Académique Documents

Professionnel Documents

Culture Documents

Saet 8 B

Transféré par

naefmubarakTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Saet 8 B

Transféré par

naefmubarakDroits d'auteur :

Formats disponibles

FLUID MECHANICS D203

SAE SOLUTIONS TUTORIAL 8B CENTRIFUGAL PUMPS

SELF ASSESSMENT EXERCISE No. 1

1. A centrifugal pump must produce a head of 15 m with a flow rate of 40 dm3/s and shaft speed of

725 rev/min. The pump must be geometrically similar to either pump A or pump B whose

characteristics are shown in the table below.

Which of the two designs will give the highest efficiency and what impeller diameter should be

used ?

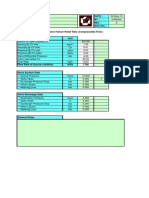

Pump A D = 0.25 m

N = 1 000 rev/min

Q (dm3/s)

H (m)

%

Ns =

8

48

11

8.1

55

15

7.9

62

Pump B D = 0.55 m

N = 900 rev/min

Q (dm3/s)

H (m)

%

8

42

65

6

55

9

36

66

19

7.3

56

6.1

11

33

58

27

NQ1/2 725 x 0.041/2

=

= 19

H 3/4

153/4

PUMP A

Q (m3/s)

H (m)

%

Ns

0.008

8.1

48

18.6

0.011

7.9

55

22.26

Q (m3/s)

H (m)

%

Ns

0.06

42

55

13.36

0.008

36

65

17.32

0.009

33

66

19.6

Pump B gives the greater efficiency when Ns = 19

Drawing a graph or interpolating we find Q = 0.085 m3/s H = 34.5 m , = 65.5% when Ns=19

Q1

Q2

0.04

0.085

=

=

3

3

3

N1D1 N 2 D 2

725D1 900 x 0.553

or using the head coefficient

H1

H 2

0.15

34.5

=

=

2 2

2 2

2 2

N1 D1 N 2 D 2

725 D1 19002 2 x0.55 2

D = 0.46 m

D = 0.45 m

Take the mean D = 0.455 m for the new pump

To commence pumping

2gH = ND/60

D=

60 2g x 15

x 725

Hence D = 0.452 m This seems to give the right answer more simply.

2. Define the Head and flow Coefficients for a pump.

Oil is pumped through a pipe 750 m long and 0.15 bore diameter. The outlet is 4 m below the oil

level in the supply tank. The pump has an impeller diameter of 508 mm which runs at 600 rev/min.

Calculate the flow rate of oil and the power consumed by the pump. It may be assumed

-0.25

3

-3

Cf=0.079(Re) . The density of the oil is 950 kg/m and the dynamic viscosity is 5 x 10 N s/m2.

The data for a geometrically similar pump is shown below.

D = 0.552 m N = 900 rev/min

Q (m3/min)

H (m)

%

0

34.1

0

1.14

37.2

22

2.27

39.9

41

3.41

40.5

56

4.55

38.1

67

5.68

32.9

72

H = Head Added to the system by the pump.

This may be put into Bernoullis equation.

hA + zA + uA2/2g + H = hB + zB + uB2/2g + hL

0 + 4 + 0 + H = 0 + 0 + uB2/2g + hL

4 + H = uB2/2g + hL

uB = Q/A = Q/( x 0.0752) = 56.588 Q

hL = 4 Cf Lu2/2gD

Re = uD/ = 950 x

(56.588 Q)0.15/0.005 = 1612758Q

Cf = 0.079 Re-0.25 = 0.079 (1612758Q)-0.25 =

0.002217 Q-0.25

hL = 4 (0.002217 Q-0.25) x 750 (56.588 Q)2/(2g x 0.15) = 7236 Q1.75

4 + H = (56.588 Q)2/2g + 7236 Q1.75

H = 163.2 Q2 + 7236 Q1.75 - 4

If Q is given in m3/min this becomes

H = 0.0453 Q2 + 5.594 Q1.75 - 4

ow create a table for the system.

