Académique Documents

Professionnel Documents

Culture Documents

SolGel Preparation of Lead Zirconate Titanate Powders and Ceramics Effect of Alkoxide Stabilizers An

Transféré par

Bis ChemCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SolGel Preparation of Lead Zirconate Titanate Powders and Ceramics Effect of Alkoxide Stabilizers An

Transféré par

Bis ChemDroits d'auteur :

Formats disponibles

See

discussions, stats, and author profiles for this publication at: http://www.researchgate.net/publication/215468341

SolGel Preparation of Lead Zirconate Titanate

Powders and Ceramics: Effect of Alkoxide

Stabilizers and Lead Precursors

ARTICLE in JOURNAL OF THE AMERICAN CERAMIC SOCIETY JANUARY 2000

Impact Factor: 2.61

CITATIONS

READS

29

463

4 AUTHORS, INCLUDING:

Paula Vilarinho

University of Aveiro

311 PUBLICATIONS 2,960 CITATIONS

SEE PROFILE

Available from: Paula Vilarinho

Retrieved on: 08 November 2015

journal

J. Am. Ceram. Soc., 83 [6] 1379 85 (2000)

SolGel Preparation of Lead Zirconate Titanate Powders and Ceramics:

Effect of Alkoxide Stabilizers and Lead Precursors

Aiying Wu, Paula M. Vilarinho, Isabel M. Miranda Salvado, and Joao L. Baptista*

Department of Ceramic and Glass Engineering, UIMC, University of Aveiro, 3810 Aveiro, Portugal

tetra-n-propoxide, and titanium tetra-isopropoxide.2,1115 Methoxyethanol (MOE) has been widely used as a solvent and stabilizer

for preparing PZT precursors, because of its chelating properties and

low viscosity.2,11,14 17 In more recent works, this toxic product has

been substituted by less hazardous solvents, such as propanediol,

acetic acid, acetone, and ethanolamine, also effective for preparing

PZT.3,4,12,13,18 20

For all of these PZT precursors, crystallization of the perovskite

phase occurs at temperatures ranging from 250 to 760C, depending on the zirconium content. As the zirconium content increases,

the perovskite crystallization temperature and the temperature at

which a single perovskite phase can be obtained increase. At

calcination temperatures of !600C, a homogeneous and stoichiometric PZT powder is obtained, whereas at 700C, a slight lead

deficiency occurs, adversely affecting the piezoelectric properties.7,21 To compensate for the lead loss, excess lead has been

widely used.6,15 However, excess PbO must be avoided in perovskite materials; the PbO excess either precipitates into the grain

boundary,21,22 damaging the electrical properties, or shifts the PZT

composition toward the titanium-lean side, because TiO2 has

higher solubility than ZrO2 in the PbO liquid phase.

The above-mentioned metal alkoxides used in synthesizing PZT

are very unstable, because of the high electropositive nature of the

metal atoms. Many works report that a controlled atmosphere (dry

argon or nitrogen gas) must be used to synthesize PZT.4,7,8

However, for industrial applications, ease of operation also should

be considered. Using some alkoxide stabilizers, which reduce the

reactivity of the metal alkoxides, enables synthesis in air.

For the present work, a series of perovskite PZT (52/48)

powders was prepared in air by the sol gel method, using a

non-MOE route and a stoichiometric starting composition. No

excess lead was used in the precursor. Because the choice of

precursors can affect the chemical-reaction kinetics, microstructures, and properties of the product, this paper compares the

crystallization behavior of PZT powders derived from different

precursors, stressing the influence of the alkoxide stabilizers and

the starting lead precursors on the phase assemblage of the

obtained products.

Detailed thermal analysis and X-ray diffractometry (XRD) were

conducted, and the relation between the preparation conditions and

the phase-forming process is described here. Dense ceramics were

prepared from the obtained submicrometer-sized PZT powders,

and the electrical properties of the sintered PZT ceramics were

measured and reported. The conditions required to obtain reasonably dense ceramics were experimentally set, and a preliminary

electrical characterization of these ceramics was undertaken. A

more detailed study of the nucleation and sintering process is

underway and will be reported in a later paper.

Lead zirconate titanate (PZT) (52/48) powders were prepared

by a sol gel process, using different raw materials to introduce

the lead component together with several solvents and chemical modifying agents. A study of the effect of these variables

on crystallization behavior was conducted to determine the

best conditions for preparing monophasic submicrometersized PZT perovskite powders in the morphotropic region. In

the present work, well-crystallized, submicrometer-sized

single-phase perovskite PZT powders were obtained after heat

treatment at 600C for 1 h. The dependence of this crystallization temperature on the preparation conditions was observed. The sol gel-derived submicrometer-sized PZT powders were sintered to !96% of relative density after 2 h at

950970C. The sintered ceramics exhibited a dielectric permittivity of 1000, a piezoelectric coefficient of 135 pC!N!1, a

remanent polarization of 20 "C!cm!2, and a coercive field of

10.6 kV!cm!1.

I. Introduction

(Pb(ZrxTi1x)O3 or PZT), with a

perovskite structure, is a piezoelectric ceramic widely used in

transducers, ferroelectric memories, sonars, optical filters, shutters,

actuators, and modulators.1

Various technological applications of PZT require a low sintering temperature for the ceramic. The typical sintering temperature

of PZT bulk ceramics is !1200C. In multilayer bulk stack

devices or integrated-memory thin-film capacitors, the different

layers and the substrate are cofired in one single step. Therefore,

low firing temperatures are desirable, to avoid interdiffusion

between layers and also to allow the use of inexpensive non-noblemetal-containing electrodes.

