Académique Documents

Professionnel Documents

Culture Documents

Design of Steel I Section BS5950

Transféré par

amachmouchiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design of Steel I Section BS5950

Transféré par

amachmouchiDroits d'auteur :

Formats disponibles

E. B.

NALDOZA Engineering Design

Registered in Dublin, Ireland (with Branch Office in

Cavite, Philippines)

Project Irish Cement Ltd. - Kiln 3

Ref. No.

Cement Mill-Silos Structure

Subject Design of Steel Beam at EL 56.40

PB9729

Beam No. 192-195, 47

Calculated

Checked

Date

E. Naldoza

E. Naldoza

26/09/07

Eddie Naldoza, BSc MIES MPICE

E: eddienaldoza@engineer.com

W: www.eddienaldoza.com

Page

of

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216

Gridlines :

(Developed by: Eddie Naldoza, BSc MIES MPICE

C-E

Limited to Plastic Section & Major Axis Bending only)

www.eddienaldoza.com)

Code / 1. Loadings : (Ultimate Loads)

Clause Maximum Moment, Mx

=

2

kN-m

3

kN

BS5950 Maximum Shear at Support,Fv =

= 700 mm

Part 1 : Total Span, L

2000 / Load factor for Imposed Loads, fi = 1.5

Point Load, P

Distance of point load from nearer support, ae

=

=

2

350

kN

mm

kN

Maximum Shear at Point Load

or at Point of Maximum Moment, Fvc

2. Member Checks :

2.1 Trial Section

127x76x13

UB

Steel Grade = S 275

From Member Capacity Tables (Blue Book)

Moment Capacity, Mc

= 0.00 kN-m

2.2 Section Properties :

D = 127.0 mm

b

B = 76.00 mm

d

t = 4.00 mm

Sx

T = 7.60 mm

Zx

=

38

mm

= 96.60 mm

=

84

cm3

=

75

cm3

r = 7.60 mm

Local Buckling Ratios :

2

E = 2.05E+05 N/mm

b/T = 5.00

Ix =

473

cm4

d/t = 24.10

ry = 18.4 mm

x = 16.3

2.3 Section Classification :

T < 16 mm

275

275

3.1.1

=

=

= 1.00 (3.5.2-Table 11 b )

py

275

Table 9 Therefore; py = 275 N/mm2

3.5.2

For Rolled Section; Outstand Element of Compression Flange Flange is Class 1 Plastic

Table 11 For Flange :

b/T ###

= ###

= x 1.0 = 9.0 ; Actual b/T = 5.00 < 9.0

Web of an I-, H- or Box Section; Neutral Axis at Mid-depth For Web :

d/t = 80 = 80 x 1.0 = 80.0 ; Actual d/t = 24.10 < 80.0

Web is Class 1 Plastic

Therefore : Section is Class 1 Plastic

4.2.3

4.2.3

2.4 Check For Shear Buckling if :

d/t > 70

70 = 70 x 1.00 = 70.0 ; Actual d/t = 24.10 < 70.0

2.5 Check For Shear Capacity : Fv or Fvc Pv

py = 275 N/mm2 ; Av = t D = 4.0 x 127.0 =

Pv = 0.6 py Av

; Pv = 0.6 x 275 N/mm2 x

508

508

No need to check for Shear Buckling

mm2

mm2 =

83820

2.6 Check For Moment Capacity : Mx Mcx

4.2.5

Check for High/Low Shear (at point of Maximum Moment, Fvm)

4.2.5.2/

Shear at point of Maximum Moment ; Fvc = 2 kN

4.2.5.3

Limiting Shear, Fve = 0.60 x Pv = 0.60 x

84

kN = 50.3 kN >

For Low Shear (for Class 1 Plastic or Class 2 Compact cross-sections)

Mcx = py Sx = 275 N/mm x

84

cm = 23.2 kN-m >

4.2.5.1

2.0

kN

84 kN > 3.0 kN

; Adequate for Shear

Low Shear

kN-m ; Adequate for Flexure

2.7 Check Limit To Avoid Irreversible Deformation Under Serviceability Loads :

For simply supported beam :

Mcx 1.2 py Zx

2

cm3

Mcx = 1.2 x 275 N/mm x

75

23.2 < 24.618 kN-m ; Adequate for Flexure

E. B. NALDOZA Engineering Design

Registered in Dublin, Ireland (with Branch Office in

Cavite, Philippines)

Project Irish Cement Ltd. - Kiln 3

Ref. No.