Q (m3/min)

H (m)

0

-4

Q1 (m3/min)

H1 (m)

%

Q2 (m3/min)

H1 (m)

0

1.14

34.1 37.2

0

22

0

0.59

12.83 14

1

1.64

4

5

60

90.6

3

N D Q

N 2 D 2 H

Now compile a table for a similar pump using Q 2 = 2 2 3 1

H 2 = 2 22 2 1

N1D1

N1 D1

N2 = 600 D2 = 508 N1 = 900 D1 = 552 produces Q 2 = 0.52Q 1 H 2 = 0.38. 1

Plotting H for the system

against Q and produces a

matching point H = 15 m

Q = 2 (m3/min) and

= 59%

P = mgH/ = 2 x (950/60)

x 9.81 x 15/0.59 = 7.89 kW

2

15

3

34.7

2.27

39.9

41

1.18

15

3.41

40.5

56

1.8

15.2

4.55

38.1

67

2.4

14.3

5.68

32.9

72

2.9

12.4

6.86

25.9

65

3,6

9.8

6.86

25.9

65

SELF ASSESSMENT EXERCISE No. 2

1. The rotor of a centrifugal pump is 100 mm diameter and runs at 1 450 rev/min. It is 10 mm

deep at the outer edge and swept back at 30o. The inlet flow is radial. the vanes take up 10% of the

outlet area. 25% of the outlet velocity head is lost in the volute chamber. Estimate the shut off head

and developed head when 8 dm3/s is pumped. (5.87 m and 1.89 m)

vR2 = Q/A2

= 0.008/( x 0.1 x 0.01 x 0.9) = 2.829 m/s

vw1 = 0

OUTLET

u2 = ND2

= x (450/60) x 0.1 = 7.592 m/s

vw2 = 7.592 2.829/tan 30o = 2.692 m/s

v2 = (2.6922 + 2.8292) = 3.905 m/s

Kinetic Head = v22/2g

= 3.9052/2g = 0.777 m

Loss in chamber = 25% x 0.777 = 0.194 m

Manometric Head = u2 vw2/g

= 7.592 x 2.692/9.81 = 2.08 m

Developed Head = 2.08 0.194 = 1.89 m

h = u2 vw2/g = (u2 Q/A2tan2)

When there is no flow Q = 0 so h = u2 vw2/g - u2 = (7.592/9.81) x 7.592 = 5.875 m

2. The rotor of a centrifugal pump is 170 mm diameter and runs at 1 450 rev/min. It is 15 mm

deep at the outer edge and swept back at 30o. The inlet flow is radial. the vanes take up 10% of the

outlet area. 65% of the outlet velocity head is lost in the volute chamber. The pump delivers 15

dm3/s of water.

Calculate

i. The head produced. (9.23 m)

ii. The efficiency. (75.4%)

iii. The power consumed. (1.8 kW)

u2 = ND2 = x (1450/60) x 0.17 = 12.906 m/s

vR2 = Q/A2

vR2 = 0.015/( x 0.17 x 0.015 x 0.9) = 2.08 m/s

vw1 = 0

OUTLET

vw2 = 12.906 2.08/tan 30o = 9.3 m/s

v2 = (9.32 + 2.082) = 9.53 m/s

Kinetic Head = v22/2g = 9.532/2g = 4.628 m

Head Recovered = 35% x 4.628 = 1.62 m

Head Loss = 3 m

Manometric Head = u2 vw2/g

= 12.906 x 9.3/9.81 = 12.23 m

Developed Head 12.23 3= 9.23 m

man = 9.23/12.23 = 75.3%

DP = m u2 vw2 = 15 x 12.906 x 9.3 = 1.8 kW

WP = m g h = 15 x 9.81 x 9.23 = 1.358 kW

= 1.358/1.8 = 75.4%

Vous aimerez peut-être aussi

- Southern Marine Engineering Desk Reference: Second Edition Volume ID'EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IPas encore d'évaluation

- Fluid Mechanics and Machinery 2E (Kothandaraman & Rudramoorthy) - 14 PDFDocument2 pagesFluid Mechanics and Machinery 2E (Kothandaraman & Rudramoorthy) - 14 PDFajaykrishna_99Pas encore d'évaluation

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlD'EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlPas encore d'évaluation

