Académique Documents

Professionnel Documents

Culture Documents

Safe Work Method Statement Worksheet

Transféré par

goodspeed_phTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Safe Work Method Statement Worksheet

Transféré par

goodspeed_phDroits d'auteur :

Formats disponibles

Safe Work Method Statement Worksheet

Use of Master Builders Generic Safe Work Method Statements

Disclaimer:

The Master Builders Association of Victoria expressly disclaim all and any liability to any person in respect of anything, and of

consequence of anything done or omitted to be done by any or such person in reliance, whether wholly or partially on this generic

safe work method statement.

Rules for the use of Master Builders generic SWMS

1. This generic SWMS is provided as a sample. It is not to be used by a builder or subcontractor for the purpose of managing

safety on their projects. It can be used as a template to enable builders and subcontractors to produce their own SWMS.

Master Builders have carbon copy pads available for sale to enable builders/subcontractors to produce their own SWMS.

2. Employers intending to use this SWMS as a template for their own SWMS must ensure they consult with their employees,

including their Health and Safety Representatives, prior to its introduction.

3. Builders and subcontractors must ensure that their SWMS is relevant to the project at hand. Generic SWMS should not be

used unless precautions have been taken to ensure that the document adequately addresses the hazards and risks relevant

to each particular project.

4. Builders and subcontractors intending to use this sample SWMS as a template for their own generic SWMS, without making

any changes to the detail, must ensure that they adhere to and implement all of the relevant risk controls.

5. The range of generic SWMS provided by Master Builders are not sufficiently broad enough to cover all hazards or risks

encountered by builders and subcontractors. It does not cover the full list of requirements for which SWMS are specifically

required under the OHS Construction Regulations. It is important that the builder or subcontractor undertake their own hazard

identification and risk control process relevant for each particular task.

It is highly recommended that persons who are responsible for preparing and reviewing SWMS undertake training so as to

understand the process of identifying and controlling risks in the workplace.

Remember: Each SWMS should be site specific. Include all workers in the development of the SWMS.

All workers should sign off to verify that they understand all the requirements of this Safe Work Method Statement.

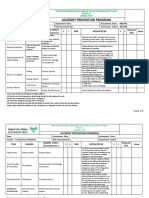

Safe Work Method Statement Worksheet

Company Name

Site Name

Safe Work Method Statement

No ______ Page

Contractor

Activity

Piling

of

Permit to Work Requirement

Yes

No

Tasks

Hazards and Risks

Risk control measures

Who is responsible?

List the tasks required to perform

the activity in the sequence they are

carried out.

What can harm you - Hazards?

What can happen - Risks?

List the control measures required to eliminate or reduce the risk of injury

and detail how the control measures will be put in place.

Write the name of the person

responsible (supervisor or

above) to implement the

control measures identified.

Site induction.

Meeting regarding safety

and job procedures

Various

Inspection for underground

services

Potential that work activities come in

contact with possible underground

services such as power, gas, water,

communication cables etc.

Inspection of overhead

services.

Potential that work activities come in

contact with overhead services such as

power lines, communication cables etc.

Traffic management on

adjacent roads and upon

entry and exit to the site.

Injury / death to the public. Property

damage including damage to vehicles.

Providing a clear and safe

work area (site setup)

Injury to the general public.

Providing a clear and safe

work area (site setup)

Injury to personnel and damage to

property and equipment / vehicles on

site

Staff will be inducted prior to the commencement of work on all sites.

Regular toolbox meetings are also required to discuss issues and

review SWMS and procedures for amending as necessary for

improvement.

Ensure relevant service providers have been contacted including dial

before you dig, to identify where these services are. The building

contractor is to notify and mark these service locations before piling

works commence. An excavation permit from the builder may be

required.

Ensure service providers have been contacted to arrange any

permits if necessary. Building contractor is to notify and provide a

specified no working zone to contractor if working under power lines

etc.

