 20 dB reference

surface, and vise versa when the

search unit is in the hid most

position. The forward and backward

position on the entry point of search

unit are also marked on the block.

b.

RAN-SOP-NDT-01

01-01-2013

Pada setiap kasus posisi titik point

dari probe

bersesuaian dengan

tingginya echo maksimum ditandai

pada block.Probe

kemudian

digerakan

maju dan mundur

sehingga target terlewat dengan

cepatnya ,perpindahan yang ekstrim

akan dicapai dimana posisi dari titik

point probe terespon 20 dB dari

maksimum tingginya( Lihat gambar .

4, a, b, c& d).

In each case the position of the entry

point of search unit corresponding to

maximum echo height is marked on

the block. The search unit is then

moved forward and backward so

that the target is swept by the beam,

the extremes of displacement being

reached when the position of the

entry

point

of

search

unit

corresponds to a fall of 20 dB from

maximum Echo Height ( See Fig. 4,

a, b, c & d ).

Similar measurements made at each

target hole are used to construct a

diagram of the beam profile, figures

4a, b, and c illustrate the plotting

sequence.

Document No

Date

Pengukuran serupa setiap lubang

target digunakan untuk membuat

suatu diagram beam profil, figur 4a,

b, dan c menggambarkan urutan

yang direncanakan.

b.

Pembacaan Y( posisi kedepan )

dihentikan di belakang tengah beam

dan pergeseran mundur didepan X

. Gambar 4d menunjukkan profil

yang lengkap dengan target.

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

7.7.

SOUND

PATH

CALIBRATION

DISTANCE

7.7.1. Straight Beam Search Unit

a.

b.

V2 Block

b.

Revision

Page

12 of 17

Kalibrasi Jarak Sound Path

7.7.1

Probe Normal

a.

Berbagai isignal dapat di-setup ke

arah 25 mm, 100 mm, interval dari

pemantulan dinding belakang.( Lihat

gambar. 1, posisi G, dan E).

b.

V2 Block disa digunakan untuk

kalibrasi.

c.

Horisontal sweep harus disesuaikan

untuk

kalibrasi

jarak

untuk

menyajikan padanan paling sedikit

dua ketebalan plat pada layar.

V2 Block can be used for calibration.

c.

RAN-SOP-NDT-01

01-01-2013

7.7.

V1 Block

The multiple signals can be set up at

25 mm, 100 mm, intervals by

reflections of back wall. ( See Fig.

1, position G, and E ).

Document No

Date

The horizontal sweep shall be

adjusted for distance calibration to

present the equivalent of at least two

plate thickness on the screen.

7.7.2. Angle Beam Search Unit.

7.7.2 Sudut Probe

a.

V1 Block

a.

The multiple signals can be set up at

100 mm intervals by the reflections

between the quadrant and the

notches on the face of the block. (

See Fig. 1, position D ).

Berbagai signal dapat di-setup ke

arah 100 mm interval oleh

pemantulan antar kwadrant dan

bentuk pada [ muka blok.( Lihat

gambar. 1, posisi D).

b.

Signal diulangi bisa di-setup ke

arah 25 mm, 100 mm, 175 mm, dll,

ketika probe diarahkan pada 25

mm kwadrant atau signal yang

diulangi bisa di-setup ke arah 50

mm, 125 mm, 200 mm, dll, ketika

probe diarahkan pada 50 mm

kwadrant( lihat gambar 5).

V2 Block.

The repeated signals can be set up

at 25 mm, 100 mm, 175 mm, etc,

when the search unit is directed to

the 25 mm quadrant or the repeated

signals can be set up at 50 mm, 125

mm, 200 mm, etc, when the search

unit is directed to the 50 mm

quadrant ( see fig. 5 ).

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

c.

The distance calibration shall be

made using either the 130 mm ( 5 in.

) range or 255 mm ( 10 in. ) range,

whichever is appropriate. The

distance calibration shall be made

using a suitable range to the

weldment under inspection.

c.

Fig. 5

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

13 of 17

Jarak Kalibrasi harus menggunakan

range 130 mm ( 5 in) atau range

255 mm (10 in.) , mana yang

sesuai. Jarak kalibrasi harus

menggunakan range yang sesuai

saat dibawah pemeriksaan.

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

14 of 17

7.7.3. Sensitivity Calibration

7.7.3

Kalibrasi Sensitivity

a.

a.

