Académique Documents

Professionnel Documents

Culture Documents

APEM7!3!187-194 Cryogenic Performance of EN8, En24, AISI1040 Tool

Transféré par

Bhuidhar VermaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

APEM7!3!187-194 Cryogenic Performance of EN8, En24, AISI1040 Tool

Transféré par

Bhuidhar VermaDroits d'auteur :

Formats disponibles

Advances in Production Engineering & Management 7 (2012) 3, 187-194

ISSN 1854-6250

Professional paper

PERFORMANCE EVALUATION OF CRYOGENIC TREATED

TOOLS IN TURNING

Gopal Krishna, P. V.*; Kishore, K.**; Ramadevudu, G.*** & Sikandar, Ali****

*Corresponding author, Associate Professor, Department of Mechanical Engineering, Vasavi

College of Engineering, Hyderabad, India

**Professor, Department of Mechanical Engineering, Vasavi College of Engineering,

Hyderabad, India

***Assistant Professor, Department of Physics, Vasavi College of Engineering, Hyderabad,

India

****P.G. Student, Department of Mechanical Engineering, Vasavi College of Engineering,

Hyderabad, India

E-mail: gopal_pola@yahoo.co.uk

Abstract:

Tool wear is a worn portion over the flank and face of the tool. Tool wear is significant for

determining tool life and hence it influences the machining economics. The wear

measurements are carried by using a tool makers microscope in the present investigations.

All the investigations are carried out using cutting fluid. Life enhancement by using cryogenic

treatment on HSS is the objective of study. Investigations are carried on different work

materials such as AISI 1040, EN8 and EN24. Improvement in tool life up to 90% is observed

for soft material AISI 1040 and enhancement up to 39% is observed on EN24. These

investigations are aimed at benefiting small industries that use aforementioned tool work

combinations. Regression models are constructed for tool wear for both untreated machining

and cryogenic treated machining.

Key Words: Turning, Cryogenic Treatment, Regression Analysis, Tool Wear, Tool Life

1. INTRODUCTION

To understand the effects of cryogenic processing, it is essential to get acquainted with the

heat treating of metals. The primary reason for heat treating steel is to improve its wear

resistance through hardening. Gears, bearings and tooling for example are hardened

because they need excellent wear resistance, improved fatigue life, stress relieving

dimensional stability and corrosion resistance for extended reliability and performance. The

steps in heat-treating are frequently explained in a simplistic manner but it takes significant

skill and experience to execute heat treatments successfully. The steel tooling in practice

would be immersed in liquid nitrogen for a period of time, allowed to warm up and then

placed into service. It was also observed that the cryogenic treatment would convert the

retained austenite into un-tempered martensite. The tools would experience a greatly

enhanced service life. It was theorized that the increase in wear resistance was a direct

result of the reduction in the amount of residual austenite. Liquid nitrogen systems have been

the customary method for achieving cryogenic temperatures. Three types of systems have

been developed viz heat exchanger systems, direct spray systems, and immersion systems.

The last method i.e immersion system is used in present investigation.

The tool wear can be measured directly by using a microscope. However several indirect

methods depending on the measurement of a parameter that influence the tool wear do

exist. Some of the methods for indirect prediction are cutting force, vibrations, acoustics,

radioactive isotopes, image processing etc. It should be noted that no method is accurate for

indirect prediction. Studies by Penn State University researchers in 1996 showed that

retained austenite was reduced from near 18% to roughly 8% in T15 tool steel upon

cryogenic treatment. Hardness increased by 2 points (HRC) with cryogenic treatment and

187

Gopal Krishna et al.: Performance Evolution of Cryogenic Treated Tools in Turning

subsequently decreased (in some cases more than 2 points) after a temper cycle. Still there

has not yet been enough investigation to precisely determine optimum processing

parameters, even for tool steels. Some researchers suggest that tools should be sharpened

after cryogenic treatment rather than before. However for present work cryogenic treatment

was carried out after grinding the single point cutting tool to the required angles. The tools

are dipped in liquid nitrogen (-1960 C) up to 24 hours and they are slowly brought to room

temperature.

