Académique Documents

Professionnel Documents

Culture Documents

Conveyors

Transféré par

Petros IosifidisCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Conveyors

Transféré par

Petros IosifidisDroits d'auteur :

Formats disponibles

For meal portioning

and crockery clearance.

N series CONVEYOR BELT WITH VIPLA SYSTEM

series

Particularly suitable for portioning

and distribution hospital meals.

VIPLA

COSTRCUTION:

Sliding surface entirely in 18/10 stainless steel (AISI 304).

18/10 stainless steel supporting frame and legs with adjustable feet

for levelling (+/- 15 mm).

Damp-proof belt suitable for contact with foodstuff (FDA / USDA certification)

consisting of a layer of polyurethane coated with white PVC.

Belt width: mm 300.

DIMENSIONS:

Carcass width 500 mm.

Carcass height: 150 mm.

Conveyor belt height: 900 mm. (to sliding plane)

OPTIONAL EXTRA S

Tray stop by mechanical limit switch.

N SERIES - CONFIGURATION:

Each conveyor belt consist of a drive and control station, a trasmission

part and one or more rectilinear parts.

Drive and control station is the part which is placed at and of belt (tray

arrival) and includes all towing, speed adjustment and control parts.

Tray stop by photo electric sensor.

Start / Stop pedal switch.

Supplementary emergency STOP switch.

Electrical speed regulator.

220 - 240 V EEC approved interlocked electrical sockets-outlets.

PVC impact strip on both sides of conveyor belt.

Application of 500 x 500 mm. fixed side shelf for tray inspection.

Trasmission part is placed at beginning of belt (tray departure) and holds

the belt stretching and trasmission parts.

Application of 500 x 500 mm. collapsible shelf for trays.

Rectilinear part is the basic for composing path of a conveyor belt.

This will bring conveyor belt height to 1020 mm.

Mounted on 100 mm wheels with pedal brake.

PC series CONVEYOR BELT WITH POLICORD SYSTEM

PC

P O L I C O RD

series

CONSTRUCTION:

Particularly suitable for trays

recovery.

Sliding surface entirely in 18/10 stainless steel (AISI 304) with 40 mm. side edges.

18/10 stainless steel supporting frame and legs with adjustable feet for

levelling (+/- 15 mm).

Equipped with two parallel running circular cords spaced 220 mm. apart, made of

moisture-proof polyurethane and suitable for foodstuffs contact.

Belt thickness, : 15 mm.

45 corner part

90 corner part

DIMENSIONS:

Carcass width 500 mm.

Carcass height: 180 mm.

Conveyor belt height: 900 mm. (to sliding plane)

PC SERIES - CONFIGURATION:

Drive and control station with

automatic stacking.

OPTIONAL EXTRA S

Tray stop by mechanical limit switch (for meals distribution).

Tray stop by photoelectric sensor (for trays recovery and clearing).

Start / Stop pedal switch.

Supplementary emergency STOP switch.

Electrical speed regulator.

220 - 240 V EEC approved interlocked electrical sockets-oulets.

PVC impact strip on both sides of conveyor belt.

Application of 500 x 500 mm. fixed side shelf for tray inspection.

Application of 500 x 500 mm. collapsible shelf for trays inspection.

Mounting on 100 mm wheels with pedal brake. This will bring

conveyor belt height to 1020 mm.

Each conveyor belt consist of a drive and control station, a trasmission part,

one or more rectilinear and 90/45 corner part. For conveyor which exceeds 15 lm,

a towing, and trasmission middle part every 10 m is required.

Drive and control station is the part which is placed at end of belt (tray arrival)

and includes all towing, speed adjustment and control parts. Its power allows towing,

up to 9 lm. Over that lenght, conveyor system is to be equipped with a towing and

transmission middle station.

Two version available:

Trays automatic stacking version (to levelling trolleys).

Trays preparation version (as for Vipla conveyor belt).

