Académique Documents

Professionnel Documents

Culture Documents

MRP DSS Simulation Project

Transféré par

Godwin RichmondCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MRP DSS Simulation Project

Transféré par

Godwin RichmondDroits d'auteur :

Formats disponibles

IE7315: Production Systems

MRP Decision Support System Project Assignment

Production Planning at Greek Manufacturing Company

Originally Developed by:

Dr. C. Basnet

Department of Management Systems, University of Waikato

Private Bag 3105, Hamilton 2020, New Zealand

Telephone: + 647 838 4562; Fax: + 647 838 4270

Chuda@waikato.ac.nz

http://www.mngt.waikato.ac.nz/depts/mnss/chuda/PMSimulation/MRPSIM.htm

In this assignment you play the role of the production planner of the Greek Manufacturing Company, and develop a decision support

system to help you in that role. All the required information is presented in the spreadsheet MRP-SIM.XLS. Obtain this file from the

course website (http://blackboard.wayne.edu).

You manage two products, Alpha ( ) and Beta ( ), for which orders are placed on you in variable quantities throughout the week.

These products are made up of components (Comma, Delta, Epsilon, Fi, and Gamma), some of which are produced within the

company, and others are sourced from vendors. In carrying out the production, the parts are routed through processing machines

(Kappa, Mu, Pi, Rho, and Sigma) within the company where processing time is spent. See the Bill of Materials and Routing in the

spreadsheet. Lead-times and other information are also available on the spread-sheet.

The production planning is done on a weekly basis. At the beginning of the week, inventories are checked and orders are

released both within the company and to the vendors. Through the week the processing of the orders takes place. As customer

orders arrive, they are filled from inventory on-hand. Orders may be filled partially if there is insufficient on-hand inventory for

the whole order. Unfilled orders are placed on file and filled when the product is available. The cycle repeats week by week.

This scenario is simulated by a simulator incorporated in the spreadsheet.

Playing the Game

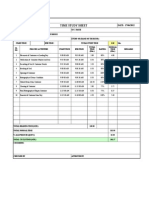

Open the spreadsheet with the application Microsoft Excel. The main screen is shown in Figure 1, next page. The upper left

corner shows the products currently being processed by the machines and their queues (quantities being produced). It also

shows orders placed with the vendor. The lower part of the screen shows the current inventory position (graphically on the

left side, and the numbers on the right side). Current pending customer orders are also shown. (It is important here to distinguish

between three kinds of orders: customer orders, which are placed by the customer with you; shop orders, which are placed by

you with the production staff, and vendor orders, which you place with the vendors, outside the company). The centre of the

screen shows the current week and day. The simulation game begins on week 21 and continues until week 32. The middle

part of the screen shows buttons that navigate you to different parts of the spreadsheet.

To play the game, you first need to initialise the game. Use the button Initialise Game for this purpose. This causes a history of

demand to be created up until week 20. You can view these by clicking the two buttons Forecast Alpha and Forecast Beta. As you

play the game, new demands are also updated and may be viewed and analysed. You may initialise the game again any time; this

will cause the game to restart.

Prepared by Dr. Ratna Babu Chinnam for IE 7315: Production Systems at Wayne State University

Page 1 of 4

IE7315: Production Systems

Figure 1. Main Screen of the Simulator

You can view the current inventory, work in progress, and vendor orders at this time. Next you need to decide on orders to place for

next week, their priorities, and overtime to authorise for the next week. Once you have made the decisions, communicate it to the

simulator by clicking on the button Make/Alter Decisions. In placing the shop orders, it is important to take into consideration the

product structure (the Bill of Materials). If the components needed for your order are not available in the inventory, the order cannot

be processed until all the components are available. The remaining on-hand inventory is updated and displayed as you enter your

decisions. Obviously, this does not apply to the purchased components, of which you can order as many as you like. If you change

your mind before the week is simulated, you can change your decisions using the same button. The Use MRP button in the order

form permits you to use MRP decision support. You need to build the MRP tables first to use this button! You can always override the

MRP table suggestions. Once the decisions are entered, you may press the Simulate! button to let the production for the week begin,

and to let the time advance to the next week. The queues of the machines, the finishing of the work, the inventory position, the arrival

of orders, and the filling of the orders are animated on the screen. You can adjust the speed of animation by moving the scroll bar at

the middle right of the screen.

Profits are accumulated for every item in the order that is filled. For every item in the order that is late (back-ordered), a penalty is

charged per day. There are also costs associated with holding inventory (both finished and work in process) and with overtime work.

