Académique Documents

Professionnel Documents

Culture Documents

Methanol Synthesis From Syngas

Transféré par

Sylvia SimonTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Methanol Synthesis From Syngas

Transféré par

Sylvia SimonDroits d'auteur :

Formats disponibles

2.

Section 1: Syngas

Chemical composition of hydrolysed Palm Oil Mill Effluent (POME) is assumed to

be:

Glucose

Hydrogen Sulphide

0.995

0.005

Hydrolysed POME is heated to 38C at 1atm before entering the anaerobic

digestor. Anaerobic digestion is a three stage biological process that consists of

acidogenesis, acetogenesis and methanogenesis to allow the degration of POME

into volatile fatty acids (VFAs) (Ling, 2007) with the presence of acid forming

bacteria. These volatile acids will be further converted into methane, carbon

dioxide and hydrogen sulphide. This process has an operating condition of 38C

and 1atm. Thus, this operation has less risks.

The reaction of methanogenesis is as follows:

C6 H12 O6 3 CH 4 +3 CO2

The gas collected from the anaerobic digestor is compressed to 8atm and

preheated to 200C before entering the Sulphur and carbon dioxide removal

units for biogas upgrading to obtain richer amount of methane. After this

process, the gas is further compressed to 100atm and heated to 700C to allow

the conversion of methane to syngas in the autothermal reformer.

In the autothermal reformer, the upgraded biogas and steam is passed through a

fixed bed catalyst to allow catalytic partial oxidation (Aasberg-Petersen and

Sandahl Christensen, 2001) at the operating conditions of 700C and 100atm.

This is the key process in the preparation of syngas from biogas.

The reaction of autothermal reforming is as follows:

4CH 4 +2H 2 O+O2 10 H 2 +4 CO

2.2 Section 2: Methanol Synthesis Loop

Hydrogen and carbon monoxide gas mixture is passed through a cooler to

decrease its temperature to 200C and is maintained in the vapour phase to be

prepared for methanol synthesis. This process takes place in the operating

conditions of 200C and 100atm.

The reaction of methanol synthesis is as follows:

CO+2 H2 CH3 OH

After the conversion of carbon monoxide and hydrogen to methanol,

unreacted carbon monoxide and methanol goes through an expander and cooler

to reduce the pressure and temperature to 1atm and 20C. This is done so that

methanol is condensed to liquid while carbon monoxide remains in vapour form

at this conditions to allow easier separation because of their different phase and

density.

2.3 Section 3: Methanol Distillation

Dissolved carbon monoxide is removed from crude methanol by distillation at

20C and atmospheric pressure to the top of the column and pure methanol

leaves at the bottom.

2.4 Assumptions

a)

b)

c)

d)

e)

Perfect mixing

No pressure lost within equipment

No pressure lost within pipeline

Compressor and expander are all isothermal

100% removal of hydrogen sulphide and carbon dioxide

2.5 Environmental Considerations

There are four streams leaving the plant excluding the methanol product (stream

26). These are:

Stream

Stream

Stream

Stream

8: Sulphur content removed

12: Carbon dioxide removed

16: Water removed from carbon dioxide scrubber

25: Unreacted carbon monoxide from methanol synthesis reactor

Two of these streams are gaseous while the remaining two are aqueous. For

stream 8, sulphur is removed in molten form at 200C. Therefore, this by-product

can be sold as feedstock to another plant to minimize waste. For stream 12 and

25, carbon dioxide and carbon monoxide is hazardous to the environment if exit

freely from the plant. Therefore, a capture method is done for both gaseous to be

sent off to a treatment center or sold to another company that requires them as

feedstock. The water removed in stream 16 can be removed from the plant

without any threat to the environment. Another environment consideration is

taken when recycled water from the carbon dioxide remover unit is used to

generate steam for the autothermal reformer in the effort of reducing fresh water

used.

