Académique Documents

Professionnel Documents

Culture Documents

Installation Data 375 Series Ring Gate Nozzle: RG3/IS

Transféré par

Esteban Vanegas AlvarezTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Installation Data 375 Series Ring Gate Nozzle: RG3/IS

Transféré par

Esteban Vanegas AlvarezDroits d'auteur :

Formats disponibles

ME-0741-PS-550-D

RG3/IS

08-08

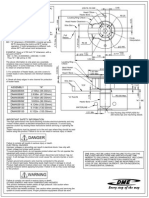

375 SERIES RING GATE NOZZLE

INSTALLATION DATA

REFER TO : MINI PRINT # 1800

NOTE: Dimensions are shown in Inches.

2.001

+0.001

0.000

NOTE: Before installing a Ring Gate Nozzle, it is important to take the nozzle's

expansion factor into consideration. For best results, please follow the

information below

DIA.

MANIFOLD LINE

MACHINING DETAILS

0.250 MIN.

0.030 X 45

CHAMFER

0.125 MIN.

1.625

DIA.

"N' Dia. (max.)

square coil or cast-In

"N' Dia. (min.)

square coil or cast-In

1.625

1.437

SQUARE COIL OR

CAST-IN HEATER

"A" + BE

30.0

0.080

BORE TO FIT TIP

("T" DIA.) +0.0005 / -0.0000

For selection of gate diameter it is important to take into consideration the materials flow characteristics, shear rate of resin, molding conditions, fill time

requirements, gate vestiage, wall thickness and configuration of part to be molded. Situations requiring high injection velocities must be considered

when selecting small gate diameters. High injection rates may require larger gates due to shear heat build up (e.g. high weight thin wall applications ).

See material manufactures literature for further information regarding material to be molded.

To compensate for the nozzle's growth when heat is applied, the linear

expansion of the nozzle (BE) at a given temperature must be added

to the nominal dimension "A". The position of the needle will now be

flush or slightly protruding thru the gate. The formula below shows

how to figure boring depth (dimension "A" + BE).The tip of the nozzle

will now be flush with cavity line.

Formula for determining this expansion factor is as follows:

BE="A" dimension x 0.00000633 x(Nozzle set point temperature - 68 F).

EXAMPLE: Given a 3 inch "A" dimension, with a nozzle set point

temperature of 500 F:

BE = 3 x 0.00000633 x (500 - 68 ) = 0.008

Thus "A" + BE will be 3.008

Note: The above information is only given as an example. variations

may occur based on mold configurations and cooling factor.

In some instances it may be necessary to obtain an empirical factor.

WIRING INFORMATION

Square Coil Heaters and Cast-In Heaters are supplied with 2"

prestripped 36" long leads.

Heaters are 240 VAC.

2 power leads are Multi Color. 1 ground lead is GREEN.

Thermocouple is "J" Type. Thermocouple is supplied with 36" leads.

1 T/C lead is WHITE and negative (-)

constantan (non-magnetic).

1 T/C lead is BLACK and positive (+)

iron (magnetic).

General Table

NOZZLE SUB-ASSEMBLY

CATALOG NUMBER

"A" DIMENSION

SQ.COIL HTR. CAST-IN HTR.

EHA0008

CIA0008

EHA0009

CIA0009

CIA0010

EHA0010

EHA0011

CIA0011

FOR NOZZLE ASSEMBLY

2.000

2.500

3.000

3.500

EHA0012

CIA0012

4.000

EHA0013

EHA0014

CIA0013

CIA0014

5.000

6.000

EHA0015

CIA0015

7.000

RING GATE TIP SUB-ASSEMBLY

CATALOG NUMBER

EHT0006

EHT0007

EHT0008

EHT0009

EHT0037

EHT0038

"O" DIA.

0.080

0.100

0.080

0.100

0.080

0.100

"T" DIA.

0.500

0.500

0.750

0.750

1.000

1.000

NOTE: Nozzle Assembly requires Nozzle Sub-assembly and Tip-assembly.

ME-0741-PS-550-D

08-08

RG3/IS

375 SERIES RING GATE NOZZLE

INSTALLATION DATA

REFER TO : MINI PRINT # 1800

OPERATING & SERVICING INSTRUCTIONS

FOR 375 SERIES RING GATE NOZZLES

6. Careful attention should be taken to the heater / thermocouple leads as

damage could occur when working on nozzle assembly.

All interchangeable nozzles are similar, and differ only in size and material flow

capacity. The information found below applies to the 375 Series Ring Gate Nozzles. 7. Seal ring for nozzle body must be replaced each time nozzle body and / or

manifold are removed to ensure seal-off.