Ensure appropriate and adequate traffic management measures

have been established. Workers to be inducted into the traffic

management plan so they are familiar with the entry/exit points, site

speed limit, etc.

Temporary fencing to be provided by principal contractor with

signage as Construction site keep out along boundary fences and

gates.

Ensure piling work activities are isolated and segregated from other

activities on site. All vehicles and property not involved in piling

activities should be isolated from the work area.

Remember: Each SWMS should be site specific. Include all workers in the development of the SWMS.

All workers should sign off to verify that they understand all the requirements of this Safe Work Method Statement.

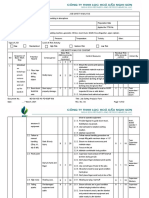

Safe Work Method Statement Worksheet

Incorporating appropriate

safety wear

The hazard risk increases substantially

when the appropriate safety apparel is

not worn.

All staff must wear the appropriate safety wear including: hard hat,

safety vest, eye and ear protection, safety boots and gloves. Long

sleeved shirts and long pants will be worn if required. Sunscreen 30+

is also to be used if working outdoors.

Machinery and equipment

plant condition check

Injury from plant failure

Off loading of drilling

equipment from vehicles and

set up of drill rigs

Damage to property and equipment.

Injury to personnel including: crushing,

striking, strains, back injuries. Lifting

chains break. Falling loads. Excavator

tilting over.

Rigging of machines

Contact with onsite personnel or

machinery

A machinery and equipment pre-start check is to be done each day

before work commences. The checklist to be completed is supplied

within the operators hire book. All defects to be rectified and

recorded before commencement of work. Ensure all plant has been

risk assessed and serviced/maintained at the required hour reading.

Work is to be done by qualified and experienced personnel. Off

loading area is clear of hazards. All personnel not involved to keep

well clear. No loads are to travel or be suspended over personnel.

Ensure the load is within the SWL of the machinery and is secured.

Lifting chains to be in working order and rated / tagged. All PPE to be

worn. No manual lifting of heavy loads. Machinery to be used on a

stable ground.

Piling rigs not allowed to work outside nominated areas. Piling

personnel only within restricted area.

Rig machinery as per manufacturers manual.

Spotter to be used at all times to observe power lines/services and

other machinery and personnel.

Select firm, level work area for rigging.

Rig machine as per manufacturers manual.

Suitably qualified personnel or trainee under supervision only to rig

machine.

Fall protection for heights over 2m.

EWP to be used when applicable. Ensure a high risk work licence is

held if used over 11 metres in height.

Harness used where applicable as a last resort.

All persons wearing harnesses must be trained in correct use.

Work to be done by qualified and experienced personnel. All

operators to hold current excavator ticket or supervised by ticketed

operator. No loads are to travel or be suspended over personnel.

Clear spoil from vicinity of pier. Drill offsider to be in full view of

machine operator at all times.

Machine collapse

Falling from height

Drilling / bored piers

Entanglement, falling, tripping, crushing,

striking. Excavator tilting over and or

colliding with objects / personnel.

Machinery / drilling noise.

Remember: Each SWMS should be site specific. Include all workers in the development of the SWMS.

All workers should sign off to verify that they understand all the requirements of this Safe Work Method Statement.

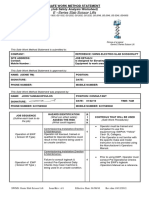

Safe Work Method Statement Worksheet

Handling drilling equipment

while in operation

Hands caught in drill tools during

changeover

Removal of spoil from drill

rig using bobcat

Bobcat hitting/running over personnel.

Collision with other onsite traffic.

Placement of hole covers

Pinched fingers, strains, back injuries

Hole inspection

Falling

Placement of reinforcement

cage

Personnel, objects, equipment being

struck, falling load, pinched fingers,

lifting chains / slings breaking. Excavator

tilting over.

Placement of concrete

including vibrating

Striking, pinched fingers, concrete

splashing in the eyes, strains, back

injuries, contamination of waterways and

environment.