Non Tubular

Non Tubular Member

Probe harus di set pada posisi A

pada V1 blok ( lihat gambar 1)

signal dimaksimalkan

kemudian

disesuaikan dari lubang 1,5 mm(

0.06 in)

untuk mencapai suatu

indikasi

tinggi

referensi

garis

horisontal( e.g. 80% tinggi layar

penuh).

The search unit shall be set in

position A on the V1 block ( see fig.

1 ) the maximized signal shall then

be adjusted from 1,5 mm ( 0.06 in. )

hole to attain a horizontal reference

line height indication ( e.g. 80% full

screen height ).

b.

Tubular Member

Standard sensitivity for examination

using :

b.

Amplitude techniques shall be :

Basic

sensitivity

+

distance

amplitude correction + transfer

correction.

7.7.4. Sensitivity Setting

a.

Distance

amplitude

correction

curves shall be constructed by the

use of the amplitude of the three

calibration holes from the applicable

basics calibration block and shall be

set up as follows :

a.1.

Determine which of the three

calibration holes produces the

highest amplitude and adjust this

amplitude at 80% ( +/-5% ) of full

screen height.This is the primary

reference amplitude.

a.2.

Position the search unit, without

changing the sensitivity with which

the primary reference amplitude was

found, for maximum response from

the other two calibration holes and

for angle beam method also 3/4 T

Tubular

Standard sensitiviti untuk pengujian

menggunakan :

Teknik amplitudo : Basic sensitiviti +

jarak koreksi amplitudo + transfer

koreksi.

7.7.4. Sensitivity Setting

a. Jarak koreksi amplitudo kurva harus

dibuat

dengan

menggunakan

amplitudo dari ke tiga lubang

kalibrasi saat melakukan kalibrasi

dasar

dan harus dipersiapkan

sebagai berikut:

a.1.

Menentukan

dimana

ke tiga

lubang

kalibrasi menghasilkan

amplitudo yang paling tinggi dan

melakukan penyesuaian amplitudo

pada 80% ( +/- 5%) tingginya layar

penuh. Ini menjadi amplitudo

referensi utama.

a.2.

Posisikan probe, tanpa mengubah

sensitiviti

amplitudo

referensi

utama ditemukan, karena respon

maksimum dari

dua

kalibrasi

lubang dan untuk metoda sudut

beam juga 3/4 T lubangi setelah

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

Mark the peaks of these amplitudes

on the plastic screen andconnect

these marks with a smooth line over

a length which will cover the

examination range.If the peaks

drops below 20% of screen height

the amplitude shall be increased to

80% screen height and process

repeated.

a.4.

This line is called the primary

reference level.

b.

Transfer mechanism shall be used

to correlate the amplitude from the

basic calibration block and the

production material. Transfer shall

be accomplished by using the

transmission method and two

identical angle probes. For material

thickness less than 25.4 mm at least

full skip shall be used. The

amplitudes of both, calibration block

and production material shall be

evaluated at 40% of full screen and

this difference shall be noted and

used for the correction of the primary

reference level.This is called the

corrected primary reference level.

RAN-SOP-NDT-01

01-01-2013

Revision

Page

15 of 17

beam mempunyai batasan

permukaan kebalikan.

hole after the beam has bounded

from the opposite surface.

a.3.

Document No

Date

dari

a.3.

Tandai puncak amplitudo pada

layar plastik dan hubungkan tanda

ini dengan garis lembut dimana

panjangnya akan meliputi range

pengujian. Jika puncak turun di

bawah 20% tinggi layar amplitudo

harus dinaikan sampai 80% tinggi

layar dan proses mengulangi.

a.4

Garis ini disebut referensi level

utama.

b.

Mekanisme

perpindahan

harus

digunakan untuk menghubungkan

amplitudo dari kalibrasi dasar blok

dan material produksi. Perpindahan

harus dengan penggunaan metoda

trans- misi dan dua pemeriksaan

probe sudut. Untuk

ketebalan

material kurang dari 25.4 mm

sedikitnya full skip akan digunakan.

kedua amplitudo , kalibrasi blok dan

material produk harus dievaluasi

pada 40% layar

penuh

dan

perbedaan ini akan dicatat dan

digunakan untuk koreksi dari

referensi level utama. Ini disebut

koreksi referensi level utama.