The application of cryo-treated tools in metal cutting is a fascinating one and many

investigators have shown keen interest in this area. Tool wear studies were carried out by

Gill [1] et al on tungsten carbide cutting tools while turning AISI 1040. Wear studies on milling

cutter treated by liquid nitrogen were performed by Young [2] et al. The influence of

cryogenic treatment on the mechanical properties of tool steels were carried out by Molinari

[3] et al. Structural changes in T-I type high speed steels when subjected to cryogenic

treatment are reported by Popandopulo [4] et al. The lucid explanation by Carlson [5] about

cold treatment of steels in his contribution for ASM hand book was a major inspiration for this

work. Most of the modern investigators in the field of metal cutting preferred to use liquid

nitrogen as a substitute coolant and they could obtain some improvements in cutting

conditions. Yakup [6] et al was one of the investigators who tried to establish improvement of

tool life due to a flood of liquid nitrogen. An overview on the performance of tool material after

cryogenic treatment was presented as a review paper by Rupinder Singh [7] et al. Machining

properties of titanium based alloy by cryogenic treated carbides and HSS tools was carried

out by Aujla [8]. Improvement in cutting conditions using various means is a significant issue

in the area of manufacturing as it effects cost. Hence present studies attain significance in

the context of extending the cryogenic treatment methods to small industries.

2. EXPERIMENTATION

Although a lot of choices are available for the industry, so far as tool materials are

concerned, it is to be noted that most of the presently used multipoint cutting tools are made

of HSS. This tool material has high toughness and is capable of taking impact loads. On the

other hand still single point cutting tools made of HSS are routinely used in small and

medium machine shops, which cannot effort experience tools made of carbides or ceramics.

An attempt is made in the present work to improve the tool life of single point cutting tools

made of HSS, by exposing them to liquid nitrogen (-1960C). This cryogenic liquid is

commercially available at very low cost.

The machining parameters considered during the current investigations to evaluate the

tool life are the cutting speed, feed and depth of cut. Experiments are conducted using an L8

orthogonal array designed by Taguchi and the response is measured. All the experiments

are conducted on work pieces of length 600mm and six passes are taken over them before

measuring the tool wear. The wear is measured by using a Tool makers microscope. All the

experiments are conducted at random to avoid error and bias, each condition is repeated for

confirmation of wear. The work materials selected in the present investigations are AISI

1040, EN8 and EN24. The reason for selecting these materials is that most of the small and

medium scale industries fabricate components made of these materials only. The present

studies are targeted to benefit only these industries which cannot afford expensive tool

materials, machines and necessary equipment for measurement of tool wear. The depth of

cut is maintained constant at 1 mm and the feed rate at 0.3mm/ rev. A total of six passes are

taken for a machining time of 24 minutes.

The tool material used in the present investigations is T-1type HSS with 5% cobalt. The

tools are ground to ASA standard 110-12070-70150200 0.5mm, on a tool and cutter

grinder. A set of these tools are subjected to liquid nitrogen treatment for a period of 24hrs

and are slowly brought to room temperature.

188

Gopal Krishna et al.: Performance Evolution of Cryogenic Treated Tools in Turning

3. RESULTS AND DISCUSSIONS

Tool wear and tool life are in separable in metal cutting industry. The machining parameters

are set based on the final constraints such as quality of surface finish and productivity. The

tool life will come to an end due to progressive wear or due to premature failure of the tool.

The former is the main reason for most of the tools used in industry. An attempt is made in

the present work to improve the tool life by performing cold (cryogenic) treatment. This

treatment brings about structural changes in cutting tools made of steel. Figures 1 and 2

respectively show microscope images of the tool before and after cryogenic treatment.

Figure 1: Image of cutting tool before cryogenic treatment (magnification X600).

