Académique Documents

Professionnel Documents

Culture Documents

Tm. VC: May 13, 1969 E. F. Cielaszyk

Transféré par

joycebaylonTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Tm. VC: May 13, 1969 E. F. Cielaszyk

Transféré par

joycebaylonDroits d'auteur :

Formats disponibles

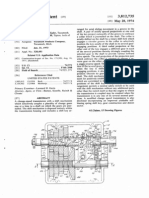

May 13, 1969

E. F. CIELASZYK

3,443,375

FRICTION MECHANISM FOR CLOCK

Filed Aug. 11, 1967

Om

N3

mm.

QB

w.

EOwm. 9

.WF vCmmTm.,05am

Arrvs.

3,443,375

United States Patent 0 rice

1

Patented May 13, 1969

Torque is supplied to the drive train by means of a

spring 25, the outer end of which is coupled to a barrel

FRICTION MECHANISM FOR CLOCK

26 connected to a winding stem 27. The inner end of the

Edward F. Cielaszyk, Oglesby, Ill., assignor to General

spring is connected to an output gear 28.

Time Corporation, Stamford, Conn., a corporation of

Drivingly connected between the spring output gear 28

Delaware

Ul

and pinion 23 is a centerwheel 30 having a pinion 31 and

Filed Aug. 11, 1967, SenNo. 660,041

integral hub 32. Telescoped within the centerwheel 30

Int. Cl. G041) 27/00

3,443,375

US. Cl. 5885.5

6 Claims

is a minute hand shaft 35. Mounted on the forward end

of the minute hand shaft is a minute hand 36. The knob

10 37, at the rear end of the shaft, is provided for setting

the hand.

ABSTRACT OF THE DISCLOSURE

For driving the associated hour hand, a pinion 40 on

A clock friction mechanism for use in a clock having

the minute hand shaft engages a reduction gear 41 having

plastic gear wheels and interposed between the gear train

a pinion 42 which meshes with a further reduction gear

and the minute hand shaft.

43. The latter has an integral quill 44, on the forward end

In clocks it is necessary to be able to manually set

hour and minute hands without rotating the gears in

gear train which normally drives the hands. This is

complished by a friction connection, referred to in

the

quill 52 mounting an alarm setting hand 56.

the

In accordance with the present invention the center

ac 20 wheel 30, its associated pinion 31, and its axially extend

the

ing hub 32, are integrally molded of plastic material, and

art as a"friction between the minute hand shaft and

gear which drives it, which gear is referred to as a cen

terwheel.

It is an object of the present invention to provide a

clock friction mechanism intended particularly for use

in clocks having plastic movements which has an easy,

smooth setting action but which insures positive driving of

the hands under normal running conditions. It is a related

object to provide a friction mechanism which is long

wearing and free of any tendency to gall or groove at the

engaged surfaces.v In this'connection it is an object to

provide a friction mechanism which has predictable and

uniform- characteristics in quantity production runs in

spite of the wide tolerances which are normally applicable 35

to low cost plastic movements.

of which is mounted the hour hand 46. An alarm set

gear 50, which is set by pinion 51 is connected to an outer

It is another object to provide a friction mechanism

which is simpler and less expensive than conventional

clock frictions and which is particularly well suited for

the cylindrical hub is separated, by axially extending slots,

into segmented jaws which embrace the shaft, the jaws

being encircled by a loop of garter spring to force the jaws

into intimate engagement with the shaft. Further in ac

cordance with the invention the shaft has a conically

tapered section which extends substantially the length of

the jaws and which terminates, at its narrow end, in a

shoulder thereby insuring that the centerwheel, although

rotatable on the shaft, is maintained in a precise axial

position.

Turning to the drawing, the hub 32 in the present em

bodiment is formed into three jaws 61, 62, and 63 which

are de?ned by equally spaced slots 64, 65, 66. Encircling

the jaws is a garter spring 70 having ends 71, 72. The

garter spring, which may be formedof spring steel or

bronze, has a normal inner diameter which is less than

the hub diameter and is of suf?cient strength, readily

determined by one skilled in the art, to apply a force

use in low priced clocks, requiring only a small garter 40 upon the jaws which is directed radially inward for gen

spring, in addition to the gear wheel and shaft normally

erating the desired friction. To facilitate installation of

present, and which, being highly compact, is suited for

the spring on the hub the tip portion of each of the jaws

use in a wide variety of clock designs.

is chamfered.

