Académique Documents

Professionnel Documents

Culture Documents

Rankine Cycle 2marksg

Transféré par

Eric CookTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Rankine Cycle 2marksg

Transféré par

Eric CookDroits d'auteur :

Formats disponibles

1. Why Rankine cycle is modified?

The work obtained at the end of the expansion is very less. The work is too inadequate to

overcome the friction. Therefore the adiabatic expansion is terminated at the point before the end

of the expansion in the turbine and pressure decreases suddenly, while the volume remains

constant.

2. Name the various vapour power cycle.

Carnot cycle and Rankine cycle.

SV

ET

3. Define efficiency ratio.

The ratio of actual cycle efficiency to that of the ideal cycle efficiency is termed as efficiency

ratio.

4. Define overall efficiency.

It is the ratio of the mechanical work to the energy supplied in the fuel. It is also defined as the

product of combustion efficiency and the cycle efficiency.

5. Define specific steam consumption of an ideal Rankine cycle.

It is defined as the mass flow of steam required per unit power output.

6. Name the different components in steam power plant working on Rankine cycle.

Boiler, Turbine, Cooling Tower or Condenser and Pump.

7. What are the effects of condenser pressure on the Rankine Cycle?

By lowering the condenser pressure, we can increase the cycle efficiency. The main

disadvantage is lowering the back pressure in release the wetness of steam. Isentropic

compression of a very wet vapour is very difficult.

8. Mention the improvements made to increase the ideal efficiency of Rankine cycle.

1. Lowering the condenser pressure.

2. Superheated steam is supplied to the turbine.

3. Increasing the boiler pressure to certain limit.

4. Implementing reheat and regeneration in the cycle.

9. Why reheat cycle is not used for low boiler pressure?

At the low reheat pressure the heat cycle efficiency may be less than the Rankine cycle

efficiency.

Since the average temperature during heating will then be low.

10. What are the disadvantages of reheating?

Reheating increases the condenser capacity due to increased dryness fraction, increases the cost

of the plant due to the reheats and its very long connections.

11. What are the advantages of reheat cycle?

1. It increases the turbine work.

2. It increases the heat supply.

3. It increases the efficiency of the plant.

4. It reduces the wear on the blade because of low moisture content in LP state of the

turbine.

12. Define latent heat of evaporation or Enthalpy of evaporation.

The amount of heat added during heating of water up to dry steam from boiling point is known

as Latent heat of evaporation or enthalpy of evaporation.

13. Explain the term super heated steam and super heating.

The dry steam is further heated its temperature raises, this process is called as superheating and

the steam obtained is known as superheated steam.

SV

ET

14. Explain heat of super heat or super heat enthalpy.

The heat added to dry steam at 100oC to convert it into super heated steam at the temperature

Tsup is called as heat of superheat or super heat enthalpy.

15. Explain the term critical point, critical temperature and critical pressure.

In the T-S diagram the region left of the waterline, the water exists as liquid. In right of the dry

steam line, the water exists as a super heated steam. In between water and dry steam line the

water exists as a wet steam. At a particular point, the water is directly converted into dry steam

without formation of wet steam. The point is called critical point. The critical temperature is the

temperature above which a substance cannot exist as a liquid; the critical temperature of water is

374.15oC. The corresponding pressure is called critical pressure.

16. Define dryness fraction (or) what is the quality of steam?

It is defined as the ratio of mass of the dry steam to the mass of the total steam.

17. Define enthalpy of steam.

It is the sum of heat added to water from freezing point to saturation temperature and the heat

absorbed during evaporation.

18. How do you determine the state of steam?

If V>vg then super-heated steam, V= vg then dry steam and V< vg then wet steam.

19. Define triple point.

The triple point is merely the point of intersection of sublimation and vapourisation curves.

20. Define heat of vapourisation.

The amount of heat required to convert the liquid water completely into vapour under this

condition is called the heat of vapourisation.

21. Explain the terms, Degree of super heat, degree of sub-cooling.

The difference between the temperature of the superheated vapour and the saturation temperature

at the same pressure. The temperature between the saturation temperature and the temperature in

the sub cooled region of liquid.

22. What is the purpose of reheating?

The purpose of reheating is to increase the dryness fraction of the steam passing out of the later

stages of the turbine.

23. What are the processes that constitute a Rankine cycle?

Process 12: Isentropic expansion of the working fluid through the turbine from saturated vapor

at state 1 to the condenser pressure.

Process 23: Heat transfer from the working fluid as it flows at constant pressure through the

condenser with saturated liquid at state 3.

Process 34: Isentropic compression in the pump to state 4 in the compressed liquid region.

Process 41: Heat transfer to the working fluid as it flows at constant pressure through the boiler

to complete the cycle.