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

7.4.8. FREQUENCY OF CALIBRATION.

RAN-SOP-NDT-01

01-01-2013

Revision

Page

16 of 17

7.4.8. KALIBRASI FREKWENSI ALAT

Re-calibration shall be made after a

change of operators, each 30 minute

maximum time interval, or when the

electrical circuitry is disturbed in any

way which includes the following :

Re-Calibration

harus

dilakukan

setelah pergantian operator, setiap

30 menit interval waktu maksimum,

atau ketika gangguan elektrik yang

mana meliputi berikut :

a. Search Unit Change

a. Penggantian Probe.

b. Battery Change

b. Penggantian Baterai

c. Electrical outlet change

c. Penggantian electrik outlet

d. Coaxial Cable Cha

d. Penggantian kabel coaxial

e. Power outage (failure)

e. Power outage ( kegagalan)

7.4.9. DEFECT SIZING

7.4.9. PENGUKURAN CACAT

Panjang cacat harus dievaluasi

menggunakan metode 6 dB drop,

dan lebar cacat harus dievaluasi

metode 20 dB drop. Penempatan

cacat akan ditentukan dengan teliti

dan di- laporkan dengan suatu sket .

The length of defect shall be

evaluated using 6 dB drop method,

and the width of defect shall be

evaluated by 20 dB drop method.

The location of defect shall be

determined accurately and reported

with an accompanying sketch.

8.0.

Document No

Date

ACCEPTANCE CRITERIA

8.0 KRETERIA PENERIMAAN

Acceptance criteria of discontinuity detected

shall be in accordance with :

Kreteria penerimaan dari discontinuity yang

terdeteksi harus sesuai dengan

AWS D 1.1,Structural Welding Code

Steel

AWS D 1.1,Structural Welding Code

Steel

ASME SECT I, Rule for contruction of

Power Boiler

ASME SECT I, Rule for contruction of

Power Boiler

ASME SECT VIII, Rule for contruction of

Pressure Vessel

ASME SECT VIII, Rule for contruction of

Pressure Vessel

API 650, Welded Steel Tank Oil For

Storage

API 650, Welded Steel Tank Oil For

Storage

PT REKAPENTA ADI NUGRAHA

STANDARD OPERATING PROCEDURE

ULTRASONIC EXAMINATION

9.0.

RELATED FORM OF SERVICE

REPORT

Record shall be in accordance with

the PT. Rekapenta Adi Nugraha

Ultrsonic

Examination

Report

attached.

9.0

Document No

Date

RAN-SOP-NDT-01

01-01-2013

Revision

Page

17 of 17

SISTEM BENTUK PELAPORAN

Bentuk pelaporan PT Rekapenta Adi

Nugraha sebagaimana terlampir.

Vous aimerez peut-être aussi

- Prosedur UTG Asu AnjingDocument15 pagesProsedur UTG Asu Anjingyusuf akbarPas encore d'évaluation

- Ultrasonic Examination Procedure (Issue 2)Document14 pagesUltrasonic Examination Procedure (Issue 2)Li Liu100% (1)

- 2 - RPD - PT - B31.3 - 02 - Penetrant, REV 00Document13 pages2 - RPD - PT - B31.3 - 02 - Penetrant, REV 00Abdul KharisPas encore d'évaluation

- 3D 301 Header AnalysisDocument19 pages3D 301 Header AnalysisMahmoud GaberPas encore d'évaluation

- Welding Material Control ProcedureDocument12 pagesWelding Material Control ProcedureWalter RuedaPas encore d'évaluation

- ENV-SPV-DR-B-003 Fabrication Procedure-Rev - ADocument11 pagesENV-SPV-DR-B-003 Fabrication Procedure-Rev - AyoeyPas encore d'évaluation

- Doc. No Revision No Revision DateDocument6 pagesDoc. No Revision No Revision DateShyam SinghPas encore d'évaluation

- 10 Juni 2020: Mild Steel: Gmaw / 3F: Asme Viii: Penetrant Test ReportDocument2 pages10 Juni 2020: Mild Steel: Gmaw / 3F: Asme Viii: Penetrant Test ReportDadang TrifiantoPas encore d'évaluation

- D. Specs For Field & Shop PaintingDocument10 pagesD. Specs For Field & Shop PaintingrajeshPas encore d'évaluation

- Prosedur Penetran TestingDocument11 pagesProsedur Penetran TestingIkhsan DalimunthePas encore d'évaluation