Cement Mill-Silos Structure

Subject Design of Steel Beam at EL 56.40

PB9729

Beam No. 192-195, 47

Calculated

Checked

Date

E. Naldoza

E. Naldoza

26/09/07

Eddie Naldoza, BSc MIES MPICE

E: eddienaldoza@engineer.com

W: www.eddienaldoza.com

Page

of

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216

Gridlines :

(Developed by: Eddie Naldoza, BSc MIES MPICE

C-E

www.eddienaldoza.com)

Limited to Plastic Section & Major Axis Bending only)

E. B. NALDOZA Engineering Design

Registered in Dublin, Ireland (with Branch Office in

Cavite, Philippines)

Project Irish Cement Ltd. - Kiln 3

Ref. No.

Cement Mill-Silos Structure

Subject Design of Steel Beam at EL 56.40

PB9729

Beam No. 192-195, 47

Calculated

Checked

Date

E. Naldoza

E. Naldoza

26/09/07

Eddie Naldoza, BSc MIES MPICE

E: eddienaldoza@engineer.com

W: www.eddienaldoza.com

Page

of

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216

Gridlines :

(Developed by: Eddie Naldoza, BSc MIES MPICE

C-E

Limited to Plastic Section & Major Axis Bending only)

www.eddienaldoza.com)

Part 1 : 2.8 Web Bearing and Buckling Under the Point Load :

2000 /

4.5.2.1

2.8.1 Bearing capacity of the unstiffened web : P Pbw ; Pbw = (b1 + nk) t pyw

; pyw

= 275

N/mm2

= 275

N/mm2

b1 = t + 1.6r + 2T

= 31.4 mm ; n ###

= (not at the end of the member) ; k = T+r = 15.2 mm

Pbw = [ 31.4 + ###

(

x 15.2 ) ] 4.0 x 275 = 118.1 kN > 2 kN

; Therefore Bearing Capacity of the unstiffened web under the point load is adequate

4.5.3.1

2.8.2 Buckling resistance of the unstiffened web : P Px ;

Check if ; ae 0.7d ; ae is the distance from the load to the nearer end of the member

= 350 mm

350 0.7 x 96.60 ; 350 > 67.6 mm ; Therefore

25 T

25 x 1.0 x 7.6 x 118.1

Px=

Pbw ; Px=

(b

+

nk)

d

+ x 15.2 ) x 96.60

1

( 31 ###

Px = 220.33 kN

>

2

kN

; Therefore Buckling Resistance of the unstiffened web under the point load is adequate

4.5.2.1

2.9 Web Bearing and Buckling at the Support :

2.9.1 Bearing capacity of the unstiffened web : Fv Pbw ; Pbw = (b1 + nk) t pyw

; pyw

b1 = t + T + 0.8r - g

= 4.0 + 7.6 + 0.8 x 7.6 - 10 = 7.68 mm (properties of the supporting element )

be is the distance to the nearer end of the member from the end of the stiff bearing

###

;

= 0 mm

n ###

= + 0.6 x 0 / 15.2 = 2.0 ###

< ; Therefore use n = 2.0 ; k = T+r = 54.1 + 30.0 = 84.1 mm

Pbw = [ 7.7 + ( 2.0 x 15.2 ) ] 4.0 x 275 = 41.9 kN > 3.0 kN

n = 2 + 0.6be/k

; Therefore Bearing Capacity of the unstiffened web at the support is adequate

4.5.3.1

2.9.2 Buckling resistance of the unstiffened web : Fv Px ;

; ae 0.7d ; ae is the distance from the reaction to the nearer end of the member

= 25 mm

25 0.7 x 96.60 ; 25 < 67.6 mm ; Therefore

25 T

ae + 0.7d

25 x 1.0 x 7.6 x 41.9

25 + 67.6

x

Px=

Pbw ; Px=

x

+ x 84.1 ) x 96.60

1.40 x 96.60

1.4 d

(b1 + nk) d

( 7.7 ###

Px = 61.059 kN x 0.68 = 41.8 kN

> 3.0 kN

Check if

; Therefore Buckling Resistance of the unstiffened web at the support is adequate