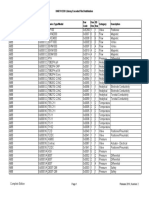

2.6 Compressors and Turbines

In total, there are two compressors and one expander in the plant. The power

required by each of the compressor and expander used in the process is

calculated by the equation:

Power Required =

ni MW i

i

First compressor:

Reference

Aasberg-Petersen, K. and Sandahl Christensen, T. (2001). PRODUCTION OF

HYDROGEN AND CARBON MONOXIDE CONTAINING SYNTHESIS GAS BY PARTIAL

OXIDATION. US 6,730,285 B2.

Ling, Y. (2007). TREATABILITY OF PALM OIL MILL EFFLUENT (POME) USING BLACK

LIQUOR IN AN ANAEROBIC TREATMENT PROCESS. 1st ed. [ebook] Penang:

Universiti Sains Malaysia. Available at:

http://eprints.usm.my/9591/1/TREATABILITY_OF_PALM_OIL_MILL_EFFLUENT_(POM

E)_USING_BLACK_LIQUOR_IN_AN_ANAEROBIC_TREATMENT_PROCESS.pdf

[Accessed 15 Mar. 2015].

Vous aimerez peut-être aussi

- Constant-Pressure Turbocharger Matching by Michael M. W. de SilvaDocument32 pagesConstant-Pressure Turbocharger Matching by Michael M. W. de SilvaMichael M. W. de Silva100% (1)

- Instrument DatasheetDocument67 pagesInstrument DatasheetMahmud RezaPas encore d'évaluation

- Methanol Synthesis 1 ScribdDocument12 pagesMethanol Synthesis 1 ScribdgilmooodPas encore d'évaluation

- HerculesDocument11 pagesHerculesSylvia SimonPas encore d'évaluation

- Honeywell Industrial Combustion Emea - Components Technical CatalogueDocument129 pagesHoneywell Industrial Combustion Emea - Components Technical CatalogueJohn HowardPas encore d'évaluation

- KAESER MOBILAIR General CatalogueDocument7 pagesKAESER MOBILAIR General CatalogueVietnam UMacPas encore d'évaluation

- Waste Plastic PyrolysisDocument32 pagesWaste Plastic PyrolysisManicks VelanPas encore d'évaluation

- Team 4 Final PresentationDocument25 pagesTeam 4 Final Presentationlux0008Pas encore d'évaluation

- Hydrogen Gas Production by Partial OxidaDocument69 pagesHydrogen Gas Production by Partial OxidaChinwuba Samuel EbukaPas encore d'évaluation

- From Syngas To Methanol and DymethyletherDocument85 pagesFrom Syngas To Methanol and Dymethylethervazzoleralex6884100% (3)

- Empirical Correlations To Predict Gas - CondensateDocument9 pagesEmpirical Correlations To Predict Gas - CondensateAysel NaibovaPas encore d'évaluation

- Conversion of Ldpe Plastic Waste Into Liquid Fuel by Thermal Degradation PDFDocument4 pagesConversion of Ldpe Plastic Waste Into Liquid Fuel by Thermal Degradation PDFandreyan zuniardiPas encore d'évaluation

- Mthanol ProductionDocument61 pagesMthanol Productionvv vvPas encore d'évaluation

- MED GAS PROD STOR TRANS DELDocument67 pagesMED GAS PROD STOR TRANS DELsantosh100% (2)

- Application of SyngasDocument10 pagesApplication of SyngasJaydeep Patel100% (1)

- 1-Butene Storage - by Philips PDFDocument19 pages1-Butene Storage - by Philips PDFD K SPas encore d'évaluation

- Aspen HYSYS Simulation of Biomass Pyrolysis For The Production of MethanolDocument5 pagesAspen HYSYS Simulation of Biomass Pyrolysis For The Production of MethanolCsk SasiPas encore d'évaluation

- Direct Methane to Methanol: Foundations and Prospects of the ProcessD'EverandDirect Methane to Methanol: Foundations and Prospects of the ProcessPas encore d'évaluation

- Case Story DK - Green Methanol - Web 1Document4 pagesCase Story DK - Green Methanol - Web 1Pao M. MorenoPas encore d'évaluation