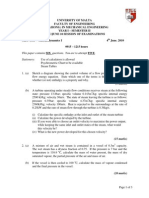

ME 6301- ENGINEERING THERMODYNAMICS

UNIT III QUESTION BANK

SV

CE

T

1. A vessel of volume 0.04m3 contains a mixture of saturated water and steam at a

temperature of 2500 C. The mass of the liquid present is 9 kg. Find the pressure, mass,

specific volume, enthalpy, entropy and internal energy.

(8)

(May/June 2003, Nov/Dec 2012)

3

2. A rigid tank of 0.03m capacity contains wet vapour at 80 kPa. If the wet vapour mass

is 12kg, calculate the heat added and the quality of the mixture when the pressure

inside the tank reaches 7 Mpa.

(Nov/ Dec 2005)

3

3. 3 kg of steam at 18bar occupy a volume of 0.2550m . During a constant volume

process, the heat rejected is 1320kJ. Determine final internal energy and final initial

dryness and work done.

(May/June 2008)

0

4. Steam initially at 0.3Mpa, 250 C is cooled at constant volume. At what temperature

will the steam become saturated vapour? What is the quality at 80 0C.Also find what is

the heat transferred per kg of steam in cooling from 2500 C to 800C.

(12)

(Nov / Dec 2013)

o

5. Ten kg of water of 45 C is heated at a constant pressure of 10 bars until it becomes

superheated vapour at 3000C. Find the changes in volume, enthalpy, internal energy

and entropy.

(May / June 2005 )

0

3

6. 2 kg of water at 200 C are contained in a 20m vessel. Determine the pressure,

enthalpy, mass and volume of vapor within the vessel.

(8)

(May / June 2007)

0

7. Steam at 30 bar and 350 C is expanded in a non flow isothermal process to a pressure

of 1 bar. The temperature and pressure of the surroundings are 250C and 100 kPa

respectively. Determine the maximum work that can be obtained from this process per

kg of steam. Also find the maximum useful work.

(10)

(May/June 2013)

8. 1 kg of steam initially dry saturated at 1.1 MPa expands in a cylinder following the

law pv1.13= C. The pressure at the end of expansion is 0.1MPa. Determine: (i) The

final volume (ii) final dryness fraction (iii) work done (iv) The change in internal

energy (v) the heat transferred.

(16)

(Nov/Dec 2006)

0

9. Steam at a pressure of 15bar and 250 C expands according to the law pV1.25=C to a

pressure of 1.5 bar. Evaluate the final conditions, work done, heat transfer and change

in entropy. The mass of the system is 0.8kg.

(Nov/Dec 2008)

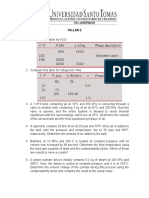

10. In steam generator compressed water at 10 MPa, 300C enters a 30 mm diameter tube

at the rate of 3 litres /sec. Steam at 9 MPa and 4000C exit the tube. Find the rate of

heat transfer.

(8)

(Nov/Dec 2003, May/June 2012)

11. Steam at 0.8 MPa, 2500C and flowing at the rate of 1 kg/s passes into a pipe carrying

wet steam at 0.8 MPa, 0.95 dry. After adiabatic mixing the flow rate is 2.3 kg/s.

Determine the properties of the steam after mixing.

(Nov/Dec 2004)

V.ANBARASAN, AP/MECH

ME 6301- ENGINEERING THERMODYNAMICS

UNIT III QUESTION BANK

12. A vessel having a capacity of 0.05 m3 contains a mixture of saturated water and

saturated steam at a temperature of 2450C. The mass of the liquid present is 10 kg.

find the following

(i)

(ii)

(iii)

(iv)

(v)

(vi)

The pressure,

The mass,

The specific volume

The specific enthalpy,

The specific entropy, and

The specific internal energy.

(16)

(May/June 2014)

13. Steam flows steadily through a turbine with a mass flow rate of 3 kg/sec. the steam is

at 70 bar and 5000C while entering the turbine and at 0.2 bar on leaving the turbine.

The expansion process may be considered as isentropic. Determine the turbine output

power.

(May/June 2004)

SV

CE

T

14. Steam expands in a nozzle from 1 MPa, 2500C to 10 kPa, the flow rate being 1 kg/sec.

determine the velocity of steam at the exit of the nozzle and the exit area of the

nozzle. The steam velocity at the inlet to the nozzle may be ignored.

(May/June 2004)

0

15. Two streams of steam, one at 2 MPa, 300 C and the other at 2 MPa, 4000C, mix in a

steady flow adiabatic process. The rates of flow of the two streams are 3 kg/min and 2

kg/min respectively. Evaluate the final temperature of the emerging steam, if there is

no pressure drop due to the mixing process. What would be the rate of increase in the

entropy of the universe? This steam with negligible velocity now expands

adiabatically in a nozzle to a pressure of 1 kPa. Determine the exit velocity of the

stream and exit area of the nozzle.