2.5.2

2.10 Serviceabilty Limit States : Deflection Check

The serviceability Loads are taken as unfactored imposed loads. In this case, as only ultimate loads are the available data,

the unfactored imposed loads will be taken as Mc or P / f i conservatively, for simplicity; fi to be the load factor =

1.5

From Maximum Moment, Mc; wi = Unfactored Distributed Load

wi Le2

8 Mc ### x

2

kN-m

Mc = 1.5

; wi =

=

= 21.8 kN/m

2

1.5 Le

8

1.5 x 0.7 ###

m

From Point Load P; W i = Unfactored Point Load

Limits for calculated deflection (2.5.2 Table 8)

P = 1.5 W i ;

P

2.1

for : Cantilever

Wi =

=

= 1.4 kN

1.5

1.5

Allowable deflection, a

The total deflection is given by:

4

w

Le

L

Wi

Le

### i

700

e

=

+

a =

=

= 3.89 mm

384 E I

48 EI

180

180

=

=

### x 21.8 x 0.7

###

384 x 2.E+05 x

473

0.081

mm <

3.89

+

mm

1.4 x 0.7 3

48 x 2.E+05 x

473

; Adequate for deflection

Therefore : 127x76x13

is Adequate, Adopt Section

UB

E. B. NALDOZA Engineering Design

Registered in Dublin, Ireland (with Branch Office in

Cavite, Philippines)

Project Irish Cement Ltd. - Kiln 3

Ref. No.

Cement Mill-Silos Structure

Subject Design of Steel Beam at EL 56.40

PB9729

Beam No. 192-195, 47

Calculated

Checked

Date

E. Naldoza

E. Naldoza

26/09/07

Eddie Naldoza, BSc MIES MPICE

E: eddienaldoza@engineer.com

W: www.eddienaldoza.com

Page

of

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216

Gridlines :

C-E

(Developed by: Eddie Naldoza, BSc MIES MPICE

www.eddienaldoza.com)

; Adequate

for deflection

0.081

mm <

3.89

mm

Limited to Plastic Section & Major Axis Bending only)

E. B. NALDOZA Engineering Design

Registered in Dublin, Ireland (with Branch Office in

Cavite, Philippines)

Project Irish Cement Ltd. - Kiln 3

Ref. No.

Cement Mill-Silos Structure

Subject Design of Steel Beam at EL 56.40

PB9729

Beam No. 192-195, 47

Calculated

Checked

Date

E. Naldoza

E. Naldoza

26/09/07

Eddie Naldoza, BSc MIES MPICE

E: eddienaldoza@engineer.com

W: www.eddienaldoza.com

Page

of

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216

Gridlines :

C-E

(Developed by: Eddie Naldoza, BSc MIES MPICE

4.3.0

Limited to Plastic Section & Major Axis Bending only)

www.eddienaldoza.com)

2.11 Lateral Torsional Buckling : Mx Mb/mLT ;

Effective Length of the segment, LE

Maximum Major axis Moment

in the segment, Mx

=

4.3.6.7

=LE/ry = 700 / 18.4 =

4.3.6.8

u = 0.9

2

38

kN-m

; /x = 38.0 / 16.3 = 2.3 ; = 0.5 (Equal flange)

(for Rolled I of Equal flange-4.3.6.8)

; LT = uvw

Equivalent Slenderness

W = 1.0

;

;