- Pelton WheelDocument4 pagesPelton WheelRyan MahoneyPas encore d'évaluation

- JayDocument13 pagesJaySam SepiolPas encore d'évaluation

- Pumps: University of The East - Caloocan Department of Mechanical EngineeringDocument14 pagesPumps: University of The East - Caloocan Department of Mechanical EngineeringJohn Patrick Abad100% (1)

- Centrifugal Pump2Document15 pagesCentrifugal Pump2limakupang_matPas encore d'évaluation

- Enhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsD'EverandEnhanced Oil Recovery: Resonance Macro- and Micro-Mechanics of Petroleum ReservoirsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Addi Examples Pipe3Document10 pagesAddi Examples Pipe3Diego MorenoPas encore d'évaluation

- Solve ItDocument12 pagesSolve ItMarvin100% (1)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- Set of Answer of Fluid Mechanics II, UTHM. Based On Cengel 11th EditionDocument6 pagesSet of Answer of Fluid Mechanics II, UTHM. Based On Cengel 11th EditionIskandar BellPas encore d'évaluation

- Report 3a Pelton Turbine - HydraulicDocument13 pagesReport 3a Pelton Turbine - HydraulicAin SherinPas encore d'évaluation

- Centrifugal Pumps PresentationDocument28 pagesCentrifugal Pumps Presentationprasoon_eilPas encore d'évaluation

- Tutorial 4 Turbomachinery v2Document4 pagesTutorial 4 Turbomachinery v2Nik JaffPas encore d'évaluation

- Tutorial Fluid Machinery 3aDocument3 pagesTutorial Fluid Machinery 3aazzraPas encore d'évaluation

- Mka-03 Pelton and Francis TurbinesDocument11 pagesMka-03 Pelton and Francis TurbineshasshosPas encore d'évaluation

- Ipd-Module IiDocument10 pagesIpd-Module Iijohn babe jeszareth CapiliPas encore d'évaluation

- ME2135E Fluid Mechanics II Tutorial 1Document3 pagesME2135E Fluid Mechanics II Tutorial 1Law Zhan Hong0% (1)

- Problems On Hydraulic Turbines (Ch-6)Document8 pagesProblems On Hydraulic Turbines (Ch-6)xan pitchuPas encore d'évaluation

- CV1012 Fluid Mechanics Tutorial 10 - Turbomachines Power and Flow CalculationsDocument4 pagesCV1012 Fluid Mechanics Tutorial 10 - Turbomachines Power and Flow CalculationsleemariosanPas encore d'évaluation

- Designing Pelton Turbines for HydropowerDocument28 pagesDesigning Pelton Turbines for HydropowerHendro CahyonoPas encore d'évaluation

- Group 4 - F5 pumps performanceDocument16 pagesGroup 4 - F5 pumps performanceParag SinghPas encore d'évaluation

- Centrifugal Pump Impeller Design CalculationsDocument8 pagesCentrifugal Pump Impeller Design CalculationsVăn Thành NguyễnPas encore d'évaluation

- Multistage Centrifugal Pump: B141753, B141758, B141866, B141812, B141860 October 8, 2018Document5 pagesMultistage Centrifugal Pump: B141753, B141758, B141866, B141812, B141860 October 8, 2018Bhanu prasadh ThandraPas encore d'évaluation

- EXP:04 - Characteristic Test of Gear PumpDocument11 pagesEXP:04 - Characteristic Test of Gear PumpDivanshu GoelPas encore d'évaluation

- Hydraulic & Pneumatic MotorsDocument14 pagesHydraulic & Pneumatic MotorsJogi Oscar SinagaPas encore d'évaluation

- NAME 409 Pump MathsDocument10 pagesNAME 409 Pump Mathsisrat jahanPas encore d'évaluation

- Centrifugal Pump Test Rig Submitfinal (1) PDFDocument7 pagesCentrifugal Pump Test Rig Submitfinal (1) PDFchinmay dasPas encore d'évaluation

- Centrifugal Pump Assignment QuestionsDocument5 pagesCentrifugal Pump Assignment QuestionsKaran UmralkarPas encore d'évaluation

