Académique Documents

Professionnel Documents

Culture Documents

Grout & Mortar Mix Design

Transféré par

Kelly BatesCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Grout & Mortar Mix Design

Transféré par

Kelly BatesDroits d'auteur :

Formats disponibles

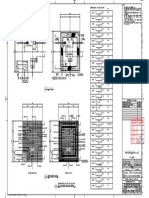

Project: LOADING RACK FACILITIES AT RT DISTRIBUTION

Subject: GROUT MIX DESIGN FOR 1 m3 BATCH

Design Strength = 2000 psi

SN

MATERIAL

1.

2.

3.

4.

5.

6.

Cement

Water

Aggregates, (max. 3/8")

Sand

Air, 3%

*Chemical

Grout Density =

(Theoretical)

Notes:

a.

b.

c.

d.

e.

f.

g.

Weight of Material

250

145

775

1,186

2,356

kg

L

kg

kg

Specific

Gravity

3.15

1.0

2.60

2.65

0.0013

-

QTY for 1 bagger mixer

(Site Mix)

1 bag

1

29 Liters

29

2.21 box

155

3.31 box

237

-

bag

Liters

kg

kg

kg/m3

Grout as per ASTM C476 requirements

Flow of 110 5%

Air percentage not more than 8% for non-air entraining cement

Minimun cement content as per Aramco specifications = 250 kg for non-structural concrete

Water-Cement ratio of not more than 0.60 conforming to Aramco non-structural concrete

Grout strength of not less than 2000 psi

Mixing time time of not more than 2 1/2 hour upon addition of water

* Adding chemicals are optional factor since the mixing shall be carried out on the site using 1 bagger mixer.

Should it will be required, addition shall not be more than 2% of the equivalent weight of cementitious material

of the design. Moreover, the chemical to be used shall be a napthalene base.

* Effect of adding chemical material:

An initial trial mix shall be carried out in order to arrived at a desired workabilitywhen mortar/grout is concerned

to fill the CHB cells. Note that 110 5% flow of slump will not be observed when chemical is to be consider.

* Box dimesion is based on a 1 cu.ft. volume (i.e. 30x30x30cm) = 0.027 m3

Project: LOADING RACK FACILITIES AT RT DISTRIBUTION

Subject: MORTAR MIX DESIGN FOR 1 m3 BATCH

Design Strength = 1800 psi

SN

MATERIAL

1.

2.

3.

4.

5.

6.

Cement

Water

Aggregates, 3/8 or 3/16"

Sand

Air, 3%

*Chemical

Mortar Density =

(Theoretical)

Notes:

a.

b.

c.

d.

e.

f.

g.

Weight of Material

250

145

1,976

2,371

kg

L

kg

kg

Specific

Gravity

3.15

1.0

2.60

2.65

0.0013

-

QTY for 1 bagger mixer

(Site Mix)

1 bag

1

29 Liters

29

box

5.52 box

395

-

bag

Liters

kg

kg

kg/m3

Mortar as per ASTM C270 requirements

Flow of 110 5%

Air percentage not more than 8% for non-air entraining cement

Minimun cement content as per Aramco specifications = 250 kg for non-structural concrete

Water-Cement ratio of not more than 0.60 conforming to Aramco non-structural concrete

Mortar strength of not less than 1800 psi

Mixing time time of not more than 2 1/2 hour upon addition of water

* Adding chemicals are optional factor since the mixing shall be carried out on the site using 1 bagger mixer.

Should it will be required, addition shall not be more than 2% of the equivalent weight of cementitious material

of the design. Moreover, the chemical to be used shall be a napthalene base.

* Effect of adding chemical material:

An initial trial mix shall be carried out in order to arrived at a desired workabilitywhen mortar/grout is concerned

to fill the CHB cells. Note that 110 5% flow of slump will not be observed when chemical is to be consider.