B.2.1

; LT

= aLT(LT-LO)/1000

34.31 )/ 1000 = 0

= 7.0 x ( 32 -

pE = E/LT2

= x 2.05E+05 / 32

Bending Strength,

4.3.6.4

LO = 0.4 x (

Perry factor & Robertson constant

LT

pb =

= 1980

pE py

2

; LT =

LT+(LT2-pE py)

Buckling Resistance Moment;

0.5

Mb = pb Sx

v = 0.93

###

; LO = 0.4(E/py)0.5

2.05E+05 /

275 )0.5 = 34.31

275 + (

###

+ ) 1980

###

1980 x 275

1111 + ( 1111

= 280 x

(Table 19)

; aLT = 7.0

py+(LT+1)pE

(for Class 1 Plastic or Class 2 Compact Sections-4.3.6.9)

Limiting equivalent slenderness

LT = 0.9 x 0.93 x 38.0 x 1.0 = 32

B.2.2

= 700 mm

84200

- 1980 x 275 )

= 1111

= 280

0.5

= 23.606 kN-m

Uniform Moment Factor for Lateral Torsional Buckling (General case); mLT

Table 18

4.3.6.2

Moments at quarter points

Moments at mid point

M2 =

M4 =

M3 =

kN-m

kN-m

mLT = 0.2 +

Mb

mLT

0.15M2+0.5M3+0.15M4

23.606

=

1.00

Mx

24

kN-m

>

kN-m

= 0.2 +

0.15 x

kN-m

+ 0.50 x

2

+ 0.15 x

; Therefore Buckling Resistance

Moment is Adequate

= 1.00

N/mm2

E. B. NALDOZA Engineering Design

Registered in Dublin, Ireland (with Branch Office in

Cavite, Philippines)

Project Irish Cement Ltd. - Kiln 3

Ref. No.

Cement Mill-Silos Structure

Subject Design of Steel Beam at EL 56.40

PB9729

Beam No. 192-195, 47

Calculated

Checked

Date

E. Naldoza

E. Naldoza

26/09/07

Eddie Naldoza, BSc MIES MPICE

E: eddienaldoza@engineer.com

W: www.eddienaldoza.com

Page

of

DESIGN OF SIMPLY SUPPORTED ROLLED STEEL I or H SECTION (Spreadsheet Calculation

Beam No. : 215-216

Gridlines :

(Developed by: Eddie Naldoza, BSc MIES MPICE

C-E

www.eddienaldoza.com)

Limited to Plastic Section & Major Axis Bending only)

Vous aimerez peut-être aussi

- Design of Steel I-Section (BS5950)Document6 pagesDesign of Steel I-Section (BS5950)Rachelle C. Abanes50% (4)

- Design of Steel I-Section (BS5950)Document3 pagesDesign of Steel I-Section (BS5950)gertjaniPas encore d'évaluation

- Cantilever BeamDocument3 pagesCantilever BeamFeliciano Esteban DominguezPas encore d'évaluation

- Beam Design MylesDocument1 278 pagesBeam Design MylesRyanRuceMelvillePas encore d'évaluation

- Design of Moment ConnectionDocument2 pagesDesign of Moment Connectiongops1963Pas encore d'évaluation

- Single Bolt Capacity To EN 1993-1-8: Bolts Diameters, Hole Sizes and AreasDocument17 pagesSingle Bolt Capacity To EN 1993-1-8: Bolts Diameters, Hole Sizes and AreasabhijitPas encore d'évaluation

- Weld CheckDocument14 pagesWeld CheckmaheshbandhamPas encore d'évaluation

- Q5.3 Example-6-1-Rectangular-Water-Tank-Design PDFDocument7 pagesQ5.3 Example-6-1-Rectangular-Water-Tank-Design PDFAboalmaail AlaminPas encore d'évaluation

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearDocument4 pagesConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part7-Pryout Strength in ShearVenu GopalPas encore d'évaluation

- Unbraced Short Column 2Document7 pagesUnbraced Short Column 2Eze AnayoPas encore d'évaluation