189

Gopal Krishna et al.: Performance Evolution of Cryogenic Treated Tools in Turning

Figure 2: Image of cutting tool after 24 hours cryogenic treatment (magnification X600).

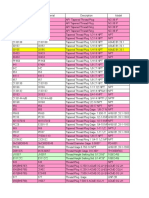

The levels selected for the machining parameters and experimental matrix used for different

work materials are shown in Tables I to IV. All experiments are carried out for wet condition

only. The cutting fluid used is a water oil emulsion.

Table I: Selection of process parameters.

Level

Level-1

Level-2

Cutting speed V (m/min)

x1

40

26

Feed S (mm/rev)

x2

0.798

0.227

190

Depth of cut t (mm)

x3

1.0

0.5

Gopal Krishna et al.: Performance Evolution of Cryogenic Treated Tools in Turning

Table II: Tool Wear for machining of AISI 1040.

S.

No

Cutting

speed (V)

(m/min)

x1

Feed

(S)

(mm/re

v) x2

Depth

of cut

(t)

(mm) x3

1.

2.

3.

4.

5.

6.

7.

8.

1

1

1

1

2

2

2

2

1

1

2

2

1

1

2

2

1

2

1

2

1

2

1

2

Tool wear

Without

cryogenic

treatment

(mm)

0.6

0.49

0.37

0.315

0.29

0.28

0.185

0.12

Tool wear with 24

hour cryogenic

treatment

(mm)

%

Increase

in Tool

life.

0.306

0.248

0.168

0.185

0.136

0.127

0.055

0.012

49.00

49.38

54.59

41.26

53.10

54.64

70.27

90.00

Table III: Tool Wear for machining of EN8.

S.

No

Cutting

speed (V)

(m/min)

x1

Feed

(S)

(mm/re

v) x2

1.

2.

3.

4.

5.

6.

7.

8.

1

1

1

1

2

2

2

2

1

1

2

2

1

1

2

2

Depth

of cut

(t)

(mm)

x3

1

2

1

2

1

2

1

2

Tool wear

Without

cryogenic

treatment

(mm)

1.05

0.88

0.61

0.56

0.48

0.45

0.315

0.24

Tool wear with 24

hour cryogenic

treatment

(mm)

%

Increase

in

Tool life.

0.675

0.655

0.41

0.385

0.345

0.315

0.145

0.105

35.71

25.56

32.78

31.25

28.12

30.00

53.96

56.25

Table IV: Tool Wear for machining of EN24.

S.

No

Cutting

speed (V)

(m/min)

x1

Feed

(S)

(mm/re

v) x2

Depth

of cut

(t)

(mm) x3

1.

2.

3.

4.

5.

6.

7.

8.

1

1

1

1

2

2

2

2

1

1

2

2

1

1

2

2

1

2

1

2

1

2

1

2

Tool wear

Without

cryogenic

treatment

(mm)

1.060

1.380

1.100

0.875

0.685

0.635

0.510

0.450

191

Tool wear with 24

hour cryogenic

treatment

(mm)

%

Increase

in

Tool life.

0.650

0.930

0.830

0.770

0.505

0.440

0.350

0.320

38.69

32.60

24.45

12.00

26.27

30.70

31.37

28.88

Gopal Krishna et al.: Performance Evolution of Cryogenic Treated Tools in Turning

The influence of tool wear on various machining parameters is analyzed on AISI 1040, EN8

and EN24 working materials. A few more experiments are conducted to obtain the relation

between cutting speed and flank wear for all the work materials.

The flank wear in the tool materials selected for the present study with the speed for

untreated and cryo-treated samples are shown in Figure 3. It was observed that for the

materials like AISI 1040, EN8, EN24 cutting speed has significant influence on tool life when

compared to feed and depth of cut for both untreated and cryogenic treated HSS single point

cutting tool. It was also found that the interaction of speed, feed and depth of cut is more for

untreated tool than cryogenic treated tool. The interaction of speed and feed is more on EN8

when compared to AISI 1040 and EN24 on both untreated and cryogenic treated tool.