- T 2Document9 pagesT 2Amaterasu Susanoo TsukuyomiPas encore d'évaluation

- A Pump Delivers 10 Dm3Document8 pagesA Pump Delivers 10 Dm3Deesee JeyPas encore d'évaluation

- Turbo Machinery Tutorial - Jan-Feb 2012Document3 pagesTurbo Machinery Tutorial - Jan-Feb 2012Suchithra RamanPas encore d'évaluation

- AIR COMPRESSOR SOLUTIONSDocument71 pagesAIR COMPRESSOR SOLUTIONSMarvin E. Villanueva100% (3)

- Basic Environmental Technology Water Supply Waste Management and Pollution Control 6th Edition Nathanson Test BankDocument7 pagesBasic Environmental Technology Water Supply Waste Management and Pollution Control 6th Edition Nathanson Test BankKenneth EbertPas encore d'évaluation

- Pump MathsDocument10 pagesPump MathsSakib RafeePas encore d'évaluation

- Centrifugal PumpDocument21 pagesCentrifugal PumpIzzul Hazim B. IbrahimPas encore d'évaluation

- Solve Problem of Hydroelectric Power PlantDocument17 pagesSolve Problem of Hydroelectric Power PlantAnonymous 1VhXp188% (25)

- CENTRIFUGAL PUMP EQUATIONSDocument38 pagesCENTRIFUGAL PUMP EQUATIONSRichard Manongsong100% (1)

- SQ - 4.7 - Pumps (Table Format)Document5 pagesSQ - 4.7 - Pumps (Table Format)Amitav MishraPas encore d'évaluation

- Car crushing hydraulic circuit analysisDocument22 pagesCar crushing hydraulic circuit analysisphankhoa83100% (1)

- Solution of Sheet 4Document15 pagesSolution of Sheet 4Muhammed FekryPas encore d'évaluation

- PeltonDocument10 pagesPeltonNazatul Zuhanis100% (1)

- Fluid Power (CH 12 p254) : P Power (W) M Mass Flow Rate (KG/S) H Total Head Change (H H - H)Document13 pagesFluid Power (CH 12 p254) : P Power (W) M Mass Flow Rate (KG/S) H Total Head Change (H H - H)rubiohotPas encore d'évaluation

- Chapter 7Document6 pagesChapter 7Marco LuigiPas encore d'évaluation

- Design of Distillation Column EquipmentDocument41 pagesDesign of Distillation Column EquipmentHardik Gandhi100% (1)

- CEE 345 Spring 2002 problem set solutions pump efficiency discharge headDocument10 pagesCEE 345 Spring 2002 problem set solutions pump efficiency discharge headAdrian Antonio TorresPas encore d'évaluation

- Renewable Energy Systems 402: Tutorial 4 Micro-Hydro Power SystemsDocument2 pagesRenewable Energy Systems 402: Tutorial 4 Micro-Hydro Power SystemsMohamed Mo Galal Hassan-GharibaPas encore d'évaluation

- Fluid System 04-Centrifugal PumpDocument46 pagesFluid System 04-Centrifugal PumpFuad AlhamidPas encore d'évaluation

- Assignment-6 Solutions - FinalDocument8 pagesAssignment-6 Solutions - FinalmaheshPas encore d'évaluation

- Sheet 4 New PDFDocument3 pagesSheet 4 New PDFMahmoud GaballaPas encore d'évaluation

- Pelton & Francis TurbinesDocument37 pagesPelton & Francis TurbinesIkhwan Z.100% (11)

- Chapter 6Document13 pagesChapter 6Marco Luigi100% (1)

- Basic Environmental Technology Water Supply Waste Management and Pollution Control 6th Edition Nathanson Test BankDocument6 pagesBasic Environmental Technology Water Supply Waste Management and Pollution Control 6th Edition Nathanson Test Bankmaryrodriguezxsntrogkwd100% (50)

- Lecture On Affinity LawsDocument10 pagesLecture On Affinity LawsCyduck GuevarraPas encore d'évaluation