- Design of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)Document30 pagesDesign of Rectangular Footing F1 A Input Data:: (Columns A1, A2, A3 and A4)raman212Pas encore d'évaluation

- GF SlabDocument8 pagesGF Slabcheligp1981Pas encore d'évaluation

- Engineering and Development Corporation of The Philippines: H P H PDocument2 pagesEngineering and Development Corporation of The Philippines: H P H Pmark ignacioPas encore d'évaluation

- Design of Steel I Section BS5950Document7 pagesDesign of Steel I Section BS5950chaPas encore d'évaluation

- 1 Design of Glass BarrierDocument12 pages1 Design of Glass BarrierAgus CnsPas encore d'évaluation

- Atasehir Gardens Podium OF: Member: LocationDocument7 pagesAtasehir Gardens Podium OF: Member: LocationklynchellePas encore d'évaluation

- Design of Water Tank On The Ground According To Bs 8007:1987Document109 pagesDesign of Water Tank On The Ground According To Bs 8007:1987minov minovitchPas encore d'évaluation

- Equalization TankDocument13 pagesEqualization Tanknataliepoison8917Pas encore d'évaluation

- 3 5mDocument8 pages3 5mSanjay sharmaPas encore d'évaluation

- Design of Stairs Design of Stairs From Ground To Landing Material PropertiesDocument3 pagesDesign of Stairs Design of Stairs From Ground To Landing Material PropertiesJohn Paul Hilary EspejoPas encore d'évaluation

- Beam Design TorsionDocument20 pagesBeam Design Torsionmailmaverick8167100% (1)

- Hollow Section Connection Using BoltDocument4 pagesHollow Section Connection Using Boltikanyu79Pas encore d'évaluation

- Design of Footing and Anchor BoltsDocument9 pagesDesign of Footing and Anchor BoltsMUTHUKKUMARAM100% (1)

- Continuous Beam Design ProgrammeDocument70 pagesContinuous Beam Design ProgrammeNikhilPas encore d'évaluation

- Water Tank SlabDocument1 pageWater Tank Slabadera1Pas encore d'évaluation

- Introduction To STAAD For Structural Analysis and DesignDocument14 pagesIntroduction To STAAD For Structural Analysis and DesignJovy NotorioPas encore d'évaluation

- Timber DesignDocument1 pageTimber DesignJohn SmithPas encore d'évaluation

- Final DesignDocument62 pagesFinal DesignNishan GajurelPas encore d'évaluation

- BeamDocument7 pagesBeamsomumallidiPas encore d'évaluation

- Asce7-10 Wind Load CalculationDocument14 pagesAsce7-10 Wind Load CalculationMANOJPas encore d'évaluation

- 5.15 Swing Barrier v.1.0Document190 pages5.15 Swing Barrier v.1.0rfvz6sPas encore d'évaluation

- Client: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarDocument3 pagesClient: Reem General Contracting Est. Al Jubail, Dammam, Commercial Street Kingdom of Saudi Arabia Al KhobarUday UdmalePas encore d'évaluation

- Wtb7 Bolt: (BS8110:1997 Table 3.26)Document5 pagesWtb7 Bolt: (BS8110:1997 Table 3.26)Asaru DeenPas encore d'évaluation

- Staircase Isolated Tread TypeDocument9 pagesStaircase Isolated Tread TypeNishan GajurelPas encore d'évaluation

- Water Tank-Base (Flat) SlabDocument15 pagesWater Tank-Base (Flat) SlabAbhishek Gupta50% (2)

- RC One Way Slab Design (ACI318-05)Document2 pagesRC One Way Slab Design (ACI318-05)emoriderPas encore d'évaluation

- Design of ColumnDocument7 pagesDesign of ColumnD SRINIVASPas encore d'évaluation

- Purlin DesignDocument6 pagesPurlin DesignAnonymous mcHqIfbnV1Pas encore d'évaluation

- Code Referenc E Calculations Outpu T Example 15 Design of Steel Column BaseplateDocument13 pagesCode Referenc E Calculations Outpu T Example 15 Design of Steel Column BaseplateMuriungi RicharsPas encore d'évaluation