Unauthorised personnel to keep well clear of all activities. Machinery

to be used on stable ground. All PPE to be worn. All personnel to

keep clear of all rotating plant.

Shovelling around a hole is only to occur when the Kelly bar is down

the hole. Spotter to ensure all onsite personnel keep clear of the spinoff area.

Use palms rather than fingers when guiding locking pins into position.

Wear gloves where practicable. Keep tight tolerances on equipment

joints

All personnel to work within full view of plant operator. Only qualified

and experienced operator or trainee under supervision to operate drill

rig.

Only ticketed, competent operator or supervised trainee to drive

bobcat. All onsite personnel to maintain safe working distance from

bobcat during operation. Never walk behind bobcat during operation.

Bobcat operator to communicate and make eye contact with drill rig

operator or offsider prior to entering slew radius to remove bored

spoil.

All onsite vehicles to be fitted with flashing orange lights and

reversing beepers.

Hole covers to be used between drilling and pouring concrete. No

manual lifting of heavy loads. PPE to be worn at all times. Machinery

or two people to be utilised for the large hole covers.

Hole cover to be in place when the hole is inspected and tested if

required

Work to be done by qualified and experienced personnel. Licenced

dogman to perform all chaining works. Swing area for excavator to be

clear of personnel. The load to be within the MRC of the machine. No

loads are to travel or be suspended over personnel. All personnel to

wear PPE. Lifting chains / slings to be tagged / rated and in working

order. Machinery to be used on stable ground. Load to be secured.

Chain register to be maintained.

All PPE to be worn. No lifting of heavy loads. The use of the

excavator may be required to lift the vibrator. Refer to Concrete

Pumping SWMS. Cleaning of the concrete chute to be washed in an

area that will not contaminate any waterways, drains, and or the

surrounding environment etc. Tremie pipes used where required.

Remember: Each SWMS should be site specific. Include all workers in the development of the SWMS.

All workers should sign off to verify that they understand all the requirements of this Safe Work Method Statement.

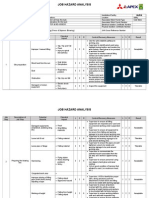

Safe Work Method Statement Worksheet

Receiving and sending

deliveries to and from the

work area

Oxycutting, welding and

grinding

Ground collapses, personnel run over,

colliding with objects, machinery and

equipment. Services above and below

ground being struck.

Radiation burns, foreign objects in the

eyes, welders flash, hot metal, possible

fire.

I have read and understood the content of this Safe Work Method

Statement

Workers name

Signature

Delivery driver to be directed by our spotter. Delivery truck to have

flashing light and reverse beeper activated. No personnel or items to

be in the path of the truck.

Refer to SWMS for Use of Grinder.

Ensure Flashback arrestors in place on bottles and handset if

required. Have fire extinguisher in place at all times. Bottles to be

secured onto a trolley.

Ensure welding shield in place as applicable.

Watch for fire outbreaks, remove flammable materials if required.

Do not wear polyester fluoro vests as they are highly flammable.

A Hot Work permit may be required.

Date

Ap

pro

ved

By

Workers name

Signature

Remember: Each SWMS should be site specific. Include all workers in the development of the SWMS.

All workers should sign off to verify that they understand all the requirements of this Safe Work Method Statement.

Vous aimerez peut-être aussi

- JSA-009a Drilling and Mon Well Construction-SonicDocument4 pagesJSA-009a Drilling and Mon Well Construction-SonicDedi Apriadi83% (6)

- Risk Assessment for Loading and Offloading of SteelDocument3 pagesRisk Assessment for Loading and Offloading of SteelSarfraz Randhawa100% (3)

- Specimen 1 ValuationDocument17 pagesSpecimen 1 ValuationLight BearerPas encore d'évaluation

- SWMS 67 - Safe Use of Nail GunsDocument4 pagesSWMS 67 - Safe Use of Nail GunsJonasPas encore d'évaluation