These and other details of the model may be viewed by pressing the button View Model Details. At the end of the week your

financial performance is shown at the top right of the screen. This shows both your current and cumulative performance.

You are now ready to make decisions for the next week and to repeat the cycle. This cycle consists of making the decisions,

simulating the system, monitoring the result, then making the decisions again ... ... until week 32. Your objective is to maximise

your cumulative profit at the end of the game.

Assignment

For the purpose of this assignment, play the game for a while until you have a good understanding of what is happening. The game

is designed to enhance your understanding of:

Prepared by Dr. Ratna Babu Chinnam for IE 7315: Production Systems at Wayne State University

Page 2 of 4

IE7315: Production Systems

Bill of Materials

Routing

Order review and release

Priority setting

Production capacity

Variability in production

Work in process

Queuing

Inventory costs

Customer service

Forecasting

Master production scheduling (MPS)

Material requirements planning (MRP)

Capacity requirements planning (CRP)

After playing the game for a while you may wish to have some sort of computer support to make your decisions. You can create this

for yourself. Past data may be used for forecasting, which leads to a MPS, and this MPS, when broken into the components through

MRP, should help you in deciding how many parts / products to order and when. A CRP module can help you decide how much

overtime to order. Your specific assignment is to create a decision support system (DSS) using these concepts. Follow the following

instructions exactly as given.

Guidelines for Completing the Assignment

Step 1. Familiarise yourself with the simulator. Play the game in an ad-hoc manner, guessing the decisions.

What is the highest profit you made while playing in an ad-hoc manner? ________________

Step 2. Play the game on a reorder point basis. The idea of a reorder point (ROP) is to set a minimum level of inventory at which you

order inventories, choosing your own order size. Try different ROPs and order sizes. Enter your best reorder policy:

Item

Alpha

Beta

Comma

Delta

Epsilon

Fi

Gamma

Reorder point

Order size

What is the highest profit you made while playing on a reorder point basis? ________________

Step 3. The next step is playing the game with a DSS, built by you. To do this, you need a forecasting model to forecast demand of

products Alpha and Beta. This should be fed into the master production schedule (MPS) of the MRP worksheet. Next you need to

explode this MPS into the MRP, which will then tell you what order to release each week. When you create the CRP model from the

MRP model, you can decide how much overtime to use.

Remember though, that the decision support system is there to help in decision-making. It suggests things for you to do,

but it does not dictate your decisions. You can override it any time.

Here are the steps to create the DSS.

A. Forecasting. I suggest you use linear regression for forecasting. Use the menu item Tools | Data Analysis | Regression. The YRange is of course the demand, and the X-Range is the number of weeks. Use the output of this analysis to create your forecast.

Prepared by Dr. Ratna Babu Chinnam for IE 7315: Production Systems at Wayne State University

Page 3 of 4

IE7315: Production Systems

The forecast formula is: Intercept + (X Variable 1) * (Number of weeks). This should create the forecast up to week 35. You need to

forecast the demand for both Alpha and Beta.

B. Master Production Scheduling. You need to link your forecasts to the MPS (in the worksheet MRP). Use the VLOOKUP

function provided in EXCEL to do this. This function will look up from the forecast table (called Forecast1 and Forecast2 for Alpha and

Beta respectively) appropriate Forecast (column D) and insert into the MPS table. (Hint: You need to insert something like

VLOOKUP (week, Forecast1, column No.) into the MPS).

The scheduled receipt row needs to be linked to the appropriate work-in-process information in the Main Screen. The current on

hand needs to be linked obviously to the current inventory from the Main Screen.

C. Material Requirements Planning. The MRP explosion should of course be based on the BOM. Do your work in the worksheet

MRP. Make sure the gross requirements are always derived from the parent, not necessarily from the finished product. I suggest you

use the lot for lot policy for all MRP explosions, with a lead-time of one week.

D. Capacity Requirements Planning. The CRP should be based on the Routing information in the workbook. Combine the

requirements of work for each of the work centres. Make sure you take into account the work requirements for order in progress

(scheduled receipts). I suggest you use the full work requirements for these.

E. Decision Support System. The summary information at the bottom of the worksheet summarises the order releases for the

current week. The overtime should come from CRP, if more than the available 40 hours are needed. Insert the appropriate formulas

to gather this information from the appropriate places. Your DSS is now complete. You can now use this DSS when using the button

Make/Alter Decisions to make your decisions. The Use MRP button will get the order releases and the overtimes from the MRP

worksheet. Remember though that this is always just a suggestion, you can change the decisions manually particularly in view of

the component availabilities and work-in-progress.