Transmission part is placed at the beginning of belt (tray departure) and holds

transmission parts.

Rectilinelar part is the basic for composing path of a conveyor belt.

90 corner part is inserted anywhere in path of conveyor system, it allows any change

of direction with a 90 or 45 angle according to needs with a 650 mm. middle radius.

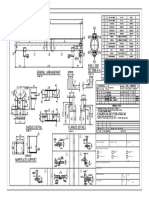

Push button key board

Start / Stop

Working direction

Dirty slide

General limit

switch

Electrical control

panel

Reducer

Variable-speed

drive

Electrical motor

Imput electrical

cable

Speed adjustment knob

DRIVE AND CONTROL STATION

AVAILABLE MODELS:

Models

mm.

N-3

PC - 3

3000 x 500 x 900

N-4

PC - 4

4000 x 500 x 900

N-6

PC - 6

6000 x 500 x 900

N-8

PC - 8

8000 x 500 x 900

N - 10

PC - 10

10000 x 500 x 900

Models 0,5 m. and models

exceeding 10 m. are available upon

request.

SERIE

N series

PC series

STANDARD EQUIPMENT

N PC

Motorised unit with speed (380 V 3Ph-E/ 50Hz-Kw 0,37) complete with all electrical and mechanical parts of conveyor belts / policord set-up.

Adjustable speed from 5 to 20 m/min with adjustable flywheel placed on motor unit.

Switch cabinet preset for plugs connection of plugs, if required.

Main switch (power).

Push botton panel (start / stop) with indicator signal.

One emergency STOP switch.

Dirt scraper with conveying chute.

Conforming to EEC 89/392 Directive and next updatings.

Switch cabinet, push-button panels and plugs are IP65 protected. (specify position on ordering).

Conveyor cords are assembled for lengts up to 5 m.

Fimi-Ali S.p.A.

Office and plant:

Via Puglie 14\16 - 20098 S. Giuliano Milanese - (Milan) Italy

Tel. +39 02.98.28.11.46 / +39 02.98.28.94.61

Fax +39 02.98.81.037

E-mail: info@fimi-inox.it

www.fimi-inox.it

F. 005 - en - 08/10

Emergency push button

Mechanical limit switch

Vous aimerez peut-être aussi

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Évaluation : 2.5 sur 5 étoiles2.5/5 (3)

- Bicycle Repair ManualDocument162 pagesBicycle Repair Manualrazvancc89% (9)

- 110 Waveform Generator Projects for the Home ConstructorD'Everand110 Waveform Generator Projects for the Home ConstructorÉvaluation : 4 sur 5 étoiles4/5 (1)

- 777 Manitowoc Lattice Truck CraneDocument40 pages777 Manitowoc Lattice Truck Cranemanurung4Pas encore d'évaluation

- Catalogo - Ge752 - Curvas PDFDocument61 pagesCatalogo - Ge752 - Curvas PDFjuanpnuss100% (1)

- Pipe ClassDocument5 pagesPipe Classmokie305100% (1)

- Pipe ClassDocument5 pagesPipe Classmokie305100% (1)

- American With Disabilities Act AdaDocument16 pagesAmerican With Disabilities Act Adaapi-376186426Pas encore d'évaluation

- 8.9 Basic Maths For Well PlanningDocument9 pages8.9 Basic Maths For Well PlanningKhanh Pham MinhPas encore d'évaluation

- P H Omega T 250 25 TonDocument9 pagesP H Omega T 250 25 TonUday Pratap0% (1)

- Canrig Product InfoDocument71 pagesCanrig Product InfoBabi Lakhdari100% (5)

- Anaerobic DigestionDocument12 pagesAnaerobic DigestionPetros IosifidisPas encore d'évaluation

- Datasheet Sp15 Us WirtgenDocument8 pagesDatasheet Sp15 Us WirtgenRobinson GuanemePas encore d'évaluation

