Académique Documents

Professionnel Documents

Culture Documents

AMT Case Study

Transféré par

jjdduntCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

AMT Case Study

Transféré par

jjdduntDroits d'auteur :

Formats disponibles

Case Study: Yanacocha Mine

Newmont Yanacocha Mine

system to create a seamless equipment management

Customer Profile

the ERP, AMT is used to create life cycle maintenance

Newmonts Minera Yanacocha (Yanacocha Mine), is

continually updated with the latest infor mation from

one of the largest gold mines in South America

delivering 49% of Perus annual gold production. It is

also one of the highest at 4,100 meters above sea

level. The mine is located in Peruvian Andes, some 48

kilometers north of the city of Cajamarca. It consists

of five open pit mines, four leach pads and three gold

recovery plants with a forth plant coming on line in

solution. Leveraging the information already held in

projections for each asset. These projections are

work orders to produce a forecast of the assets life

cycle cost. In addition, the availability and required

labour, components and other resources required are

included in the forecast.

Graeme Elgie, Managing Director of iSolutions talks

about AMTs life cycle methodology.

2008. The mine produces around 1.6 million ounces

This methodology forms the basis of the

annually.

maintenance budget. By collecting maintenance

information against each maintenance task instead of

buried in work orders, you gain a much greater

understanding of the performance of individual

systems and components. This understanding helps

maintenance managers optimise the budget,

understand cost drivers and reduce the life cycle cost

of the asset.

To continually improve equipment productivity and

drive down the cost of maintenance, Newmont

needed a smarter approach to equipment

management.

Why AMT?

While Yanacocha utilised an ERP (Enterprise Resource

Planning) system to handle work order transactions,

inventory management and basic maintenance

planning, there was no easy way to produce and

analyse a first principles maintenance budget. The

previous method of trawling through reams of

transactional data in spreadsheets was cumbersome

and prone to error. To combat rising costs and

quickly understand changes to budget conditions, a

new approach was required.

To plug the systems gap, Yanacocha management

chose to implement iSolutions AMT Equipment

Management Tool. AMT is integrated with

Yanacochas ERP work order and daily planning

`

Phone +61 2 9966 9096

sales@isipl.com

Web

www.isipl.com

Case Study: Yanacocha Mine

Once the base projections are built, a maintenance

the long term resource plans, assess the impact of

budget can be quickly and easily produced with

changes to the maintenance strategy as well as

greater accuracy than before. A process that may

determine the optimal life for assets.

have taken up to a week to complete can be done in

an hour with the ability to audit and validate of the

results.

By performing their jobs, completing work orders

and updating the maintenance plan, the mechanics

and planners are helping complete the budget

process and improve maintenance performance.

Without a tool like AMT it would be very difficult to

produce a maintenance budget as quickly or as

accurately. - Graeme Robinson, Mobile

Maintenance Superintendent

Once the budget is complete, there are a suite of

tools to analyse and improve maintenance

performance. One such tool is the compliance to plan

method. The compliance to plan method not only

These tools are built in to AMT and provide a

structured way to optimise maintenance expenditure

and improve productivity.

On the back of the success of AMT at Yanacocha,

Newmont have since deployed AMT in both the USA,

Australia and Indonesia.

Key Points

Improved maintenance budget

development cycle from weeks to days

Reduce life cycle cost of equipment by

identifying cost saving opportunities

Tight integration with ERP system to

provide seamless solution

looks at the maintenance expenditure, but also looks

at where the money was spent on a component by

component basis.

Contact iSolutions

Of course the budgeting module of AMT is only one

Telephone

+61 2 9966 9096

part of a well-rounded suite of maintenance

sales@isipl.com

Web

www.isipl.com

management tools. The very task of setting up

detailed life cycle projections for assets allows users

to dynamically review the equipment strategy, review

About iSolutions

iSolutions is a leading provider of asset management

Our solutions are used across mining and construction

solutions to mining and construction companies.

assets to improve equipment uptime and long term

Our flagship software package, AMT, utilises the

productivity, and to reduce life cycle costs.

Framework methodology and is recognised as a market

With offices in Australia and South Africa, we have a

leader in maintenance management, life cycle costing,

proven track record managing large, global projects.

budgeting and maintenance strategy optimisation.

Our blue chip customers include; Caterpillar Dealers,

Established in 1997, we specialise in providing mining

Newmont Mining, Downer EDI Mining, Newcrest Mining,

companies, OEMs, dealers and contractors with the know-

Komatsu, Wesfarmers, Glencore and BHP Billiton.

how, processes, systems and training to achieve Asset

Management Excellence.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Failure Modes, Effects and Criticality Analysis (FMECA)Document75 pagesFailure Modes, Effects and Criticality Analysis (FMECA)Nguyễn Thanh SơnPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Chrysler Line Balancing Case Study PDFDocument3 pagesChrysler Line Balancing Case Study PDFjjdduntPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Chrysler Line Balancing Case Study PDFDocument3 pagesChrysler Line Balancing Case Study PDFjjdduntPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Isbn9780987179913 Landscape PDFDocument22 pagesIsbn9780987179913 Landscape PDFjjdduntPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Isbn9780987179913 Landscape PDFDocument22 pagesIsbn9780987179913 Landscape PDFjjdduntPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Isbn9780987179913 Landscape PDFDocument22 pagesIsbn9780987179913 Landscape PDFjjdduntPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- SmartFlow For Composites Manufacturing CenterDocument15 pagesSmartFlow For Composites Manufacturing CenterjjdduntPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- N G Ày 2 0 T H Á NG B A N Ă M 2 0 2 0: Brand ManagementDocument10 pagesN G Ày 2 0 T H Á NG B A N Ă M 2 0 2 0: Brand ManagementThịnh NguyễnPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Game World History PDFDocument26 pagesGame World History PDFprayudha pratriesyaPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Urban Jungle 8Document3 pagesUrban Jungle 8Angel Medez GonzalezPas encore d'évaluation