* Box dimesion is based on a 1 cu.ft. volume (i.e. 30x30x30cm) = 0.027 m3

Vous aimerez peut-être aussi

- Grout Mix DesignDocument4 pagesGrout Mix DesignjaymarPas encore d'évaluation

- Yield of ConcreteDocument19 pagesYield of ConcreteSuvranil BanerjeePas encore d'évaluation

- ESTOP TDS - Estogard CS Lining R002.i.21Document2 pagesESTOP TDS - Estogard CS Lining R002.i.21Dewi OktoraPas encore d'évaluation

- Pile Integrity TestDocument7 pagesPile Integrity TestRolly Marc G. SoteloPas encore d'évaluation

- Mass ConcreteDocument20 pagesMass ConcreteDhanushka Srimal100% (1)

- Drilling Slurry - Bentonite Vs PolymerDocument1 pageDrilling Slurry - Bentonite Vs PolymerAdam Lim100% (1)

- Control Temp in Mass ConcreteDocument9 pagesControl Temp in Mass ConcretechrtromPas encore d'évaluation

- Methodstatement For Back Filling in StructuresDocument2 pagesMethodstatement For Back Filling in StructuresLaxminarayana SastryPas encore d'évaluation

- Curing of ConcreteDocument46 pagesCuring of Concretepmonica0850% (2)

- Non-Shrink Grout Application ProcedureDocument6 pagesNon-Shrink Grout Application Proceduremoytabura96Pas encore d'évaluation

- Method Statement For Pile Load Test by Kentledge MDocument4 pagesMethod Statement For Pile Load Test by Kentledge MCza ManPas encore d'évaluation

- Method Statement For Water Proofing of UG TankDocument5 pagesMethod Statement For Water Proofing of UG TankSagar ParabPas encore d'évaluation

- Method Statement For Shrinkage CracksDocument2 pagesMethod Statement For Shrinkage Cracksluvvie87Pas encore d'évaluation

- PQC Cracks Repair MethodsDocument5 pagesPQC Cracks Repair MethodsBattinapati Lakshmana RaoPas encore d'évaluation

- Cebex 100 PDFDocument2 pagesCebex 100 PDFBijaya RaulaPas encore d'évaluation

- Moisture Correction SheetDocument4 pagesMoisture Correction SheetSasanka SekharPas encore d'évaluation

- Approval of - Concurewb309-As Concrete Curing CompoundDocument4 pagesApproval of - Concurewb309-As Concrete Curing Compoundsalman tariqPas encore d'évaluation

- Method Statement For Concrete ProductionDocument20 pagesMethod Statement For Concrete ProductionAnduel SelamajPas encore d'évaluation

- Method Statement For Approval of Layer Thickness - Rev.01Document9 pagesMethod Statement For Approval of Layer Thickness - Rev.01Jox Biol100% (1)

- CD - Rfi .WM.22.1 Soil Engineering Method StatementDocument17 pagesCD - Rfi .WM.22.1 Soil Engineering Method Statementcristhian9ares9oboPas encore d'évaluation

- C938Document3 pagesC938jorgepitaPas encore d'évaluation

- Lab Concrete Mix Design C25aDocument17 pagesLab Concrete Mix Design C25aSoundar PachiappanPas encore d'évaluation

- HMA Mix Design Report-2Document11 pagesHMA Mix Design Report-2yustinokwingwa100% (1)

- Antiwashout Admixtures For Underwater ConcreteDocument2 pagesAntiwashout Admixtures For Underwater Concretemanil_5Pas encore d'évaluation

- Concrete Mix DesignDocument3 pagesConcrete Mix DesignSheik Mohamed LiakathPas encore d'évaluation

- Method Statement For Casting, Prestressing & Grounting of PSC GirdersDocument15 pagesMethod Statement For Casting, Prestressing & Grounting of PSC Girdersrohit singhPas encore d'évaluation

- Method Statement For Embankment and SubgradeDocument19 pagesMethod Statement For Embankment and SubgradeBiswajit BarikPas encore d'évaluation

- Proportioning Concrete Mixtures With Graded AggregatesDocument86 pagesProportioning Concrete Mixtures With Graded AggregatesM HAFEEZ RAJA100% (1)

- M55 With GGBS and MicrosilicaDocument1 pageM55 With GGBS and MicrosilicaLegendary GamingPas encore d'évaluation

- Wsdot Fop For Waqtc T 168: SignificanceDocument4 pagesWsdot Fop For Waqtc T 168: SignificanceDiegito RecaldePas encore d'évaluation

- WMS (Method Statement For Pouring Concrete On Slab On Grade)Document4 pagesWMS (Method Statement For Pouring Concrete On Slab On Grade)PUI CHEE KHIANPas encore d'évaluation

- Method Statement - PilingDocument65 pagesMethod Statement - PilingNaseer IsmailPas encore d'évaluation

- Guideline Static Axial Compression Pile Load TestDocument15 pagesGuideline Static Axial Compression Pile Load Testcecdesign09Pas encore d'évaluation

- Quality Control For PrecastDocument7 pagesQuality Control For PrecastvirajcsPas encore d'évaluation

