Académique Documents

Professionnel Documents

Culture Documents

Balcan Junior Exercises A Version 1

Transféré par

Goran MićovićDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Balcan Junior Exercises A Version 1

Transféré par

Goran MićovićDroits d'auteur :

Formats disponibles

Exercise 1a: Transfer station

Workpieces are inserted into the gravity feed magazine by hand. Using a transfer station workpieces are

to be transferred from a gravity feed magazine to a processing station.

The workpieces are pushed out of the gravity feed magazine by cylinder 1A and transferred to the

processing station by cylinder 2A.

The magazine is monitored by means of a optical proximity switch B5. If there are no more workpieces

in the magazine lamp H turns on and it is not possible to start the cycle.

In one cycle is transferred one workpiece.

Cycle description:

Piston rod of cylinder 1A is in retracted end position. Piston rod of cylinder 2A is in retracted end

position.

By pressing a pushbutton switch START workpiece is pushed out of the gravity feed magazine by

piston rod of cylinder 1A. Piston rod of cylinder 1A reaches the forward end position and staies in that position

4 seconds. After that, piston rod of cylinder 1A returnes to his initial position. Five seconds after the piston rod

of cylinder 1A has reached the retracted end position the piston rod of cylinder 2A is pulled out and transferred

workpiece to the processing station. When piston rod of cylinder 2A reaches the forward end position he

returns to his initial position.

The piston rod positions are monitored by means of the inductive proximity switches B1 to B4 (options

1) or magnetic proximity switches B1 to B4 ( options 2 ).

Veba 1a: Ureaj za prebacivanje

Radni komadi se u magacin ubacuju rukom. Cilindar 1A izbacuje komade iz magacina. Cilindar 2A prebacuje

komade dalje u procesnu stanicu.

Magacin se nadgleda optikim senzorom B5. Ukoliko nema komada u magacinu nije mogue startovati ciklus i

sija lampica H.

U jednom ciklusu moe se samo prebaciti jedan komad.

Opis ciklusa:

Svi cilindri su u uvuenom poloaju.

Pritiskom na taster START cilindar 1A izbacuje komad iz magacina, izvlai se u prednji krajnji poloaj i u

njemu ostaje 4 sekunde. Nakon toga se vraa u poetni poloaj. Pet sekundi nakon povratka cilindra 1A u

poetni poloaj, izlazi cilindar 2A u svoj krajnji izvueni poloaj i prebacuje predmet. Nakon toga se

automatski vraa u svoj poetni poloaj.

Poloaji cilindra se kontroliu induktivnim ili magnetnim senzorima B1 do B4 ( po izboru ).

Exercise 2a: Transfer station

Workpieces are inserted into the gravity feed magazine by hand. Using a transfer station workpieces are

to be transferred from a gravity feed magazine to a processing station.

The workpieces are pushed out of the gravity feed magazine by cylinder 1A and transferred to the

processing station by cylinder 2A.

The magazine is monitored by means of a optical proximity switch B5. If there are no more workpieces

in the magazine lamp H turns on and it is not possible to start the cycle.

In one cycle are transferred 2 workpieces one by one.

Cycle description:

Piston rod of cylinder 1A is in retracted end position. Piston rod of cylinder 2A is in retracted end

position.

The program cycle is started by means of a pushbutton switch START.

By pressing a pushbutton switch START workpiece is pushed out of the gravity feed magazine by

piston rod of cylinder 1A. Piston rod of cylinder 1A reaches the forward end position and staies in that position

2 seconds. After that piston rod of cylinder 1A returnes to his initial position. After the piston rod of cylinder 1A

has reached the retracted end position the piston rod of cylinder 2A is pulled out and transferred workpiece to

the processing station. When piston rod of cylinder 2A reaches the forward end position he returns to his initial

position.

The new cycle begins by pressing a pushbutton switch START.

The piston rod positions are monitored by means of the inductive proximity switches B1 to B4 (options

1) or magnetic proximity switches B1 to B4 ( options 2 ).

Veba 2a: Ureaj za prebacivanje

Radni komadi se u magacin ubacuju rukom. Cilindar 1A izbacuje komade iz magacina. Cilindar 2A prebacuje

komade dalje u procesnu stanicu.

Magacin se nadgleda optikim senzorom B5. Ukoliko nema komada u magacinu nije mogue startovati ciklus i

sija lampica H.

U jednom ciklusu prebacuju se 2 komada jedan po jedan.