(16)

(Nov/Dec 2011)

3

16. A 0.5 m vessel contains 10 kg refrigerant 134a at -20C. Determine the pressure, the

total internal energy and the volume occupied by the liquid phase.

(6)

(Nov/Dec 2010)

17. A rigid tank with a volume of 2.5 m3 contains 15 kg of saturated liquid vapour

mixture of water at 75C. Now the water is slowly heated. Determine the temperature

at which the liquid in the tank is completely vaporized. Also, show the processes on

T-v diagram with respect to saturation lines.

(10)

(Nov/Dec 2010)

18. Steam flows through a small turbine at the rate of 5000 kg/h entering at 15 bar, 3000C

and leaving at 0.1bar with 4% moisture. The steam enters at 80m/s at a point 2 m

above the discharge and leaves at 40m/s. compute the shaft power assuming that the

device is adiabatic but considering kinetic and potential energies. Calculate the

diameters of the inlet and discharge tubes.

(8)

(May/June 2010)

19. Steam expands isentropically in a nozzle from 1 MPa, 2500C to 10 kPa. The steam

flow rate is 1 kg/s. find the velocity of steam at the exit from the nozzle, and the exit

area of the nozzle. Neglect the velocity of steam at inlet to the nozzle. The exhaust

steam from the nozzle flows in a condenser and flows out as saturated water. The

V.ANBARASAN, AP/MECH

ME 6301- ENGINEERING THERMODYNAMICS

UNIT III QUESTION BANK

SV

CE

T

cooling water enters the condenser at 250C and leaves at 350C. Determine the mass

flow rate.

(8)

(May/June 2010)

20. In a closed vessel the 100 kg of steam at 100 kPa, 0.5 dry is to be brought to a

pressure of 1000 kPa inside vessel. Determine the mass of dry saturated steam

admitted at 2000 kPa for raising pressure. Also determine the final quality.

(16)

(May/June 2011)

21. A steam power plant running on Rankine cycle has steam entering HP turbine at 20

MPa, 5000C and leaving LP turbine at 90% dryness. Considering condenser pressure

of 0.005 MPa and reheating occurring up to the temperature of 5000C determine,

(i) The pressure at which steam leaves HP turbine

(ii) The thermal efficiency.

(iii) Work done.

(16)

(May/June 2011)

22. In a Rankine cycle, the steam at inlet to turbine is saturated at a pressure of 35 bar and

the exhaust pressure is 0.2 bar. The flow rate of steam is 9.5 kg/s. Determine (1) the

pump work (2) the turbine work (3) Rankine efficiency (4) condenser heat flow (5)

work ratio and (6) specific steam consumption.

(10)

(Nov/Dec 2011)

23. Steam at a pressure of 2.5 MPa and 500C is expanded in a steam turbine to a

condenser pressure of 0.05 MPa. Determine for Rankine cycle:

(i) The thermal efficiency of Rankine cycle

(ii) Specific steam consumption.

If the steam pressure is reduced to 1 MPa and the temperature is kept same 500C.

Determine the thermal efficiency and the specific steam consumption. Neglect feed

pump work,

(16)

(Nov/Dec 2006)

24. Consider a steam power plant operating on the ideal Rankine cycle. Steam enters the

turbine at 3 MPa and 623 K and is condensed in the condenser at a pressure of 10 kPa.

Determine (i) the thermal efficiency of this power plant, (ii) the thermal efficiency if

steam is superheated to 873 K instead of 623 K, and (iii) the thermal efficiency if the

boiler pressure is raised to 15 MPa while the turbine inlet temperature is maintained at

873 K.

(16)

(Nov/Dec 2009)

25. Consider a steam power plant operating on the ideal reheat Rankine cycle. Steam

enters the high-pressure turbine at 15 MPa and 873 K and is condensed in the

condenser at a pressure of 10 kPa. If the moisture content of the steam at the exit of

the low-pressure turbine is not to exceed 10.4 percent, determine (i) the pressure at

which the steam should be reheated and (ii) the thermal efficiency of the cycle.

Assume the steam is reheated to the inlet temperature of the high-pressure turbine.

(16)

(Nov/Dec 2009)

26. Consider a steam power plant that operates on a reheat Rankine cycle and has a net

power output of 80 MW. Steam enters the high-pressure turbine at 10 MPa and 500C

and the low-pressure turbine at 1 MPa and 500C. Steam leaves the condenser as a

saturated liquid at a pressure of 10 kPa. The isentropic efficiency of the turbine is 80

percent, and that of the pump is 95 percent. Show the cycle on a T-s diagram with

respect to saturation lines, and determine

(i) The quality (or temperature, if superheated) of the steam at the turbine exit,

V.ANBARASAN, AP/MECH

ME 6301- ENGINEERING THERMODYNAMICS

UNIT III QUESTION BANK

(ii) The thermal efficiency of the cycle, and

(iii) The mass flow rate of the steam.