OPERATING PROCEDURE

8. Wait a minimum of 5 minutes after set point has been achieved for sufficient

The nozzles are supplied with a Square (flat) Coil Heater or Cast-In Heater

heat to transfer into the tip before molding.

equipped with type J thermocouple.

It is recommended to use a D-M-E closed loop Temperature Controller for

optimumTemperature Control.

IMPORTANT SAFETY INFORMATION

When starting the nozzle, set the temperature to 10% voltage if using in open loop

A hot-runner system includes electrical elements and may contain molten

manual type or to 200 F if using closed loop automatic type. In either case this

plastic at elevated temperature and pressure. To avoid injury, exercise

procedure will allow the heater to dissipate any moisture.

caution by reading these instructions before servicing or operating the

Make sure you maintain this start-up setting for 15 minutes.

system.

Controller equipped with Step Smart , Smart Step

These instructions must be passed on to the end user where they should

or other heater warm-up circuitry will change automatically.

be read before using this product. Failure to do so can result in serious

It is essential to use controllers with the proper voltage and wattage capabilities.

injury or death.

The voltage and wattage of each heater is clearly marked on the heater tag.

DANGER

Step Smart , Smart Start and DME are all registered trademarks

of DME Company.

DISASSEMBLY PROCEDURE

1. Place the nozzle in a vice using "V" Block, then secure it firmly at the nozzle head.

2. For removal of tip from nozzle, a six point deep well socket is recommended. The

nozzle must be at processing temperature and the heater should be turned off

when removing tip counter-clockwise from the nozzle. If nozzle is still in the mold,

the nozzle must be "keyed" to prevent wire damages.

3. Tip and needle must be cleaned of any material before reassembling.

4. Remove the heater using a Square Coil Heater wrench (Wrench is included with

replacement heater).

5. Cast-In Heater may be removed if failure occurs and replaced with a Square Coil

Heater. Follow assembly procedures for Square Coil Heater.

ASSEMBLY PROCEDURE

Failure to comply will result in serious injury or death:

ELECTRICAL HAZARDS

Improper voltages or grounding can result in electrical shock. Use only

with proper voltage and a proper earth ground.

To avoid electrical shock, do not operate product when wet.

Do not operate this equipment with covers or panels removed.

To avoid electrical shock, turn off main power disconnect and lockout /

tag out before servicing this device. Do not connect temperature sensors to

electrical power. It will damage the product and it can cause fire, severe

injuries or even death.

If green ground wire present wire must be connected to the ground.

Do not rebend rigid leads. Rebending leads might result in damage to circuit.

Product might absorb moisture when cool. Use low Voltage or power to drive

out residual moisture before applying full power. Failure to do so may cause

damage to this product.

WARNING

1. Nozzle body must be cleaned of any material in the seal off area and threaded

Failure to comply can result in serious injury or death:

areas before reassembling.

STORED ENERGY AND HIGH TEMPERATURE HAZARDS

2. Careful attention should be taken to the needle as damage could occur if needle

This product maintains molten plastic at high pressure. Use caution when

is dropped or strikes a rigid material. Treat needle like a glass or ceramic material. operating and servicing the system.

3. Install the heater using a Square Coil Heater wrench (Wrench included with

Physical contact with molten plastic may result in severe burns. Proper

replacement heater). After the heater is installed, it should cover the entire length

protective equipment, including eye protection, must be worn. This product

of the nozzle body - stretch the heater by hand if necessary.

has heated surfaces. Use caution when operating and servicing the system

4. Apply an anti-seize compound on the tip threads.

to avoid severe burns. Proper protective equipment should be worn.

5. Firmly screw the tip sub-assembly into the shank of the nozzle body. Tighten an

untighten two or three times making sure there is a good contact between the tip

and the shank. Torque the sub-assembly into the nozzle body using 30 5 ft-lbs.

For protection of the tip sub-assembly, a six point deep well socket is recommended.

29111 STEPHENSON HIGHWAY

MADISON HEIGHTS

D-M-E SHALL NOT BE LIABLE FOR MISUSE OR FAILURE TO FOLLOW THE ENCLOSED

INSTRUCTIONS AND SPECIFICATIONS. D-M-E HERBY TO DISCLAIMS ALL IMPLIED

MICHIGAN 48071 USA

WARRANTIES, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR

US 800-656-6656

PURPOSE. IN NO EVENT SHALL D-M-E BE RESPONSIBLE FOR LOSS OF USE, REVENUE

CANADA 800-387-6600

OR PROFIT, OR FOR INCIDENTAL OR CONSEQUENTIAL DAMAGED.