Opis ciklusa:

Svi cilindri su u uvuenom poloaju.

Ciklus zapoinje pritiskom na taster START.

Pritiskom na taster START cilindar 1A izbacuje komad iz magacina, izvlai se u prednji krajnji poloaj i u

njemu ostaje 2 sekunde. Nakon toga se vraa u poetni poloaj. Nakon povratka cilindra 1A u poetni poloaj,

izlazi cilindar 2A u svoj krajnji izvueni poloaj i prebacuje predmet. Nakon toga se automatski vraa u svoj

poetni poloaj.

Nakon izbacivanja dva komada rad se zavrava.

Novi ciklus zapoinje ponovnim pritiskom na taster START.

Poloaji cilindra se kontroliu induktivnim ili magnetnim senzorima B1 do B4 ( po izboru ).

Exercise 3a: Transfer station

Workpieces are inserted into the gravity feed magazine by hand. Using a transfer station workpieces are

to be transferred from a gravity feed magazine to a processing station.

The workpieces are pushed out of the gravity feed magazine by cylinder 1A and transferred to the

processing station by cylinder 2A.

The magazine is monitored by means of a optical proximity switch B5. If there are no more workpieces

in the magazine lamp H turns on and it is not possible to start the cycle.

In one cycle is transferred one workpiece.

Cycle description:

Piston rod of cylinder 1A is in retracted end position. Piston rod of cylinder 2A is in retracted end

position.

The program cycle is started by means of a pushbutton switch START.

By pressing a pushbutton switch START workpiece is pushed out of the gravity feed magazine by

piston rod of cylinder 1A. Piston rod of cylinder 1A reaches the forward end position and staies in that position

4 seconds. After that piston rod of cylinder 1A returnes to his initial position. After the piston rod of cylinder 1A

has reached the retracted end position the piston rod of cylinder 2A is pulled out and transferred workpiece to

the processing station. Piston rod of cylinder 2A reaches the forward end position and staies in that position 4

seconds. After that piston rod of cylinder 1A returns to his initial position.

The new cycle begins by pressing a pushbutton switch START.

The piston rod positions are monitored by means of the inductive proximity switches B1 to B4 (options

1) or magnetic proximity switches B1 to B4 ( options 2 ).

Veba 3a: Ureaj za prebacivanje

Radni komadi se u magacin ubacuju rukom. Cilindar 1A izbacuje komade iz magacina. Cilindar 2A prebacuje

komade dalje u procesnu stanicu.

Magacin se nadgleda optikim senzorom B5. Ukoliko nema komada u magacinu nije mogue startovati ciklus i

sija lampica H.

U jednom ciklusu moe se samo prebaciti jedan komad.

Opis ciklusa:

Svi cilindri su u uvuenom poloaju.

Pritiskom na taster START cilindar 1A izbacuje komad iz magacina, izvlai se u prednji krajnji poloaj i u

njemu ostaje 4 sekunde. Nakon toga se vraa u poetni poloaj. Nakon povratka cilindra 1A u poetni poloaj,

izlazi cilindar 2A u svoj krajnji izvueni poloaj i prebacuje predmet. U izvuenom poloaju ostaje 4 sekunde.

Nakon toga se vraa u svoj poetni poloaj.

Poloaji cilindra se kontroliu induktivnim ili magnetnim senzorima B1 do B4 ( po izboru ).

Exercise 4a: Transfer station

Workpieces are inserted into the gravity feed magazine by hand. Using a transfer station workpieces are

to be transferred from a gravity feed magazine to a processing station.

The workpieces are pushed out of the gravity feed magazine by cylinder 1A and transferred to the

processing station by cylinder 2A.

The magazine is monitored by means of a optical proximity switch B5. If there are no more workpieces

in the magazine lamp H turns on and it is not possible to start the cycle.

In one cycle is transferred 2 workpieces one by one.

Cycle description:

Piston rod of cylinder 1A is in retracted end position. Piston rod of cylinder 2A is in retracted end

position.

The program cycle is started by means of a pushbutton switch START.

By pressing a pushbutton switch START workpiece is pushed out of the gravity feed magazine by

piston rod of cylinder 1A. Piston rod of cylinder 1A reaches the forward end position and staies in that position

2 seconds. After that piston rod of cylinder 1A returnes to his initial position. After the piston rod of cylinder 1A

has reached the retracted end position the piston rod of cylinder 2A is pulled out and transferred workpiece to

the processing station. Piston rod of cylinder 2A reaches the forward end position and staies in that position 2

seconds. After that piston rod of cylinder 1A returns to his initial position.