UT

0.9

CT

Flank wear (mm)

flank wear (mm)

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

AISI 1040

0

0

10

20

30

40

Speed (m/min)

50

60

1.4

1.5

1.4

1.3

1.2

1.1

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0

UT

1.3

UT

CT

1.2

CT

1.1

1

flank wear (mm)

1.1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

EN8

EN24

0.1

0

10

20

30

40

Speed (m/mim)

50

60

10

20

30

40

50

speed (m/mim)

Figure 3: Variation of flank wear with speed in untreated and cryo-treated tools AISI 1040, EN8

and EN24 for a machining period of 24 minute.

It is evident from Figure 3 that the flank wear is less in all the cryo-treated sample tools i.e.

AISI 1040, EN8 and EN24 compared to untreated tools at various speeds. So the low wear in

the cryo-treated tools can be attributed to micro-hardening of the tools due to immersion in

liquid nitrogen. The grain size on surface of the tool might have changed due to the

cryogenic treated and hardened the tool.

A negative influence has been observed in the interaction of speed and depth of cut on

both the tools. However, the interaction of feed and depth of cut has little influence on both

treated and untreated material.

The regression analysis has been conducted on the data and the results are presented in

Table V. The parameters in the regression analysis are speed (x1), feed (x2) and depth of cut

(x3). From the regression analysis it can be concluded that the life of the tool increases by

cryogenic treatment for both soft and hard materials. Hence cryogenic treated tools are found

to be most effective at high speeds and feeds.

192

Gopal Krishna et al.: Performance Evolution of Cryogenic Treated Tools in Turning

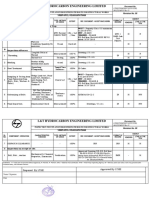

Table V: Regression equations for various working materials.

Working

Material

Tool wear (mm) for Untreated HSS

AISI

1040

y = 0.33125 + 0.1125x1+ 0.08375 x2 +

0.03 x3 + 0.28 x1 x2- 0.2 x3 x1 +

0.22 x1 x2 x3.

EN8

EN24

y = 0.575625 + 0.201875 x1 +

0.140625 x2 + 0.039375 x3 + 0.75

x1 x2 + 0.15 x2 x3 0.31 x3 x1+ 0.33

x1 x2 x3.

y = 0.899375 + 0.329375 x1+

0.165625 x2 + 0.064375 x3 + 1.21

x1x2 - 0.11x2x3 +

0.09 x3 x1 0.07 x1 x2 x3

Tool wear (mm) for Cryogenic

treated HSS for 24 hours

y = 0.143688 + 0.060813x1

+0.038188x2 + 0.000313x3

0.171x1x2-0.099x2x30.489x3x1

+ 0.0399 x1 x2 x3

y = 0.379375 + 0.151875 x1 +

0.118125 x2 + 0.014375 x3 + 0.25

x1 x2 - 0.03 x2 x3 - 0.73 x3 x1 + 0.01

x1 x2 x3.

y = 0.651875 + 0.244375 x1 +

0.084375 x2 - 0.01438 x3 + 0.15

x1x2 + 1.05 x2x3 - 0.25 x3 x1 0.79 x1 x2 x3

4. CONCLUSIONS

The cold treatment on HSS single point cutting tools in the present study has shown

significant influence on the tool life. The tool life improvement up to 90%, 50% and 39%

respectively are observed while machining AISI 1040, EN8 and EN24 during the

experiments. The interaction of speed, feed and depth of cut is more for untreated tool than

cryogenic treated tool, this is evident from the regression analysis. The interaction of speed

and feed is more on EN8 when compared to AISI 1040 and EN24 on both untreated and

cryogenic treated tool. It can be concluded that the life of the tools has increased due to

cryogenic treatment while machining both soft and hard materials. The cryogenic treated

tools are found to be most productive at high speeds and feeds. These findings will benefit

small and medium machining shops.