- Eave Valley Gutter Design SheetDocument1 pageEave Valley Gutter Design SheetIshaan AgarwalPas encore d'évaluation

- RCC11 Element DesignDocument6 pagesRCC11 Element DesignSovich82Pas encore d'évaluation

- Design of C 120x60x20x2.5 PurlinsDocument12 pagesDesign of C 120x60x20x2.5 PurlinscarsotPas encore d'évaluation

- Daniel T. Li: Flagpole Footing Design Based On Chapter 18 Both IBC & UBC Input Data & Design SummaryDocument1 pageDaniel T. Li: Flagpole Footing Design Based On Chapter 18 Both IBC & UBC Input Data & Design SummaryJustinCharlesAmorPas encore d'évaluation

- Design of Isolated Footing With Vertical Load Only - According To ACI 318M-99Document1 pageDesign of Isolated Footing With Vertical Load Only - According To ACI 318M-99mahmoud IbrahemPas encore d'évaluation

- Portal Frame DesignDocument4 pagesPortal Frame DesignUlasi IfeanyiPas encore d'évaluation

- Purlin DesignDocument9 pagesPurlin DesignAjayvidyanand SharmaPas encore d'évaluation

- Armare RadierDocument5 pagesArmare RadierRepanovici Alexandru100% (1)

- Structural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Document39 pagesStructural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Henj MirasolPas encore d'évaluation

- The Design Is Inadequate, See AnalysisDocument1 pageThe Design Is Inadequate, See AnalysisZiyad MonierPas encore d'évaluation

- Calculation StandardsDocument40 pagesCalculation Standardsraghav abudhabiPas encore d'évaluation

- RCC95 Continuous Beams (Tables)Document9 pagesRCC95 Continuous Beams (Tables)Murthy GunaPas encore d'évaluation

- Check For Punching Shear:: Pile Cap Design (PC3a)Document6 pagesCheck For Punching Shear:: Pile Cap Design (PC3a)Sheikh Mizanur RahmanPas encore d'évaluation

- AnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTDocument3 pagesAnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTRobert Díaz CornejoPas encore d'évaluation

- Column Wall DesignDocument42 pagesColumn Wall DesignCivilax.comPas encore d'évaluation

- Splice 03Document15 pagesSplice 03LexPas encore d'évaluation

- TCC51 Column Load Take-Down DesignDocument202 pagesTCC51 Column Load Take-Down DesignSorinStanescuPas encore d'évaluation

- Design of Steel I Section BS5950Document6 pagesDesign of Steel I Section BS5950Haffizul SaidPas encore d'évaluation

- Design of Vertical Lift Service Gates of Budaun Irrigation ProjectDocument33 pagesDesign of Vertical Lift Service Gates of Budaun Irrigation ProjectVikash Yadav83% (6)

- TCC82 Pilecap DesignDocument122 pagesTCC82 Pilecap DesignKamal Gm100% (1)

- Timber Examples - TeddsDocument19 pagesTimber Examples - TeddsTom KwoPas encore d'évaluation

- Texture WallDocument2 pagesTexture WallamachmouchiPas encore d'évaluation

- 2 - 4 Gutter and Downspout Sizing and LocationDocument5 pages2 - 4 Gutter and Downspout Sizing and LocationWinnie ChungPas encore d'évaluation

- Cost EstimationDocument28 pagesCost Estimationmayur1980100% (1)

- Abus Overhead Cranes InfoDocument12 pagesAbus Overhead Cranes Infoamachmouchi100% (1)

- Plan SketchDocument43 pagesPlan SketchIngenieria Estructural AplicadaPas encore d'évaluation

- TrussDocument6 pagesTrussamachmouchiPas encore d'évaluation

- This Is To Calculate The Input Values For Crane Software: 1,769 KG 6,580 KGDocument1 pageThis Is To Calculate The Input Values For Crane Software: 1,769 KG 6,580 KGamachmouchiPas encore d'évaluation