, it is a more speci?c object of the present invention to

For the purpose of locating the centerwheel axially

provide a clock friction whichv is easily assembled and

with respect to the shaft and simultaneously improving

which has a novel provision for automatically and posi

the smoothness of the setting action, the shaft is formed

tively locating the associated gear and shaft at the time

with a conically tapered section 80 which begins at a line

of assembly and during the life of the clock.

or region 81 located at the base portion of the jaws and

Other objects and advantages of the invention will be

which tapers down to de?ne a relatively abrupt shoulder

come apparent upon reference to the attached detailed

82 alined with the tips of the jaws. Prior to installation

description and to the drawings in which:

, ' '

of and compression by the garter spring, the hub has a

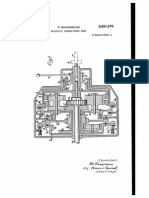

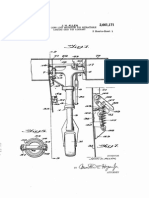

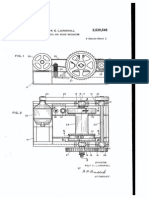

FIGURE 1 is a sectional-view, partially diagrammatic, sectional pro?le as indicated by the dot-dash lines 60a.

taken through a clock mechanism employing the present

When the centerwheel is installed on the shaft 35 the tips

invention;

FIG. 2 is an, enlarged fragmentary section taken

through the clock centerwheel; and

of the jaws, being inwardly biased, snap into position

adjacent the shoulder. There is no tendency for the center

wheel to move away from this position since the jaws

are constantly urged in the down hill or bottoming

FIG. 3 is a fragmentary perspective showing the hub

portion of the gear of FIG. 2.

direction .by the force of the spring; thus the conflicting

While the invention has been described in connection

requirements of slippage and accurate axial positioning

with a preferred embodiment, it will be understood that I 60 are both achieved.

do not intend to be limited to the particular embodiment

The invention may be practiced using any one of a

shown but intend on the contrary to cover such alterna

tives, modi?cations and equivalents as may be included

within the spirit and scope of the invention.

number of plastics having adequate strength, dimensional

stability, surface hardness, and elastic modulus. An acetal

plastic is found to combine the desired qualities in high

Turning now to the drawing there is shown, in simpli 65 measure, one example of an acetal plastic being Delrin

?ed sectional view, a clock mechanism mounted on frame

manufactured by E. I. du Pont de Nemours of Wilming

plates 11, 12 and 13. The clock drive train, generally indi

ton, Del.

cated at 15, is conventional having a balance 16, an es

Such material has an unlubricated coe?icient of fric

capement pawl 17, and an escapement wheel 18. The pin

tion, against steel, within the range of 0.1 to 0.3. This

ion 19 of the latter is driven by a gear 20 having a pinion 70 relatively low coef?cient, which is equal for the static and

21. This pinion is, in turn, driven by a gear 22 having a

dynamic states, combined with relatively high per unit

pinion 23.

pressure, is considered to contribute to the unusual

3,443,375

ing an integral axially projecting hub, said hub being sepa

rated by axial slots into segmental jaws embracing the

smoothness of the setting action. It is found that by using

more than one convolution of spring there is a tendency

for the spring to resist retrograde, or expanding, move

ment so that spring wire of relatively light gauge may be

shaft, said shaft having a conically tapered section extend

ing the length of the jaws and terminating in a shoulder,

and a garter spring encircling the jaws for pressing the

employed to develop appreciable squeezing pressures.

same against the conically tapered section of the shaft

However, it is found that where more than two convolu

tions are employed the non-retrograde feature tends to

be accentuated to the extent that the spring locks-up

on the hub so that the jaws ?nd it impossible to yield

in the face of minor dimensional irregularities of the hub

and shaft. Consequently in carrying out the invention

it is proposed that between one and two convolutions be

with the tips of the jaws positioned adjacent said shoulder

for locating the center wheel in predetermined axial posi

tion on said shaft while permitting relative slippage upon

exceeding of predetermined torque.