- SWMS - PlumberDocument7 pagesSWMS - PlumberSiddiqueShaikhPas encore d'évaluation

- Removing Staircase with Crane Lifts SteelDocument3 pagesRemoving Staircase with Crane Lifts Steelmarvin100% (1)

- Drilling Soil Bores SWMSDocument3 pagesDrilling Soil Bores SWMSEngr Faheem AkhtarPas encore d'évaluation

- JHA For Manual Excavation Near On Control RoomDocument9 pagesJHA For Manual Excavation Near On Control RoomFrancis Enriquez Tan100% (1)

- Lifting Plan For Equipment - MMSPDocument14 pagesLifting Plan For Equipment - MMSPClifford100% (1)

- Tranter Platecoil Data Manual PDFDocument106 pagesTranter Platecoil Data Manual PDFgoodspeed_phPas encore d'évaluation

- CHM Analysis and Comparisons of CRUS MULTHULLS2013Document60 pagesCHM Analysis and Comparisons of CRUS MULTHULLS2013kkd108Pas encore d'évaluation

- Concrete Formwork Suspended SlabDocument5 pagesConcrete Formwork Suspended SlabKate HopleyPas encore d'évaluation

- Plumber - Drainer SWMSDocument12 pagesPlumber - Drainer SWMSallen2912100% (1)

- Suroj Buildcon Pvt. LTD.: Job Safety AnalysisDocument6 pagesSuroj Buildcon Pvt. LTD.: Job Safety AnalysisKiran ChenchalaPas encore d'évaluation

- 45 - Method Statements For Erection of Steel PDFDocument1 page45 - Method Statements For Erection of Steel PDFAbdul RahmanPas encore d'évaluation

- 0025 Concerte Poring With Concrete PumpDocument5 pages0025 Concerte Poring With Concrete PumpNibhaPas encore d'évaluation

- Construction Safety: Page 1 of 4Document4 pagesConstruction Safety: Page 1 of 4ryan.anicetePas encore d'évaluation

- 20-RAS-Transformer InstallationDocument2 pages20-RAS-Transformer InstallationWalid MarhabaPas encore d'évaluation

- Doku - Pub Risk-AssessmentDocument10 pagesDoku - Pub Risk-AssessmentUlviyye ElesgerovaPas encore d'évaluation

- JSA For Pressure Test 2ND REVISIONDocument10 pagesJSA For Pressure Test 2ND REVISIONMuthu AlaguRaj100% (1)

- Part-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykeDocument4 pagesPart-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykevivekaramanaPas encore d'évaluation

- Job Safety Analysis: Manual ExcavationDocument2 pagesJob Safety Analysis: Manual Excavationfdfddf dfsdfPas encore d'évaluation

- SOP SOP0022 Concrete Core DrillDocument3 pagesSOP SOP0022 Concrete Core Drillkristian08Pas encore d'évaluation

- 0019 JSA Crane LiftingDocument4 pages0019 JSA Crane LiftingViron BaxhiaPas encore d'évaluation

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 pagesJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- JSA For Pipe Installation TS 3Document8 pagesJSA For Pipe Installation TS 3Shilpiengg SafetyPas encore d'évaluation

- Civil Works Construction Laydown AreaDocument4 pagesCivil Works Construction Laydown AreaMohammed MinhajPas encore d'évaluation

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDocument3 pagesLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINPas encore d'évaluation

- Rigging JSA RiggerDocument12 pagesRigging JSA RiggeraQiLGunawanPas encore d'évaluation

- JSA for safe fence installationDocument5 pagesJSA for safe fence installationMoaatazz Nouisri50% (2)

- Electrical work safetyDocument3 pagesElectrical work safetyCristina Rican50% (2)

- Work Method Statement: Confined SpaceDocument3 pagesWork Method Statement: Confined SpaceKarthik babu0% (1)