- Design of Pressure Vessel Using Asme Code, Section Viii, Division 1Document7 pagesDesign of Pressure Vessel Using Asme Code, Section Viii, Division 1bbmoksh100% (2)

- TT1815 & TT1512 ClippersDocument4 pagesTT1815 & TT1512 ClippersLuana Chirilă100% (1)

- Inspection of Unfired Pressure VesselsDocument35 pagesInspection of Unfired Pressure Vesselstbmari100% (7)

- Capacitor BanksDocument49 pagesCapacitor BanksAmal P RaviPas encore d'évaluation

- Pneumatic Damper Actuator GuideDocument13 pagesPneumatic Damper Actuator Guidejuliyanto88Pas encore d'évaluation

- Creative IndustriesDocument433 pagesCreative IndustriesDanielTavaresPas encore d'évaluation

- Audi A3 Injeção DiretaDocument109 pagesAudi A3 Injeção Diretawesley candido100% (1)

- Prime Drilling HDDsDocument20 pagesPrime Drilling HDDsarisan47Pas encore d'évaluation

- Pulse Jet Bag Filters PDFDocument12 pagesPulse Jet Bag Filters PDFPetros IosifidisPas encore d'évaluation

- History of Stainless SteelDocument65 pagesHistory of Stainless SteelMayank100% (1)

- Katja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)Document383 pagesKatja Kruckeberg, Wolfgang Amann, Mike Green-Leadership and Personal Development - A Toolbox For The 21st Century Professional-Information Age Publishing (2011)MariaIoanaTelecan100% (1)

- Optimum D240x500GDocument2 pagesOptimum D240x500Gjavi_mr50% (2)

- Grove GMK 4075 BrochureDocument22 pagesGrove GMK 4075 Brochurejpablop12100% (2)

- Stainless Steel PassivationDocument9 pagesStainless Steel Passivationpiyusharora1964100% (1)

- Dust Collection Technical HandbookDocument106 pagesDust Collection Technical HandbookcassindromePas encore d'évaluation

- Mobile Crusher 900x600Document7 pagesMobile Crusher 900x600macross086100% (7)

- Ucc 900 Sor em Wpi 0001 - B01Document73 pagesUcc 900 Sor em Wpi 0001 - B01JonesPas encore d'évaluation

- LMSRDocument8 pagesLMSRRaul TudoricaPas encore d'évaluation

- Flour Siever / Flour Sifter: SpecificationDocument9 pagesFlour Siever / Flour Sifter: SpecificationJustine AbanadorPas encore d'évaluation

- Specification Data: Self Aligning RotatorsDocument4 pagesSpecification Data: Self Aligning RotatorsOdprirodePas encore d'évaluation

- In Oerlikon CitolineDocument10 pagesIn Oerlikon CitolineJavid Ibrahim MohamedPas encore d'évaluation

- Technical Specification For EP-12PN800 SZ Cabling MachineDocument6 pagesTechnical Specification For EP-12PN800 SZ Cabling Machinemehran khamsehzadehPas encore d'évaluation

- Column Drilling MachineDocument8 pagesColumn Drilling MachineShubhadeep MajumdarPas encore d'évaluation

- Product Manual - Juki PLC-2700 (2 Needle Post)Document6 pagesProduct Manual - Juki PLC-2700 (2 Needle Post)WillPas encore d'évaluation

- Data Sheet LEO50GTDocument2 pagesData Sheet LEO50GTMelissa BrownPas encore d'évaluation

- Specification Data: Self Aligning RotatorsDocument4 pagesSpecification Data: Self Aligning RotatorsOdprirodePas encore d'évaluation

- Complete CatalogueDocument41 pagesComplete CatalogueRad AlexPas encore d'évaluation

- Kaltfräse W 200 Slipform Paver SP 25 / SP 25 I: Technische Daten Technical SpecificationDocument8 pagesKaltfräse W 200 Slipform Paver SP 25 / SP 25 I: Technische Daten Technical SpecificationRobertHeningPas encore d'évaluation