- Velocity in the pipe = 2m/s Using the formula Diameter of penstock (Dm) = ( (4 ×Q m3/s) / (π ×Vm/s) ) = ( (4 ×0.15) / (π ×2) ) = 0.31mDocument4 pagesVelocity in the pipe = 2m/s Using the formula Diameter of penstock (Dm) = ( (4 ×Q m3/s) / (π ×Vm/s) ) = ( (4 ×0.15) / (π ×2) ) = 0.31mSujan JoshiPas encore d'évaluation

- Autoregressive Processes: Dennis Sun Stats 253Document34 pagesAutoregressive Processes: Dennis Sun Stats 253naefmubarakPas encore d'évaluation

- Efficiency of Displacement Processes ChapterDocument115 pagesEfficiency of Displacement Processes ChapterHidayahSazli100% (1)

- 4 Field Lab EquipmentDocument19 pages4 Field Lab EquipmentnaefmubarakPas encore d'évaluation

- 2008 TPG4145 Lecture Notes UpdateDocument66 pages2008 TPG4145 Lecture Notes UpdatenaefmubarakPas encore d'évaluation

- Steady Incompressible Flow in Pressure Conduits (PartB)Document21 pagesSteady Incompressible Flow in Pressure Conduits (PartB)naefmubarakPas encore d'évaluation

- Well Test - 2006Document48 pagesWell Test - 2006naefmubarakPas encore d'évaluation

- Open Channel FlowDocument34 pagesOpen Channel Flowjss_devPas encore d'évaluation

- IMEX Product OverviewDocument2 pagesIMEX Product OverviewnaefmubarakPas encore d'évaluation

- Class09 Ex1Document2 pagesClass09 Ex1naefmubarakPas encore d'évaluation

- ch8 Steady Incompressible Flow in Pressure Conduits (Partb) PDFDocument66 pagesch8 Steady Incompressible Flow in Pressure Conduits (Partb) PDFnaefmubarak0% (1)

- TPG4145 2008 InformationDocument4 pagesTPG4145 2008 InformationnaefmubarakPas encore d'évaluation

- Project ManagementDocument57 pagesProject ManagementnaefmubarakPas encore d'évaluation

- Well Test - 2Document14 pagesWell Test - 2naefmubarak100% (1)

- Me19b Hw3 SolutionsDocument7 pagesMe19b Hw3 SolutionsnaefmubarakPas encore d'évaluation

- ARPS Effect of Temp On Density and Electrical Resistivity of Sodium Chloride SolutionsDocument4 pagesARPS Effect of Temp On Density and Electrical Resistivity of Sodium Chloride SolutionsnaefmubarakPas encore d'évaluation

- P306 91C HW 09Document10 pagesP306 91C HW 09naefmubarakPas encore d'évaluation

- P306 91C HW 09Document10 pagesP306 91C HW 09naefmubarakPas encore d'évaluation

- Pete603 10Document21 pagesPete603 10naefmubarakPas encore d'évaluation

- P306 91C HW 01Document1 pageP306 91C HW 01naefmubarakPas encore d'évaluation

- P306 91C Ex 01 PDFDocument23 pagesP306 91C Ex 01 PDFnaefmubarakPas encore d'évaluation

- Flow in Channels and Fractures Analogies To Darcy's LawDocument11 pagesFlow in Channels and Fractures Analogies To Darcy's LawnaefmubarakPas encore d'évaluation

- Notes From PETE P620 KRDocument157 pagesNotes From PETE P620 KRnaefmubarakPas encore d'évaluation

- PETE311 06A Class15Document12 pagesPETE311 06A Class15naefmubarakPas encore d'évaluation

- Notes From PETE 620 RTDocument121 pagesNotes From PETE 620 RTnaefmubarakPas encore d'évaluation

- PETE311 06A Class17Document16 pagesPETE311 06A Class17naefmubarakPas encore d'évaluation

- PETE311 06A Class06 (Maggard)Document17 pagesPETE311 06A Class06 (Maggard)Unflagging1983Pas encore d'évaluation

- P306 91C Ex 01 PDFDocument23 pagesP306 91C Ex 01 PDFnaefmubarakPas encore d'évaluation

- PETE311 06A Class24Document13 pagesPETE311 06A Class24naefmubarakPas encore d'évaluation