- Risk Assessment PDFDocument4 pagesRisk Assessment PDFAnonymous iI88LtPas encore d'évaluation

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyPas encore d'évaluation

- Boom Lift PDFDocument2 pagesBoom Lift PDFcityofdarwingisPas encore d'évaluation

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelPas encore d'évaluation

- Safe Work Procedure, Gem MaintenanceDocument46 pagesSafe Work Procedure, Gem MaintenanceAsif Khanzada100% (1)

- Job Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureDocument2 pagesJob Safety Analysis Sheet: Activity Potential Hazard Likely Causes Control MeasureM Waqas HabibPas encore d'évaluation

- Excavation and TrenchingDocument2 pagesExcavation and TrenchingvikasPas encore d'évaluation

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- JOB SAFETY ANALYSISDocument21 pagesJOB SAFETY ANALYSISThái Đạo Phạm Lê100% (1)

- Rapid P20ai Jsa Box CulvertDocument8 pagesRapid P20ai Jsa Box Culvertfadli.lpgPas encore d'évaluation

- Jha For - TransformerDocument7 pagesJha For - Transformermujahid1137Pas encore d'évaluation

- Safe Unloading of Cut and BentDocument16 pagesSafe Unloading of Cut and BentAbhinav SinhaPas encore d'évaluation

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpPas encore d'évaluation

- Hydro Testing On Piping System Utility and Plant Piping Jsa 2012Document4 pagesHydro Testing On Piping System Utility and Plant Piping Jsa 2012AldrinPas encore d'évaluation

- Pre-Job Safety Assessment ChecklistDocument2 pagesPre-Job Safety Assessment Checklistgueettaf faresPas encore d'évaluation

- Risk assessment lifting pipelinesDocument3 pagesRisk assessment lifting pipelinesPerwez21Pas encore d'évaluation

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument5 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz NouisriPas encore d'évaluation

- Site Specific Safety Plan ChecklistDocument22 pagesSite Specific Safety Plan ChecklistAnonymous y1pIqcPas encore d'évaluation

- Mie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationDocument6 pagesMie-Hse-Jha-007 - Cable Pulling, Laying, Dressing Work, TerminationLuqman Osman100% (3)

- Risk Assessment Foundation WorkDocument2 pagesRisk Assessment Foundation WorkMihirduttaPas encore d'évaluation

- Jsa For Manual Backfiling Usin Hand Roller CompactorDocument5 pagesJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadPas encore d'évaluation

- Pa Hsec 02 040 002 F03Document4 pagesPa Hsec 02 040 002 F03Abdul KhaliqPas encore d'évaluation

- Steel Structure Installation Risk AssessmentDocument8 pagesSteel Structure Installation Risk Assessmentjameel100% (3)

- JHA Blowing PressDocument5 pagesJHA Blowing PressLuqman OsmanPas encore d'évaluation

- File - 20200905 - 105458 - Jsa Wind PowerDocument10 pagesFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnPas encore d'évaluation

- Mobilization and Installation of CHW PipesDocument8 pagesMobilization and Installation of CHW PipesYounis KhanPas encore d'évaluation

- Tool Box Talk - MK - Emergency Response ProceduresDocument2 pagesTool Box Talk - MK - Emergency Response ProceduresPaul McGahanPas encore d'évaluation

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- Precast Erection JSWDocument6 pagesPrecast Erection JSWPrabhakaran GurunathanPas encore d'évaluation

- DLF RCC HiraDocument8 pagesDLF RCC HiraskfahimuddinPas encore d'évaluation

- SCP-aircoolers Cu Al en LR 04 PDFDocument56 pagesSCP-aircoolers Cu Al en LR 04 PDFgoodspeed_phPas encore d'évaluation

- Insulation Gasket KitsDocument4 pagesInsulation Gasket Kitsgoodspeed_phPas encore d'évaluation