- Actuators Cat Andco f10 08Document52 pagesActuators Cat Andco f10 08Thalavai Balamurugan100% (1)

- NOAH KatalogDocument6 pagesNOAH KatalogtalayPas encore d'évaluation

- Automatizari Porti Culisante BFT DeimosDocument2 pagesAutomatizari Porti Culisante BFT DeimosChristopher WatsonPas encore d'évaluation

- Specification Data: Self Aligning RotatorsDocument4 pagesSpecification Data: Self Aligning RotatorsOdprirodePas encore d'évaluation

- Bug ODocument24 pagesBug ORogo CatalinPas encore d'évaluation

- SSF2000Document2 pagesSSF2000sujinssridaPas encore d'évaluation

- BUG-O Welding and CuttingDocument264 pagesBUG-O Welding and Cuttingtanase_v100% (1)

- Grove RT700E: Product GuideDocument20 pagesGrove RT700E: Product GuideLuis Miguel Rivera SoplopucoPas encore d'évaluation

- The Loader Specialist: System 180Document8 pagesThe Loader Specialist: System 180dm1680Pas encore d'évaluation

- FP-30 - UadDocument12 pagesFP-30 - UadUday SharmaPas encore d'évaluation

- Tracked Paver Finisher with Multiple Screed OptionsDocument2 pagesTracked Paver Finisher with Multiple Screed OptionsDem Hasi100% (1)

- ORBITA - Car TurntableDocument1 pageORBITA - Car TurntableDivya AhujaPas encore d'évaluation

- Sankyo FN - FA CatDocument29 pagesSankyo FN - FA CatquaxesPas encore d'évaluation

- DS MinarcMig Adaptive 170 180 AD706 1010 enDocument3 pagesDS MinarcMig Adaptive 170 180 AD706 1010 enjannw0% (1)

- SVF 1800 enDocument4 pagesSVF 1800 ensami ben chikhaPas encore d'évaluation

- Grove 60 Ton PDFDocument24 pagesGrove 60 Ton PDFFabrizzio ZuñigaPas encore d'évaluation

- Easeweld Pdfs Saw Thyristorised Saw Welding MachineDocument2 pagesEaseweld Pdfs Saw Thyristorised Saw Welding MachinesimsonPas encore d'évaluation

- SC1 40Document4 pagesSC1 40Wijayanto BekasiPas encore d'évaluation

- Entech ControlsDocument12 pagesEntech Controlsmanmohansingh1999Pas encore d'évaluation

- Tabla de CargaDocument32 pagesTabla de Cargavpizarro_23Pas encore d'évaluation

- The Loader Specialist: System 180Document8 pagesThe Loader Specialist: System 180dm1680Pas encore d'évaluation

- Uromac T-Rail MV - BrochureDocument2 pagesUromac T-Rail MV - BrochureCristiano RonaldoPas encore d'évaluation

- TR-500EX: Tadano LTDDocument6 pagesTR-500EX: Tadano LTDMuhammadFaridPas encore d'évaluation

- Alfra Amts en Flyer 0813 NeutralDocument2 pagesAlfra Amts en Flyer 0813 Neutralhizbi7Pas encore d'évaluation

- Ybm 15 TDocument12 pagesYbm 15 Tdoanthanh_hpPas encore d'évaluation

- Cable Pull Switches OverviewDocument18 pagesCable Pull Switches OverviewMauricio Pacaje AramayoPas encore d'évaluation

- Articulated Arms Brochure - AtlasDocument12 pagesArticulated Arms Brochure - Atlasyudo0807Pas encore d'évaluation

- Cable Pulling WenchesDocument2 pagesCable Pulling Wenchesthapa786mPas encore d'évaluation

- SwedVent Flexible DuctingDocument5 pagesSwedVent Flexible DuctingNikhil CherukuriPas encore d'évaluation