- BES - IsO - UT - 12 - Ultrasonic Test - Rev 00Document43 pagesBES - IsO - UT - 12 - Ultrasonic Test - Rev 00Ciety Ma100% (1)

- QP - 01 Liquid Penetrant Rev 03 - ASME 2010Document15 pagesQP - 01 Liquid Penetrant Rev 03 - ASME 2010Hary SasmayaPas encore d'évaluation

- Form Lampiran Penetrant TestDocument1 pageForm Lampiran Penetrant Testary rizki100% (1)

- Radiography Permit: Al-Dur 2 Iwpp ProjectDocument1 pageRadiography Permit: Al-Dur 2 Iwpp ProjectJianping KePas encore d'évaluation

- EmbankmentDocument5 pagesEmbankmentAmila Priyadarshana Dissanayake100% (1)

- Procedure For Magnetic Particle ExaminationDocument2 pagesProcedure For Magnetic Particle ExaminationsrinivasansmPas encore d'évaluation

- Leak Test Procedure of Atmospheric VesselDocument9 pagesLeak Test Procedure of Atmospheric VesselRicardo NapitupuluPas encore d'évaluation

- Form PENETRANT TEST REPORTDocument1 pageForm PENETRANT TEST REPORTDadang TrifiantoPas encore d'évaluation

- Training Schedule 2021 - SLVDocument4 pagesTraining Schedule 2021 - SLVFerdie OSPas encore d'évaluation

- Hydrotest - 333 AG FW 0001 - Rev03 PDFDocument26 pagesHydrotest - 333 AG FW 0001 - Rev03 PDFIhsan IchwansyahPas encore d'évaluation

- Radiographic Testing ProcedureDocument12 pagesRadiographic Testing ProcedureAdham AhmedPas encore d'évaluation

- MSDS Polyken 955Document5 pagesMSDS Polyken 955raditia2205Pas encore d'évaluation

- 002 DPB PT Asme 2012 PT AsmeDocument43 pages002 DPB PT Asme 2012 PT AsmeAozoraLazoraPas encore d'évaluation

- Up Date CV - AndiDocument11 pagesUp Date CV - AndiDoc TorPas encore d'évaluation

- Welding Procedure Specification (WPS) : As Per Attached Joints Detail SheetDocument1 pageWelding Procedure Specification (WPS) : As Per Attached Joints Detail SheetMohammed JaveedPas encore d'évaluation

- Penetrant (NDT SOP)Document14 pagesPenetrant (NDT SOP)aditya apriana100% (1)

- Inspection of Test Plan: Rotating EquipmentDocument7 pagesInspection of Test Plan: Rotating Equipmentzvlcar nainPas encore d'évaluation

- Radiation Protection and Safety ProceduresDocument2 pagesRadiation Protection and Safety ProceduressrhlynPas encore d'évaluation

- Pmi Procedure: Superflow Pumps Pvt. LTDDocument6 pagesPmi Procedure: Superflow Pumps Pvt. LTDashish tiwariPas encore d'évaluation

- JK Pipeline Welding & Installation Traceability Procedure CoDocument1 pageJK Pipeline Welding & Installation Traceability Procedure Cogst ajahPas encore d'évaluation

- 16 - SGU - RT - ASME - 16 - Radiographic - REV - 00Document53 pages16 - SGU - RT - ASME - 16 - Radiographic - REV - 00pankrasius herbudiPas encore d'évaluation

- Method of Statement For RadiationDocument4 pagesMethod of Statement For RadiationFiras AlbaweiPas encore d'évaluation

- Prosedur Penangkal PetirDocument3 pagesProsedur Penangkal Petirhendra silalahiPas encore d'évaluation

- O/D (MM) Time/film 24 42.4 8.8 0.3 160 244.5 42 36 120 181.8 30 11 70 106.5 18 1.7 90 139.5 24.5 3.3 58 82.5 14.2 1 DN THK (MM)Document3 pagesO/D (MM) Time/film 24 42.4 8.8 0.3 160 244.5 42 36 120 181.8 30 11 70 106.5 18 1.7 90 139.5 24.5 3.3 58 82.5 14.2 1 DN THK (MM)Adhitya BayuPas encore d'évaluation

- Dye Penetrant ProcedureDocument7 pagesDye Penetrant Procedurezaki fadl100% (1)