In contrast to the traditional mixed-oxide solid-state reaction

methods, wet chemical preparation allows mixing of the components at a molecular level, resulting in materials with high

compositional homogeneity and lower sintering temperatures.

Considerable work has been conducted on the chemical preparation of PZT powders and films, with different degrees of

success.29 A very recent report10 indicated that monophasic PZT

powders can be obtained at a nominal temperature of 450C from

a triethanolamine solution containing Pb2", Zr4", and Ti4" ions.

The obtained result is attributed to a high in situ temperature

caused by exothermic decomposition of the carbonaceous triethanolamine residue.

The alkoxide-based sol gel process is one of the most promising methods for synthesizing ceramic powders and, especially, films

at relatively low temperatures. The most commonly used starting

chemicals for PZT synthesis are lead acetate trihydrate, zirconium

EAD ZIRCONATE TITANATE

II.

Experimental Procedure

To study the effects of the starting chemicals, solvents, and

stabilizers on the sol gel formation of PZT (52/48) powders,

different reagents were used. Table I shows the starting chemicals,

together with solvents and stabilizers, used in the present work.

Acetic acid (HAc) and 1,2-propanediol were used to dissolve the

lead acetate. Acetylacetone (HAcAc) was used as a stabilizer for

W. A. Schulzecontributing editor

Manuscript No. 189316. Received June 1, 1999; approved November 11, 1999.

*Member, American Ceramic Society.

1379

1380

Journal of the American Ceramic SocietyWu et al.

Vol. 83, No. 6

Table I. Chemicals Used for the Preparation of PZT (52/48) Powders

Sample

designation

Chemicals to introduce

lead and solvents

Chemicals to introduce

titanium and stabilizers

Chemicals to introduce

zirconium and stabilizers

Pb(Ac)2!3H2O

1,2-Propanediol, HAc

Ti(i-Pr)4

HAcAc

Zr(n-Pr)4

HAc

Pb(Ac)2!3H2O

1,2-Propanediol, HAc

Ti(i-Pr)4

HAcAc

Zr(n-Pr)4

HAcAc

Pb(Ac)2!3H2O

1,2-Propanediol, HAc

Ti(i-Pr)4

HAcAc

Zr(n-Pr)4

HNO3

Pb(Ac)2!3H2O

1,2-Propanediol, HAc

Ti(i-Pr)4

HAcAc

Zr(n-Pr)4

1,2-Propanediol

CP1

Pb(NO3)2

Ethylene glycol

Ti(i-Pr)4

HAcAc

Zr(n-Pr)4

HNO3

CP2

Pb(NO3)2

Propanol, H2O

Ti(i-Pr)4

HAcAc

Zr(n-Pr)4

HNO3

CP3

Pb(NO3)2

H2O

Ti(i-Pr)4

HAcAc

Zr(n-Pr)4

HNO3

CP1, CP2, and CP3 are based on sample C but change the lead precursor and solvents.

the titanium alkoxide. Acetic acid, acetylacetone, nitric acid

(HNO3), and 1,2-propanediol were used as stabilizers for the

zirconium precursor compound. Ethylene glycol, 2-propanol, and

distilled water were used as solvents for the Pb(NO3)2. In each

sample, the ratio of Pb:Zr:Ti was always 1:0.52:0.48, and no

excess lead was added.

Figure 1 shows a flow chart of the synthesis process for the PZT

(52/48) powders. The obtained sols were maintained at 60C until

gelification occurred. The gels were dried at 120C for 24 h and

then crushed in an agate mortar and calcined in air between 400

and 800C for 1 h.

A Fourier transform infrared (FTIR) spectrometer with a resolution of 1 cm#1 (Model No. 7000, Mattson Technology, Inc.,

Fremont, CA) was used to study the structure of some precursors.

For FTIR analysis of the solutions, a small drop of the sol was

placed on a KBr disk, and the sample was analyzed after

evaporation. The powder samples were blended with KBr, pressed

into pellets, and analyzed.

Dried, crushed gels and calcined powders were analyzed by

XRD (Model No. Geigerflex D/Max-B, Rigaku Co., Ltd., Tokyo,

Japan). The enhanced resolution achieved through a longer counting time was used to detect the minor phases.23 Differential

thermal analysis (DTA) and thermogravimetric analysis (TGA)

(Model No. L18, Linseis International, Selb, Germany) were used

in conjunction with XRD to follow the decomposition and crystallization of the dried gels and powders. The average particle size

was measured using an instrument (Model No. ZetaSizer 4,

Malvern Instruments, Malvern, U.K.) equipped with a series 7032

Multi-8 Correlator and a scanning electron microscope (SEM;

Model No. S-4100, Hitachi, Co., Ltd., Tokyo, Japan) connected to

an image analysis system (Model No. Quantimet 500", Leica

Cambridge, Ltd., Cambridge, U.K.).

The calcined powders were isostatically pressed directly into a

disk shape at 200 MPa, without milling, and sintered at various

temperatures for 2 h in an oxygen atmosphere. To avoid lead losses

during the sintering step, a PbZrO3 powder was used to cover the

sample. The density of the ceramic samples was measured by the

Archimedes method. The dielectric properties were measured

using an impedance/gain-phase analyzer (Model No. 1260, Solartron Instruments, Farnborough, U.K.). Hysteresis curves were

obtained using a SawyerTower circuit at 60 Hz. The piezoelectric

coefficient (d33) was measured (Model No. CADT-3300 Piezo

d-meter, Berlincourt) at 60 Hz. Before the d33 value was measured,

the samples were poled with 4 kV/mm at 130C for 1 h and aged

for 24 h.