F. Play! See if your DSS is any good. Play the game using your MRP models to make the decisions.

What is the highest profit you made while playing with your DSS? ________________

Prepared by Dr. Ratna Babu Chinnam for IE 7315: Production Systems at Wayne State University

Page 4 of 4

Vous aimerez peut-être aussi

- Long Term PlanningDocument20 pagesLong Term PlanningSameer BagalkotPas encore d'évaluation

- GPAODocument2 pagesGPAOZakariaChardoudiPas encore d'évaluation

- The ERP-MICSS Case: Activating the Smart Industries Inc. ScenarioDocument17 pagesThe ERP-MICSS Case: Activating the Smart Industries Inc. ScenarioOscar Javier TorresPas encore d'évaluation

- Production & Planning - SynopsisDocument22 pagesProduction & Planning - Synopsisbrijesh99Pas encore d'évaluation

- Manage Computer Shop Inventory & SalesDocument62 pagesManage Computer Shop Inventory & Salesvickram jainPas encore d'évaluation

- Introduction To ERP SystemsDocument7 pagesIntroduction To ERP SystemsShella MatrizPas encore d'évaluation

- Production Tracking Excel Sheet With Tables For Small ManufacturersDocument4 pagesProduction Tracking Excel Sheet With Tables For Small ManufacturersArdhi SuryaPas encore d'évaluation

- Computer Shop Management SystemDocument33 pagesComputer Shop Management Systemvickram jainPas encore d'évaluation

- Case Study: Stock Management SystemDocument3 pagesCase Study: Stock Management SystemAvishchal ChandPas encore d'évaluation

- GBC Apo 3 Digit Tut1Document31 pagesGBC Apo 3 Digit Tut1MehboobKhanPas encore d'évaluation

- Experiment No.5Document6 pagesExperiment No.5Muhammad Irfan AkramPas encore d'évaluation

- Rulebook En.0eb4406e480b9ec1ab32Document11 pagesRulebook En.0eb4406e480b9ec1ab32shireenPas encore d'évaluation

- Littlefield Simulation UCL 2021-22Document7 pagesLittlefield Simulation UCL 2021-22Krishna SharmaPas encore d'évaluation

- Temperature records app with searchDocument4 pagesTemperature records app with searchMitiku AbebePas encore d'évaluation

- Combined Production Order Processing (DIMP) - SCNDocument9 pagesCombined Production Order Processing (DIMP) - SCNmohameds1988100% (1)

- Computer Shop MGMT IntroductionDocument5 pagesComputer Shop MGMT IntroductionManoj Kumar MohanPas encore d'évaluation

- PP-PROCUREMENT-INTEGRATIONDocument8 pagesPP-PROCUREMENT-INTEGRATION4ArunPas encore d'évaluation

- COST OF GOODS SOLDDocument9 pagesCOST OF GOODS SOLDAmitava SahaPas encore d'évaluation

- Online Inventory Management SystemDocument6 pagesOnline Inventory Management SystemDebjeet BhowmikPas encore d'évaluation

- Report, Performance, and Game Guide for Littlefield Lab 2Document2 pagesReport, Performance, and Game Guide for Littlefield Lab 2Prerana Rai BhandariPas encore d'évaluation

- What Is A Planned IndependentDocument8 pagesWhat Is A Planned IndependentRizwan SiddiquiPas encore d'évaluation

- Fast ReactDocument25 pagesFast Reactmmiks200878% (9)

- SAP PP 50 Interview Questions and Answers PDFDocument20 pagesSAP PP 50 Interview Questions and Answers PDFHemamber ReddyPas encore d'évaluation

- Hardware Purchase and Sales System Project ProfileDocument43 pagesHardware Purchase and Sales System Project Profilesanjaykumarguptaa100% (2)

- Oracle Demantra Demand Management Forecasting and PlanningDocument6 pagesOracle Demantra Demand Management Forecasting and Planninganishokm2992Pas encore d'évaluation

- Solving IB Problems With CG50Document197 pagesSolving IB Problems With CG50armandPas encore d'évaluation

- Production Order in SAP PPDocument13 pagesProduction Order in SAP PPGuillermo SierraltaPas encore d'évaluation

