Académique Documents

Professionnel Documents

Culture Documents

Soil Compaction 1

Transféré par

Francisco TavarezCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Soil Compaction 1

Transféré par

Francisco TavarezDroits d'auteur :

Formats disponibles

CHAPTER

Construction Planning, Equipment,

and Methods

Sixth Edition

GEOTECHNICAL MATERIALS,

COMPACTION, AND STABILIZATION

A. J. Clark School of Engineering Department of Civil and Environmental Engineering

4c

By

Dr. Ibrahim Assakkaf

ENCE 420 Construction Equipment and Methods

Spring 2003

Department of Civil and Environmental Engineering

University of Maryland, College Park

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 146

COMPACTION CONTROL

ENCE 420 Assakkaf

The specifications for a project

may require a contractor to

compact the soil to to a 100%

relative density, based on

standard Proctor test or a

laboratory test at some other

energy level.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION CONTROL

Slide No. 147

ENCE 420 Assakkaf

If the maximum laboratory

density of the soil is

determined to be 120 lb per cu

ft, the contractor must compact

the soil to a density of 120 lb

per cu ft.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION CONTROL

Slide No. 148

ENCE 420 Assakkaf

Field verification tests of

achieved compaction can be

conducted by any of several

accepted methods:

1) Sandcone

2) Balloon

3) Nuclear

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION CONTROL

Slide No. 149

ENCE 420 Assakkaf

The first two methods are

destructive tests. They involve

9excavating a hole in the compacted

fill and weighing the excavated

material.

9determining the water content of the

excavated material.

9measuring the volume of the resulting

hole.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION CONTROL

Slide No. 150

ENCE 420 Assakkaf

Disadvantages of using

sandcone and balloon methods:

1) time-consuming to conduct

sufficient tests for statistical

analysis.

2) problems with oversized

particles.

3) the determination of water

content takes time

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

NUCLEAR COMPACTION

TEST

Slide No. 151

ENCE 420 Assakkaf

Nuclear methods are used

extensively to determine the water

content and density of soils.

The instrument required for this test

can be easily transported to the fill,

placed at the desired test location,

and within a few minutes the results

can be read directly from the digital

display.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

NUCLEAR COMPACTION

TEST

Slide No. 152

ENCE 420 Assakkaf

Advantages of the nuclear

method when compared with

other methods include the

following:

1) Decreases the time required for a

test from as much as a day to a few

minutes, thereby eliminating

potentially excessive construction

delays.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

NUCLEAR COMPACTION

TEST

Slide No. 153

ENCE 420 Assakkaf

2) It is nondestructive in that it does

not require the removal of soil

samples from the site of the tests.

3) Provides a means of performing

density tests on soils containing

large-sized aggregates and on

frozen materials.

4) Reduces or eliminates the effect of

the personal element, and possible

errors. Erratic results can be easily

and quickly rechecked.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

NUCLEAR COMPACTION

TEST

Slide No. 154

ENCE 420 Assakkaf

Disadvantages of the nuclear

method when compared with

other methods include the

following:

1) Nuclear test instruments, it not

used properly, present a potential

source of radiation that can be

harmful to humans

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

NUCLEAR COMPACTION

TEST

Slide No. 155

ENCE 420 Assakkaf

2) These instruments usually

require a skilful operator who

exercise care to ensure that no

harm can result from the use of

the instruments.

3) In the U.S., a license is required

to possess, own, or use nucleartype instruments

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

GEOGAUGE

Slide No. 156

ENCE 420 Assakkaf

A Geogauge device is a

nondestructive devise that does not

require the removal of soil samples

from the site of the tests.

This device is very new to the field.

The Minnesota Department of

transportation tested the first

prototype models in 1994.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

GEOGAUGE

Slide No. 157

ENCE 420 Assakkaf

Production models are currently

available and each year more

agencies are conducting

independent field evaluation.

This portable device can provide a

simple, rapid, and precise means of

directly measuring lift stiffness and

soil modulus.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

LABORATORY VERSUS

FIELD

Slide No. 158

ENCE 420 Assakkaf

Maximum dry density is only

a maximum for a specific

compaction effort (input

energy level) and the method

by which that effort is

applied.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

LABORATORY VERSUS

FIELD

Slide No. 159

ENCE 420 Assakkaf

If more energy is applied in the

field, a density greater than 100%

of the laboratory value can be

achieved.