III.

Fig. 1.

Flow chart for the sol gel processing of PZT (52/48) powders.

Results and Discussion

(1) SolGel Formation

Transition-metal alkoxides are very reactive and experience

hydrolysis and condensation rapidly when water is added. Control

of the hydrolysis and condensation reaction is important in a

multicomponent system, such as PZT. Unequal hydrolysis and

condensation rates for each metal alkoxide result in phase separation during hydrolysis or thermal treatment. The preparation of

highly homogeneous gels, in which the various cations (lead,

zirconium, and titanium) are uniformly distributed at an atomic

scale through MOM$ bridges and that will have similar hydrolysis and condensation rates, requires chemical modification of the

starting alkoxides.

When titanium and zirconium alkoxides are added into a

solution to form a sol or a gel, precipitates often form. To provide

a stable and homogeneous sol, titanium and zirconium alkoxides

must be chemically modified.

(A) Stabilization of Titanium Alkoxide: HAcAc is effective

in stabilizing titanium alkoxides because the enolic form of

%-diketones contains a reactive hydroxy group that reacts readily

with metal alkoxides.24 In addition, the gelation behavior of

June 2000

SolGel Preparation of PZT Powders and Ceramics: Effect of Alkoxide Stabilizers and Lead Precursors

1381

Table II. Stabilizing Results for Zirconium Propoxide (Zr(n-Pr)4)

Stabilizers (molar ratio)

Zr(n-Pr)4

Zr(n-Pr)4

Zr(n-Pr)4

Zr(n-Pr)4

Fig. 2.

in

in

in

in

HAc (1:1)

HNO3 (1:1)

1,2-propanediol (1:11:5)

HAcAc (1:11:5)

Stirring for 30 min

Transparent solution

Transparent solution

Gelification

Turbid solution

IR spectra of Zr(n-Pr)4 modified with different stabilizers.

titanium alkoxides can be modified by HAc.24 In the present work

HAc, 1,2-propanediol, HAcAc, and 2-propanol were used as

stabilizers for titanium alkoxide. Clear and transparent sols were

obtained with all of these stabilizers, although HAcAc, suggested

to act as a chelating ligand with the formation of a stable titanium

compound,24 proved to be the most efficient.

(B) Stabilization of Zirconium Alkoxide: Although it has

been reported that HAcAc and HAc can also be used as stabilizers

for zirconium,19,24 in the present work, HNO3, as well as HAcAc,

1,2-propanediol, and HAc, were compared as stabilizers for

zirconium propoxide. The obtained results are listed in Table II,

which shows that HNO3 was the most efficient stabilizer for

zirconium, in agreement with previous results for the system

xZrO2!(100 x)SiO2.25 In the present work, a similar molar ratio,

HNO3/Zr & 1, was found sufficient to prepare homogeneous sols.

To obtain information on how the zirconium coordination

changes when different stabilizers are added, the infrared (IR)

spectra of Zr(n-Pr)4 modified with different stabilizers were

recorded; those results are shown in Fig. 2. The IR spectrum of

pure zirconium propoxide, without stabilizers, shows a band at

!1144 cm#1, attributed to the Zr(OC) stretching vibration of the

propoxy groups of zirconium propoxide.26

In the HAc-stabilized solution, the band at !1144 cm#1 is

much weaker. The HAc had partially substituted the alkoxy groups

of the zirconium alkoxide and formed acetate groups. According to

the literature,27,28 the set of two bands at !1500 cm#1 may result

from acetate ligands. The zirconium propoxide acetate was not

stable (Table II); the solution became more and more viscous and

Observations

24 h later

Transparent gel

Transparent solution

White precipitate

Yellow solution (1:1)

Precipitate (*1:1)

5 d later

Colorless gel

Transparent solution

White precipitate

Yellow gel

finally lost its fluidity, forming a clear gel after 24 h. Acetate

groups behaved, more likely, as bridging ligands (bonded to two

zirconiums) in the present work. The two IR bands at 1566 and

1450 cm#1 could result from 'COO-.28 This theory also could

explain the increase in viscosity with HAc-stabilized zirconium

solutions.

In a similar work, Yi and Sayer19 reported that the acetate

groups on zirconium propoxide acetate could probably be removed

by the alcohol created during the reaction, to form an ester. Based

on the present results, the band at !960 cm#1 can be assigned to

the '(CO) vibration of the propanol29 created in the reactions.

The formation of Zr-O-Zr links can cause gelation as time elapses.