www.dme.net

D-M-E COMPANY

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- American Standard Mold Base QRFDocument4 pagesAmerican Standard Mold Base QRFEsteban Vanegas AlvarezPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- DME Single Zone Timer TCM-03-024DDocument1 pageDME Single Zone Timer TCM-03-024DEsteban Vanegas AlvarezPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Abrasive Stones - General Purpose Type A and BDMEabstonesab-msdsDocument6 pagesAbrasive Stones - General Purpose Type A and BDMEabstonesab-msdsEsteban Vanegas AlvarezPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- D-M-E In2 Innovative Interlocks: Mold Base MachiningDocument2 pagesD-M-E In2 Innovative Interlocks: Mold Base MachiningEsteban Vanegas AlvarezPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Cut Off WheelDMEcutoffwh-msdsDocument4 pagesCut Off WheelDMEcutoffwh-msdsEsteban Vanegas AlvarezPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- J Type Therm StandardsDocument1 pageJ Type Therm StandardsEsteban Vanegas AlvarezPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Abrasive Stones - General Purpose Type E and MDMEabstonestypeem-msds PDFDocument6 pagesAbrasive Stones - General Purpose Type E and MDMEabstonestypeem-msds PDFEsteban Vanegas AlvarezPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Mold SaverDMEsav-msds 1Document7 pagesMold SaverDMEsav-msds 1Esteban Vanegas Alvarez100% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- SDS271 Diamond CompoundDocument7 pagesSDS271 Diamond CompoundEsteban Vanegas AlvarezPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Abrasive Stones - General Purpose Type E and MDMEabstonestypeem-msds PDFDocument6 pagesAbrasive Stones - General Purpose Type E and MDMEabstonestypeem-msds PDFEsteban Vanegas AlvarezPas encore d'évaluation

- PR Oc Ess Contr OlsDocument8 pagesPR Oc Ess Contr OlsEsteban Vanegas AlvarezPas encore d'évaluation

- Abrasive Sheets - ABW TypeDME ABW Abrasive SheetsDocument6 pagesAbrasive Sheets - ABW TypeDME ABW Abrasive SheetsEsteban Vanegas AlvarezPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Jumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsDocument2 pagesJumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsEsteban Vanegas AlvarezPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Me M741 PS 999 PDFDocument2 pagesMe M741 PS 999 PDFEsteban Vanegas AlvarezPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- D-M-E Mold Straps: Important Safety InformationDocument1 pageD-M-E Mold Straps: Important Safety InformationEsteban Vanegas AlvarezPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Distibutor Tubes: Important Safety InformationDocument2 pagesDistibutor Tubes: Important Safety InformationEsteban Vanegas AlvarezPas encore d'évaluation

- Me 0708 PS 014Document2 pagesMe 0708 PS 014Esteban Vanegas AlvarezPas encore d'évaluation

- Jumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsDocument2 pagesJumbo Gate-Mate Nozzle Assemblies Installation Data: ME-0739-PS-051-C Gmn-PsEsteban Vanegas AlvarezPas encore d'évaluation

- Heater Replacement Instructions For Point Gate and Thru Hole TipsDocument2 pagesHeater Replacement Instructions For Point Gate and Thru Hole TipsEsteban Vanegas AlvarezPas encore d'évaluation

- Me 0508 PS 059Document5 pagesMe 0508 PS 059Esteban Vanegas AlvarezPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Thinswitch Installation InstructionsDocument2 pagesThinswitch Installation InstructionsEsteban Vanegas AlvarezPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Me 0508 PS 059Document5 pagesMe 0508 PS 059Esteban Vanegas AlvarezPas encore d'évaluation

- Drum Heater Installation English Sept 2015Document1 pageDrum Heater Installation English Sept 2015Esteban Vanegas AlvarezPas encore d'évaluation

- Me 0508 PS 058 PDFDocument3 pagesMe 0508 PS 058 PDFEsteban Vanegas AlvarezPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Me 0704 PS 069Document2 pagesMe 0704 PS 069Esteban Vanegas AlvarezPas encore d'évaluation

- High Performance Hot Sprue Bushing Installation DataDocument2 pagesHigh Performance Hot Sprue Bushing Installation DataEsteban Vanegas AlvarezPas encore d'évaluation

- Me 0508 PS 057Document3 pagesMe 0508 PS 057Esteban Vanegas AlvarezPas encore d'évaluation

- S-Series Straight-Shot T-Series Straight-ShotDocument2 pagesS-Series Straight-Shot T-Series Straight-ShotEsteban Vanegas AlvarezPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- DMEInternalLatchLock DKL CAMFingerRemoval InstallationDocument5 pagesDMEInternalLatchLock DKL CAMFingerRemoval InstallationEsteban Vanegas AlvarezPas encore d'évaluation