Dissimilar materials have individual

curves and maximum values for the

same input energy as shown in the

following figure (Figure 7)

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

LABORATORY VERSUS

FIELD

Slide No. 160

ENCE 420 Assakkaf

Figure 7

Comparison Curves for Eight

Soils Compacted according to

AASHTO T99

(Highway Research Board)

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

SOIL PROCESSING

Slide No. 161

ENCE 420 Assakkaf

The optimum water content ()

9Fine-grained soils from 12 to 25%

9Well-graded granular from 7 to 12%

9Normal Practice to work at 2% of

optimum or 95% of maximum dry unit

weight.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION

SPECIFICATIONS

Slide No. 162

ENCE 420 Assakkaf

Typically

specifications

give an

acceptable range

of water content,

OMC 2% for

example.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION

SPECIFICATIONS

The specification

also sets a

minimum

density, 95% of

max. dry density

for a specific

test.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

SOIL PROCESSING

Slide No. 163

ENCE 420 Assakkaf

123.5

Slide No. 164

ENCE 420 Assakkaf

Adding Water to Soil

9Water must be added prior to

compaction if the water content

() is below the optimum

moisture range.

9Water can be added to soil at the

borrow pit or in-place (at the

construction site).

10

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

ADDING WATER TO SOIL

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

ADDING WATER TO SOIL

Slide No. 165

ENCE 420 Assakkaf

Slide No. 166

ENCE 420 Assakkaf

11

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

SOIL PROCESSING

Slide No. 167

ENCE 420 Assakkaf

When it necessary to add water,

the following items are to be

considered:

9Amount of water required.

9Rate of water application.

9Method of application.

9Effects of the climate and weather.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

SOIL PROCESSING

Slide No. 168

ENCE 420 Assakkaf

Amount of Water Required

9It is important to determine the

amount of water required to achieve a

soil water content () within the

acceptable range for compaction.

9The amount of water that must added

or removed is normally computed in

gallons per station (100 ft length).

12

Slide No. 169

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

Earthwork

The horizontal

dimensions of

a project are

in stations.

One station

equals 100 ft.

0+00

00

ft

1+00

Slide No. 170

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

SOIL PROCESSING

Amount of Water Required

9The following formula can used to

compute the amount of water

added or removed from soil:

Gallons = desired dry density (pcf)

(desired water content % ) (water content borrow % )

100

compacted volume of soil (cf)

8.34 lb per gallon

(37a)

13

Slide No. 171

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

WATER REQUIREMENT

Gallons, water requirements =

d emb (pcf)

emb(%) cut(%)

100

Vol. emb(cf)

8.33

(37b)

Slide No. 172

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

SOIL PROCESSING

Water Application Rate

9Once the total amount of water has

been calculated, the application rate

can be calculated. The following

formula can be used:

Gallons per square yard =

d emb (pcf)

emb (% ) cut (%)

(38)

100

lift thickness (ft) (compacted)

9 sf / sy

8.34 lb /gal

14

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Example 6

Slide No. 173

ENCE 420 Assakkaf

Job specifications require placement of

the embankment fill soil in 6-in.

(compacted) fills. The desired dry unit

weight of the embankment is 120 pcf.

The laboratory compaction curve

indicates that the optimum water

content (OMC) of the soil is 12%. Soil

tests indicated that the moisture content

of the borrow material is 5%. The

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Example 6 (contd)

Slide No. 174

ENCE 420 Assakkaf

roadway lift to be placed is 40 ft wide.

Compute the amount of water in gallons

to add on a per station basis for each lift

material.

12 5 (40 ft 100 ft 0.5 ft )

Gallons = 120 pcf

8.34 lb/gal

100

= 2,015 gallons per station

15

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 175

ENCE 420 Assakkaf

Example 7

Using the data from Example 6,

determine the required application

rate in gallons per square yard.

Using Eq. 38, we have

9 sf / sy

12 5

Gallons per square yard = 120 pcf

(0.5 ft )

8.34 lb /gal

100

= 4.5 gallons per sy

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 176

ENCE 420 Assakkaf

COMPACTION OF

GEOTECHNICAL MATERIALS

Engineering properties of soils can

be improved by compaction.