- 03 IndexDocument38 pages03 Indexgoodspeed_phPas encore d'évaluation

- SFD and BMDDocument278 pagesSFD and BMDRama KumarPas encore d'évaluation

- Flange Insulation Brochure Rev3Document10 pagesFlange Insulation Brochure Rev3Gilberto YoshidaPas encore d'évaluation

- Material Data Sheets For Piping: 1 ForewordDocument50 pagesMaterial Data Sheets For Piping: 1 ForewordhsdePas encore d'évaluation

- Financial Statements SampleDocument53 pagesFinancial Statements SampleArshad IqbalPas encore d'évaluation

- SCP-aircoolers Cu Al en LR 04 PDFDocument56 pagesSCP-aircoolers Cu Al en LR 04 PDFgoodspeed_phPas encore d'évaluation

- Line ListDocument22 pagesLine Listgoodspeed_phPas encore d'évaluation

- Panele Scienne Lipiec 2009 en InternetDocument88 pagesPanele Scienne Lipiec 2009 en Internetgoodspeed_phPas encore d'évaluation

- B B: P I: ACK TO Asics IPE NsulationDocument34 pagesB B: P I: ACK TO Asics IPE NsulationJose Luis Lázaro Pascual100% (3)

- B B: P I: ACK TO Asics IPE NsulationDocument34 pagesB B: P I: ACK TO Asics IPE NsulationJose Luis Lázaro Pascual100% (3)

- Gea Screw CompressorsDocument206 pagesGea Screw Compressorsgoodspeed_phPas encore d'évaluation

- Sleeves & WashersDocument7 pagesSleeves & Washersgoodspeed_phPas encore d'évaluation

- S118content PDFDocument5 pagesS118content PDFgoodspeed_phPas encore d'évaluation

- Platecoil Brochure PCC 6Document12 pagesPlatecoil Brochure PCC 6sunil601Pas encore d'évaluation

- Brochure Kit Aislamiento APSDocument8 pagesBrochure Kit Aislamiento APSjulian2282254Pas encore d'évaluation

- p2813 PDFDocument1 pagep2813 PDFgoodspeed_phPas encore d'évaluation

- Platecoil Album 2009 PDFDocument28 pagesPlatecoil Album 2009 PDFsunil601Pas encore d'évaluation

- Corrosion Behavior of Materials in Ammonia and Aqueous Ammonia SolutionsDocument2 pagesCorrosion Behavior of Materials in Ammonia and Aqueous Ammonia Solutionsgoodspeed_phPas encore d'évaluation

- TP 108 15 All About Temp Plate®Document56 pagesTP 108 15 All About Temp Plate®goodspeed_ph100% (1)

- Price QUOTE: Item # 60D Serpentine Platecoil, Tranter 60D Serpentine PlatecoilDocument1 pagePrice QUOTE: Item # 60D Serpentine Platecoil, Tranter 60D Serpentine Platecoilgoodspeed_phPas encore d'évaluation

- AusteniteDocument10 pagesAustenitekameshvvPas encore d'évaluation

- Tranter-Platecoil Applications PDFDocument12 pagesTranter-Platecoil Applications PDFDeepan MangalPas encore d'évaluation

- Chemical Compatibility ChartDocument52 pagesChemical Compatibility Chartusamamalik1989Pas encore d'évaluation

- Steel Standards PDFDocument50 pagesSteel Standards PDFstallone21Pas encore d'évaluation

- Grade 304 304L 304HDocument9 pagesGrade 304 304L 304HjandrodfPas encore d'évaluation

- Tables - TechnicalProperties - EN 10088 PDFDocument24 pagesTables - TechnicalProperties - EN 10088 PDFeugenio.gutenbertPas encore d'évaluation

- Vietnam & Angkor Wat (PDFDrive) PDFDocument306 pagesVietnam & Angkor Wat (PDFDrive) PDFChristine TranPas encore d'évaluation