In the spectrum of the 1,2-propanediol-stabilized zirconium

propoxide solution, the Zr(OC) stretching vibration band is still

present at 1144 cm#1, indicating that the alkoxy groups of

zirconium propoxide are not completely removed. In fact, the

spectrum is very similar to that of pure Zr(n-Pr)4. A small band at

720 cm#1 might be assigned to the Zr-O-Zr linkage formed,30 and

this result indicates that 1,2-propanediol is not effective in stabilizing this alkoxide, confirming the results reported in Table II,

although a dihydroxy alcohol (diol) has been mentioned to be

sufficiently reactive with metal alkoxides to form the corresponding glycolate or mixed alkoxide glycolate derivatives.26

In the spectrum of the HAcAc-stabilized zirconium propoxide

solution, the band at !1144 cm#1 still appears, and two bands at

!1600 and 1530 cm#1 are observed. These bands could indicate

that the alkoxy groups of zirconium propoxide Zr(OC) are only

partially removed and that a zirconium tripropoxide monoacetylacetonate chelate (bands at 1600 and 1530 cm#1) has formed.31

However, it has been observed (Table II) that precipitation occurs

after zirconium propoxide is mixed with HAcAc. The IR spectrum

of the isolated precipitates shows that the structure of zirconium

acetylacetonate is present, as indicated by comparison with an IR

spectrum obtained for pure zirconium acetylacetonate (ZrAcAc,

Merck, Darmstadt, Germany) (Fig. 3).Therefore, zirconium acetylacetonate may form in this condition:

Zr(OC3H7) 4 "xCH3COCH2COCH33

(CH3COCHCOCH3) x Zr(OC3H7) 4#x "xC3H7OH (1)

(CH3COCHCOCH3)xZr(OC3H7)4#x"(4#x)CH3COCH2COCH33

(CH3COCHCOCH3)4Zr"(4#x)C3H7OH (2)

Zirconium acetylacetonate has a poor solubility in the propanol

formed during the reaction (see band at !960 cm#1, Fig. 3), which

explains the observed precipitation.

In the spectrum obtained for the HNO3-stabilized solution, the

Zr(OC) stretching vibration band disappears, indicating that the

propoxy groups of zirconium propoxide are no longer bonded to

the zirconium cation in the same way. The NO2 vibration bands

(1697, 1311, and 660 cm#1), NO$ stretch (902 cm#1), and the

ONO$ bend band (597 cm#1) of free HNO332 are not observed.

Thus, the zirconium propoxide and HNO3 have reacted to form a

new complex ligand, which is rather stable. In fact, the solution

stabilized with HNO3 is still clear and fluid, with low viscosity

(0.009 Pa!s) after 5 d (Table II).

(2) Phase Development

(A) Effect of Stabilizers: The influence of the chemicals used

to modify the stability of the zirconium alkoxide on the phase

1382

Journal of the American Ceramic SocietyWu et al.

Vol. 83, No. 6

Fig. 3. IR spectra of the Zr(AcAc)4 powder and the precipitates isolated

from the turbid solution of Zr(n-Pr)4 with HAcAc.

development of the PZT powder also was studied. The crystallization behavior of the different gels was followed by thermal

analysis and XRD. The DTA and TGA results for the dried gels,

together with the XRD results, indicated the critical temperature

ranges for the removal of organic species and for crystallization of

the pyrochlore and perovskite phases.

In the temperature range 200 400C, all of the samples show

several exothermic peaks in the DTA curves (Fig. 4). The TGA

curves present marked weight losses in this temperature region.

The XRD results (Fig. 5) for all of the samples treated at

temperatures +400C evidence amorphous structures (except for

sample B and CP3, which will be discussed later). By combining

the DTA, TGA, and XRD results (Figs. 4 and 5), the DTA peaks

in this temperature range can be attributed to the decomposition of

most of the organic species. The different temperatures, intensities,

and shapes of the thermal peaks probably are related to the

Fig. 4.

Fig. 5. XRD patterns of dried gels (sample A) heat-treated at different

temperatures (other gels, except gel B and CP3, have similar XRD patterns

versus temperature).

different natures of the organic species and, consequently, caused

by the removal of species differently bounded in the network.

In the temperature range 400 600C, two exothermic peaks

are observed in the DTA curves of all of the samples (except for

samples B and CP3). In this region, the samples present a more

gradual weight loss. The XRD results reveal the coexistence of a

pyrochlore phase and a perovskite-type phase at 450C, for all of

the samples. When the calcination temperature is increased, the

pyrochlore phase is gradually eliminated, and the amount and

degree of crystallization of the perovskite phase increases. Thus,

the exothermic peak at !400 450C (415C for sample CP1,

426C for sample A, 440C for sample C, 447C for sample CP2,

(a) DTA and (b) TGA spectra of dried gels (heating rate of 5C/min).

June 2000

SolGel Preparation of PZT Powders and Ceramics: Effect of Alkoxide Stabilizers and Lead Precursors

Fig. 6. XRD patterns of gels derived from different stabilizers for

zirconium, calcined at 600C for 1 h.

and 434C for sample D) may be caused by crystallization of the

pyrochlore phase, and the last exothermic peak at 497570C

(497C for sample CP1, 515C for sample A, 548C for sample C,

563C for sample D, and 568C for sample CP2) may result from

perovskite phase crystallization, both probably accompanied by

the decomposition of organic residuals.

At temperatures *600C, according to DTA and TGA results,

the chemical reactions are complete. However, the complete

transformation of the pyrochlore to the perovskite phase seems to

differ for the differently prepared samples, depending on the

precursor chemicals used for each preparation, as evidenced by the

XRD results.

Figure 6 illustrates the powder phase assemblage obtained from

the gels prepared with different zirconium stabilizers after calcination at 600C for 1 h (samples A, B, C, and D). A perovskite

phase with less second phase was obtained when HNO3 was used

to stabilize the zirconium precursor.