- Grout MixDocument1 pageGrout MixThein Htun AungPas encore d'évaluation

- Effect of Steam Curing Cycles On Strength and Durability of SCC A Case Study in Precast Concrete 2013 Construction and Building MaterialsDocument7 pagesEffect of Steam Curing Cycles On Strength and Durability of SCC A Case Study in Precast Concrete 2013 Construction and Building MaterialsWilliam GossPas encore d'évaluation

- Sand Calibration FormetDocument2 pagesSand Calibration FormetAnish PanchalPas encore d'évaluation

- Fly Ash As Binder in ConcreteDocument10 pagesFly Ash As Binder in ConcreteZuhair NadeemPas encore d'évaluation

- Cement & Concrete 2023Document42 pagesCement & Concrete 2023Joel MisaPas encore d'évaluation

- Ms For Concrete PilesDocument16 pagesMs For Concrete PilesahmadPas encore d'évaluation

- rev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONDocument7 pagesrev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONMahaboob PashaPas encore d'évaluation

- DBM 507Document7 pagesDBM 507Mark Moni Mary ManoPas encore d'évaluation

- 2020-06-25 Method Statement of RCBC Construction CH402+737Document33 pages2020-06-25 Method Statement of RCBC Construction CH402+737施智捷100% (2)

- Method Statement For Pile GroutingDocument2 pagesMethod Statement For Pile Groutingsaman2580Pas encore d'évaluation

- Placing of Geo Textile 005Document7 pagesPlacing of Geo Textile 005Vinod VasanPas encore d'évaluation

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURK100% (1)

- PDS - SikaSeal-402 Fillerboard MYDocument2 pagesPDS - SikaSeal-402 Fillerboard MYSiji OktoberPas encore d'évaluation

- Rubble ConcreteDocument537 pagesRubble ConcreteRoshan Nanjundaiah100% (3)

- 3M Straight Edge TestDocument3 pages3M Straight Edge TestSoundar PachiappanPas encore d'évaluation

- ITP-CI-026a-02 (Building Finishing Works)Document4 pagesITP-CI-026a-02 (Building Finishing Works)Delta akathehuskyPas encore d'évaluation

- Cold-Mix RecyclingDocument6 pagesCold-Mix RecyclingKandikanti Ashok ChiganshiPas encore d'évaluation

- 04 - TDS Meyco FlowcableDocument3 pages04 - TDS Meyco FlowcablebossbobPas encore d'évaluation

- Method Statement Concrete Coring (ASTM C 142)Document2 pagesMethod Statement Concrete Coring (ASTM C 142)Twin Bulls100% (1)

- Method Statement of Static Tension Load Test PLTU Suralaya Jawa 9 & 10 - Page 9 Rev PDFDocument12 pagesMethod Statement of Static Tension Load Test PLTU Suralaya Jawa 9 & 10 - Page 9 Rev PDFFendi Rang TigorPas encore d'évaluation

- Concrete Mix DesignDocument14 pagesConcrete Mix Designchaos_atulPas encore d'évaluation

- QC and Mix Design DataDocument39 pagesQC and Mix Design Dataइंजि कौस्तुभ पवारPas encore d'évaluation

- Concrete Mix Design: A S M Fahad Hossain Assistant Professor Department of Civil Engineering, AUSTDocument28 pagesConcrete Mix Design: A S M Fahad Hossain Assistant Professor Department of Civil Engineering, AUSTshifatPas encore d'évaluation

- Conc - Tech Lec-4Document26 pagesConc - Tech Lec-4kassawPas encore d'évaluation

- Romero Rodriguez Emmanuel Takahihsy TraduccionDocument9 pagesRomero Rodriguez Emmanuel Takahihsy TraduccionEmmanuel Takahishy Romero RodriguezPas encore d'évaluation

- Mix DesignDocument52 pagesMix DesignsorowarePas encore d'évaluation

- ASTM A352 18aDocument7 pagesASTM A352 18aKelly BatesPas encore d'évaluation

- DIN-En-10056-01 Structural Steel Equal&Unequal Leg AnglesDocument9 pagesDIN-En-10056-01 Structural Steel Equal&Unequal Leg AnglesbacheghoulPas encore d'évaluation

- High-Strength Low-Alloy Columbium-Vanadium Structural Steel: Standard Specification ForDocument4 pagesHigh-Strength Low-Alloy Columbium-Vanadium Structural Steel: Standard Specification ForCarlosPas encore d'évaluation