- Stair Calculator: Calculate Approx Number of Steps Calculate Approx Number of StepsDocument2 pagesStair Calculator: Calculate Approx Number of Steps Calculate Approx Number of StepstannuPas encore d'évaluation

- 022012Document2 pages022012amachmouchiPas encore d'évaluation

- Connection Tips For Steel Wide Flange SectionsDocument7 pagesConnection Tips For Steel Wide Flange SectionsJuan Carlos VillalbaPas encore d'évaluation

- Connection Tips For Steel Wide Flange SectionsDocument7 pagesConnection Tips For Steel Wide Flange SectionsJuan Carlos VillalbaPas encore d'évaluation

- Jan10 Steelwise Web PDFDocument4 pagesJan10 Steelwise Web PDFamachmouchiPas encore d'évaluation

- 022012Document2 pages022012amachmouchiPas encore d'évaluation

- Welders Visual Inspection Handbook 2013 WEB New PDFDocument77 pagesWelders Visual Inspection Handbook 2013 WEB New PDFamachmouchiPas encore d'évaluation

- Step ColDocument21 pagesStep ColamachmouchiPas encore d'évaluation

- Ebsl Quote Request Form / Work Order Form Page 1 of 1: Arjun Bhise West WestDocument2 pagesEbsl Quote Request Form / Work Order Form Page 1 of 1: Arjun Bhise West WestamachmouchiPas encore d'évaluation

- 3.3.9-LRFD Shear Connector DesignDocument21 pages3.3.9-LRFD Shear Connector DesignvklsPas encore d'évaluation

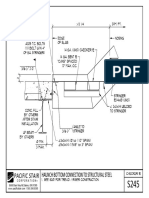

- s245 Checker Plate Haunch Bottom Stair Connection To Structural SteelDocument1 pages245 Checker Plate Haunch Bottom Stair Connection To Structural SteelamachmouchiPas encore d'évaluation

- Roof DeckDocument9 pagesRoof DeckDhimas Surya NegaraPas encore d'évaluation

- Advantages and Disadvantages of Composite Materials - Resin SystemsDocument2 pagesAdvantages and Disadvantages of Composite Materials - Resin SystemsAdil Alper CoskunPas encore d'évaluation

- AISC ExamI1&2&3Document11 pagesAISC ExamI1&2&3Dhurai KesavanPas encore d'évaluation

- Ebsl Quote Request Form / Work Order Form Page 1 of 1: Arjun Bhise West WestDocument2 pagesEbsl Quote Request Form / Work Order Form Page 1 of 1: Arjun Bhise West WestamachmouchiPas encore d'évaluation

- CladdingDocument1 pageCladdingamachmouchiPas encore d'évaluation

- Gutter and Down Spout CalculationDocument1 pageGutter and Down Spout CalculationzelmishaPas encore d'évaluation

- Roof Bracing DesignDocument4 pagesRoof Bracing Designrodriguez.gaytanPas encore d'évaluation

- Gutter CalculationDocument5 pagesGutter CalculationamachmouchiPas encore d'évaluation

- Step ColDocument21 pagesStep ColamachmouchiPas encore d'évaluation

- Pds Hempathane Hs 55610 En-GbDocument2 pagesPds Hempathane Hs 55610 En-GbThines KumarPas encore d'évaluation

- Hollow Core Building BrochureDocument16 pagesHollow Core Building Brochurelbhnsw5930Pas encore d'évaluation

- A325m 12165Document8 pagesA325m 12165amachmouchiPas encore d'évaluation

- Advanced Survey MethodsDocument83 pagesAdvanced Survey MethodsMaxine MukokiPas encore d'évaluation

- Physics Project Final1Document15 pagesPhysics Project Final1sohamPas encore d'évaluation

- Aadesh Pathare Tom Micro ProjectDocument18 pagesAadesh Pathare Tom Micro ProjectAKASH THORATPas encore d'évaluation

- Training CourseDocument44 pagesTraining CourseTugay ArıçPas encore d'évaluation

- Laws of Collision Cobra3Document5 pagesLaws of Collision Cobra3ErlinaPas encore d'évaluation