Although HAcAc is very efficient for stabilizing titanium, it did

not work as well as HNO3 in stabilizing zirconium under the

present experimental conditions. The thermal behavior of sample

B was different from that of the other samples in the temperature

range 400 600C. The DTA spectra of sample B (Fig. 4(a)) show

only one peak in this temperature range, whereas the other sample

spectra show two peaks, suggesting different crystallization behavior for gel B. Indeed, for sample B, segregation and subsequent

multicrystallization occurred during the drying of the gel; the

phases ZrTiO4, ZrO2, TiO2, and Ti3.2Pb0.8 already were observed

in the dried gels. After calcination, a single-phase perovskite PZT

was difficult to obtain from this gel, even at temperatures as high

as 800C.

(B) Effect of Lead Precursor and Solvent Used to Dissolve

Pb(NO3)2: Two lead precursors, lead acetate and lead nitrate,

were used in the present work, and their effect on the final powder

phase assemblage was analyzed. The XRD pattern of these

samples calcined at 600C revealed a pure perovskite phase for

sample CP1 (within the detection limits of the equipment) and

small amounts of pyrochlore, together with the perovskite phase,

for sample C (Fig. 7).

In the DTA spectra of samples C and CP1 (Fig. 4(a)), the last

exothermic peak of the sample derived from Pb(Ac)2!3H2O (sample C) occurred at higher temperatures (548C) than that of the

sample derived from Pb(NO3)2 (sample CP1) (497C), which

seems to correlate with the ease of formation for the PZT

perovskite phase.

Dissolution of Pb(NO3)2 into different solvents also influenced

the phase-assemblage development. Figure 8 shows the XRD

patterns of PZT gels prepared using lead nitrate, with different

solvents, after calcination at 600C for 1 h. Samples CP2 and CP3,

1383

Fig. 7. XRD patterns of gels derived from different chemicals used to

introduce lead, calcined at 600C for 1 h.

in which 2-propanol plus water and water alone were used,

respectively, to dissolve the lead nitrate, did not form a pure

perovskite PZT, even after calcination for 1 h at 800C. In the

dried CP3 gel, in which water only was used as a solvent,

Pb(NO3)2 and PbTiO3 segregated out from the precursor gel.

However, when ethylene glycol was used as a solvent for lead

nitrate (sample CP1), the pure PZT perovskite phase was obtained

at 600C. The differences observed are probably attributable to the

polar nature of the solvents, because water and 2-propanol plus

water are much more polar than ethylene glycol. The formation of

(Zr(n-Pr)4)n (n ! 4) oligomers is favored in a nonpolar solvent,

and oligomeric species are less reactive than their monomers.33

Furthermore, the hydrolysis of a transition-metal alkoxide is an SN2

(nucleophilic substitution) reaction, and the polarity of the solvent

medium also has an effect on the reaction rate.33 The solvents used

for the lead precursor may, in this way, interfere with the

hydrolysis rate of the different components of this multicomponent

system, causing phase segregation when more polar solvents are

used.

(3) Characteristics of SolGel-Derived Ceramics

After calcination, the powders have similar morphologies, as

shown in Fig. 9. They consist of small agglomerates of fine

particles that are easily broken after dispersal in water by ultrasonic agitation. The individual particles have sizes of !30 60 nm,

and the agglomerates measure 200 300 nm (Fig. 9).

Fig. 8. XRD patterns of Pb(NO3)2-derived gels prepared with different

solvents, calcined at 600C for 1 h.

1384

Journal of the American Ceramic SocietyWu et al.

Fig. 9.

Vol. 83, No. 6

SEM photographs of PZT powders of sample CP1: (a) as-calcined powder and (b) after dispersal in water.

Table III. Dielectric and Piezoelectric Properties of PZT Ceramics Derived from Powder CP1

r

tan ,

d33 (pC!N#1)

1060

1130

1100

1080

1070

1050

1010

0.0001

0.0252

0.0124

0.0102

0.0125

0.0245

0.1518

135 (60 Hz)

20 (60 Hz)

730 (Ref. 34)

0.008 (Ref. 9)

121 (Ref. 9)

1728 (Ref. 35)

Frequency

1 Hz

10 Hz

100 Hz

1 kHz

10 kHz

100 kHz

1 MHz

Literature values

Pr (-C!cm#2)

Ps (-C!cm#2)

Ec (kV!cm#1)

38.3 (60 Hz)

10.58 (60 Hz)

814 (Ref. 35)

Sintered at 970C for 2 h.

The submicrometer-sized PZT powders derived from the CP1

gel calcined at 600C for 1 h were used to prepare PZT ceramics.

Dense ceramics were obtained (!96% of theoretical density) after

sintering for 2 h at temperatures between 950 and 970C. A

weight loss of !1.5% was observed.

The dielectric and piezoelectric properties of the samples

sintered at 970C for 2 h are shown in Table III. The dielectric

constants (r) of CP1-derived PZT ceramics in the frequency range

1 Hz1 MHz are !1000. The dielectric loss (tan ,) of these

ceramics is close to 0.01 in the frequency range 100 Hz1 kHz.

Compared with traditionally prepared PZT ceramics,34 the present

ceramic shows a higher dielectric constant, possibly related to its

dense microstructure and, because no excess lead oxide was used,

the absence of a lead-rich intergranular phase. Excess lead oxide

used to control the stoichiometry of a lead-based perovskite may

form an intergranular phase rich in lead, which damages the

dielectric permittivity of the ceramic.21,22 The present piezoelectric coefficient (d33) is slightly lower than that of conventionally

prepared PZT ceramics.34 The remanent polarization (Pr) and

coercive field (Ec), calculated from the hysteresis loop, are all in

agreement with literature values.35

IV.