ACKNOWLEDGEMENT

The authors are sincerely thankful to the Principal and Management of Vasavi College of

Engineering for extending their support in carrying out this work. The cooperation extended

by Mr. T. Manohar Reddy, Lab Technician, during experimentations is highly appreciated.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

Gill, S.S., Singh, R. and Singh,J., 2008, Wear behavior of cryogenically treated tungsten

carbide inserts under dry and wet turning conditions, International Journal of Machine Tools

Manufacturing, 49(3-4), 256-260

Young, A.Y.L., Seah, K.H.W. and Rahman, M. 2006, Performance evaluation of

Cryogenically treated tungsten carbide tools in turning Operation, International journal of

machine tools manufacturing technology, 46, 2051-2056

Molinari, A., Pellizzari.M., Gialanella, S., Straffelini, G. and Stiasny, K.H., 2001 effect of deep

cryogenic treatment on the mechanical properties of tool steels, Journal of Material

Processing Technology 118(1-3) 35-355

Popandopulo, N. and Zhukova, L.T., 1980, Transformation in high speed steels during Cold

treatment, Met Sci Heat Treat, 22(10), 708-71

Caarlson,E.A., 1990, Cold treating and cryogenic treatment of steel in ASM Hand book,

Vol.4 Heat Treating, ASM international, 1oth Ed., Metals Park, OH

Yakup Yildiz, Muammer Nalbant, 2008 A review of cryogenic cooling in machining

processes, International Journal of Machine Tools and Manufacture, 48 (9) 947-964

Rupinder Singh and Kamalijit Singh, 2010, Enhancement of Toll Material Machining

Characteristics with Cryogenic Treatment: A Review, proceedings of the 2010 International

193

Gopal Krishna et al.: Performance Evolution of Cryogenic Treated Tools in Turning

[8]

[9]

[10]

[11]

[12]

[13]

[14]

Conference on Industrial Engineering and operations management, Dhaka, Bangladesh,

January 9-10,2010

Aujla,H.S. and Singh,R., 2008, Applications of cryogenic treatment for Enhancing the

Machining Properties of Titanium Alloy (Ti-6Al-4V), Manufacturing Technology Today, 7(10),

22-26

Vishal S. Sharma, Manu Dogra, N.M. Suri , 2009, Cooling techniques for improved

productivity in turning, International Journal of Machine Tools and Manufacture, Volume 49,

Issue 6, Pages 435-453

M. Dhananchezian, M. Pradeep Kumar, 2010 Experimental investigation of cryogenic cooling

by liquid nitrogen in the orthogonal machining of aluminium 6061-T6 alloy International

Journal of Machining and machinability of Materials - Vol. 7, No.3/4 pp. 274 - 285

S.Chatterjee,1992,Performance characteristics of cryogenically treated high speed drills,

International journal of production research volume 30, no 4, 773-786

David N. Collins, 1999 Cryogenic treatment of tool steels, Advanced materials and Process,

December

R.F. Barron, 1982 Cryogenic treatment to improve wear resistance, Butterworth & Co Ttd,

Reitz.W, Pendray.J, 2001 Cryoprocessing of materials- A review of current status, Materials

and manufacturing process

194

Vous aimerez peut-être aussi

- Waterproofing of Foundations of Buildings and Special StructuresDocument18 pagesWaterproofing of Foundations of Buildings and Special StructuresBhuidhar Verma100% (1)

- GE QA QC PlanDocument103 pagesGE QA QC PlanchezzkonsultPas encore d'évaluation

- Construction Material Management On Project SitesDocument5 pagesConstruction Material Management On Project SitesArathi KrishnaPas encore d'évaluation

- Criteria for Design of RCC Staging for Overhead Water TanksDocument44 pagesCriteria for Design of RCC Staging for Overhead Water TanksSyed Mohd MehdiPas encore d'évaluation

- Road GlossaryDocument26 pagesRoad GlossaryBhuidhar VermaPas encore d'évaluation