- Engeniero Methanol Task 1&2Document61 pagesEngeniero Methanol Task 1&2sasi100% (1)

- E4tech 2009 ReportDocument130 pagesE4tech 2009 ReportMR XPas encore d'évaluation

- About DmeDocument23 pagesAbout DmeImran AzmanPas encore d'évaluation

- Manufacturing Methods: 1. Methanol Carbonylation 2. Acetaldehyde Oxidation 3. Ethylene Oxidation 4. Anerobic FermentationDocument39 pagesManufacturing Methods: 1. Methanol Carbonylation 2. Acetaldehyde Oxidation 3. Ethylene Oxidation 4. Anerobic Fermentationkumari svgPas encore d'évaluation

- 4 - HX PresentationDRAFT 3Document14 pages4 - HX PresentationDRAFT 3Islam SolimanPas encore d'évaluation

- Syngas To DMEDocument2 pagesSyngas To DMEMichael Ezeanaka.O.Pas encore d'évaluation

- ACETONADocument6 pagesACETONAvanesaPas encore d'évaluation

- Optimization of Synthesis Gas (Autothermal) Reactor in Methanol Production Process Using Natural Gas As Feed StockDocument18 pagesOptimization of Synthesis Gas (Autothermal) Reactor in Methanol Production Process Using Natural Gas As Feed StockainmnrhPas encore d'évaluation

- Modelling and Optimization of a Biomass-to-Liquid ProcessDocument65 pagesModelling and Optimization of a Biomass-to-Liquid ProcessObatarhe Ogra100% (1)

- Introduction of Dung Quat RefineryDocument67 pagesIntroduction of Dung Quat RefineryKamejoku NguyenPas encore d'évaluation

- Direct Dimethyl Ether SynthesisDocument9 pagesDirect Dimethyl Ether SynthesissltnrmnPas encore d'évaluation

- Simulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsDocument9 pagesSimulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsKelly TorresPas encore d'évaluation

- Dimethyl Ether SDS E4589Document7 pagesDimethyl Ether SDS E4589Daniil GhilescuPas encore d'évaluation

- Plant Experience - Molecular Sieve Dehydration of Gas Containing OxygenDocument23 pagesPlant Experience - Molecular Sieve Dehydration of Gas Containing OxygenHoang-Vu BuiPas encore d'évaluation

- Process Design and Simulation of Gasification and FischerTropsch Process For Biofuels Production From Lignocellulosic BiomassDocument101 pagesProcess Design and Simulation of Gasification and FischerTropsch Process For Biofuels Production From Lignocellulosic BiomassMohammed GhanemPas encore d'évaluation

- Dme Report Word Own LATESTDocument73 pagesDme Report Word Own LATESTvyas reddyPas encore d'évaluation

- Alternate Fuel From Synthetic Plastics Waste - ReviewDocument5 pagesAlternate Fuel From Synthetic Plastics Waste - ReviewSachin SahaniPas encore d'évaluation

- Design and Fabrication of Extraction of Fuel From Waste Plastics Using PyrolysisDocument5 pagesDesign and Fabrication of Extraction of Fuel From Waste Plastics Using PyrolysisVishal BhagwatPas encore d'évaluation

- DME UlmannDocument4 pagesDME UlmannLeonard SaftaPas encore d'évaluation

- Reactor Types Characteristics/usages Benefits in A DME Plant CautionsDocument4 pagesReactor Types Characteristics/usages Benefits in A DME Plant CautionsNeha MadanPas encore d'évaluation

- Direct DME Synthesis from Natural GasDocument9 pagesDirect DME Synthesis from Natural GasM Alim Ur RahmanPas encore d'évaluation

- Modelling of Fischer Tropsch ReactorDocument8 pagesModelling of Fischer Tropsch Reactorvenky1134Pas encore d'évaluation

- Viewcontent11 PDFDocument54 pagesViewcontent11 PDFEr Mayur PatilPas encore d'évaluation