Compaction can:

9Reduce or prevent settlements.

9Increase strength.

9Improve bearing capacity.

9Control volume changes.

9Lower permeability.

16

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 177

ENCE 420 Assakkaf

COMPACTION OF

GEOTECHNICAL MATERIALS

Because there is a correlation

between compaction properties and

dry density, construction

documents usually call for

achieving a specified density.

There may be other methods

whereby the desired compaction

properties can be attained.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 178

ENCE 420 Assakkaf

COMPACTION OF

GEOTECHNICAL MATERIALS

By far the most widely used method

of soil strengthening for use as a

subgrade under a pavement

structure or other foundation is

compaction of the soil at optimum

moisture.

17

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 179

ENCE 420 Assakkaf

COMPACTION OF

GEOTECHNICAL MATERIALS

Typically, a uniform layer, or lift, of

soil from 4 to 12 in thickness is

compacted by means of several

passes of heavy mechanized

compaction equipment.

It should be noted that good

compaction can cost more money.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION

SPECIFICATIONS

Slide No. 180

ENCE 420 Assakkaf

Specifications governing compaction

may be one of the following types:

a) Method only (often termed

"recipe").

b) End result only (often termed

"performance").

c) Method and end result.

18

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

FIELD COMPACTION

Slide No. 181

ENCE 420 Assakkaf

Densification is accomplished

by:

9Static weight (pressure)

9Kneading (manipulation)

9Impact (sharp blow)

9Vibration (shaking)

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

FIELD COMPACTION

Slide No. 182

ENCE 420 Assakkaf

Ordinary compaction in the field is

accomplished by means of rollers

Several types of rollers are used:

9Smooth wheel rollers (drum rollers).

9 Pneumatic rubber-tired rollers.

9 Sheepsfoot rollers (Tamping rollers).

9 Vibratory rollers.

19

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

SMOOTH-WHEEL

ROLLERS

Slide No. 183

ENCE 420 Assakkaf

9Smooth-wheel rollers are suitable for

proof-rolling subgrades and for

finishing operation of fills with sandy

and clayey soils.

9They provide 100% coverage under

the wheels with ground contact

pressures as high as 45 to 55 lb/in2.

9They are not suitable for producing

high unit weights of compaction

when used on relatively thick layers.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

SMOOTH-WHEEL

ROLLERS

Slide No. 184

ENCE 420 Assakkaf

20

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

COMPACTION

Slide No. 185

ENCE 420 Assakkaf

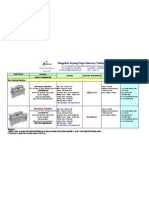

Roller Capabilities

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

PNEUMATIC RUBBERTIRED ROLLERS

Slide No. 186

ENCE 420 Assakkaf

9Pneumatic rubber-tired rollers are better

in many than smooth-wheel rollers.

9They are heavily-loaded wagons with

several rows rows of tires.

9The tires are closely spaced, four to six

in a row.

9They provide 70% to 85% coverage

under the wheels with ground contact

pressures as high as 85 to 100 lb/in2.

21

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

PNEUMATIC RUBBERTIRED ROLLERS

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 187

ENCE 420 Assakkaf

Slide No. 188

ENCE 420 Assakkaf

PNEUMATIC

22

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

PNEUMATIC

Slide No. 189

ENCE 420 Assakkaf

Front and rear

tire paths overlap.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

PNEUMATIC

Slide No. 190

ENCE 420 Assakkaf

All-wheel oscillation.

23

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 191

ENCE 420 Assakkaf

PNEUMATIC COMPACTOR

Pneumatic-tired (rubber-tired)

rollers are suitable for

compacting most granular soils.

They are not effective in

compacting fine-grained clays.

They compact by static-load and

kneading action.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

SHEEPSFOOT ROLLERS

Slide No. 192

ENCE 420 Assakkaf

9Sheepsfoot rollers are drums with a

large number of projections.

9The area of each of these projections

may range from 4 to 13 in2.

9These rollers are most effective in

compacting clayey soils.

9The contact pressure under the

projections can range from 200 to

1000 lb/in2.