- Inspchecklist PDFDocument139 pagesInspchecklist PDFBhuidhar VermaPas encore d'évaluation

- CIA Concrete Durability Tests GuideDocument97 pagesCIA Concrete Durability Tests GuideRush Yoganathan100% (1)

- Design-Rcc Over Head TankDocument82 pagesDesign-Rcc Over Head Tankjay_p_shah60% (5)

- Goran Mohammed AbobakerDocument13 pagesGoran Mohammed AbobakerShriPas encore d'évaluation

- Updated FIDIC Contracts 2017 Mar 2018 PDFDocument3 pagesUpdated FIDIC Contracts 2017 Mar 2018 PDFBhuidhar VermaPas encore d'évaluation

- Implementation of The Maturity Method For Zero-Slump Concrete ProductsDocument12 pagesImplementation of The Maturity Method For Zero-Slump Concrete ProductsBhuidhar VermaPas encore d'évaluation

- ASTM C-403 Needle Penetration Test PDFDocument6 pagesASTM C-403 Needle Penetration Test PDFJohn PaulsyPas encore d'évaluation

- Geometric DesignDocument16 pagesGeometric DesignBhuidhar VermaPas encore d'évaluation

- Chapter Washim PDFDocument34 pagesChapter Washim PDFBhuidhar VermaPas encore d'évaluation

- Code of Practice For Precast Concrete ConstructionDocument73 pagesCode of Practice For Precast Concrete ConstructionAlaaGaballa100% (4)

- Bitumen SpecDocument1 pageBitumen SpecvikasbadhanPas encore d'évaluation

- Yavatmal Dips 12-13 PDFDocument23 pagesYavatmal Dips 12-13 PDFBhuidhar VermaPas encore d'évaluation

- Hyderabad Metro MSSDocument272 pagesHyderabad Metro MSSplakrabhelPas encore d'évaluation

- SataraDocument35 pagesSataraBhuidhar VermaPas encore d'évaluation

- PMC - Kalyan Smart CityDocument56 pagesPMC - Kalyan Smart CityBhuidhar Verma0% (1)

- Dindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - IIDocument89 pagesDindigul Bypass To Samyanallore On NH 7 in The State of Tamil Nadu Vol - IIrangarajan1989Pas encore d'évaluation

- PMC - Kalyan Smart CityDocument56 pagesPMC - Kalyan Smart CityBhuidhar Verma0% (1)

- Traffic Validation Study For Gadag City Bypass - A Case StudyDocument8 pagesTraffic Validation Study For Gadag City Bypass - A Case StudyBhuidhar VermaPas encore d'évaluation

- 0 1713 1 PDFDocument104 pages0 1713 1 PDFBhuidhar VermaPas encore d'évaluation

- Traffic Validation Study For Gadag City Bypass - A Case StudyDocument8 pagesTraffic Validation Study For Gadag City Bypass - A Case StudyBhuidhar VermaPas encore d'évaluation

- Ips NandedDocument21 pagesIps NandedBhuidhar VermaPas encore d'évaluation

- Bitumen SpecDocument1 pageBitumen SpecvikasbadhanPas encore d'évaluation

- Yavatmal Dips 12-13 PDFDocument23 pagesYavatmal Dips 12-13 PDFBhuidhar VermaPas encore d'évaluation

- Mumbai Corporation Unified Rates ScheduleDocument210 pagesMumbai Corporation Unified Rates Scheduletops123100% (1)

- Chapter WashimDocument34 pagesChapter WashimBhuidhar VermaPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- British Standards and Codes of Practice Relating To Steel ConstructionDocument23 pagesBritish Standards and Codes of Practice Relating To Steel ConstructionChris LiuPas encore d'évaluation

- Bend TestDocument14 pagesBend TesttengkustrengthPas encore d'évaluation

- Is 1367 8 2002Document24 pagesIs 1367 8 2002Palani JayaramanPas encore d'évaluation