The new cycle begins by pressing a pushbutton switch START.

The piston rod positions are monitored by means of the inductive proximity switches B1 to B4 (options

1) or magnetic proximity switches B1 to B4 ( options 2 ).

Veba 4a: Ureaj za prebacivanje

Radni komadi se u magacin ubacuju rukom. Cilindar 1A izbacuje komade iz magacina. Cilindar 2A prebacuje

komade dalje u procesnu stanicu.

Magacin se nadgleda optikim senzorom B5. Ukoliko nema komada u magacinu nije mogue startovati ciklus i

sija lampica H.

U jednom ciklusu prebacuju se 2 komada jedan po jedan.

Opis ciklusa:

Svi cilindri su u uvuenom poloaju.

Ciklus zapoinje pritiskom na taster START.

Pritiskom na taster START cilindar 1A izbacuje komad iz magacina, izvlai se u prednji krajnji poloaj i u

njemu ostaje 2 sekunde. Nakon toga se vraa u poetni poloaj. Nakon povratka cilindra 1A u poetni poloaj,

izlazi cilindar 2A u svoj krajnji izvueni poloaj i prebacuje predmet. U izvuenom poloaju ostaje 2 sekunde.

Nakon toga se vraa u svoj poetni poloaj.

Nakon izbacivanja dva komada rad se zavrava.

Novi ciklus zapoinje ponovnim pritiskom na taster START.

Poloaji cilindra se kontroliu induktivnim ili magnetnim senzorima B1 do B4 ( po izboru ).

Exercise 5a: Transfer station

Workpieces are inserted into the gravity feed magazine by hand. Using a transfer station workpieces are

to be transferred from a gravity feed magazine to a processing station.

The workpieces are pushed out of the gravity feed magazine by cylinder 1A and transferred to the

processing station by cylinder 2A.

The magazine is monitored by means of a optical proximity switch B5. If there are no more workpieces

in the magazine lamp H turns on and it is not possible to start the cycle.

In one cycle is transferred 2 workpieces one by one.

Cycle description:

Piston rod of cylinder 1A is in retracted end position. Piston rod of cylinder 2A is in retracted end

position.

The program cycle is started by means of a pushbutton switch START.

By pressing a pushbutton switch START workpiece is pushed out of the gravity feed magazine by

piston rod of cylinder 1A. Piston rod of cylinder 1A reaches the forward end position and staies in that position

2 seconds. After that piston rod of cylinder 1A returnes to his initial position. Three seconds after the piston rod

of cylinder 1A has reached the retracted end position the piston rod of cylinder 2A is pulled out and transferred

workpiece to the processing station. Piston rod of cylinder 2A reaches the forward end position and staies in

that position 2 seconds. After that piston rod of cylinder 1A returns to his initial position.

The new cycle begins by pressing a pushbutton switch START.

The piston rod positions are monitored by means of the inductive proximity switches B1 to B4 (options

1) or magnetic proximity switches B1 to B4 ( options 2 ).

Veba 5a: Ureaj za prebacivanje

Radni komadi se u magacin ubacuju rukom. Cilindar 1A izbacuje komade iz magacina. Cilindar 2A prebacuje

komade dalje u procesnu stanicu.

Magacin se nadgleda optikim senzorom B5. Ukoliko nema komada u magacinu nije mogue startovati ciklus i

sija lampica H.

U jednom ciklusu prebacuju se 2 komada jedan po jedan.

Opis ciklusa:

Svi cilindri su u uvuenom poloaju.

Ciklus zapoinje pritiskom na taster START.

Pritiskom na taster START cilindar 1A izbacuje komad iz magacina, izvlai se u prednji krajnji poloaj i u

njemu ostaje 2 sekunde. Nakon toga se vraa u poetni poloaj. Tri sekunde nakon povratka cilindra 1A u

poetni poloaj, izlazi cilindar 2A u svoj krajnji izvueni poloaj i prebacuje predmet. U izvuenom poloaju

ostaje 2 sekunde. Nakon toga se vraa u svoj poetni poloaj.

Nakon izbacivanja dva komada rad se zavrava.

Novi ciklus zapoinje ponovnim pritiskom na taster START.

Poloaji cilindra se kontroliu induktivnim ili magnetnim senzorima B1 do B4 ( po izboru ).