24

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

SHEEPSFOOT ROLLERS

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

SHEEPS FOOT

ROLLER

Slide No. 193

ENCE 420 Assakkaf

Slide No. 194

ENCE 420 Assakkaf

25

Slide No. 195

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

ENCE 420 Assakkaf

TAMPING FOOT COMPACTOR

Leveling blade

Slide No. 196

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

PAD CONFIGURATION

Tamping foot

ENCE 420 Assakkaf

Pad foot

26

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 197

ENCE 420 Assakkaf

TAMPING FOOT COMPACTOR

It is suitable for compacting

all fined-grained soils, but is

generally not suitable for

use on cohesionless granular

soils.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 198

ENCE 420 Assakkaf

TAMPING FOOT COMPACTOR

This roller compacts the soil

from the bottom of the lift

to the top.

Lift thickness is generally

limited to 8 inches

compacted depth.

27

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 199

ENCE 420 Assakkaf

TAMPING FOOT COMPACTOR

This type roller does not

adequately compact the upper

2 or 3 inches of a lift.

Therefore, for the last lift it

should be followed with a

pneumatic or smooth-drum

roller.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 200

ENCE 420 Assakkaf

TAMPING FOOT COMPACTOR

Working in tandem

28

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

VIBRATORY ROLLERS

Slide No. 201

ENCE 420 Assakkaf

Vibratory rollers are very efficient in

compacting granular soils.

Vibrators can be attached to the

following rollers:

9smooth-wheel rollers.

9 pneumatic rubber-tired rollers.

9 sheepsfoot rollers.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

VIBRATORY ROLLERS

Slide No. 202

ENCE 420 Assakkaf

Principles of Vibratory Rollers

The vibration is

Produced by

rotating

off-center weights

29

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

VIBRATORY SOIL

COMPACTOR

Slide No. 203

ENCE 420 Assakkaf

Smooth-drum

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 204

ENCE 420 Assakkaf

SMOOTH DRUM VIBRATORY

SOIL COMPACTOR

This roller uses vibratory

action in conjunction with

ballast weight of the drum

to compact.

30

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 205

ENCE 420 Assakkaf

SMOOTH DRUM VIBRATORY

SOIL COMPACTOR

One of the most effective means

of attaining density for

cohesionless materials.

It is a relatively light roller,

therefore maximum loose-lift

depth is 9 inches.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 206

ENCE 420 Assakkaf

VIBRATORY SOIL COMPACTOR

Padded drum

31

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 207

ENCE 420 Assakkaf

DUAL-DRUM VIBRATORY

COMPACTOR

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

DUAL-DRUM VIBRATORY

COMPACTOR

Slide No. 208

ENCE 420 Assakkaf

Use this roller to compact

cohesionless subgrade,

base courses, wearing

surfaces, and asphalt.

32

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

DUAL-DRUM VIBRATORY

COMPACTOR

Slide No. 209

ENCE 420 Assakkaf

Because it compacts from

the top down, only

relatively shallow lifts (less

than 4 inches) can be

worked.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

ROLLERS PRODUCTION

ESTIMATING

Slide No. 210

ENCE 420 Assakkaf

The production formula for a

compactor is given as

Compacted Volume (cu yd) per hour =

where

W S L 16.3

P

(39)

W = compacted width per roller pass, ft

S = average roller speed, mph

L = compacted lift (layer) thickness, in

P = number of passes required to achieve the

required density

Note:The computed production in above equation is in cubic yards. It is

necessary to apply shrinkage factor to convert it to bank cubic yard

33

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 211

ENCE 420 Assakkaf

Example 8

A self-propelled tamping foot compactor

will be used to compact a fill being

constructed of clay material. Field tests

have shown that the required density

can be achieved with four passes of the

roller operating at an average speed of

1.5 mph. The compacted lift will have a

thickness of 5 in. The compacting width

of this machine is 7 ft. One bcy equals

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Example 8 (contd)

Slide No. 212

ENCE 420 Assakkaf

0.83 compacted cubic yards. The

scraper production estimated for the

project is 510 bcy per hour. How many

rollers will be required to maintain this

production?