- Grade 9 Mechanical Energy 4th QuarterDocument6 pagesGrade 9 Mechanical Energy 4th QuarterEmilePas encore d'évaluation

- Vibration Analysis of Structure Using Tune Mass DamperDocument7 pagesVibration Analysis of Structure Using Tune Mass DamperAnonymous kw8Yrp0R5rPas encore d'évaluation

- E MC2 ProofDocument5 pagesE MC2 ProofKartikeya BagraPas encore d'évaluation

- Vibration Sign of Over Hung Unknown Initial CondsDocument16 pagesVibration Sign of Over Hung Unknown Initial Condsridzim4638Pas encore d'évaluation

- Pelevic LNG Flow Module v2Document40 pagesPelevic LNG Flow Module v2DiwanEfendiEfendiPas encore d'évaluation

- AvcDocument18 pagesAvcgulshanPas encore d'évaluation

- Start Download: Orifice Equations Formulas Design CalculatorDocument4 pagesStart Download: Orifice Equations Formulas Design CalculatorPriesilia PresleyPas encore d'évaluation

- HWCH 12 BDocument3 pagesHWCH 12 BfcordPas encore d'évaluation

- Determination of Mixed-Mode Stress Intensity Factors, FractureDocument16 pagesDetermination of Mixed-Mode Stress Intensity Factors, FractureSoupramanien KathirvelouPas encore d'évaluation

- Assignment 2Document6 pagesAssignment 2Praveen ChaudharyPas encore d'évaluation

- Dynamics: CHE412 Process and ControlDocument11 pagesDynamics: CHE412 Process and ControlAdil AminPas encore d'évaluation

- Experiment 2: StatementDocument7 pagesExperiment 2: StatementabubakarPas encore d'évaluation

- Inductance - Inductors - Energy StoredDocument2 pagesInductance - Inductors - Energy Storedsteve_yPas encore d'évaluation

- Moment-Distribution Method: Clifford Jay C. Ansino Theory of Structure Ii 5-BSCE-BDocument7 pagesMoment-Distribution Method: Clifford Jay C. Ansino Theory of Structure Ii 5-BSCE-BKhen CatayasPas encore d'évaluation

- CCB 2092 Experiment 3 - Fluid StaticsDocument6 pagesCCB 2092 Experiment 3 - Fluid StaticsFahmi EsaPas encore d'évaluation

- Me 544 Course OutlineDocument2 pagesMe 544 Course OutlineMohamed H. ShedidPas encore d'évaluation

- Joule's Apparatus IPDocument31 pagesJoule's Apparatus IP--MsKahokoHino--Pas encore d'évaluation

- Roark's Formulas For Stress and Strain - REF.09Document64 pagesRoark's Formulas For Stress and Strain - REF.09tylerstearnsPas encore d'évaluation

- GuideDocument770 pagesGuidepavankumar001Pas encore d'évaluation

- Steady and Unsteady Pressure Measurements in A Transonic Turbine StageDocument1 pageSteady and Unsteady Pressure Measurements in A Transonic Turbine StageVarun Karthikeyan ShettyPas encore d'évaluation

- 01.class 01 Introduction To Dynamic of MachineryDocument25 pages01.class 01 Introduction To Dynamic of MachinerylasldnjPas encore d'évaluation

- Full Download Ebook Ebook PDF Orbital Mechanics For Engineering Students Aerospace Engineering 4th Edition PDFDocument42 pagesFull Download Ebook Ebook PDF Orbital Mechanics For Engineering Students Aerospace Engineering 4th Edition PDFjanet.martino412100% (40)

- E103 - Moment of InertiaDocument5 pagesE103 - Moment of InertiaStephh LouisPas encore d'évaluation

- PID Controller - WikipediaDocument41 pagesPID Controller - WikipediaHaroon Mohamed MorshedPas encore d'évaluation

- Design of PCC Abutment - Open FoundationDocument31 pagesDesign of PCC Abutment - Open FoundationAnantPawarPas encore d'évaluation