Summary

The sol gel processing of PZT powders involves numerous

variables, namely the starting reagents and types of solvents and

stabilizers, which affect the hydrolysis and condensation reaction

of the metal alkoxides and, consequently, the final phase assemblage, morphology, microstructure, and properties of the material.

In the present study, we investigated the role of the starting

chemicals that introduce the lead component, the role of their

solvents, and the role of the zirconium precursor stabilizers on PZT

perovskite phase formation. The substitution of Pb(Ac)2!3H2O,

widely used in the preparation of PZT powders, by Pb(NO3)2,

together with the use of HNO3 as a stabilizer for the zirconium

alkoxide and ethylene glycol as a solvent for the lead nitrate,

allowed the formation of the pure perovskite PZT phase at lower

temperatures (!600C).

Although the pure perovskite PZT phase does not form directly

from the precursor solution, achievement of the desired phase at a

low calcination temperature seems to be related to the ability to

maintain, in such a multicomponent system, the highest possible

degree of homogeneity in solution, during the gelification process,

in order to avoid precipitation and dissociation from the atomic

mixture level attainable in solution.

The high reactivity of sol gel-derived submicrometer-sized

PZT powders enables them to lower the sintering temperature of

ceramics. The ceramics derived from these powders exhibit a high

dielectric constant, 1000 at room temperature, and piezoelectric

and ferroelectric characteristics similar to those mentioned in the

literature.

The simplicity of the process described here, together with the

low temperatures of phase formation and sintering, could eventually lead to an attractive method for the industrial fabrication of

PZT materials. A more detailed study of the nucleation and

sintering process is underway and will be reported in a later paper.

Acknowledgments

The authors thank the Portuguese FCT (Foundation for Science and Technology)

for financial support. A. W. thanks the Portuguese Program PRAXIS XXI for

Maintenance Grant No. Praxis XXI/BD/9007/96.

References

1

R. C. Buchanan, Ceramic Materials for Electronics, 2nd ed.; p.182. Marcel

Dekker, New York, 1991.

June 2000

SolGel Preparation of PZT Powders and Ceramics: Effect of Alkoxide Stabilizers and Lead Precursors

2

C. D. E. Lakeman and D. A. Payne, Processing Effects in the SolGel

Preparation of PZT-Derived Gels, Powders, and Ferroelectric Thin Layers, J. Am.

Ceram. Soc., 75 [11] 309196 (1992).

3

M. L. Calzada and S. J. Milne, Lead Zirconate Titanate Films from a Diol-Based

SolGel Method, J. Mater. Sci. Lett., 12, 122123 (1993).

4

Y. Takahashi, Y. Matsuoka, K. Yamaguchi, M. Matsuki, and K. Kobayashi, Dip

Coating of PT, PZ, and PZT Films Using an Alkoxide-Diethanolamine Method, J.

Mater. Sci., 25, 3960 64 (1990).

5

R. Zimmermann-Chopin and S. Auer, Spray Drying of SolGel Precursors for the

Manufacturing of PZT Powders, J. SolGel Sci. Technol., 3, 101107 (1994).

6

C. T. Lin, B. W. Scanlan, J. D. McNeill, J. S. Webb, L. Li, R. A. Lipeles, P. M.

Adams, and M. S. Leung, Crystallization Behavior in a Low-Temperature Acetate

Process for Perovskite PbTiO3, Pb(Zr,Ti)O3, and (Pb1x,Lax)(Zry,Ti1y)1x/4O3 bulk

Powders, J. Mater. Res., 7 [9] 2546 54 (1992).

7

B. Malic and M. Kosec, Electron Microscope Study of Alkoxide-Derived

Compositions within the PbZrO3PbTiO3 Phase Diagram, J. SolGel Sci. Technol.,

2, 443 46 (1994).

8

S. P. Faure, P. Barboux, P. Gaucher, and J. P. Ganne, Synthesis of Ferroelectric

Thin Films and Ceramics from Solution Processes, Ferroelectrics, 128, 19 24

(1992).

9

B. G. Muralidharan, A. Sengupta, G. S. Rao, and D. C. Agrawal, Powders of

Pb(ZrxTi1x)O3 by SolGel Coating of PbO, J. Mater. Sci., 30, 323137 (1995).

10

R. Das, A. Pathak, and P. Pramanik, Low-Temperature Preparation of Nanocrystalline Lead Zirconate Titanate and Lead Lanthanum Zirconate Titanate Powders

Using Triethanolamine, J. Am. Ceram. Soc., 81 [12] 3357 60 (1998).

11

J. S. Kim, D. S. Yoon, and K. No, Physical and Electrical Properties of

MnO2-Doped Pb(ZrxTi1x)O3 Ceramics, J. Mater. Sci., 29, 6599 603 (1994).

12

C. Livage, A. Safari, and L. C. Klein, Glycol-Based SolGel Process for the

Fabrication of Ferroelectric PZT Thin Films, J. SolGel Sci. Technol., 2, 605 609

(1994).

13

G. Yi, Z. Wu, and M. Sayer, Preparation of Pb(Zr,Ti)O3 Thin Films by SolGel

Processing: Electrical, Optical, and Electro-Optic Properties, J. Appl. Phys., 64 [5]

271724 (1988).

14

C. J. Kim, D. S. Yoon, J. S. Lee, C. G. Choi, W. J. Lee, and K. No, Electrical

Characteristics of (100), (111), and Randomly Aligned Lead Zirconate Titanate Thin

Films, J. Appl. Phys., 76 [11] 7478 82 (1994).