2. The combination as claimed in claim 1 in which the

jaws each have a base portion at the end of the slots

in which the transverse cross section is less than the cross

used, preferably one and a half as shown.

section at the tip portion for bodily bending of each of the

'In accordance with one of the more detailed aspects

of the invention the transverse sectional area taken 15 jaws about the base portion into conformity with the con

ically tapered section of the shaft.

through the base of each of the jaws is less than the

3. In a clock the combination comprising a driving

sectional area at the tip portions of the jaws, with the

train having a centerwheel and source of driving torque,

result that the jaws, under the urging of the spring force,

a minute hand shaft telescoped through the centerwheel,

tend to bend bodily about the base, thereby to follow

more closely the surface of the conical section of the 20 said centerwheel being formed of molded plastic and hav

ing an integral axially projecting hub, said hub being

shaft. This is brought out in FIG. 2 where it will be

separated by axial slots into segmental jaws embracing

noted that the radial thickness of each of the jaws is

the shaft, and a garter spring encircling the jaws for

somewhat greater at the mid portion and approaching

pressing the same into intimate engagement with said

the end than it is at the base.

shaft while permitting relative slippage upon exceeding

It is found that the above friction provides a setting

of predetermined torque.

action, which is predictable and consistent in quantity

4. The combination as claimed in claim 3 in which the

garter spring is formed of a helical loop of spring metal

tolerances applicable to low cost components. Life tests

having between one and two convolutions and pre-sprung

indicate that using a conventional shaft material, for ex

ample, steel, with a centerwheel made of Delrin or any 30 to a diameter less than the diameter of the hub.

5. In a gear mechanism the combination comprising

one of a number of the durable plastics currently avail

a driving train having a drive member and source of driv

able, there is no tendency toward galling or grooving,

ing torque, a shaft telescoped through the drive member,

even after the setting of the clock hundreds of times more

said drive member being formed of molded plastic and

frequently than would be encountered in normal usage.

The invention is ideally suited for use in clocks having 35 having an integral, axially projecting hub of cylindrical

shape, said hub being separated by equally spaced axial

a so-called plastic movement in which substantially all

slots into segmental jaws embracing the shaft, said shaft

of the gears in the timing train are formed of plastic in

having a conically tapered section extending the length

lieu of the brass and steel used in the past. It will be ap

of the jaws and terminating in a shoulder, and a garter

parent that the frictional connection has been very simply

achieved with only a single added part, the spring, the 40 spring encircling the jaws for pressing the same against

production manufacture in spite of the relatively wide

the conically tapered section of the shaft with the tips of

the jaws positioned adjacent said shoulder for maintain

ing the drive member in predetermined axial position on

said shaft while permitting relative slippage upon exceed

other elements being integral with the gear and shaft

respectively. Since the construction in addition to possess

ing the features usually sought in a friction, is inherent

ly compact, the invention is applicable to a wide range

ing of predetermined torque.

of clock designs, including clocks of premium quality.

6. The combination as claimed in claim 5 in which the

plastic material has an unlubricated coe?icient of fric

tion against the material of the shaft which is approxi

mately equal in the static and dynamic states and which

lies in the range of 0.1 to 0.5.

The centerwheel is easily molded since the center open

ing is cylindrical, notwithstanding the fact that it is de

formed, upon installation, into conical shape.

Although the term conical has been applied to the

surface 80, it will be understood that the side walls need 50

not be perfectly straight provided that a circular cross

section is maintained and provided that a shoulder is

References Cited

UNITED STATES PATENTS

de?ned at the narrow end.

While a coe?icient of friction, both static and dynamic,

within the range of 0.1 to 0.3 is preferred, it is found that

satisfactory operation is achieved where the coefficient in

the static and dynamic states is approximately equal and

Within the range of 0.1 to 0.5.

I claim as my invention:

1,265,598

3,057,647

5/1918

10/1962

Borresen ___________ __ 58-59

Wood ___________ __ 64-11 X

3,213,645

10/1965

Pease ______________ __ 64-30

RICHARD B. WILKINSON, Primary Examiner,

1. In a clock the combination comprising a driving 60 G. H. MILLER, JR., Assistant Examiner.

train having a centerwheel and source of driving torque,

US. Cl. X.R.

a minute hand shaft telescoped through the centerwheel,

64--30

said centerwheel being formed of molded plastic and hav

Vous aimerez peut-être aussi

- Us3443375 PDFDocument3 pagesUs3443375 PDFRamos GabePas encore d'évaluation

- US2631476Document17 pagesUS2631476Stefan IlicPas encore d'évaluation

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiPas encore d'évaluation

- Reverse Energy Bow Patent US 7743760 B2Document8 pagesReverse Energy Bow Patent US 7743760 B2DoukhoborPas encore d'évaluation

- 322 (W422i / /41i3/3i 4) (1 Im: (19) United StatesDocument9 pages322 (W422i / /41i3/3i 4) (1 Im: (19) United StatesdjsfPas encore d'évaluation