Vous aimerez peut-être aussi

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsD'EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsPas encore d'évaluation

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- Electron Pneumatic CircuitDocument59 pagesElectron Pneumatic CircuitArun SìvaPas encore d'évaluation

- Pneumatics ProblemsDocument22 pagesPneumatics ProblemsMatthew Laureano ResurreccionPas encore d'évaluation

- Soalan Lab Pneumatik 1Document6 pagesSoalan Lab Pneumatik 1Kubheran SelvathuraiPas encore d'évaluation

- 4..circuits Design (Slides)Document48 pages4..circuits Design (Slides)ESLAM salahPas encore d'évaluation

- EXERCISE Pneumatic and HydraulicDocument20 pagesEXERCISE Pneumatic and HydraulicNurafida Kusumawardani50% (2)

- TUTORIAL 2-NewDocument17 pagesTUTORIAL 2-NewGeetha Sai KumarPas encore d'évaluation

- A06 Development of Multiple Actuator CircuitsDocument14 pagesA06 Development of Multiple Actuator CircuitsJose CamachoPas encore d'évaluation

- PNEUMATICS Final ProjectDocument8 pagesPNEUMATICS Final ProjectJeet ManesPas encore d'évaluation

- A 6Document14 pagesA 6stolehaPas encore d'évaluation

- C 1Document30 pagesC 1stoleha100% (1)

- Activity 7Document6 pagesActivity 7ron Joshua QuirapPas encore d'évaluation

- Standard Hydraulic Punching Machine For Verticals Operation Manual (English)Document10 pagesStandard Hydraulic Punching Machine For Verticals Operation Manual (English)Jay Dee (Deathbringer)Pas encore d'évaluation

- Lecture - 16 - System - Design - Dev - Pneumatics and Hydraulics - Part5 - FinalDocument39 pagesLecture - 16 - System - Design - Dev - Pneumatics and Hydraulics - Part5 - FinalRadwa MagdyPas encore d'évaluation

- SRI PneumaticsDocument42 pagesSRI Pneumaticsadaptive4u4527Pas encore d'évaluation

- Anlysis SopDocument7 pagesAnlysis Sopbandameedi.ramu2819Pas encore d'évaluation

- Pneumatic Circuit DesignDocument17 pagesPneumatic Circuit DesignSriram SastryPas encore d'évaluation

- Module 3: Electropneumatics: Relay Control SystemDocument36 pagesModule 3: Electropneumatics: Relay Control Systemanon_444174592Pas encore d'évaluation

- Àktuator PneumatikDocument8 pagesÀktuator PneumatikWeirs FreezePas encore d'évaluation

- Worksheet On Pneumatic CircuitDocument2 pagesWorksheet On Pneumatic CircuitSamuel WozabPas encore d'évaluation

- PLC Problems PDFDocument5 pagesPLC Problems PDFNyan Linn HtunPas encore d'évaluation

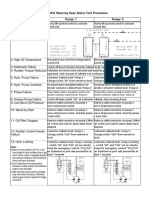

- 10K Ships - Steering Gear Alarm Test ProcedureDocument3 pages10K Ships - Steering Gear Alarm Test ProcedureDhammika AbeysinghaPas encore d'évaluation

- Práctica GrafcetDocument11 pagesPráctica GrafcetJaimePas encore d'évaluation

- ElectropneumaticsDocument11 pagesElectropneumaticsSandeep MandaliPas encore d'évaluation

- EXERCISE 1-WPS OfficeDocument2 pagesEXERCISE 1-WPS OfficeChristine Joy LabradoPas encore d'évaluation

- Tab 17 RHS 140 RDocument20 pagesTab 17 RHS 140 RAdotevi Eric AkuePas encore d'évaluation

- Double Acting Cylinder: PneumaticsDocument21 pagesDouble Acting Cylinder: PneumaticsShanela MicaPas encore d'évaluation

- PLC Applications Level-1: First Second ThirdDocument5 pagesPLC Applications Level-1: First Second ThirdnaveenPas encore d'évaluation

- Esguerra, Christian Earl L. - Self-Test - Quiz 2Document4 pagesEsguerra, Christian Earl L. - Self-Test - Quiz 2CHRISTIAN EARL ESGUERRAPas encore d'évaluation

- EE2327L 01 PNEUMATICS BDocument34 pagesEE2327L 01 PNEUMATICS BRONALD LUIS D. BOQUIRENPas encore d'évaluation