SV

CE

T

(16)

(Nov/Dec 2010)

27. A steam boiler generates steam at 30bar, 3000C at the rate of 2kg/s. this steam is

expanded isentropically in a turbine to a condenser pressure of 0.05bar, condensed at

constant pressure and pumped back to boiler.

(i)

Draw the schematic arrangement of the above plant and T-S diagram

of Rankine cycle.

(ii)

Find heat supplied in the boiler per hour.

(iii) Determine the quality of steam after expansion.

(iv)

What is the power generated by the turbine?

(v)

Estimate the Rankine efficiency considering pump work.

(May/June 2004)

28. A cyclic steam power plant is to be designed for a steam temperature at turbine inlet

of 633K and an exhaust pressure of 8kPa. After isentropic expansion of steam in the

turbine, the moisture content at the turbine exhaust is not to exceed 15%. Determine

the greatest allowable steam pressure at the turbine inlet, and calculate the Rankine

cycle efficiency for these steam conditions. Estimate also the mean temperature of

heat addition.

(16)

(Nov/Dec 2007)

29. Steam at 20bar, 3600C is expanded in a steam turbine to 0.08bar. It then enters a

condenser, where it is condensed to saturated liquid water. The pump feeds back the

water into the boiler.

(i)

Assuming ideal processes find the net-work and the cycle efficiency per kg of

steam.

(ii)

If the pump and the turbine have 80% efficiency, find the percentage reduction

in the net-work and cycle efficiency.

(8)

(May/June 2012)

30. In a steam power plant operating on an ideal reheat Rankine cycle, the steam enters

the high-pressure turbine at 3MPa and 4000C. After expansion to 0.6 MPa, the steam

is reheated to 4000C and then expanded the low-pressure turbine to the condenser

pressure of 10kPa. Determine the thermal efficiency of the cycle and the quality of the

steam at the outlet of the low pressure turbine.

(Nov/Dec 2002)

31. In a thermal power plant operating on a Rankine cycle, superheated steam at 50 bar

and 5000C enters a turbine, the isentropic efficiency of which is 0.8. The condenser

pressure is 0.05 bar and it delivers saturated liquid to a feed pump, the isentropic

efficiency of which is 0.7. Determine the thermal efficiency of the power plant and

the mass flow rate of steam required for 50 MW net power generation.

(8)

(May/June 2010)

32. A reheat cycle operating between 30 and 0.04bar has a superheat and reheat

temperature of 4500C. The first expansion takes place till the steam is dry saturated

and then reheat is given. Neglecting feed pump work. Determine the ideal cycle

efficiency.

(Nov/Dec2003)

33. A steam power plant operates on a theoretical reheat cycle. Steam at boiler at 150 bar,

5500C expands through the high pressure turbine. It is reheated at a constant pressure

of 40bar to 5500C and expands through the low pressure turbine to a condenser at 0.1

bars. Draw T-s and h-s diagrams. Find :

(i)

Quality of steam at turbine exhaust

V.ANBARASAN, AP/MECH

ME 6301- ENGINEERING THERMODYNAMICS

UNIT III QUESTION BANK

(ii)

(iii)

Cycle efficiency

Steam rate in kg/kWh.

SV

CE

T

(16)

(May/June2004, May/June 2014)

34. In a reheat steam cycle, the maximum steam temperature is limited to 773K. The

condenser pressure is 10kPa and the quality at turbine exhaust is 0.8778. Had there

been no reheat, the exhaust quality would have been 0.7592. Assuming ideal

processes, determine (i) reheat pressure (ii) the boiler pressure (iii) the cycle

efficiency (iv) the steam rate.

(16)

(Nov/Dec2007)

35. In a regenerative cycle, the steam pressure at turbine inlet is 30bar and the exhaust is

at 0.04bar. The steam is initially saturated. Enough steam is bled off at the optimum

pressure of 3bar to heat the feed water. Determine the cycle efficiency. Neglect pump

work.

(Nov/Dec2003)

36. In a single heater regenerative cycle the steam enters the turbine at 30bar and 400 0C

and the turbine exhaust pressure is 0.10bar. The condensate is heated in a direct

contact type heater which operates at 5bar. Find the efficiency and the steam rate of

the cycle and the increase in mean temperature of heat addition, efficiency and steam

rate as compared to the Rankine cycle. Neglect pump work.

(May/June2004)

37. Steam enters the turbine at 3MPa and 4000C and is condensed at 10kPa. Some

quantity of steam leaves the turbine at 0.6MPa and enters open feed water heater.