- Methanol plaNT HYSYSDocument1 pageMethanol plaNT HYSYSarufatoPas encore d'évaluation

- C4 Hydrocarbon Derivatives Separation and PurificationDocument2 pagesC4 Hydrocarbon Derivatives Separation and PurificationdaabgchiPas encore d'évaluation

- A Steady-State Kinetic Model For Methanol Synthesis and The Water Gas Shift Reaction On A Commercial Cu/ZnO/Al2O3 CatalystDocument10 pagesA Steady-State Kinetic Model For Methanol Synthesis and The Water Gas Shift Reaction On A Commercial Cu/ZnO/Al2O3 CatalystHector100% (1)

- Rozovskii Et Al. (2003) - Fundamentals of Methanol Synthesis and DecompositionDocument14 pagesRozovskii Et Al. (2003) - Fundamentals of Methanol Synthesis and DecompositionbltzkrigPas encore d'évaluation

- Techno Economic Evaluation of Bio Hydrogen ProductionDocument157 pagesTechno Economic Evaluation of Bio Hydrogen ProductionacikkalpgermanPas encore d'évaluation

- Final ReportDocument29 pagesFinal ReportpratikPas encore d'évaluation

- Growth of Escherichia Coli in A 5 Litre Batch Fermentation VesselDocument15 pagesGrowth of Escherichia Coli in A 5 Litre Batch Fermentation VesselAs'ad Mughal100% (2)

- Butene-1: Trans-2-Butene, Isobutylene, and ButadieneDocument1 pageButene-1: Trans-2-Butene, Isobutylene, and ButadieneYESIKBMARTIN100% (1)

- Use of DME & DEE As FuelDocument24 pagesUse of DME & DEE As FuelHarshit DhawanPas encore d'évaluation

- Chemical Looping Syngas Production by Partial Oxidation of Mixed Iron Oxides and Methane Thermodynamic Evaluation and Process SimulationDocument29 pagesChemical Looping Syngas Production by Partial Oxidation of Mixed Iron Oxides and Methane Thermodynamic Evaluation and Process SimulationAlejandro López OrtizPas encore d'évaluation

- Introduction to Phosphazene ChemistryDocument15 pagesIntroduction to Phosphazene ChemistryEthan Poll100% (1)

- Chapter V Regional Market Analysis PDFDocument222 pagesChapter V Regional Market Analysis PDFester dPas encore d'évaluation

- TK01 - Report - FinalDocument264 pagesTK01 - Report - FinalHafiz HakimPas encore d'évaluation

- Methanol SdsDocument9 pagesMethanol SdsLeslieBigbearPas encore d'évaluation

- Production of Methanol from Synthesis GasDocument1 pageProduction of Methanol from Synthesis GasAdibHelmiPas encore d'évaluation

- FYP ProposalDocument11 pagesFYP ProposalArslan SamPas encore d'évaluation

- Methanol Reactor ModelDocument11 pagesMethanol Reactor ModeljoePas encore d'évaluation

- 64788Document35 pages64788ghatak2100% (1)

- Fuel DME Plant in East AsiaDocument10 pagesFuel DME Plant in East AsiaHim KungPas encore d'évaluation

- Nhóm (Đ.Anh+ Hiếu + Ý) Syngas to MethanolDocument40 pagesNhóm (Đ.Anh+ Hiếu + Ý) Syngas to MethanolStrong NguyenPas encore d'évaluation

- University of Lagos: Process Description For The Production of Mtbe A Presentation by Group 10 ConsistingDocument7 pagesUniversity of Lagos: Process Description For The Production of Mtbe A Presentation by Group 10 ConsistingJide Williams100% (1)

- Formic Acid TechnologyDocument3 pagesFormic Acid Technologyatharnadim_osPas encore d'évaluation

- Methanol SynthesisDocument6 pagesMethanol SynthesisGaurav BurdePas encore d'évaluation

- Methyl Tertiary Butyl Ether (MTBE) Full ReportDocument369 pagesMethyl Tertiary Butyl Ether (MTBE) Full Reportnasnazir100% (1)