- PETE311 06A Class29Document9 pagesPETE311 06A Class29naefmubarakPas encore d'évaluation

- Input Data: Water-Oil System:: Ro RW WDocument1 pageInput Data: Water-Oil System:: Ro RW WAhmed RaafatPas encore d'évaluation

- Master Plumbing 2018Document43 pagesMaster Plumbing 2018Danielle Nicole del Mundo100% (1)

- K91.51 Fig F112 en FinalDocument1 pageK91.51 Fig F112 en FinaladrianioantomaPas encore d'évaluation

- LMI Milton Roy P SeriesDocument2 pagesLMI Milton Roy P SeriesPT Tirtapure EnvirotekPas encore d'évaluation

- Instrument Hookup 8Document1 pageInstrument Hookup 8Wael ZakariaPas encore d'évaluation

- 092 M-002 Mechanical Symbols and LegendsDocument1 page092 M-002 Mechanical Symbols and Legendseuri08Pas encore d'évaluation

- CHECK LIST FOR FIRE PUMP NFPA 20 SYSTEMSDocument2 pagesCHECK LIST FOR FIRE PUMP NFPA 20 SYSTEMSsaus sambalPas encore d'évaluation

- Expro Landing String Running Drawing Rev 11Document14 pagesExpro Landing String Running Drawing Rev 11jimxuPas encore d'évaluation

- ResourcesFrictionLossData PDFDocument4 pagesResourcesFrictionLossData PDFhmid007Pas encore d'évaluation

- 3/2 AH-WRT™ - Horizontal Pump: InstallationDocument3 pages3/2 AH-WRT™ - Horizontal Pump: InstallationGuiver Santisteban IbañezPas encore d'évaluation

- NFPA 13 - Aboveground Piping Test Certificate Zona 1 PDFDocument3 pagesNFPA 13 - Aboveground Piping Test Certificate Zona 1 PDFsamantha guerreroPas encore d'évaluation

- Continuing Education From Plumbing Systems & DesignDocument1 pageContinuing Education From Plumbing Systems & Designexfireex1Pas encore d'évaluation

- Cheng Fluid Systems, Inc. - Pump CavitationDocument3 pagesCheng Fluid Systems, Inc. - Pump CavitationjpalauguillemPas encore d'évaluation

- Accumulator Charging Valve Drive Axle Block: Brake LightsDocument20 pagesAccumulator Charging Valve Drive Axle Block: Brake LightsCarlo ArevaloPas encore d'évaluation

- 63-A703-DC-008 Bund Wall Calculation PIT.ADocument5 pages63-A703-DC-008 Bund Wall Calculation PIT.ATu Tu DarPas encore d'évaluation

- Prop. directional spool valve overviewDocument4 pagesProp. directional spool valve overviewY.EbadiPas encore d'évaluation

- Diploma in Mechanical Engineering: Pedal Powered Water PumpDocument31 pagesDiploma in Mechanical Engineering: Pedal Powered Water PumpSHAIK NISHARPas encore d'évaluation

- Accessories: Spare Parts and AccessoriesDocument1 pageAccessories: Spare Parts and AccessoriesHafiz Muhammad Azeem NoorPas encore d'évaluation

- Hydraulic Mining Shovel Cat 6020B: 09. Hydraulic Oil Cooling SystemDocument8 pagesHydraulic Mining Shovel Cat 6020B: 09. Hydraulic Oil Cooling SystemSatrio Teguh0% (1)

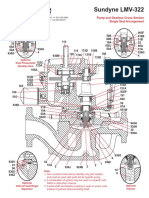

- Sundyne Pump API610 OH6 Gear Driven Vertical LMV-322 Cross SectionDocument1 pageSundyne Pump API610 OH6 Gear Driven Vertical LMV-322 Cross SectionRodrigo DonosoPas encore d'évaluation

- Buxton-IOM TEST PUMP S10G-M THRU S30G-M TestUnits IOM rvB1 2Document16 pagesBuxton-IOM TEST PUMP S10G-M THRU S30G-M TestUnits IOM rvB1 2WaynePas encore d'évaluation

- Presentation 1Document41 pagesPresentation 1Gianna Alvarez BalibagPas encore d'évaluation