- April 2, 1968.: Filed Sept 26, 1966Document7 pagesApril 2, 1968.: Filed Sept 26, 1966Pedja Bekic100% (1)

- Combined GearboxDocument8 pagesCombined Gearboxkats2404Pas encore d'évaluation

- Dec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Document8 pagesDec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Rezicky ImamPas encore d'évaluation

- No. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed GearingDocument4 pagesNo. 687,172. Patlmtedl Nov. I9, I90I.: Variable Speed Gearingbelchior alvaroPas encore d'évaluation

- Sept. 11, 1951 B. B. Scott 2,567,735: His AttorneyDocument3 pagesSept. 11, 1951 B. B. Scott 2,567,735: His AttorneyTri PujiyantoPas encore d'évaluation

- United States Patent (191: Von Kale! Et AlDocument18 pagesUnited States Patent (191: Von Kale! Et AlJoão Paulo Canto RibeiroPas encore d'évaluation

- Us955823 PDFDocument3 pagesUs955823 PDFSashikant SharmaPas encore d'évaluation

- The Art of Watch Repair - Including Descriptions of the Watch Movement, Parts of the Watch, and Common Stoppages of Wrist WatchesD'EverandThe Art of Watch Repair - Including Descriptions of the Watch Movement, Parts of the Watch, and Common Stoppages of Wrist WatchesPas encore d'évaluation

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongPas encore d'évaluation

- Apron MechanismDocument7 pagesApron Mechanismgopalpaul0% (2)

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduPas encore d'évaluation

- 507 Mechanical Movements: Mechanisms and DevicesD'Everand507 Mechanical Movements: Mechanisms and DevicesÉvaluation : 4 sur 5 étoiles4/5 (28)

- United States Patent: Gow (10) Patent N0.: (45) Date of PatentDocument5 pagesUnited States Patent: Gow (10) Patent N0.: (45) Date of PatentAdam SalehPas encore d'évaluation

- 6ave. E: Sept. 13, 1966 F. Rompelen Etal 3,273,061Document4 pages6ave. E: Sept. 13, 1966 F. Rompelen Etal 3,273,061mohamed hemdanPas encore d'évaluation

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocument6 pagesDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloPas encore d'évaluation

- Project ReportDocument9 pagesProject Reportanilkumar529283% (12)

- Us 3090578Document3 pagesUs 3090578mohamad zarePas encore d'évaluation

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Document12 pagesL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniPas encore d'évaluation

- Project ZDocument31 pagesProject ZADITYAPas encore d'évaluation

- Project ReportDocument5 pagesProject ReportAshley Sam100% (1)

- Bellcrank Mechanisms For Stirling EnginesDocument6 pagesBellcrank Mechanisms For Stirling Engineshmwong76Pas encore d'évaluation

- United States Patent (191: Swearingen (11) 4,287,758Document7 pagesUnited States Patent (191: Swearingen (11) 4,287,758NicandroGonzalesPas encore d'évaluation

- Engineering Vol 69 1900-04-06Document35 pagesEngineering Vol 69 1900-04-06ian_new100% (1)

- Us2996100 PDFDocument8 pagesUs2996100 PDFerzrzretgertfertgePas encore d'évaluation

- United States Patent: Primary Examiner-Benjamin W. WycheDocument5 pagesUnited States Patent: Primary Examiner-Benjamin W. WycheMarc GlebPas encore d'évaluation

- Military Searchlight Truck (1937)Document8 pagesMilitary Searchlight Truck (1937)CAP History LibraryPas encore d'évaluation

- United States Patent (191: Andersen Et A1Document5 pagesUnited States Patent (191: Andersen Et A1khoaglePas encore d'évaluation

- Patent Application Publication (10) Pub. No.: US 2010/0105516 A1Document11 pagesPatent Application Publication (10) Pub. No.: US 2010/0105516 A1KrozePas encore d'évaluation

- Honing ToolDocument3 pagesHoning ToolKyle YsitPas encore d'évaluation

- Dec. 27, 1955 H. Hettch 2,728,188: Af470 Ae/7cMDocument3 pagesDec. 27, 1955 H. Hettch 2,728,188: Af470 Ae/7cMparasara66Pas encore d'évaluation

- European Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorDocument16 pagesEuropean Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorSelvaraji MuthuPas encore d'évaluation

- Us 2120533asfafafDocument5 pagesUs 2120533asfafafankitsarvaiyaPas encore d'évaluation