- Me 100005 0827Document2 pagesMe 100005 0827Esteban Vanegas AlvarezPas encore d'évaluation

- Bunker SiloDocument3 pagesBunker SiloManju Civil PPas encore d'évaluation

- 03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1Document352 pages03-2ezii (Ex-Lx-Dx) Codde 3 QRH1 V1sadh94Pas encore d'évaluation

- Introduction To CAL ProgrammingDocument198 pagesIntroduction To CAL ProgrammingSalam Mohamed RiyadPas encore d'évaluation

- Direct Stiffness Method for Truss AnalysisDocument28 pagesDirect Stiffness Method for Truss Analysisgilberthufana446877Pas encore d'évaluation

- 92v Parts List ViperDocument194 pages92v Parts List Viperreltih18Pas encore d'évaluation

- Measure Wood DimensionsDocument6 pagesMeasure Wood DimensionsThilak BalakrishnanPas encore d'évaluation

- Lab Report Building TransportationDocument8 pagesLab Report Building TransportationshahPas encore d'évaluation

- University Institute of Information Technology: Ouick Learn - MCQDocument53 pagesUniversity Institute of Information Technology: Ouick Learn - MCQvimalPas encore d'évaluation

- Hardness Vs TextureDocument5 pagesHardness Vs TextureShofa R HaqPas encore d'évaluation

- Bondek Design & Construct ManualDocument131 pagesBondek Design & Construct ManualAkuma.Gokai7328100% (12)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Evaporation: (I) Vapour PressureDocument15 pagesEvaporation: (I) Vapour Pressurevenka07Pas encore d'évaluation

- CCH Power CalculateDocument4 pagesCCH Power Calculateangga measPas encore d'évaluation

- Common Base (BJT) - Common Gate (MOSFET) CircuitsDocument3 pagesCommon Base (BJT) - Common Gate (MOSFET) CircuitsUtpal100% (3)

- AC 43-9-1 Amdt 0Document15 pagesAC 43-9-1 Amdt 0Harry NuryantoPas encore d'évaluation

- PLKKKDocument36 pagesPLKKKelecompinnPas encore d'évaluation

- Concept of Stress: DR Atul JAIN Mechanical Engineering Department Indian Institute of Technology KharagpurDocument57 pagesConcept of Stress: DR Atul JAIN Mechanical Engineering Department Indian Institute of Technology Kharagpursneha KumariPas encore d'évaluation

- Part Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Document11 pagesPart Ii - Particular Technical Specifications Chapter 13 - Permanent Access Bridge 13. PERMANENT ACCESS BRIDGE........................................................ 13-1Anonymous KHIyWRIWmaPas encore d'évaluation

- Lincoln FC ElectrodesDocument44 pagesLincoln FC ElectrodeszmcgainPas encore d'évaluation

- CRI PumpsDocument13 pagesCRI Pumpscrigroups0% (1)

- HYDRO VesselsDocument5 pagesHYDRO VesselsMarvinPatricioNarca0% (1)

- Quality Criterion of Road Lighting Measurement and ExploringDocument96 pagesQuality Criterion of Road Lighting Measurement and ExploringNitin UpadhyayPas encore d'évaluation

- Column and Wall Load Take Down Spreadsheet v1.0 - CLDocument28 pagesColumn and Wall Load Take Down Spreadsheet v1.0 - CLBilal KhattabPas encore d'évaluation

- Computer Aided Design Course Code: 3341904Document7 pagesComputer Aided Design Course Code: 3341904Dhaval UpadhyayPas encore d'évaluation

- PraveenKumar - Java Developer - Broadridge - HydDocument4 pagesPraveenKumar - Java Developer - Broadridge - HydAllagadda Mahesh BabuPas encore d'évaluation

- PTH Crusher GBDocument16 pagesPTH Crusher GBElvis Eberth Huanca MachacaPas encore d'évaluation

- Coverage of Quiz 1Document24 pagesCoverage of Quiz 1Ben RileyPas encore d'évaluation

- XPol Panel 806–960 65° 0°–14°TDocument3 pagesXPol Panel 806–960 65° 0°–14°TkenansabPas encore d'évaluation

- MCP HistoryDocument18 pagesMCP HistoryStanciu VladPas encore d'évaluation

- Ci-2001 Ab OmDocument30 pagesCi-2001 Ab OmEnrique FlowersPas encore d'évaluation

- Physical Chem 1 (Combined)Document35 pagesPhysical Chem 1 (Combined)Yit JuanPas encore d'évaluation