- Manual 3 PDFDocument66 pagesManual 3 PDFciobiiuliPas encore d'évaluation

- Eeng110 Lab2Document3 pagesEeng110 Lab2ReparrPas encore d'évaluation

- Testing Method StatementDocument9 pagesTesting Method StatementsardarmkhanPas encore d'évaluation

- Problems of Pneumatic Circuit DesignDocument13 pagesProblems of Pneumatic Circuit Designvijay75% (4)

- Ceutics SopDocument19 pagesCeutics Sopbandameedi.ramu2819Pas encore d'évaluation

- DX-ZB2 Hydraulic Jet Machine ManualDocument18 pagesDX-ZB2 Hydraulic Jet Machine ManualNguyễn ChungPas encore d'évaluation

- Description of The Operation of The Separating StationDocument16 pagesDescription of The Operation of The Separating StationChi Nguyen NgocPas encore d'évaluation

- Manual Book Mesin FillingDocument17 pagesManual Book Mesin FillingNafiza AneskaPas encore d'évaluation

- Sequence of Operation Screen Printing Machine AutomationDocument4 pagesSequence of Operation Screen Printing Machine AutomationKoti Veera BhadramPas encore d'évaluation

- NTC45LED Floodlight Operating ProcedureDocument9 pagesNTC45LED Floodlight Operating ProcedureDerrickPas encore d'évaluation

- Activity 3Document4 pagesActivity 3ron Joshua QuirapPas encore d'évaluation

- SD Operation SD Operation: SEP. 2012 Ce, Ap/E, Am Product Support TeamDocument21 pagesSD Operation SD Operation: SEP. 2012 Ce, Ap/E, Am Product Support Teamcarlos andres salazar sanchezPas encore d'évaluation

- Assignment MOTOR CTRLDocument7 pagesAssignment MOTOR CTRLhady_mirzaPas encore d'évaluation

- 950g Test Pressure RobelloDocument10 pages950g Test Pressure RobelloMiguel Angel Garrido Cardenas100% (2)

- Automation Lab ManualDocument99 pagesAutomation Lab Manualmanikandan_murugaiahPas encore d'évaluation

- Maxim OP ManualDocument6 pagesMaxim OP ManualCris Zotto100% (1)

- Dead Weight Tester KY SeiresDocument7 pagesDead Weight Tester KY SeiresIbnu HamdunPas encore d'évaluation

- PracticalTask 1Document2 pagesPracticalTask 1zatulsyera19Pas encore d'évaluation

- Experiment: PT1 Title: Basic Pneumatic Circuit Duration: 2 HoursDocument2 pagesExperiment: PT1 Title: Basic Pneumatic Circuit Duration: 2 HoursS. ThivyanPas encore d'évaluation

- Assignment 7 - Fluidsim Pneumatics - Group 2Document10 pagesAssignment 7 - Fluidsim Pneumatics - Group 2muhammad izharPas encore d'évaluation

- 영문TC-15 Manual,PaintingdurabilitytesterDocument5 pages영문TC-15 Manual,PaintingdurabilitytesterHanbo ENC Vina Công ty TNHHPas encore d'évaluation

- Electrohydraulic Actuators SKD.. enDocument32 pagesElectrohydraulic Actuators SKD.. enfahd alawadhiPas encore d'évaluation

- Handwheel Operation ManualDocument14 pagesHandwheel Operation ManualBahar UddinPas encore d'évaluation

- Electro-Hydraulic Actuators For Valves: Acvatix™Document31 pagesElectro-Hydraulic Actuators For Valves: Acvatix™Imre NadjPas encore d'évaluation

- Sheet 2Document14 pagesSheet 2Lina M. Abd ElSalamPas encore d'évaluation

- Distribution of Crates: Exercise No.1Document10 pagesDistribution of Crates: Exercise No.1RA LumogdangPas encore d'évaluation

- 07-01 TroubleshootingDocument33 pages07-01 TroubleshootingVinod GuptaPas encore d'évaluation

- Loading Sample in Chamber, 1.1 Open BoltsDocument8 pagesLoading Sample in Chamber, 1.1 Open Boltssudeepta mukherjeePas encore d'évaluation

- WT600 2J Operating ManualDocument6 pagesWT600 2J Operating ManualАндрей ЛосевPas encore d'évaluation

- COMPLETE LIST OF ATRsDocument63 pagesCOMPLETE LIST OF ATRslevi metzgarPas encore d'évaluation