- Surface Roughness Measurement - MitutoyoDocument2 pagesSurface Roughness Measurement - MitutoyoSelvaraj BalasundramPas encore d'évaluation

- Steam Turbine Unloading and Shut-Down of Operation Turbine/Generator Shut-Down Diagram (General)Document1 pageSteam Turbine Unloading and Shut-Down of Operation Turbine/Generator Shut-Down Diagram (General)parthibanemails5779Pas encore d'évaluation

- HTTP Verbs GET POST PUT PATCH DELETE (39Document12 pagesHTTP Verbs GET POST PUT PATCH DELETE (39Jefferson EducacionPas encore d'évaluation

- Welding Defects and AcceptanceDocument76 pagesWelding Defects and Acceptancearavindan100% (1)

- Everything You Need to Know About Centrifugal FansDocument65 pagesEverything You Need to Know About Centrifugal Fansahmed100% (1)

- Vedic Astrology OverviewDocument1 pageVedic Astrology Overviewhuman999100% (8)

- Convection: Example 3.1Document5 pagesConvection: Example 3.1MChobind RivaldoPas encore d'évaluation

- Avh p6050dvd EngDocument119 pagesAvh p6050dvd EngcaimanaterPas encore d'évaluation

- Conflict and Factional Disputes - Siegel & BealsDocument12 pagesConflict and Factional Disputes - Siegel & BealsDanielPas encore d'évaluation

- Sco 2Document15 pagesSco 2rkhandelwal9604Pas encore d'évaluation

- 2tak Vs 4takDocument3 pages2tak Vs 4takTaufiq AlhakimPas encore d'évaluation

- Weekly Report 52Document196 pagesWeekly Report 52Erceanu DanPas encore d'évaluation

- Meditations on Ancient Astrology Principles from Brihat Parashari HorāDocument87 pagesMeditations on Ancient Astrology Principles from Brihat Parashari HorāPrasanna KumarPas encore d'évaluation

- Your Song RitaDocument1 pageYour Song Ritacalysta felix wPas encore d'évaluation

- Educ 211 Ancient EgyptDocument27 pagesEduc 211 Ancient Egyptapi-207262700Pas encore d'évaluation

- Matlab For SolidworksDocument18 pagesMatlab For SolidworksAle' AmoudiPas encore d'évaluation

- M O Publications Index Worldwide CoverageDocument5 pagesM O Publications Index Worldwide CoverageloloPas encore d'évaluation

- Grade 9 Unit 1 - Part 1: Square RootsDocument20 pagesGrade 9 Unit 1 - Part 1: Square RootsWilson ZhangPas encore d'évaluation

- 0580 w15 QP 42Document16 pages0580 w15 QP 42Shahrizan Noor100% (1)

- Divide and Conquer (Closest Pair, Convex Hull, Strassen Matrix Multiply) DemoDocument27 pagesDivide and Conquer (Closest Pair, Convex Hull, Strassen Matrix Multiply) DemoAnand KumarPas encore d'évaluation

- Instrukcja Pellets Fuzzy Logic - ENGDocument53 pagesInstrukcja Pellets Fuzzy Logic - ENGxilef84Pas encore d'évaluation

- TGN Level 1 No. 5 Derivation of Snow LoadDocument4 pagesTGN Level 1 No. 5 Derivation of Snow LoadjeddijPas encore d'évaluation

- Well Serve CingDocument140 pagesWell Serve CingYounes MakPas encore d'évaluation

- P198 Software and Atlases For Evaluating Thermal Bridges 0Document10 pagesP198 Software and Atlases For Evaluating Thermal Bridges 0cm08909Pas encore d'évaluation

- Msds PentaneDocument6 pagesMsds PentaneMuhammad FikriansyahPas encore d'évaluation

- Mic ProjectDocument12 pagesMic Projectsarthakjoshi012Pas encore d'évaluation

- Physical PropertiesDocument4 pagesPhysical PropertiesKolliparaDeepakPas encore d'évaluation