- 3 - RPD - RT - B31.3 - 03 - Radiographic, Rev 00Document25 pages3 - RPD - RT - B31.3 - 03 - Radiographic, Rev 00Abdul KharisPas encore d'évaluation

- Dye Penetrant Inspection ProcedureDocument7 pagesDye Penetrant Inspection ProcedureNDTInstructor100% (1)

- SOP Pipe InsulationDocument5 pagesSOP Pipe Insulationnida ahmad musyafa ptasrPas encore d'évaluation

- Form ITP Bejana Tekan & Tangki TimbunDocument8 pagesForm ITP Bejana Tekan & Tangki Timbunsuratno 25100% (1)

- A-Qac-Pro-730-38930 Rev ADocument10 pagesA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiPas encore d'évaluation

- Vc-Api 650 PDFDocument6 pagesVc-Api 650 PDFShinta ShowiantariPas encore d'évaluation

- Report-1683-1 B1 25mm 14 10 2020Document7 pagesReport-1683-1 B1 25mm 14 10 2020sakthi velPas encore d'évaluation

- Repair Procedure Slug CatcherDocument4 pagesRepair Procedure Slug Catchershabbir626100% (1)

- Quad Pipe Hydrotest Procedure Rev1Document16 pagesQuad Pipe Hydrotest Procedure Rev1Trust EmmaPas encore d'évaluation

- Method Statement For Near Field Test: DCSM Project 2019Document5 pagesMethod Statement For Near Field Test: DCSM Project 2019Thinh NguyenPas encore d'évaluation

- Inspeksi Pipa BajaDocument5 pagesInspeksi Pipa BajaBahtiar YudhistiraPas encore d'évaluation

- 010 NDT-RT TSE API 1104 - Rev 00-2-27Document27 pages010 NDT-RT TSE API 1104 - Rev 00-2-27zainal100% (1)

- RT Procedure - API 1104 Standard PDFDocument28 pagesRT Procedure - API 1104 Standard PDFDanang Edi Prasetyo100% (2)

- PCN Renewal Forms Regulation PDFDocument5 pagesPCN Renewal Forms Regulation PDFEswaranPas encore d'évaluation

- NDT Report - Dovetail WheelsDocument4 pagesNDT Report - Dovetail WheelsOm Ar TanPas encore d'évaluation

- Procedure of UT-TestDocument2 pagesProcedure of UT-TestJohn ShermanPas encore d'évaluation

- RT ProcedureDocument12 pagesRT ProcedurePRASHANTPas encore d'évaluation

- SMS-602-RT-003 Radiographic API 1104 - B31.8 - Rev 3Document27 pagesSMS-602-RT-003 Radiographic API 1104 - B31.8 - Rev 3Cak Nhass100% (1)

- 001 Itp For Painting Rev 0Document7 pages001 Itp For Painting Rev 0Alif Rahmat FebriantoPas encore d'évaluation

- Sand Blast and Painting Work ProsedurDocument8 pagesSand Blast and Painting Work ProsedurRizki AgustiarPas encore d'évaluation

- WIS QCWT GE 15 Rev.1 - Painting InspectionDocument6 pagesWIS QCWT GE 15 Rev.1 - Painting Inspectionfajar aljogjaPas encore d'évaluation

- Welding Inspection ReportDocument1 pageWelding Inspection ReportabdiPas encore d'évaluation

- PT - Mcci Document Register List Rev.B 110811Document3 pagesPT - Mcci Document Register List Rev.B 110811adityadhPas encore d'évaluation

- UT ProcedureDocument14 pagesUT Procedureshifa0% (1)

- 1744 - UT PROCEDURE (For Final) PDFDocument27 pages1744 - UT PROCEDURE (For Final) PDFpvdang8453100% (1)

- NYC Government Positions With DriversDocument12 pagesNYC Government Positions With DriversCity & State NYPas encore d'évaluation

- Tablas H2O NISTIR5078-completaDocument39 pagesTablas H2O NISTIR5078-completaLeila Cheikh AliPas encore d'évaluation

- AGREEMENT OF AGENCY FOR SOLE SELLING BY A MANUFACTURING COMPANY - Deeds & DraftsDocument5 pagesAGREEMENT OF AGENCY FOR SOLE SELLING BY A MANUFACTURING COMPANY - Deeds & DraftsAzak ShaikhPas encore d'évaluation

- Micros F& B Staff NotesDocument4 pagesMicros F& B Staff NotesPrince HakimPas encore d'évaluation