- Broschuere Perfekt in Schweissers Hand en Aufl3 DSDocument5 pagesBroschuere Perfekt in Schweissers Hand en Aufl3 DSRadu RusPas encore d'évaluation

- SAW - TLP - TL E02Document2 pagesSAW - TLP - TL E02Clementine94Pas encore d'évaluation

- Simba M7 - 9851 2194 01Document4 pagesSimba M7 - 9851 2194 01Rodrigo ContrerasPas encore d'évaluation

- Data Sheet LEO13GTDocument2 pagesData Sheet LEO13GTperestotnikPas encore d'évaluation

- 09.2.Cnc Machining Centers Rais m650 m800Document5 pages09.2.Cnc Machining Centers Rais m650 m800Gross Meltiade AlexanderPas encore d'évaluation

- P40PB (1004G) GensetDocument4 pagesP40PB (1004G) GensetBudi WaskitoPas encore d'évaluation

- Basic Data Viper40 15066 enDocument10 pagesBasic Data Viper40 15066 enArmando RiveraPas encore d'évaluation

- Walter Tech Bulletin 03ENDocument8 pagesWalter Tech Bulletin 03ENPetros IosifidisPas encore d'évaluation

- Help Logitrace PDFDocument70 pagesHelp Logitrace PDFvhmaturaPas encore d'évaluation

- Sag16 Pipe Spans ChartDocument1 pageSag16 Pipe Spans ChartPetros IosifidisPas encore d'évaluation

- 13 Outokumpu Supra Range Datasheet May 2015Document12 pages13 Outokumpu Supra Range Datasheet May 2015Petros IosifidisPas encore d'évaluation

- Corrugated Web BeamDocument67 pagesCorrugated Web BeampsewagPas encore d'évaluation

- Sag16 Pipe Spans ChartDocument1 pageSag16 Pipe Spans ChartPetros IosifidisPas encore d'évaluation

- Murcia 09 S. VerstichelDocument48 pagesMurcia 09 S. VerstichelPetros IosifidisPas encore d'évaluation

- Griffin LauraDocument103 pagesGriffin LauraPetros IosifidisPas encore d'évaluation

- Protego Er/V: Self Closing Emergency Pressure Relief ValveDocument2 pagesProtego Er/V: Self Closing Emergency Pressure Relief ValvePetros IosifidisPas encore d'évaluation

- Report 2014 SfogliabileDocument92 pagesReport 2014 SfogliabilePetros IosifidisPas encore d'évaluation

- Report 2014 SfogliabileDocument92 pagesReport 2014 SfogliabilePetros IosifidisPas encore d'évaluation

- Design Variations in ASP Systems S-Gamble CH2M HillDocument20 pagesDesign Variations in ASP Systems S-Gamble CH2M HillPetros IosifidisPas encore d'évaluation

- B 2804 e 7754Document14 pagesB 2804 e 7754Petros IosifidisPas encore d'évaluation

- Cold Formed Heads PDFDocument0 pageCold Formed Heads PDFDumitru SorinaPas encore d'évaluation

- Ijetae 0113 77Document5 pagesIjetae 0113 77Petros IosifidisPas encore d'évaluation

- Man Wrt1900ac 8820-01897 Reva00 en Fr-CA ComprehensiveDocument108 pagesMan Wrt1900ac 8820-01897 Reva00 en Fr-CA ComprehensivePetros IosifidisPas encore d'évaluation

- 3D PV 2017 BrochureDocument4 pages3D PV 2017 BrochurePetros Iosifidis100% (1)

- Equipments / Tags No. Purchase Ordener No. Project No.: Rejected Reviewed With Commets Reviewed Without CommentsDocument1 pageEquipments / Tags No. Purchase Ordener No. Project No.: Rejected Reviewed With Commets Reviewed Without CommentsPetros IosifidisPas encore d'évaluation

- LPPJFF RL - Envi - 2013 04 04Document10 pagesLPPJFF RL - Envi - 2013 04 04Petros IosifidisPas encore d'évaluation