- Examples V4.1 PDFDocument39 pagesExamples V4.1 PDFgerPas encore d'évaluation

- Fundamental Neuroscience For Basic and Clinical Applications 5Th Edition Duane E Haines Full ChapterDocument67 pagesFundamental Neuroscience For Basic and Clinical Applications 5Th Edition Duane E Haines Full Chaptermaxine.ferrell318100% (8)

- Pump NPSHDocument3 pagesPump NPSHDurjoy ChakrabortyPas encore d'évaluation

- Solutions Through Dowsing PDFDocument106 pagesSolutions Through Dowsing PDFkumar100% (6)

- DISS TOS Q3 TESTDocument3 pagesDISS TOS Q3 TESTMichelle GariandoPas encore d'évaluation

- Bicycle: From Wikipedia, The Free EncyclopediaDocument17 pagesBicycle: From Wikipedia, The Free Encyclopedialunwen100% (1)

- Assignment Strategic ManagementDocument18 pagesAssignment Strategic ManagementDarmmini MiniPas encore d'évaluation

- E Katalog 2019Document15 pagesE Katalog 2019Dwi Putri BastiyantiPas encore d'évaluation

- MCE Cambridge Primary Maths 2E Stage6 PPT C05Document25 pagesMCE Cambridge Primary Maths 2E Stage6 PPT C05Novi YufitriPas encore d'évaluation

- Bahria University (Karachi Campus) : Department of Electrical Engineering Assignment # 03Document11 pagesBahria University (Karachi Campus) : Department of Electrical Engineering Assignment # 03rizwan ahmedPas encore d'évaluation

- Scheme of Answers TUTORIAL WEEK 5Document2 pagesScheme of Answers TUTORIAL WEEK 5hdyhPas encore d'évaluation

- Resume of P Sateesh Kumar PDFDocument6 pagesResume of P Sateesh Kumar PDFsateesh kumarPas encore d'évaluation

- Bushman 2005Document8 pagesBushman 2005SOULAIMANE EZZOUINEPas encore d'évaluation

- PHY11L E201: Work, Energy, and PowerDocument16 pagesPHY11L E201: Work, Energy, and PowerMikaella TambisPas encore d'évaluation

- Elastic CollisionDocument1 pageElastic CollisionTeo Hui pingPas encore d'évaluation

- My Intro To ChatGPT SlideshowDocument38 pagesMy Intro To ChatGPT SlideshowKamelia SavovaPas encore d'évaluation

- Experiencing Meanings in Spark S The Prime of Miss Jean BrodieDocument18 pagesExperiencing Meanings in Spark S The Prime of Miss Jean BrodieMaria AgusPas encore d'évaluation

- About The ProjectDocument5 pagesAbout The Projectanand kumarPas encore d'évaluation

- Gkournelos Triantafillou 2023 Out of Plane Behavior of in Plane Damaged Masonry Infills Retrofitted With TRM andDocument14 pagesGkournelos Triantafillou 2023 Out of Plane Behavior of in Plane Damaged Masonry Infills Retrofitted With TRM andN.prem kumarPas encore d'évaluation

- Lec 5 (Welded Joint)Document38 pagesLec 5 (Welded Joint)Ahmed HassanPas encore d'évaluation

- Ice305 Lab5Document13 pagesIce305 Lab5Arnab SarkerPas encore d'évaluation

- Hamara FoundationDocument7 pagesHamara Foundationshruti chavanPas encore d'évaluation

- LR Chapter 5 - Input and OutputDocument6 pagesLR Chapter 5 - Input and OutputAakash KumarPas encore d'évaluation

- Evaluation of Chick Quality Which Method Do You Choose - 4Document4 pagesEvaluation of Chick Quality Which Method Do You Choose - 4Dani GarnidaPas encore d'évaluation

- Unit - 1 HTDocument57 pagesUnit - 1 HTSoham PendsePas encore d'évaluation

- Akash IntenshipDocument28 pagesAkash IntenshipAkash TaradalePas encore d'évaluation

- Epf011acd Ug V02-7302Document124 pagesEpf011acd Ug V02-7302sluz2000Pas encore d'évaluation

- The Road To Reinvention Linkner en 22668.simpleDocument10 pagesThe Road To Reinvention Linkner en 22668.simplePrateek AroraPas encore d'évaluation

- Who Am I MemoDocument2 pagesWho Am I Memoapi-652685391Pas encore d'évaluation