Compute the fraction of the steam extracted per kg of steam and cycle thermal

efficiency.

(10)

(Nov/Dec2005, Nov/Dec2012)

38. In an ideal reheat cycle, the steam enters the turbine at 30bar and 5000C. After

expansion to 5bar, the steam is reheated to 5000C and then expanded to the condenser

pressure of 0.1 bar. Determine the cycle thermal efficiency, mass flow rate of steam.

Take power output as 100 MW.

(10)

(May/June2007)

39. Steam at 50bar, 4000C expands in a Rankine cycle to 0.34 bar. For a mass flow rate of

150 kg/s of steam, determine

(i)

Power developed

(ii)

Thermal efficiency

(iii) Specific steam consumption.

(8)

(May/June 2013)

39. Steam at 4800C, 90 bar is supplied to a Rankine cycle. It is reheated to 12bar and

4800C. The minimum pressure is 0.07 bar. Find the work output and cycle efficiency

using steam tables with and without considering pump work.

(16)

(Nov / Dec 2013)

V.ANBARASAN, AP/MECH

Vous aimerez peut-être aussi

- Thermodynamics question bank analyzedDocument10 pagesThermodynamics question bank analyzedRaj PratyushPas encore d'évaluation

- Important QuestionsDocument5 pagesImportant Questionstamilselvan nPas encore d'évaluation

- Thermodynamics Review ProblemsDocument3 pagesThermodynamics Review ProblemssayanPas encore d'évaluation

- Instruction: Attempt All Questions. (ASSIGNMENT:-section A: Odd Numbers and Section B: Even Numbers) 1. 2. 3. 4. 5. 6. 7. 8. 9Document2 pagesInstruction: Attempt All Questions. (ASSIGNMENT:-section A: Odd Numbers and Section B: Even Numbers) 1. 2. 3. 4. 5. 6. 7. 8. 9Abi DemPas encore d'évaluation

- Assignment 1 First Law 2016Document8 pagesAssignment 1 First Law 2016PabitraBadhuk0% (1)

- Thermodynamics QBDocument15 pagesThermodynamics QBrajasamygopalPas encore d'évaluation

- Engineering Thermodynamics Important QuestionsDocument2 pagesEngineering Thermodynamics Important QuestionsPrasobh ShamohanPas encore d'évaluation

- ETD Model IV QPDocument2 pagesETD Model IV QPtagoreboopathyPas encore d'évaluation

- Me8391 Important QuestionsDocument4 pagesMe8391 Important QuestionsMohsin EngrPas encore d'évaluation

- U15MET303-ENGINEERING THERMODYNAMICS-ASSIGNMENTDocument8 pagesU15MET303-ENGINEERING THERMODYNAMICS-ASSIGNMENTKumaran RPas encore d'évaluation

- Thermo ProblemsDocument12 pagesThermo ProblemsElainePas encore d'évaluation

- Our Official Android App - REJINPAUL NETWORK FromDocument2 pagesOur Official Android App - REJINPAUL NETWORK FromPradeep KumarPas encore d'évaluation

- TDCE Question Bank - 2018 Unit IDocument11 pagesTDCE Question Bank - 2018 Unit IvinodPas encore d'évaluation

- Thermodynamics Question Set ADocument4 pagesThermodynamics Question Set AVivek NegiPas encore d'évaluation

- Me3391-Engineering Thermodynamics-805217166-Important Question For Engineering ThermodynamicsDocument10 pagesMe3391-Engineering Thermodynamics-805217166-Important Question For Engineering ThermodynamicsRamakrishnan NPas encore d'évaluation

- ETD Important QuestionsDocument6 pagesETD Important QuestionsRavi KîshôrePas encore d'évaluation

- Thermodynamics HomeworkDocument5 pagesThermodynamics HomeworktendoPas encore d'évaluation

- ASSIGNMENT Me PDFDocument3 pagesASSIGNMENT Me PDFmahfuzPas encore d'évaluation

- MEC1405 - Thermodynamics I (2009Document3 pagesMEC1405 - Thermodynamics I (2009Maria CutajarPas encore d'évaluation

- Assignment Basics ATDocument2 pagesAssignment Basics ATXerox WorldPas encore d'évaluation

- ThermoDocument4 pagesThermowong zhi chengPas encore d'évaluation

- Taller 2 2023-1Document8 pagesTaller 2 2023-1anderson ortizPas encore d'évaluation

- Pset 1 CombustionDocument13 pagesPset 1 CombustionMicaella Jaime De LeonPas encore d'évaluation

- MI-106 Tut ThermoDocument37 pagesMI-106 Tut ThermoDhananjayLekshmiNarayan100% (7)