- Introduction To Parallel Programming 1st Edition Pacheco Solutions ManualDocument5 pagesIntroduction To Parallel Programming 1st Edition Pacheco Solutions Manualyvonnewelchdoafexwzcs100% (11)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Case Analysis: A Simple Strategy at Costco: Informative Background InformationDocument15 pagesCase Analysis: A Simple Strategy at Costco: Informative Background InformationFred Nazareno CerezoPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Chem 111a - Activity No. 2Document5 pagesChem 111a - Activity No. 2MARY KATE FATIMA BAUTISTAPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Desktop Window Manager: DWM Overviews DWM Reference DWM Sample CodeDocument3 pagesDesktop Window Manager: DWM Overviews DWM Reference DWM Sample Codekris_onlinePas encore d'évaluation

- Yosys+Nextpnr: An Open Source Framework From Verilog To Bitstream For Commercial FpgasDocument4 pagesYosys+Nextpnr: An Open Source Framework From Verilog To Bitstream For Commercial FpgasFutsal AlcoletgePas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- DocumentDocument2 pagesDocumentAddiePas encore d'évaluation

- Material Submission Form Register - STR (20210929)Document1 pageMaterial Submission Form Register - STR (20210929)HoWang LeePas encore d'évaluation

- Topic 7Document18 pagesTopic 7Anonymous 0fCNL9T0Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- BOOK2Document201 pagesBOOK2Chetan Satish PadolePas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Cover LetterDocument2 pagesCover LetterSasi Gangadhar BPas encore d'évaluation

- ALLOY 7150-T7751 PLATE AND 7150-T77511 EXTRUSIONS: Alcoa Mill ProductsDocument4 pagesALLOY 7150-T7751 PLATE AND 7150-T77511 EXTRUSIONS: Alcoa Mill Productshitesh_tilalaPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Union of India v. Mohit Minerals Pvt. LTD.-GST Validity AnalysisDocument4 pagesUnion of India v. Mohit Minerals Pvt. LTD.-GST Validity Analysissandhya parimalaPas encore d'évaluation

- Istqb Agile Tester Learning Objectives SingleDocument3 pagesIstqb Agile Tester Learning Objectives SingleSundarPas encore d'évaluation

- Pythonbiogeme: A Short Introduction: Michel Bierlaire July 6, 2016Document19 pagesPythonbiogeme: A Short Introduction: Michel Bierlaire July 6, 2016asasdasdPas encore d'évaluation

- Freelance Contract AgreementDocument10 pagesFreelance Contract AgreementGayathri Prajit100% (1)

- 2000B - Row - Crop - Parts - F-247-0512 - 031214 Model 2000 SeriesDocument48 pages2000B - Row - Crop - Parts - F-247-0512 - 031214 Model 2000 SeriesvanchinatanyaPas encore d'évaluation

- Sick - Photoelectric 4-180 MM v2Document7 pagesSick - Photoelectric 4-180 MM v2Muhammad SumeetPas encore d'évaluation

- Nacc NCCRDocument6 pagesNacc NCCRChaitra Gn100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Degree 21-22 INTERNSHIPDocument4 pagesDegree 21-22 INTERNSHIPkoushik royalPas encore d'évaluation

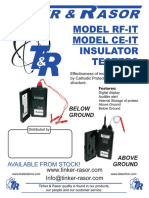

- R R O S A: Model Rf-It Model Ce-It Insulator TestersDocument2 pagesR R O S A: Model Rf-It Model Ce-It Insulator Testersvictor raul sandoval martinezPas encore d'évaluation

- Project Execution and Control: Lunar International College July, 2021Document35 pagesProject Execution and Control: Lunar International College July, 2021getahun tesfayePas encore d'évaluation

- SCH 415 Computer Applications in Chemistry: at The End of This Unit You Should Be Able To General ObjectiveDocument21 pagesSCH 415 Computer Applications in Chemistry: at The End of This Unit You Should Be Able To General ObjectiveFELIX ORATIPas encore d'évaluation

- Ariando Purba: Nov 2017-: CV. Mulia Abadi (Knitto Textiles) - Present System Development and ImplementationDocument3 pagesAriando Purba: Nov 2017-: CV. Mulia Abadi (Knitto Textiles) - Present System Development and ImplementationariandoPas encore d'évaluation

- Guidelines in Research Proposal WritingDocument19 pagesGuidelines in Research Proposal WritingMark RelloresPas encore d'évaluation

- Business PlanDocument20 pagesBusiness PlanRona BautistaPas encore d'évaluation

- Cover LetterDocument16 pagesCover LetterAjmal RafiquePas encore d'évaluation

- NISE3600EDocument2 pagesNISE3600ENgo CuongPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)