- AWS - Design Handbook For Calculating Fillet Weld Sizes 1997 PDFDocument27 pagesAWS - Design Handbook For Calculating Fillet Weld Sizes 1997 PDFMustafaSaylav100% (1)

- Normalized High-Strength Low-Alloy Structural Steel Plates: Standard Specification ForDocument3 pagesNormalized High-Strength Low-Alloy Structural Steel Plates: Standard Specification ForKelly BatesPas encore d'évaluation

- DIN-En-10056-01 Structural Steel Equal&Unequal Leg AnglesDocument9 pagesDIN-En-10056-01 Structural Steel Equal&Unequal Leg AnglesbacheghoulPas encore d'évaluation

- Coronavirus and Food HygieneDocument2 pagesCoronavirus and Food HygieneKelly BatesPas encore d'évaluation

- Headache and Neck PainDocument3 pagesHeadache and Neck PainKelly BatesPas encore d'évaluation

- Astm B443.8889Document7 pagesAstm B443.8889Kelly BatesPas encore d'évaluation

- Coronavirus e Influenza. What DifferencesDocument2 pagesCoronavirus e Influenza. What DifferencesKelly BatesPas encore d'évaluation

- Covid-19 How The Virus Has Changed Scientific CommunicationDocument2 pagesCovid-19 How The Virus Has Changed Scientific CommunicationKelly BatesPas encore d'évaluation

- Dewatering Construction ProcedureDocument5 pagesDewatering Construction ProcedureKelly BatesPas encore d'évaluation

- Memory: What Is It, How It WorksDocument2 pagesMemory: What Is It, How It WorksKelly BatesPas encore d'évaluation

- Coronavirus The Risk of SmokingDocument3 pagesCoronavirus The Risk of SmokingKelly BatesPas encore d'évaluation

- Splice Length in ColumnsDocument1 pageSplice Length in ColumnsKelly BatesPas encore d'évaluation

- Paint & CoatingDocument43 pagesPaint & CoatingKelly Bates80% (5)

- Coating Data SheetDocument4 pagesCoating Data SheetKelly Bates50% (2)

- Rebar Devt. Length, LDDocument1 pageRebar Devt. Length, LDKelly BatesPas encore d'évaluation

- MS-Exploratory ExcavationDocument6 pagesMS-Exploratory ExcavationKelly BatesPas encore d'évaluation

- MS Exploratory ExcavationDocument6 pagesMS Exploratory ExcavationKelly BatesPas encore d'évaluation

- Autocad Text and ScalingDocument2 pagesAutocad Text and ScalingKelly BatesPas encore d'évaluation

- Installation of Car Parking ShadesDocument6 pagesInstallation of Car Parking ShadesKelly Bates100% (3)

- AISC Shapes TablesDocument64 pagesAISC Shapes TablesJose ManuelPas encore d'évaluation

- JSA For Excavation WorksDocument4 pagesJSA For Excavation WorksKelly Bates100% (12)

- AutoCAD Scale FactorDocument2 pagesAutoCAD Scale FactorKelly BatesPas encore d'évaluation

- Autocad Text and ScalingDocument2 pagesAutocad Text and ScalingKelly BatesPas encore d'évaluation

- Issued For Construction: Eastern Trading & Cont. EstDocument1 pageIssued For Construction: Eastern Trading & Cont. EstKelly BatesPas encore d'évaluation

- Beam Rebar DetailDocument1 pageBeam Rebar DetailKelly BatesPas encore d'évaluation

- Concrete BeamDocument1 pageConcrete BeamKelly BatesPas encore d'évaluation

- BBS For BeamDocument1 pageBBS For BeamKelly BatesPas encore d'évaluation

- 1.161000 702010 New Perspectives 2ndedDocument43 pages1.161000 702010 New Perspectives 2ndedbimobimoprabowoPas encore d'évaluation

- Possessive Determiners: A. 1. A) B) C) 2. A) B) C) 3. A) B) C) 4. A) B) C) 5. A) B) C) 6. A) B) C) 7. A) B) C)Document1 pagePossessive Determiners: A. 1. A) B) C) 2. A) B) C) 3. A) B) C) 4. A) B) C) 5. A) B) C) 6. A) B) C) 7. A) B) C)Manuela Marques100% (1)

- A Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyDocument11 pagesA Teachers' Journey: Phenomenological Study On The Puritive Behavioral Standards of Students With Broken FamilyNova Ariston100% (2)

- June 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelDocument16 pagesJune 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelNyraStardollPas encore d'évaluation