Compacted Volume (cu yd) per hour =

W S L 16.3 7(1.5)(5)16.3)

=

= 214 cy yd /hr

P

4

214

= 258 bcy/hr

0.83

510

Number of rollers needed =

= 1.98 2 rollers

258

Volume in bcy =

34

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

DYNAMIC COMPACTION

Slide No. 213

ENCE 420 Assakkaf

Dynamic compaction is a

technique that has gained

popularity in the U.S. for the

densification of granular soil

deposits.

The method can produce

densification to depth greater

than 35 ft

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

DYNAMIC COMPACTION

Slide No. 214

ENCE 420 Assakkaf

This process primarily consists of

dropping a heavy weight repeatedly

on the ground at regular intervals.

The weight of the hammer varies

over a range of 18 to 80 kips.

The height of the hammer drop

varies between 25 to 100 ft.

Conventional cranes are used to

drop the weights.

35

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 215

ENCE 420 Assakkaf

DYNAMIC

COMPACTION

This is a

20 ton weight

from 42 feet

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 216

ENCE 420 Assakkaf

DYNAMIC

COMPACTION

Usually only make

contact with about

50% of the actual

ground surface

being compacted.

36

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

DYNAMIC COMPACTION

Slide No. 217

ENCE 420 Assakkaf

Can achieve densification

to a depths of about 30 ft

using 30 ton weights and

100 ft drop heights.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

DYNAMIC COMPACTION

Slide No. 218

ENCE 420 Assakkaf

The degree of compaction

achieved at a given site depends

on the following factors:

9Weight of the hammer.

9Height of the hammer drop.

9Spacing of the locations at which the

hammer is dropped.

37

Slide No. 219

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

DYNAMIC COMPACTION

ENCE 420 Assakkaf

The significance depth of influence for

compaction can be given approximately

by the following expression:

D = n WH

(40a)

where

D = depth of improvement or significant depth (m)

n = an empirical coefficient (0.5)

W = dropping weight (metric ton)

H = height of drop (m)

Slide No. 220

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

DYNAMIC COMPACTION

ENCE 420 Assakkaf

The significance depth of influence for

compaction can also be given in English

units as

D = 0.61 WH

(40b)

where

D = depth of improvement or significant depth (ft)

W = dropping weight (kip)

H = height of drop (ft)

38

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Example 9

Slide No. 221

ENCE 420 Assakkaf

For a dynamic compaction test we are

given: weight of hammer = 33,070 lb,

and the height of drop = 40 ft.

Determine the significant depth of

influence for compaction in feet?

33,070 lb = 33.07 kip

D = 0.61 WH = 0.61 33.07(40) = 22.2 ft

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 222

ENCE 420 Assakkaf

VIBRATORY PLATE

COMPACTOR

For

granular

soils and

asphalt.

39

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 223

ENCE 420 Assakkaf

RAMMER

Also known as

a backfill

tamper. Selfcontained hand

operated for

use in confined

spaces.

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 224

ENCE 420 Assakkaf

TRENCH ROLLER

40

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

Slide No. 225

ENCE 420 Assakkaf

WHEEL

ATTACHMENT

COMPACTORS

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

SOIL STABILIZATION

Slide No. 226

ENCE 420 Assakkaf

Admixtures are used to stabilize

soils in the field.

Most common of these admixtures

are:

9lime

9Lime-fly ash

9cement

41

CHAPTER 4c. GEOTECHNICAL MATERIALS & COMPACTION

SOIL STABILIZATION

Slide No. 227

ENCE 420 Assakkaf

The main purpose of soil

stabilization are to:

9modify the soil.

9expedite construction.

9improve the strength and

durability of the soil.

42

Vous aimerez peut-être aussi

- The Asphalt Compaction Technology Guide: Best Practices For Using Technology To Increase Pavement Durability & SmoothnessDocument17 pagesThe Asphalt Compaction Technology Guide: Best Practices For Using Technology To Increase Pavement Durability & Smoothnessjude tally100% (1)

- Study of Strength Properties of Polyester Fibre Reinforced ConcreteDocument5 pagesStudy of Strength Properties of Polyester Fibre Reinforced ConcreteJournal 4 ResearchPas encore d'évaluation

- Road ConstructionDocument5 pagesRoad ConstructionmetincetinPas encore d'évaluation

- BS ConsolidationDocument25 pagesBS ConsolidationKamukwema johnPas encore d'évaluation