15

J. Chen, M. P. Harmer, and D. M. Smyth, Compositional Control of Ferroelectric Fatigue in Perovskite Ferroelectric Ceramics and Thin Films, J. Appl. Phys., 76

[9] 5394 98 (1994).

16

L. M. Reaney, K. Brooks, R. Klissuraka, C. Pawlaczyk, and N. Setter, Use of

Transmission Electron Microscopy for the Characterization of Rapid Thermally

Annealed, SolutionGel, Lead Zirconate Titanate Films, J. Am. Ceram. Soc., 77 [5]

1209 16 (1994).

17

V. K. Seth and W. A. Schulze, Fabrication and Characterization of Ferroelectric

PLZT 7/65/35 Ceramic Thin Films and Fibers, Ferroelectrics, 112, 283307 (1990).

1385

18

A. Wu, I. M. Miranda Salvado, P. M. Vilarinho, and J. L. Baptista, Lead

Zirconate Titanate Prepared from Different Zirconium and Titanium Precursors by

SolGel, J. Am. Ceram. Soc., 81 [10] 2640 44 (1998).

19

G. Yi and M. Sayer, An Acetic Acid/Water-Based SolGel PZT Process, I:

Modification of Zr and Ti Alkoxide with Acetic Acid, J. SolGel Sci. Technol., 6,

6574 (1996).

20

T. Fukui, C. Sakurai, and M. Okuyama, Preparation of Pb(ZrxTi1x)O3 powders

from Complex Alkoxides and Their Lower-Temperature Crystallization, J. Mater.

Res., 7 [4] 79194 (1992).

21

M. Villegas, C. Moure, J. R. Jurado, and P. Duran, Processing and Properties of

Pb(Mg1/3Nb2/3)O3PbZrO3PbTiO3 Ceramic Relaxors, J. Mater. Sci., 29, 4975 83

(1994).

22

K. Kakegawa, O. Matsunaga, T. Kato, and Y. Sasaki, Compositional Change

and Compositional Fluctuation in Pb(Zr,Ti)O3-Containing Excess PbO, J. Am.

Ceram. Soc., 78 [4] 107175 (1995).

23

J. A. T. Taylor, Microphase Detection Using XRD, Am. Ceram. Soc. Bull., 74

[6] 81 82 (1995).

24

C. Sanchez, J. Livage, M. Henry, and F. Babonneau, Chemical Modification of

Alkoxide Precursors, J. Non-Cryst. Solids, 100, 56 76 (1988).

25

I. M. Miranda Salvado, Preparation and Characterization of Materials in the

System of ZrO2SiO2, TiO2SiO2, and Al2O3SiO2. Application as Coatings; Ph.D.

Thesis. University of Aveiro, Portugal, Spain, 1990.

26

D. C. Bradley, R. C. Mehrotra and D. P. Gaur, Metal Alkoxides. Academic Press,

New York, 1978.

27

K. Nakamoto, Infrared and Raman Spectra of Inorganic and Coordination

Compounds, 4th ed.; pp. 23139. Wiley, New York, 1986.

28

S. Doeuff, M. Henry, C. Sanchez, and J. Livage, Hydrolysis of Titanium

Alkoxides: Modification of the Molecular Precursor by Acetic Acid, J. Non-Cryst.

Solids, 89, 206 16 (1987).

29

C. J. Pouchert, The Aldrich Library of Infrared Spectra, 2nd ed. Aldrich

Chemical Company, Milwaukee, WI, 1975.

30

Y. Kanno and T. Suzuki, Synthesis of Fine Spherical ZrO2SiO2 Particles by

Ultrasonic Spray Pyrolysis, J. Mater. Sci. Lett., 7, 386 88 (1988).

31

U. B. Saxena, A. K. Rai, V. K. Mathur, R. C. Mehrotra, and D. Radford,

Reaction of Zirconium Isopropoxide with %-diketones and %-keto-Esters, J. Chem.

Soc. (A), 904 907 (1970).

32

W. A. Guillory and M. L. Bernstein, Infrared Spectral Frequencies for Matrix

Nitric Acid in an N2 Matrix, J. Chem. Phys., 62, 1059 (1975).

33

C. J. Brinker and G. W. Scherer, SolGel Science: The Physics and Chemistry of

SolGel Processing. Academic Press, San Diego, CA, 1990.

34

B. Jaffe, W. R. Cook Jr., and H. Jaffe, Piezoelectric Ceramics; pp. 145 48.

Academic Press, New York, 1971.

35

T. Yamamoto, Optimum Preparation Methods for Piezoelectric Ceramics and

Their Evaluation, Am. Ceram. Soc. Bull., 71 [6] 978 85 (1992).

"

Vous aimerez peut-être aussi

- Great Orthogonality TheoremDocument6 pagesGreat Orthogonality TheoremBis ChemPas encore d'évaluation

- Mo (CN) 8Document17 pagesMo (CN) 8Bis ChemPas encore d'évaluation

- Solvation ModelsDocument66 pagesSolvation ModelsBis ChemPas encore d'évaluation

- ch1 PDFDocument2 pagesch1 PDFBis ChemPas encore d'évaluation

- GCEMDocument42 pagesGCEMBis ChemPas encore d'évaluation

- CHARMMDocument189 pagesCHARMMBis ChemPas encore d'évaluation

- Researchers in An Entropy Wonderland: A Review of The Entropy ConceptDocument29 pagesResearchers in An Entropy Wonderland: A Review of The Entropy ConceptBis ChemPas encore d'évaluation