- Introduction To Welding - 1 GCDocument66 pagesIntroduction To Welding - 1 GCkr_abhijeet72356587Pas encore d'évaluation

- 4.4.4 Gold PlatingDocument12 pages4.4.4 Gold PlatingSalem GarrabPas encore d'évaluation

- Name List For Induction at BOMCDocument2 pagesName List For Induction at BOMCWahyu PambudiPas encore d'évaluation

- Investment Casting: Lab Report ME-223 Advance Workshop PracticeDocument2 pagesInvestment Casting: Lab Report ME-223 Advance Workshop PracticeMomina ShakeelPas encore d'évaluation

- Thread GageDocument30 pagesThread GageRosendo RizoPas encore d'évaluation

- Literature ReviewDocument15 pagesLiterature Reviewnwaokorie_thaddeusPas encore d'évaluation

- Paintry Finance Room Floor PlanDocument1 pagePaintry Finance Room Floor PlanSanjay JangirPas encore d'évaluation

- Manual de Roscas EstandaresDocument136 pagesManual de Roscas EstandaresDavid AgPas encore d'évaluation

- L&T Hydrocarbon Engineering LimitedDocument2 pagesL&T Hydrocarbon Engineering LimitedAnonymous vchjQ9CQvePas encore d'évaluation

- Drilling & BoringDocument14 pagesDrilling & BoringDanur M' PahleviPas encore d'évaluation

- Tools and Equipments AviationDocument72 pagesTools and Equipments AviationJustus JosephPas encore d'évaluation

- O1 Tool Steels Material Property Data Sheet - Product Availability and Request A QuoteDocument3 pagesO1 Tool Steels Material Property Data Sheet - Product Availability and Request A QuoteKar GayeePas encore d'évaluation

- Jeep-Willys DmiDocument14 pagesJeep-Willys DmiGabriel Fodor100% (1)

- Replacement Wear Parts For KMMP HENLEYDocument24 pagesReplacement Wear Parts For KMMP HENLEYCyeCyePas encore d'évaluation

- BS 00919 4 2007Document70 pagesBS 00919 4 2007jimPas encore d'évaluation

- BT1340G/1 Bench Lathe Operation ManualDocument55 pagesBT1340G/1 Bench Lathe Operation ManualJhon SantosPas encore d'évaluation

- Nut and bolt thread load ratiosDocument1 pageNut and bolt thread load ratiosaataylor830% (1)

- Shopnotes 88 Dovetailed Shoulder PlaneDocument8 pagesShopnotes 88 Dovetailed Shoulder PlaneJulio Cesar OliveiraPas encore d'évaluation

- 45 Manufacturing of High Precision BoresDocument169 pages45 Manufacturing of High Precision BoresTuấnAnhPas encore d'évaluation

- GN4 - Hand Tools and Power Tools - Heavy Equipment SafetyDocument123 pagesGN4 - Hand Tools and Power Tools - Heavy Equipment SafetyNavi AgeinPas encore d'évaluation

- Machining Process-Ii: (Assignment)Document5 pagesMachining Process-Ii: (Assignment)Sobia JamilPas encore d'évaluation

- Drilling-Machine Group 5Document19 pagesDrilling-Machine Group 5Chandra Kiran HjPas encore d'évaluation

- ME 2252 MANUFACTURING TECHNOLOGY – II: Abrasive Processes and Gear CuttingDocument87 pagesME 2252 MANUFACTURING TECHNOLOGY – II: Abrasive Processes and Gear CuttingTariq Aziz100% (2)

- Dorian Tool Milling System CatalogDocument180 pagesDorian Tool Milling System CatalogJuan Carlos CandelarioPas encore d'évaluation

- Rosan Insert CatalogueDocument59 pagesRosan Insert CatalogueRussell GouldenPas encore d'évaluation

- Uddeholm Impax Supreme: EfitsDocument12 pagesUddeholm Impax Supreme: Efitsbhq76Pas encore d'évaluation

- 1 5736Document2 pages1 5736solidwormPas encore d'évaluation