- Thermal Engineering - Department of Mechanical EngineeringDocument8 pagesThermal Engineering - Department of Mechanical EngineeringPrashant KumarPas encore d'évaluation

- KF 1Document19 pagesKF 1Diana Fitriani SurtikaPas encore d'évaluation

- Me8595 Iq R17Document2 pagesMe8595 Iq R17Narayanan SubramanianPas encore d'évaluation

- Combus Eng'g Homework 1Document5 pagesCombus Eng'g Homework 1Alecsia NuguidPas encore d'évaluation

- Thermodynamics Problems & SolutionsDocument2 pagesThermodynamics Problems & SolutionsDiego Cuarenta JaureguiPas encore d'évaluation

- ME LAB 3 ReportDocument37 pagesME LAB 3 ReportwijawijaPas encore d'évaluation

- 8 Vapor and Combined Power CyclesDocument14 pages8 Vapor and Combined Power CyclesAbdur RashidPas encore d'évaluation

- R14 - Steam Power Cycles PDFDocument10 pagesR14 - Steam Power Cycles PDFnotoriousneal12Pas encore d'évaluation

- Full ReportDocument16 pagesFull ReportafiqahanuwarPas encore d'évaluation

- Department of Biomedical Engineering (Aait) : Work Sheet #3Document4 pagesDepartment of Biomedical Engineering (Aait) : Work Sheet #3gfsfPas encore d'évaluation

- Tutorial Sheet No2Document7 pagesTutorial Sheet No2عبدالله عمرPas encore d'évaluation

- PS Compilation For 2019Document10 pagesPS Compilation For 2019Nicole RamirezPas encore d'évaluation

- Mechanical Engineering Department Unit 1 NotesDocument5 pagesMechanical Engineering Department Unit 1 NotesNallappan Rajj APas encore d'évaluation

- Question Bank-Thermal EngineeringDocument4 pagesQuestion Bank-Thermal EngineeringIrfan ShaikhPas encore d'évaluation

- Borgnakke's Fundamentals of Thermodynamics: Global EditionDocument94 pagesBorgnakke's Fundamentals of Thermodynamics: Global Edition정윤서Pas encore d'évaluation

- ETD Chapter 3Document17 pagesETD Chapter 3Vasantha SeelanPas encore d'évaluation

- ChE 204 HW-4 and HW-5 Together, Spring 2014, See Changes!Document5 pagesChE 204 HW-4 and HW-5 Together, Spring 2014, See Changes!Irene Kaye AceroPas encore d'évaluation

- PomeDocument17 pagesPomeAnirudh KaushikPas encore d'évaluation

- Tutorial Questions On Heat Ex ChangersDocument3 pagesTutorial Questions On Heat Ex ChangersPuneet Garg100% (1)

- Tutorial 1 (ME206)Document2 pagesTutorial 1 (ME206)deshrajPas encore d'évaluation

- ETD - Question BankDocument6 pagesETD - Question BankGopinath VPas encore d'évaluation

- Me2202 PDFDocument15 pagesMe2202 PDFvis3012Pas encore d'évaluation

- 11me201 Thermodynamics QuestionsDocument12 pages11me201 Thermodynamics QuestionsramsastryPas encore d'évaluation

- 11me201 Thermodynamics QuestionsDocument12 pages11me201 Thermodynamics QuestionsJustin Cox0% (2)

- ME6301 Engineering Thermodynamics Question BankDocument15 pagesME6301 Engineering Thermodynamics Question BankAnantha Kumar0% (1)

- Sal Institute Thermodynamics AssignmentsDocument4 pagesSal Institute Thermodynamics AssignmentsAyush2273Pas encore d'évaluation

- Assignment2 Btech Sem3 TD Mu207Document3 pagesAssignment2 Btech Sem3 TD Mu207nageshPas encore d'évaluation

- Thermodynamics QuestionsDocument4 pagesThermodynamics Questionsprateek vyasPas encore d'évaluation

- Metallurgical Thermodynamics Tutorial Work, Heat & EnergyDocument6 pagesMetallurgical Thermodynamics Tutorial Work, Heat & EnergyRebekka Ndahafa100% (1)

- IDEAL GAS PROCESSESDocument2 pagesIDEAL GAS PROCESSESfitriPas encore d'évaluation

- Screenshot 2023-01-11 at 8.11.58 PMDocument15 pagesScreenshot 2023-01-11 at 8.11.58 PMAbdla DoskiPas encore d'évaluation

- Anna University online students community mechanical engineering question bank thermodynamicsDocument12 pagesAnna University online students community mechanical engineering question bank thermodynamicspraveenrajjPas encore d'évaluation

- Tutorial Sheet 6Document2 pagesTutorial Sheet 6Syed YousufuddinPas encore d'évaluation