- Migracion WAS8Document472 pagesMigracion WAS8ikronos0Pas encore d'évaluation

- КАТАЛОГ РОБИТ 2012г - lowresDocument94 pagesКАТАЛОГ РОБИТ 2012г - lowresДамир НазиповPas encore d'évaluation

- Conceptualization and Measurement of Fan Engagement: Empirical Evidence From A Professional Sport ContextDocument20 pagesConceptualization and Measurement of Fan Engagement: Empirical Evidence From A Professional Sport ContextBảo Đạt LêPas encore d'évaluation

- Dynaudio Professional Air Manual EnglishDocument129 pagesDynaudio Professional Air Manual EnglishEren AlemdarPas encore d'évaluation

- San Miguel vs. Khan (Valera)Document2 pagesSan Miguel vs. Khan (Valera)ASGarcia24Pas encore d'évaluation

- Get Rich Young - Kishore MDocument85 pagesGet Rich Young - Kishore MArmand Dagbegnon TossouPas encore d'évaluation

- Field Work ReportDocument20 pagesField Work ReportShahibu Shabani73% (11)

- Aromatic Waters - Liniments Lab NotesDocument9 pagesAromatic Waters - Liniments Lab NotesElaine Sombrano100% (7)

- Between The Wars - Global CrisisDocument3 pagesBetween The Wars - Global CrisisShivani RameshPas encore d'évaluation

- En 13369 PDFDocument76 pagesEn 13369 PDFTemur Lomidze100% (2)

- (Amaleaks - Blogspot.com) Programming (Prog-111) - Grade 11 Week 1-9Document88 pages(Amaleaks - Blogspot.com) Programming (Prog-111) - Grade 11 Week 1-9johnPas encore d'évaluation

- Dwnload Full Abnormal Child Psychology 7th Edition Mash Test Bank PDFDocument35 pagesDwnload Full Abnormal Child Psychology 7th Edition Mash Test Bank PDFthrenodyvoxlkio100% (16)

- HTML Cheat SheetDocument53 pagesHTML Cheat SheetmszsohailPas encore d'évaluation

- Syllabus-Aerodrome Engineering and ManagementDocument8 pagesSyllabus-Aerodrome Engineering and Managementaero2011Pas encore d'évaluation

- Wauu (MKW) - RendaniDocument3 pagesWauu (MKW) - RendaniAbang FayyadPas encore d'évaluation

- He A IgnitorDocument36 pagesHe A IgnitorE.C.MADHUDUDHANA REDDYPas encore d'évaluation

- The Solar XXI Building in Lisbon, PortugalDocument4 pagesThe Solar XXI Building in Lisbon, PortugalSagar GheewalaPas encore d'évaluation

- Product Overview Brochure. ABB Medium Voltage Products Our One-Stop Approach For Every Medium Voltage ApplicationDocument12 pagesProduct Overview Brochure. ABB Medium Voltage Products Our One-Stop Approach For Every Medium Voltage ApplicationhafezasadPas encore d'évaluation

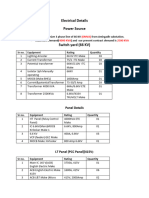

- 10, Electrical DetailDocument4 pages10, Electrical Detailrp63337651Pas encore d'évaluation

- CSWIP Welding Inspection Notes and QuestionsDocument132 pagesCSWIP Welding Inspection Notes and QuestionsfahreezPas encore d'évaluation

- Problem 1.6Document1 pageProblem 1.6SamerPas encore d'évaluation

- Companion: Material Safety Data Sheet ® Liquid Biological FungicideDocument2 pagesCompanion: Material Safety Data Sheet ® Liquid Biological FungicideNatalie TorresPas encore d'évaluation

- Lab Session 13: Generics in JavaDocument11 pagesLab Session 13: Generics in JavaParsa ShereenPas encore d'évaluation

- Lesson 6 Similarities KNNDocument25 pagesLesson 6 Similarities KNNDyuti IslamPas encore d'évaluation

- BMA5318 YWY 1213 Sem2 (A)Document3 pagesBMA5318 YWY 1213 Sem2 (A)Sumedha Shocisuto Das JpsPas encore d'évaluation

- 10.00 Heinrich Höse, Aumund Fördertechnik GMBHDocument25 pages10.00 Heinrich Höse, Aumund Fördertechnik GMBHMohd Ali100% (1)