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsD'EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsPas encore d'évaluation

- Heat of Solution and Heat Transfer Efficiency Lab ManualDocument13 pagesHeat of Solution and Heat Transfer Efficiency Lab ManualSylvia SimonPas encore d'évaluation

- APA Referencing 2006Document11 pagesAPA Referencing 2006hjarotesis100% (3)

- 44-74482BRO WorldLeaderAAICPMSICPMSDocument16 pages44-74482BRO WorldLeaderAAICPMSICPMSOshin ParranganPas encore d'évaluation

- Enviromental Quiz FactsDocument8 pagesEnviromental Quiz FactsSylvia SimonPas encore d'évaluation

- HYDRAULICSDocument5 pagesHYDRAULICSMaureenPas encore d'évaluation

- Chapter 3 and Chapter 4Document77 pagesChapter 3 and Chapter 4Amey gaikwadPas encore d'évaluation

- CFX Multi Phase 12.0 WS02 Non Drag ForcesDocument14 pagesCFX Multi Phase 12.0 WS02 Non Drag ForcesMaher ShehabPas encore d'évaluation

- HART EDD Library Encoded File Distribution DDList19 - 2Document53 pagesHART EDD Library Encoded File Distribution DDList19 - 2A N ArunkumarPas encore d'évaluation

- GA75VSD+ - GA75 Atlas CopoDocument22 pagesGA75VSD+ - GA75 Atlas CopoNyoman SuryasaPas encore d'évaluation

- Che CalDocument1 pageChe CalJulius CagampangPas encore d'évaluation

- 07-EC-II-Nafees P - KhanDocument52 pages07-EC-II-Nafees P - KhanAnanthPas encore d'évaluation

- Roots PD General CatalogDocument20 pagesRoots PD General CatalogRoss ClardyPas encore d'évaluation

- Layers of The AtmosphereDocument19 pagesLayers of The AtmosphereRalph Andrew AgustinPas encore d'évaluation

- 18ME54 Turbo Machines Module 02 Question No 3a & 3bDocument14 pages18ME54 Turbo Machines Module 02 Question No 3a & 3bThanmay JSPas encore d'évaluation

- Part I Refrigeration Chapter 1Document43 pagesPart I Refrigeration Chapter 1eskewt0% (1)

- P133 Pressure Regulator Specifications and ApplicationsDocument12 pagesP133 Pressure Regulator Specifications and ApplicationsNag RajPas encore d'évaluation

- 7 Osborne Reynold'S Demonstration: Mapúa UniversityDocument11 pages7 Osborne Reynold'S Demonstration: Mapúa UniversityJemuel FloresPas encore d'évaluation

- Hierarchy of O2 Delivery SystemsDocument1 pageHierarchy of O2 Delivery SystemsRevPas encore d'évaluation

- Amanah Nur Permata: ObjectiveDocument1 pageAmanah Nur Permata: ObjectiveNandia NandaPas encore d'évaluation

- CátalogoDocument132 pagesCátalogoyeseniaPas encore d'évaluation

- GA 808 Sr. No.: APR 865094 SN Drawing Ref. Part No. Description QntyDocument7 pagesGA 808 Sr. No.: APR 865094 SN Drawing Ref. Part No. Description QntyraizoPas encore d'évaluation

- 189 010 - en 15.710057 V3.0Document12 pages189 010 - en 15.710057 V3.0balzac191Pas encore d'évaluation

- Pitot TubeDocument30 pagesPitot Tubepushpzala86Pas encore d'évaluation

- VITOGAS 100-F Low Temperature Gas Fired Boiler DatasheetDocument12 pagesVITOGAS 100-F Low Temperature Gas Fired Boiler DatasheetCorina RosuPas encore d'évaluation

- AA210A Course Introduction 2017 2018 BJ CantwellDocument8 pagesAA210A Course Introduction 2017 2018 BJ CantwellAbhishek KulkarniPas encore d'évaluation