- MCL142 Thermal Science Tutorial - 3 Key ConceptsDocument4 pagesMCL142 Thermal Science Tutorial - 3 Key ConceptsSamarthPas encore d'évaluation

- Insc Awards ListDocument188 pagesInsc Awards ListEric CookPas encore d'évaluation

- Apartment Rules and RegulationsDocument2 pagesApartment Rules and RegulationsAvreilePas encore d'évaluation

- IIT Madras Research Admission BrochureDocument42 pagesIIT Madras Research Admission BrochureEric CookPas encore d'évaluation

- ICIME 2020 BrochureDocument2 pagesICIME 2020 BrochureDr J KandasamyPas encore d'évaluation

- Me6702 Mech QBDocument2 pagesMe6702 Mech QBEric CookPas encore d'évaluation

- Feb - 19 (Supply Exam)Document1 pageFeb - 19 (Supply Exam)Eric CookPas encore d'évaluation

- Cad Cam Mech2 PDFDocument1 pageCad Cam Mech2 PDFHARINADH REDDY GONTUPas encore d'évaluation

- GJFHJFJFJGFJDocument2 pagesGJFHJFJFJGFJEric CookPas encore d'évaluation

- Nov-18 (Reg Exam)Document5 pagesNov-18 (Reg Exam)Eric CookPas encore d'évaluation

- CAD/CAM Code Revision R13 Exam GuideDocument1 pageCAD/CAM Code Revision R13 Exam GuideMohamed ElagibPas encore d'évaluation

- Cad Cam Mech2 PDFDocument1 pageCad Cam Mech2 PDFHARINADH REDDY GONTUPas encore d'évaluation

- 5725r09 MechatronicsDocument1 page5725r09 MechatronicsEric CookPas encore d'évaluation

- Me6702 Mech QBDocument183 pagesMe6702 Mech QBEric CookPas encore d'évaluation

- Academic Calalnder Even17 18Document31 pagesAcademic Calalnder Even17 18Eric CookPas encore d'évaluation

- MCT 2014Document1 pageMCT 2014Eric CookPas encore d'évaluation

- 4 Semester MU-202: Kinematics of Machines Course Outcomes: After Completion of This Course, The Successful Students Will Be Able To: CO StatementDocument6 pages4 Semester MU-202: Kinematics of Machines Course Outcomes: After Completion of This Course, The Successful Students Will Be Able To: CO StatementEric CookPas encore d'évaluation

- PANIMALAR INSTITUTE OF TECHNOLOGY QUESTION BANK MECHATRONICSDocument6 pagesPANIMALAR INSTITUTE OF TECHNOLOGY QUESTION BANK MECHATRONICSNandha KumarPas encore d'évaluation

- BoilersDocument38 pagesBoilersAshlin Augusty92% (24)

- T Variables On Heat TR PDFDocument6 pagesT Variables On Heat TR PDFEric CookPas encore d'évaluation

- Laser Beam Spark Plug PDFDocument32 pagesLaser Beam Spark Plug PDFEric CookPas encore d'évaluation

- PANIMALAR INSTITUTE OF TECHNOLOGY QUESTION BANK MECHATRONICSDocument6 pagesPANIMALAR INSTITUTE OF TECHNOLOGY QUESTION BANK MECHATRONICSNandha KumarPas encore d'évaluation

- FORM-1 Application for Physical Fitness DeclarationDocument2 pagesFORM-1 Application for Physical Fitness DeclarationGulshan Kumar Sinha100% (1)

- Cylinder PetrolDocument1 pageCylinder PetrolEric CookPas encore d'évaluation

- JNTUH B.tech 3 Year ME R16 SyllabusDocument34 pagesJNTUH B.tech 3 Year ME R16 SyllabusEric CookPas encore d'évaluation

- CFD Applications in Mechanical EngineeringDocument2 pagesCFD Applications in Mechanical EngineeringEric CookPas encore d'évaluation

- Group Four of Diploma Civil "A"Document21 pagesGroup Four of Diploma Civil "A"Eric CookPas encore d'évaluation

- JNTUH B.tech 3 Year ME R16 SyllabusDocument34 pagesJNTUH B.tech 3 Year ME R16 SyllabusEric CookPas encore d'évaluation

- Engineering Drawing Short QuestionsDocument11 pagesEngineering Drawing Short QuestionsTarish Mittal89% (47)

- Machines Dynamics & Refrigeration CoursesDocument6 pagesMachines Dynamics & Refrigeration CoursesEric CookPas encore d'évaluation

- Jntuk 1-1 r16 Q.P Dec 2016 - Engineering Drawing (Ece Eie)Document8 pagesJntuk 1-1 r16 Q.P Dec 2016 - Engineering Drawing (Ece Eie)mahesh babu bandiPas encore d'évaluation