- Control Valve Failure Relief Rate - Gas ServiceDocument3 pagesControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (1)

- Service Chart B1: Cylinder SpecificationDocument3 pagesService Chart B1: Cylinder SpecificationGhaffar YaakopPas encore d'évaluation

- Parts Information: Eaton Hydraulics DivisionDocument4 pagesParts Information: Eaton Hydraulics DivisionFernando SabinoPas encore d'évaluation

- Unit Iv-Pumps: PART - A (2 Marks) (NOV-02)Document1 pageUnit Iv-Pumps: PART - A (2 Marks) (NOV-02)mohanrajmeed2012Pas encore d'évaluation

- Hydraulic Calculation Report - PSDocument289 pagesHydraulic Calculation Report - PSAob AprilPas encore d'évaluation

- Screw Pump Construction, Working & Applications in 40 CharactersDocument3 pagesScrew Pump Construction, Working & Applications in 40 CharactersPanji Kresno Wijanarko100% (1)

- Parallel Pump Curves TA2538 X 4, 1760 RPM : L/Sec 200 300 400 500 600 700 800 900 1000 1100 1200Document1 pageParallel Pump Curves TA2538 X 4, 1760 RPM : L/Sec 200 300 400 500 600 700 800 900 1000 1100 1200Rubi AbionPas encore d'évaluation

- Module 1to 4Document18 pagesModule 1to 4Punith JayramPas encore d'évaluation

- 6050 Hydraulic Mining Shovel Tank Pump PMS: Global Service TrainingDocument7 pages6050 Hydraulic Mining Shovel Tank Pump PMS: Global Service TrainingEnso RosalesPas encore d'évaluation

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionD'EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionÉvaluation : 4.5 sur 5 étoiles4.5/5 (542)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesD'EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026D'EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Évaluation : 5 sur 5 étoiles5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressD'EverandNuclear Energy in the 21st Century: World Nuclear University PressÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionÉvaluation : 5 sur 5 étoiles5/5 (1)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentD'EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Asset Integrity Management for Offshore and Onshore StructuresD'EverandAsset Integrity Management for Offshore and Onshore StructuresPas encore d'évaluation

- High Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsD'EverandHigh Performance Loudspeakers: Optimising High Fidelity Loudspeaker SystemsÉvaluation : 4 sur 5 étoiles4/5 (1)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successD'EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialD'EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialPas encore d'évaluation

- Renewable Energy: A Very Short IntroductionD'EverandRenewable Energy: A Very Short IntroductionÉvaluation : 4.5 sur 5 étoiles4.5/5 (12)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyD'EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyPas encore d'évaluation

- Shorting the Grid: The Hidden Fragility of Our Electric GridD'EverandShorting the Grid: The Hidden Fragility of Our Electric GridÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersD'Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersÉvaluation : 5 sur 5 étoiles5/5 (1)

- Off-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemD'EverandOff-Grid Projects: Step-by-Step Guide to Building Your Own Off-Grid SystemPas encore d'évaluation

- Lithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsD'EverandLithium-Ion Battery: The Power of Electric Vehicles with Basics, Design, Charging technology & Battery Management SystemsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Implementing an Integrated Management System (IMS): The strategic approachD'EverandImplementing an Integrated Management System (IMS): The strategic approachÉvaluation : 5 sur 5 étoiles5/5 (2)

- Ramblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowD'EverandRamblings of a Mad Scientist: 100 Ideas for a Stranger TomorrowPas encore d'évaluation

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionD'EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionÉvaluation : 4 sur 5 étoiles4/5 (331)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesD'EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesÉvaluation : 5 sur 5 étoiles5/5 (1)

- 8051 Microcontroller: An Applications Based IntroductionD'Everand8051 Microcontroller: An Applications Based IntroductionÉvaluation : 5 sur 5 étoiles5/5 (6)

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionPas encore d'évaluation

- The Grid: The Fraying Wires Between Americans and Our Energy FutureD'EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureÉvaluation : 3.5 sur 5 étoiles3.5/5 (48)

- Handbook on Battery Energy Storage SystemD'EverandHandbook on Battery Energy Storage SystemÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)