- The Demag wheel range for loads up to 60,000 kgDocument20 pagesThe Demag wheel range for loads up to 60,000 kgPetros IosifidisPas encore d'évaluation

- Kapitel 01 DINO Techn TeilDocument12 pagesKapitel 01 DINO Techn TeilPetros IosifidisPas encore d'évaluation

- Optimization Module For Abaqus/CAE Based On Genetic AlgorithmDocument1 pageOptimization Module For Abaqus/CAE Based On Genetic AlgorithmSIMULIACorpPas encore d'évaluation

- Primera actividad economicaDocument3 pagesPrimera actividad economicamaria fernanda parraPas encore d'évaluation

- Methanol Technical Data Sheet FactsDocument1 pageMethanol Technical Data Sheet FactsmkgmotleyPas encore d'évaluation

- Kompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminDocument9 pagesKompres Panas Dingin Dapat Mengurangi Nyeri Kala I Persalinan Di Rumah Sakit Pertamina Bintang AminHendrayana RamdanPas encore d'évaluation

- Topic 3Document28 pagesTopic 3Ashraf YusofPas encore d'évaluation

- CitationCJ4-CB Checklists B v1.2Document4 pagesCitationCJ4-CB Checklists B v1.2Joao Vitor RojasPas encore d'évaluation

- Gmail LogoDocument12 pagesGmail Logovinodram993480Pas encore d'évaluation

- Techniques-Of-Attitude-Scale-Construction FullDocument344 pagesTechniques-Of-Attitude-Scale-Construction FullLuthfi fharuq Al Fairuz67% (3)

- Advance Distributed ComputingDocument2 pagesAdvance Distributed ComputingValia Centre of ExcellencePas encore d'évaluation

- Atpl Formula MergedDocument74 pagesAtpl Formula Mergeddsw78jm2mxPas encore d'évaluation

- Wavemakers For Physical Models: EquipmentDocument10 pagesWavemakers For Physical Models: Equipmentesmaeil013Pas encore d'évaluation

- DVOR Principle 코이카 양식Document71 pagesDVOR Principle 코이카 양식Undral Batbayar100% (1)

- CA 1 - Đề thi AV5 - CLC - Made - efDocument5 pagesCA 1 - Đề thi AV5 - CLC - Made - efQuang NguyenPas encore d'évaluation

- Keynote Proficient End-Of-Course Test BDocument7 pagesKeynote Proficient End-Of-Course Test Bana maria csalinasPas encore d'évaluation

- Designing of 3 Phase Induction Motor Blackbook DoneDocument30 pagesDesigning of 3 Phase Induction Motor Blackbook Donetryd0% (1)

- 2022 Anambra State ITN Mass Campaign Report in Nnewi North LGA by Idongesit EtukudoDocument15 pages2022 Anambra State ITN Mass Campaign Report in Nnewi North LGA by Idongesit EtukudoIdongesit EtukudoPas encore d'évaluation

- Chem 361 Separation Methods IntroDocument8 pagesChem 361 Separation Methods IntroTwum SomoahPas encore d'évaluation

- CanReg5 InstructionsDocument150 pagesCanReg5 InstructionsdiyafersanPas encore d'évaluation

- Active-Passive VoiceDocument18 pagesActive-Passive VoiceDivya JainPas encore d'évaluation

- Innovations in Drill Stem Safety Valve TechnologyDocument22 pagesInnovations in Drill Stem Safety Valve Technologymiguel mendoza0% (1)

- As Biology Revision L3 Cells Microscopes and IAM PPQ 2Document7 pagesAs Biology Revision L3 Cells Microscopes and IAM PPQ 2Anonymous fFKqcYPas encore d'évaluation

- Examining Language in Romeo and Juliet - The Prologue - Mastery TestDocument5 pagesExamining Language in Romeo and Juliet - The Prologue - Mastery TestPhạm MyPas encore d'évaluation