- Ground InvestigationDocument128 pagesGround Investigationthuy giangPas encore d'évaluation

- Em - 1110 2 1911Document101 pagesEm - 1110 2 1911ujosec6138Pas encore d'évaluation

- Brooklyn Bridge Park Preventative Maintenance Plan ReportDocument77 pagesBrooklyn Bridge Park Preventative Maintenance Plan ReportcrainsnewyorkPas encore d'évaluation

- Materials TestingDocument391 pagesMaterials TestingChristopher Gibbs50% (2)

- Tank TacticsDocument241 pagesTank TacticsSlobodan Petrovic100% (1)

- 600 Series Highways Vol 2Document28 pages600 Series Highways Vol 2Temur LomidzePas encore d'évaluation

- High Performance Repairing of Reinforced Concrete StructuresDocument7 pagesHigh Performance Repairing of Reinforced Concrete StructuresCarlos CallePas encore d'évaluation

- Design of Piles Under Cyclic Loading: SOLCYP RecommendationsD'EverandDesign of Piles Under Cyclic Loading: SOLCYP RecommendationsAlain PuechPas encore d'évaluation

- DCP Manual K100 Models OCT2007Document36 pagesDCP Manual K100 Models OCT2007arypauloPas encore d'évaluation

- Minimizing Sand Content in ConcreteDocument2 pagesMinimizing Sand Content in ConcreteInternational Journal of Research in Engineering and TechnologyPas encore d'évaluation

- UnderpinningDocument6 pagesUnderpinningPraveenkumar ShanmugamPas encore d'évaluation

- MASONARYDocument117 pagesMASONARYAhamed A L TPas encore d'évaluation

- Rehabilitation of Shear-Damaged Reinforced Concret PDFDocument14 pagesRehabilitation of Shear-Damaged Reinforced Concret PDFAbdulkhaliq AbdulyimahPas encore d'évaluation

- Return Material Authorization: 1/2 RMA Number Customer No. Purchase Order No. Sales Order DateDocument2 pagesReturn Material Authorization: 1/2 RMA Number Customer No. Purchase Order No. Sales Order DateMichelle PadillaPas encore d'évaluation

- Construction Techniques For Bored Piling in Sand Using Polymer FluidsDocument10 pagesConstruction Techniques For Bored Piling in Sand Using Polymer FluidsjohnPas encore d'évaluation

- Mix DesignDocument52 pagesMix DesignsorowarePas encore d'évaluation

- MebraDrain GeosyntheticDocument5 pagesMebraDrain GeosyntheticAndika Satria AgusPas encore d'évaluation

- Earthwork DesignDocument33 pagesEarthwork DesignMangiPas encore d'évaluation

- Human Resources Assistant Resume, HR, Example, Sample, Employment, Work Duties, Cover LetterDocument3 pagesHuman Resources Assistant Resume, HR, Example, Sample, Employment, Work Duties, Cover LetterDavid SabaflyPas encore d'évaluation

- TRH13Document84 pagesTRH13ahgreyling01Pas encore d'évaluation

- CIV 4100 Assignment No3Document13 pagesCIV 4100 Assignment No3tamoosePas encore d'évaluation

- Behavior of Unsaturated Soils For Road Pavement Structure Under Cyclic LoadingDocument272 pagesBehavior of Unsaturated Soils For Road Pavement Structure Under Cyclic LoadingDiana CapisondaPas encore d'évaluation

- Compaction TestDocument9 pagesCompaction TestFernando PascualPas encore d'évaluation

- New Trends in Concrete TechnologyDocument17 pagesNew Trends in Concrete TechnologyAmar Khandve67% (3)

- City University Department of Civil Engineering TDocument4 pagesCity University Department of Civil Engineering TanarPas encore d'évaluation

- CompactionDocument118 pagesCompactionSaleh HassanPas encore d'évaluation

- Sustainability in Geotechnical Engineering, 2015 PDFDocument9 pagesSustainability in Geotechnical Engineering, 2015 PDFSergio Andres Martinez CamachoPas encore d'évaluation

- Chapter 1 : Limit State Design of Reinforced Concrete StructuresDocument39 pagesChapter 1 : Limit State Design of Reinforced Concrete Structurespeter wongPas encore d'évaluation