- A Literary Nightmare, by Mark Twain (1876)Document5 pagesA Literary Nightmare, by Mark Twain (1876)skanzeniPas encore d'évaluation

- All India Civil Services Coaching Centre, Chennai - 28Document4 pagesAll India Civil Services Coaching Centre, Chennai - 28prakashPas encore d'évaluation

- Liquitex Soft Body BookletDocument12 pagesLiquitex Soft Body Booklethello belloPas encore d'évaluation

- The Body Shop Case Analysis. The Challenges of Managing Business As Holistic ConfigurationDocument28 pagesThe Body Shop Case Analysis. The Challenges of Managing Business As Holistic ConfigurationHanna AbejoPas encore d'évaluation

- X - WORMWOOD EVENT IMMEDIATE - Paranormal - 4chanDocument7 pagesX - WORMWOOD EVENT IMMEDIATE - Paranormal - 4chanAnonymous dIjB7XD8ZPas encore d'évaluation

- A Semi-Detailed Lesson Plan in MAPEH 7 (PE)Document2 pagesA Semi-Detailed Lesson Plan in MAPEH 7 (PE)caloy bardzPas encore d'évaluation

- Ahmad Syihabudin: BiodataDocument2 pagesAhmad Syihabudin: BiodatabhjjqrgrwmPas encore d'évaluation

- Introduction To Password Cracking Part 1Document8 pagesIntroduction To Password Cracking Part 1Tibyan MuhammedPas encore d'évaluation

- Measurement and Scaling Techniques1Document42 pagesMeasurement and Scaling Techniques1Ankush ChaudharyPas encore d'évaluation

- UAV Design TrainingDocument17 pagesUAV Design TrainingPritam AshutoshPas encore d'évaluation

- Newsletter 1-2021 Nordic-Baltic RegionDocument30 pagesNewsletter 1-2021 Nordic-Baltic Regionapi-206643591100% (1)

- CLA Brochure - 2022-3Document10 pagesCLA Brochure - 2022-3Streamer AccountPas encore d'évaluation

- E-Mobility and SafetyDocument77 pagesE-Mobility and SafetySantosh KumarPas encore d'évaluation

- Fire Prevention Plan Template - FINAL 5-30-08Document5 pagesFire Prevention Plan Template - FINAL 5-30-08Peter GeorgePas encore d'évaluation

- Fortigate Firewall Version 4 OSDocument122 pagesFortigate Firewall Version 4 OSSam Mani Jacob DPas encore d'évaluation

- Tyler Nugent ResumeDocument3 pagesTyler Nugent Resumeapi-315563616Pas encore d'évaluation

- Notice: Premerger Notification Waiting Periods Early TerminationsDocument5 pagesNotice: Premerger Notification Waiting Periods Early TerminationsJustia.comPas encore d'évaluation

- Web-Based Attendance Management System Using Bimodal Authentication TechniquesDocument61 pagesWeb-Based Attendance Management System Using Bimodal Authentication TechniquesajextopePas encore d'évaluation

- Plain English Part 2Document18 pagesPlain English Part 2ابو ريمPas encore d'évaluation

- Transparency and Digitalization in The Public Administration of RomaniaDocument8 pagesTransparency and Digitalization in The Public Administration of RomaniaMădălina MarincaşPas encore d'évaluation

- Advertisement: National Institute of Technology, Tiruchirappalli - 620 015 TEL: 0431 - 2503365, FAX: 0431 - 2500133Document4 pagesAdvertisement: National Institute of Technology, Tiruchirappalli - 620 015 TEL: 0431 - 2503365, FAX: 0431 - 2500133dineshPas encore d'évaluation

- On Animal Language in The Medieval Classification of Signs PDFDocument24 pagesOn Animal Language in The Medieval Classification of Signs PDFDearNoodlesPas encore d'évaluation

- The Great Muslim Scientist - Imam Jaffer Sadiq (ADocument78 pagesThe Great Muslim Scientist - Imam Jaffer Sadiq (ASalman Book Centre100% (2)

- Masoneilan - 78 Series Air Filter Regulators IOMDocument8 pagesMasoneilan - 78 Series Air Filter Regulators IOMNithyAPas encore d'évaluation

- Animal Health ChecklistDocument4 pagesAnimal Health ChecklistcapsfastPas encore d'évaluation

- IOT Questions and Answers - SolutionDocument8 pagesIOT Questions and Answers - SolutionOmar CheikhrouhouPas encore d'évaluation