- Stephenson Versus Walschaert Vlave GearDocument16 pagesStephenson Versus Walschaert Vlave Gearmaes.daan1Pas encore d'évaluation

- United States Patent (19) : Brown (45) Date of PatentDocument9 pagesUnited States Patent (19) : Brown (45) Date of Patentapsint12Pas encore d'évaluation

- Patent Dscharge VV of FIP PDFDocument12 pagesPatent Dscharge VV of FIP PDFRajesh CPas encore d'évaluation

- Dec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LDocument5 pagesDec. 24, 1963 A. K. Kline 3,115,186: Gln/I301. '6 Bym Fda LcheesewizzPas encore d'évaluation

- US3200917Document5 pagesUS3200917张淼Pas encore d'évaluation

- US2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)Document2 pagesUS2726694 - Single Screw Actuated Pivoted Clamp (Saxton Clamp - Kant-Twist)devheadbot100% (1)

- Scientific American Supplement, No. 441, June 14, 1884.D'EverandScientific American Supplement, No. 441, June 14, 1884.Pas encore d'évaluation

- Compliant Linkage MechanismsDocument8 pagesCompliant Linkage MechanismsKGSG100Pas encore d'évaluation

- Kinematics and Dynamics of Machinery - Experiments PDFDocument47 pagesKinematics and Dynamics of Machinery - Experiments PDFUtkarsh SinghPas encore d'évaluation

- (Patente 1) US1489458Document3 pages(Patente 1) US1489458diegoPas encore d'évaluation

- Patent USPTO 4098523 Traction DeviceDocument5 pagesPatent USPTO 4098523 Traction Devicexeron7126Pas encore d'évaluation

- Us2028583 PDFDocument8 pagesUs2028583 PDFMurthy YegginaPas encore d'évaluation

- Scotch Yoke Mechanis1Document17 pagesScotch Yoke Mechanis1Saravanan ViswakarmaPas encore d'évaluation

- Us 1893840Document6 pagesUs 1893840Robert BercovitzPas encore d'évaluation

- BrakesDocument17 pagesBrakesumitothmanPas encore d'évaluation

- United States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f PatentDocument10 pagesUnited States Patent: (10) Patent N0.: Hoifman Et Al. (45) Date 0f Patentmohammadreza91Pas encore d'évaluation

- BY 4W1?" Mal/MM : July 4, 1957 A. Roque V 3,329,192Document2 pagesBY 4W1?" Mal/MM : July 4, 1957 A. Roque V 3,329,192Namelezz ShadowwPas encore d'évaluation

- Anti-Aircraft Fire Control Device (1937)Document10 pagesAnti-Aircraft Fire Control Device (1937)CAP History LibraryPas encore d'évaluation

- Illlllllllllilllllllllilllllllllli: United States Patent (191Document3 pagesIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioPas encore d'évaluation

- X III 110111113////////////////////////////11ml: (12) Ulllted States Patent (10) Patent N0.: US 8,453,633 B2Document9 pagesX III 110111113////////////////////////////11ml: (12) Ulllted States Patent (10) Patent N0.: US 8,453,633 B2djsfPas encore d'évaluation

- US3173686 (Coin-Op Kiddie Ride)Document8 pagesUS3173686 (Coin-Op Kiddie Ride)EPas encore d'évaluation

- The Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsD'EverandThe Inner Workings of a Watch - A Simple Guide for Enthusiasts of Clockwork MechanismsPas encore d'évaluation

- Scientific American Supplement, No. 312, December 24, 1881D'EverandScientific American Supplement, No. 312, December 24, 1881Pas encore d'évaluation

- Romeo C. Lagman For Petitioners. Jardeleza, Sobrevinas, Diaz, Mayudini & Bodegon For RespondentsDocument5 pagesRomeo C. Lagman For Petitioners. Jardeleza, Sobrevinas, Diaz, Mayudini & Bodegon For RespondentsjoycebaylonPas encore d'évaluation

- Today Is Tuesday, January 12, 2016: v. NorielDocument3 pagesToday Is Tuesday, January 12, 2016: v. NorieljoycebaylonPas encore d'évaluation

- Bustos v. LuceroDocument7 pagesBustos v. LucerojoycebaylonPas encore d'évaluation

- Sim v. NLRCDocument14 pagesSim v. NLRCjoycebaylonPas encore d'évaluation

- Perez v. MendozaDocument11 pagesPerez v. Mendozajoycebaylon0% (1)