- Comparison of Maximum Dry Density, Optimum Moisture Content and Strength of Granular Soils Using Different Methods of CompactionDocument5 pagesComparison of Maximum Dry Density, Optimum Moisture Content and Strength of Granular Soils Using Different Methods of CompactionIAEME PublicationPas encore d'évaluation

- Liquid Limit TestDocument44 pagesLiquid Limit Testtmt_salesPas encore d'évaluation

- Remedial Measures To A Building Settlement ProblemDocument5 pagesRemedial Measures To A Building Settlement ProblemEswara PrasadPas encore d'évaluation

- Sand Replacement by Glass PowderDocument41 pagesSand Replacement by Glass Powderwaquar khan100% (2)

- Concrete Block Paving - Cost Comparison Between Concrete Block Paving and Premix AsphaltDocument6 pagesConcrete Block Paving - Cost Comparison Between Concrete Block Paving and Premix AsphaltTrương KhảiPas encore d'évaluation

- Nondestructive Testing of Concrete Leg FoundationsDocument5 pagesNondestructive Testing of Concrete Leg Foundationsأحمد دعبسPas encore d'évaluation

- Concrete Mix Design ProcedureDocument9 pagesConcrete Mix Design ProcedureSaroj BhattaraiPas encore d'évaluation

- Geotechnical LabDocument76 pagesGeotechnical LabJAZIRA BINTI JEFFRY -Pas encore d'évaluation

- Remedial Measures To A Building Settlement Problem PDFDocument4 pagesRemedial Measures To A Building Settlement Problem PDFAntony Prasanth M APas encore d'évaluation

- The Use of Basalt Aggregates in Concrete Mixes in Jordan PDFDocument8 pagesThe Use of Basalt Aggregates in Concrete Mixes in Jordan PDFPamela Victoria GalangPas encore d'évaluation

- Numerical List SABSDocument1 143 pagesNumerical List SABSJason GlassPas encore d'évaluation

- Concrete Tests PDFDocument2 pagesConcrete Tests PDFDeRudyPas encore d'évaluation

- Road MaterialDocument7 pagesRoad MaterialShe LiedPas encore d'évaluation

- Tests On Aggregate: 1.crushing TestDocument10 pagesTests On Aggregate: 1.crushing TestzeeshanPas encore d'évaluation

- Stablisation of SoilDocument105 pagesStablisation of Soilmeena100% (1)

- Improvement of Soft Clay With Cement and Bagasse Ash WasteDocument11 pagesImprovement of Soft Clay With Cement and Bagasse Ash WasteAnonymous NxpnI6jC100% (1)

- Department of Civil Engineering Sydney NSW 2006 Australia: Centre For Geotechnical Research Research Report No R814Document68 pagesDepartment of Civil Engineering Sydney NSW 2006 Australia: Centre For Geotechnical Research Research Report No R814Probal SomPas encore d'évaluation

- TRH 21Document49 pagesTRH 21AnantPas encore d'évaluation

- 1 IntroductionDocument4 pages1 Introductionmgi100% (1)

- Tech Note 74 Gabion Aggregates LRDocument6 pagesTech Note 74 Gabion Aggregates LRpetruciosobralPas encore d'évaluation

- Enhancement of Soil Index Properties by Adding Stone Dust MixDocument7 pagesEnhancement of Soil Index Properties by Adding Stone Dust MixInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Skid ResistanceDocument7 pagesSkid Resistanceebinsams007Pas encore d'évaluation

- Retaining Walls 0113Document16 pagesRetaining Walls 0113sossaifjmPas encore d'évaluation

- 5.section-Xi Interim Report On Geotechnical InvestigationDocument27 pages5.section-Xi Interim Report On Geotechnical InvestigationRaghavPas encore d'évaluation

- Slip Resistance Test MethodsDocument4 pagesSlip Resistance Test MethodsparagbholePas encore d'évaluation

- Tropical SoilsDocument88 pagesTropical SoilsBernard Kipng'eno100% (1)

- Recommendations For SC PDFDocument15 pagesRecommendations For SC PDFPau VallsPas encore d'évaluation

- D 6758 - 02 - Rdy3ntgDocument5 pagesD 6758 - 02 - Rdy3ntgAntonio Harry PoncePas encore d'évaluation