- ITC Kuningan Ambas1Document8 pagesITC Kuningan Ambas1amriadi amiruddinPas encore d'évaluation

- Gas field production and reserves analysisDocument23 pagesGas field production and reserves analysisRoba SaidPas encore d'évaluation

- Espectofotometro Uv 1900iDocument16 pagesEspectofotometro Uv 1900iAlecitaGutierrezMartinezPas encore d'évaluation

- TrainingDocument66 pagesTrainingandiPas encore d'évaluation

- Astm B 98M-98Document5 pagesAstm B 98M-98Fa ChPas encore d'évaluation

- Treatment of Jean-Wash Wastewater by Combined Coagulation Hydrolysisacidification and Fenton OxidatiDocument7 pagesTreatment of Jean-Wash Wastewater by Combined Coagulation Hydrolysisacidification and Fenton OxidatiJúlio César Spillere RonchiPas encore d'évaluation

- Astm A194Document13 pagesAstm A194Himanshu KanungoPas encore d'évaluation

- Chap 1 Introduction To Chem Eng Profession - 2Document31 pagesChap 1 Introduction To Chem Eng Profession - 2SyafiyatulMunawarahPas encore d'évaluation

- Desalting Part 1 May 2009Document104 pagesDesalting Part 1 May 2009ermusatPas encore d'évaluation

- Fractional Distillation WorksheetDocument2 pagesFractional Distillation WorksheetdodoPas encore d'évaluation

- Safety Rules for Chemistry LabDocument2 pagesSafety Rules for Chemistry LabFritz ManyauPas encore d'évaluation

- 24150Document3 pages24150B.yaswanth KumarPas encore d'évaluation

- Anaerobic Co Digestion of Food Waste and Dairy Manure Effects of Food Waste Particle Size and Organic Loading RateDocument7 pagesAnaerobic Co Digestion of Food Waste and Dairy Manure Effects of Food Waste Particle Size and Organic Loading RateAnonymous MVHQ97KEoPPas encore d'évaluation

- Current Trends in Explosive Detection Techniques PDFDocument16 pagesCurrent Trends in Explosive Detection Techniques PDFSandra LuizPas encore d'évaluation

- Certificate of Analysis: DEC DEC DECDocument2 pagesCertificate of Analysis: DEC DEC DECAlejandro PalaciosPas encore d'évaluation

- Fire Safety NotesDocument13 pagesFire Safety Notesrescueone93% (14)

- Waste ManagementDocument28 pagesWaste Managementkeerthishankar p100% (4)

- Mec Fact Sheet Cell Phone 0Document2 pagesMec Fact Sheet Cell Phone 0api-259266305Pas encore d'évaluation

- Matter Separation Tech Notes Myp4Document21 pagesMatter Separation Tech Notes Myp4anitPas encore d'évaluation

- Appendix A. Thermodynamic Parameters PDFDocument10 pagesAppendix A. Thermodynamic Parameters PDFMawar Rahmah AnggrainiPas encore d'évaluation

- Question (Descriptive) Bank Unit - 1 and Unit-4Document19 pagesQuestion (Descriptive) Bank Unit - 1 and Unit-4Ziyaul AijazPas encore d'évaluation

- Vibration and Rotation SpectrosDocument6 pagesVibration and Rotation SpectrosWendyLimPas encore d'évaluation

- Irrigation Water Quality Criteria - Colorado State Univ, May 2011 PDFDocument4 pagesIrrigation Water Quality Criteria - Colorado State Univ, May 2011 PDFengr123Pas encore d'évaluation

- Ch05 Answerkey Hoefnagels EssDocument7 pagesCh05 Answerkey Hoefnagels EssCry The WolffPas encore d'évaluation

- Emergency Response and Spill ControlDocument5 pagesEmergency Response and Spill ControlbaluchakpPas encore d'évaluation

- Relating To Thermophysical Properties: Standard TerminologyDocument7 pagesRelating To Thermophysical Properties: Standard Terminologysabaris ksPas encore d'évaluation

- Henkel at Work in The Defense IndustryDocument7 pagesHenkel at Work in The Defense IndustrydatkoloPas encore d'évaluation

- Ethanol-wet bonding may enhance bonding of etch-and-rinse adhesivesDocument10 pagesEthanol-wet bonding may enhance bonding of etch-and-rinse adhesivesSergio Llufire MendozaPas encore d'évaluation

- Water Sorption and The Plasticization Effect in WafersDocument8 pagesWater Sorption and The Plasticization Effect in WafersElkin G ArcosPas encore d'évaluation

- Neet Booster Test Series (NBTS) For Neet-2021 Test - 8: PhysicsDocument15 pagesNeet Booster Test Series (NBTS) For Neet-2021 Test - 8: PhysicsupsahuPas encore d'évaluation