- Central Universities Common Entrance Test (Cucet) - 2013: Time Table Entrance Tests For PG ProgrammesDocument4 pagesCentral Universities Common Entrance Test (Cucet) - 2013: Time Table Entrance Tests For PG ProgrammesBis ChemPas encore d'évaluation

- Book TextDocument12 pagesBook TextBis ChemPas encore d'évaluation

- 12 March 2013 16:17: Unfiled Notes Page 1Document3 pages12 March 2013 16:17: Unfiled Notes Page 1Bis ChemPas encore d'évaluation

- Molecular Dynamics Simulations Reveal The Mechanisms of Allosteric Activation of Hsp90 by Designed LigandsDocument13 pagesMolecular Dynamics Simulations Reveal The Mechanisms of Allosteric Activation of Hsp90 by Designed LigandsBis ChemPas encore d'évaluation

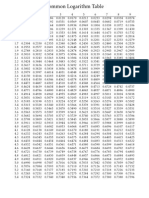

- Common Log TableDocument2 pagesCommon Log TableBis ChemPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Alternative To Practical Ig1Document10 pagesAlternative To Practical Ig1Sandeep NehraPas encore d'évaluation

- Bill of Material: 103PW2 - PL5/16"X4" - 1'-3" - 2 REQ'DDocument1 pageBill of Material: 103PW2 - PL5/16"X4" - 1'-3" - 2 REQ'Dai ambaraPas encore d'évaluation

- Bollard Column Base Plate (Fixed Type)Document15 pagesBollard Column Base Plate (Fixed Type)GANESHPas encore d'évaluation

- Normal ResistivityDocument1 pageNormal ResistivityShahzad KhanPas encore d'évaluation

- Bumper Systems - An IntroductionDocument25 pagesBumper Systems - An IntroductionMichaelPas encore d'évaluation

- 2nd Year Chemistry Important Questions PDFDocument4 pages2nd Year Chemistry Important Questions PDFHemanshu Ghanshani80% (15)

- Structural Geology and Rock Mechanics-3Document23 pagesStructural Geology and Rock Mechanics-3francessich0% (1)

- 11 Heat and Material BalanceDocument26 pages11 Heat and Material BalanceCristhofer HernandezPas encore d'évaluation

- Types of EvporatorsDocument18 pagesTypes of EvporatorsJaya Aravinth RajPas encore d'évaluation

- Outline SpecsDocument171 pagesOutline Specsmohamed fawzyPas encore d'évaluation

- Heat Intake LabDocument3 pagesHeat Intake LabTajay BillingsPas encore d'évaluation

- Mineral Processing Lab ManualDocument11 pagesMineral Processing Lab ManualChimwemwe KaongaPas encore d'évaluation

- Anna Sheryl F. Dimacali-Le-Science-5-Q1-Wk-3-5Document6 pagesAnna Sheryl F. Dimacali-Le-Science-5-Q1-Wk-3-5Anna Sheryl DimacaliPas encore d'évaluation

- The Powder Coaters ManualDocument209 pagesThe Powder Coaters ManualOvation Audio Labs100% (4)

- Spent Bleaching Earth Sbe The Hidden Treasure From Waste of The Palm Oil Refinery PlantDocument6 pagesSpent Bleaching Earth Sbe The Hidden Treasure From Waste of The Palm Oil Refinery PlantAgustina TriyaniPas encore d'évaluation

- PolymorphismDocument14 pagesPolymorphismPrem SinghPas encore d'évaluation

- S001Document1 pageS001Yong Hui OngPas encore d'évaluation

- General Chemistry Grade 12 ModuleDocument86 pagesGeneral Chemistry Grade 12 ModuleprincessssmtlbPas encore d'évaluation

- Science6 - q1 - Mod1les3 - Factors Affecting Solubility - EDITEDDocument10 pagesScience6 - q1 - Mod1les3 - Factors Affecting Solubility - EDITEDGene-Beth Cacho Garce50% (2)

- 175 026510Document2 pages175 026510Abu Anas M.SalaheldinPas encore d'évaluation

- Cascade Data Sheet PDFDocument28 pagesCascade Data Sheet PDFvisutsiPas encore d'évaluation

- Marvets Eric PaulDocument44 pagesMarvets Eric PaulEugenu DragoescuPas encore d'évaluation

- 7 The Mole ConceptDocument8 pages7 The Mole ConceptCris CorsinoPas encore d'évaluation

- Coordination CompoundsDocument8 pagesCoordination CompoundsAbhishek SharmaPas encore d'évaluation

- 4024q1 Specimen PaperdocxDocument12 pages4024q1 Specimen PaperdocxLeses MayPas encore d'évaluation

- Earth Pressures CoulombDocument15 pagesEarth Pressures CoulombDhananjay ShahPas encore d'évaluation

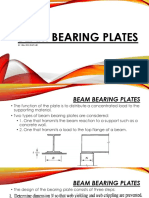

- 7-B. Beam Bearing PlatesDocument14 pages7-B. Beam Bearing PlatesMelchizedek EllPas encore d'évaluation

- Understanding Sour Service Performace of Coiled TubingDocument12 pagesUnderstanding Sour Service Performace of Coiled TubingMubeenPas encore d'évaluation

- Coating Thickness GaugesDocument5 pagesCoating Thickness GaugesSheikh Muhammad AsifPas encore d'évaluation

- Novolastic Subsea Thermal InsulationDocument3 pagesNovolastic Subsea Thermal InsulationCarloBardoliPas encore d'évaluation