- Supervising Highway Engineer: Passbooks Study GuideD'EverandSupervising Highway Engineer: Passbooks Study GuidePas encore d'évaluation

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionD'Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotPas encore d'évaluation

- Track 3 Tuesday MobilarisDocument15 pagesTrack 3 Tuesday Mobilarissaleema2010Pas encore d'évaluation

- ECSS E ST 50 03C (31july2008)Document43 pagesECSS E ST 50 03C (31july2008)jsadachiPas encore d'évaluation

- Capitulo 9 - Flujo de DatosDocument24 pagesCapitulo 9 - Flujo de DatosOrlando Espinoza ZevallosPas encore d'évaluation

- 2501 Solid Drawn Copper Tubes For General Engineering PurposesDocument8 pages2501 Solid Drawn Copper Tubes For General Engineering PurposesKaushik SenguptaPas encore d'évaluation

- Long+term+storage+procedure 1151enDocument2 pagesLong+term+storage+procedure 1151enmohamadhakim.19789100% (1)

- Engg Prospect1usDocument20 pagesEngg Prospect1usArun KumarPas encore d'évaluation

- Assign#1Document2 pagesAssign#1Edrielle ValdezPas encore d'évaluation

- RFQ - Tank DemuckingDocument12 pagesRFQ - Tank Demuckingmuhamadrafie1975100% (1)

- JeeleDocument9 pagesJeeleAnonymous SZDGk7SvGPas encore d'évaluation

- Profile of The Aerospace Industry in Greater MontrealDocument48 pagesProfile of The Aerospace Industry in Greater Montrealvigneshkumar rajanPas encore d'évaluation

- Broaching PrsDocument41 pagesBroaching PrsParag PatelPas encore d'évaluation

- Infineon IKFW50N65DH5Document15 pagesInfineon IKFW50N65DH5nithinmundackal3623Pas encore d'évaluation

- Topic 5 FB Stability PDFDocument26 pagesTopic 5 FB Stability PDFAbdulrahman NasserPas encore d'évaluation

- Toshiba NB520 Compal LA-6859PDocument38 pagesToshiba NB520 Compal LA-6859Pash thonPas encore d'évaluation

- Ne40 Ne80 PDFDocument192 pagesNe40 Ne80 PDFณัชชา ธนปัญจาภรณ์Pas encore d'évaluation

- Electricalprep Com Transformers More 5Document16 pagesElectricalprep Com Transformers More 5gokulchandruPas encore d'évaluation

- HTK Fortune Delivery NoteDocument3 pagesHTK Fortune Delivery NoteVu Duc QuangPas encore d'évaluation

- S9300&S9300E V200R001C00 Hardware Description 05 PDFDocument282 pagesS9300&S9300E V200R001C00 Hardware Description 05 PDFmike_mnleePas encore d'évaluation

- Quotation For Blue Star Printek From Boway2010 (1) .09.04Document1 pageQuotation For Blue Star Printek From Boway2010 (1) .09.04Arvin Kumar GargPas encore d'évaluation

- K60-HSS Install GuideDocument2 pagesK60-HSS Install GuidedakidofdaboomPas encore d'évaluation

- ASSA ABLOY - Digital Cam LocksDocument12 pagesASSA ABLOY - Digital Cam LocksSales Project 2 VCPPas encore d'évaluation

- Dacell Dn-10w, Dn-15w, Dn-20w SpecDocument1 pageDacell Dn-10w, Dn-15w, Dn-20w SpecmegacobPas encore d'évaluation

- Summary of Change ASME 2021Document8 pagesSummary of Change ASME 2021Asep DarojatPas encore d'évaluation

- Analyzing and Securing Social Media: Cloud-Based Assured Information SharingDocument36 pagesAnalyzing and Securing Social Media: Cloud-Based Assured Information SharingakrmbaPas encore d'évaluation

- Service Pack 2Document149 pagesService Pack 2billwong169Pas encore d'évaluation

- Bombillas LedDocument1 pageBombillas LedElviore PeruPas encore d'évaluation

- Alimentacion Baterias TiposDocument11 pagesAlimentacion Baterias TiposjulioclavijoPas encore d'évaluation