- 1c PDFDocument62 pages1c PDFherrerafaridcrPas encore d'évaluation

- VAG Control ValvesDocument12 pagesVAG Control ValvesVignesh NadimuthuPas encore d'évaluation

- Module 3 Heat EffectsDocument41 pagesModule 3 Heat EffectsJatskinesisPas encore d'évaluation

- HTB17PaDGFXXXXcIXXXX PRXFXXXs PDFDocument17 pagesHTB17PaDGFXXXXcIXXXX PRXFXXXs PDFDark DungeonPas encore d'évaluation

- Kinetics of The Iodination of Acetone PDFDocument6 pagesKinetics of The Iodination of Acetone PDFsamPas encore d'évaluation

- ASTM C1240-15Microsilica Specification 硅灰Document7 pagesASTM C1240-15Microsilica Specification 硅灰杨过Pas encore d'évaluation

- Topic 12 - Acid-Base Equilibria MCQsDocument11 pagesTopic 12 - Acid-Base Equilibria MCQsmegaordinaryday0% (1)

- Claus Process: Claus, The Claus Process Has Become The Industry StandardDocument23 pagesClaus Process: Claus, The Claus Process Has Become The Industry StandardNhan Nguyen VanPas encore d'évaluation

- Testing of AggregatesDocument6 pagesTesting of AggregatesMegelJoshuaRamiterrePas encore d'évaluation

- Code For Electrical Installations at Oil and Gas Facilities-2015 4edDocument58 pagesCode For Electrical Installations at Oil and Gas Facilities-2015 4edMarijan Utroša100% (1)

- 1100 XC Airless SprayerDocument28 pages1100 XC Airless SprayerR Fonseca GomezPas encore d'évaluation

- Pollutants and Its MeasurementDocument70 pagesPollutants and Its MeasurementECRDPas encore d'évaluation

- Sample 03.62 Water System Validation - SOPDocument44 pagesSample 03.62 Water System Validation - SOPKenechukwu Igwagu100% (2)

- Biochemistry Unit ConversionDocument4 pagesBiochemistry Unit ConversionTran Trong NghiaPas encore d'évaluation

- Finite Element Analysis of Delamination in Laminated Composite PlatesDocument44 pagesFinite Element Analysis of Delamination in Laminated Composite PlatesSrini RaoPas encore d'évaluation

- Salitex Expansion Joint Filler BoardDocument2 pagesSalitex Expansion Joint Filler BoardSandipPas encore d'évaluation

- Ocr Gateways c1c2c3Document36 pagesOcr Gateways c1c2c3Jatinder BathPas encore d'évaluation

- APEG Polyester Fabric Belt EPDocument1 pageAPEG Polyester Fabric Belt EPmuhammad IhsanPas encore d'évaluation

- Pitting Corrosion Due To Deposits in Cooling Water SystemsDocument12 pagesPitting Corrosion Due To Deposits in Cooling Water SystemsAnonymous 1XHScfCIPas encore d'évaluation

- Hysys CourseDocument5 pagesHysys CourseWael HannonPas encore d'évaluation

- A Review On Biological Properties of Aloe Vera PlantDocument4 pagesA Review On Biological Properties of Aloe Vera PlantIJIRSTPas encore d'évaluation

- Project ReportDocument67 pagesProject ReportDivyanshu DkPas encore d'évaluation

- Watercut Monitors-Delta CDocument8 pagesWatercut Monitors-Delta CShakeel AhmedPas encore d'évaluation

- Ammonia Based Refrigeration SystemsDocument19 pagesAmmonia Based Refrigeration SystemsHoainam NguyenPas encore d'évaluation

- Biology Term One Q&ADocument136 pagesBiology Term One Q&AKhang Ni 康妮 FooPas encore d'évaluation

- Avaleha Criticalreview PDFDocument9 pagesAvaleha Criticalreview PDFArunPas encore d'évaluation

- The Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating MethodsDocument4 pagesThe Lease Pumper Testing, Treating, and Selling Crude Oil Section B Methods Used To Treat BS&W B-1. Overview of Treating Methodsgad48050% (2)

- Preparation of 4-Vinylbenzoic Acid by A Wittig Reaction in Aqueous MediumDocument9 pagesPreparation of 4-Vinylbenzoic Acid by A Wittig Reaction in Aqueous MediumohhiPas encore d'évaluation

- Multiple Choice LachingDocument3 pagesMultiple Choice Lachingraghu_iict100% (1)

- General Chemistry II USTHDocument12 pagesGeneral Chemistry II USTHNguyễn Phương ThảoPas encore d'évaluation