- System 1Document4 pagesSystem 1nabil160874Pas encore d'évaluation

- Solving IB Exam Questions Using the fx-CG50Document197 pagesSolving IB Exam Questions Using the fx-CG50Hansal Pravin KachharaPas encore d'évaluation

- Group Activity For Inventory and ProductionDocument3 pagesGroup Activity For Inventory and ProductionMILDRED SAN ANDRESPas encore d'évaluation

- How to Reposition and Market a ProductDocument13 pagesHow to Reposition and Market a ProductsupremedictatorPas encore d'évaluation

- SAP APO Interview Questions & AnswersDocument7 pagesSAP APO Interview Questions & AnswersnileshPas encore d'évaluation

- Bulacan State UniversityDocument17 pagesBulacan State UniversityJashi SiñelPas encore d'évaluation

- B1 90 MRP ProcessDocument55 pagesB1 90 MRP ProcessmongkonyPas encore d'évaluation

- Strategy Guide for Starting a Microcomputer BusinessDocument92 pagesStrategy Guide for Starting a Microcomputer BusinessAnirudh NarlaPas encore d'évaluation

- Configuration Is Backend SAP System Activity and Must Occur Only Once During An SAP Implementation ProjectDocument2 pagesConfiguration Is Backend SAP System Activity and Must Occur Only Once During An SAP Implementation ProjectRemove NamePas encore d'évaluation

- Let's Get Down To Business!Document15 pagesLet's Get Down To Business!Saravanan PanneervelPas encore d'évaluation

- Restaurant POS 2.0: Figure 1: Customer-Drawing WorkflowDocument4 pagesRestaurant POS 2.0: Figure 1: Customer-Drawing WorkflowAnh NguyễnPas encore d'évaluation

- Informatics Practices: Project WorkDocument10 pagesInformatics Practices: Project Workamit248262Pas encore d'évaluation

- Computer-Shop-Management-System Non-CompleteDocument29 pagesComputer-Shop-Management-System Non-CompleteVikram MaliPas encore d'évaluation

- Manufacturing Foundation White PaperDocument28 pagesManufacturing Foundation White PaperIbrahim TurjmanPas encore d'évaluation

- M Arkstrat Rules & Help: (Also Available at Inside - Insead.edu/carmon/mm2)Document2 pagesM Arkstrat Rules & Help: (Also Available at Inside - Insead.edu/carmon/mm2)Sardar AftabPas encore d'évaluation

- Archive Material Master in SAPDocument31 pagesArchive Material Master in SAPAswathyAkhoshPas encore d'évaluation

- Global Supply Chain Management SimulationDocument9 pagesGlobal Supply Chain Management SimulationJawadPas encore d'évaluation

- SAP MRP (Material Requirement Planning)Document8 pagesSAP MRP (Material Requirement Planning)niranjan100% (2)

- Organisational InformaticsDocument21 pagesOrganisational Informaticsotg92165Pas encore d'évaluation

- Production Order in SAP CO01 MD16 CO02 CO15Document13 pagesProduction Order in SAP CO01 MD16 CO02 CO15Muhammad GamalPas encore d'évaluation

- SOP and LTPDocument10 pagesSOP and LTPVijaya Bhasker JPas encore d'évaluation

- SAP Credit MGMT Mis3510Document34 pagesSAP Credit MGMT Mis3510javatwojavaPas encore d'évaluation

- TNRCC Pollution Prevention Cost Accounting Software User Training Manual February 1, 1998Document15 pagesTNRCC Pollution Prevention Cost Accounting Software User Training Manual February 1, 1998Ramzy Elsayed TawfikPas encore d'évaluation

- SAP PP - Production Order CreationDocument14 pagesSAP PP - Production Order CreationKoustubha KharePas encore d'évaluation

- Atm SimulationDocument22 pagesAtm Simulationpratiyush juyal63% (8)

- MRP in SAP Business One: A Business ScenarioDocument11 pagesMRP in SAP Business One: A Business ScenarioKrishna ManiPas encore d'évaluation

- Mobile App Breakeven AnalysisDocument15 pagesMobile App Breakeven AnalysisMohd Ikhwan0% (2)

- Global Bike IncDocument39 pagesGlobal Bike IncSameet DoshiPas encore d'évaluation

- Excel Formulas That Automate Tasks You No Longer Have Time ForD'EverandExcel Formulas That Automate Tasks You No Longer Have Time ForÉvaluation : 5 sur 5 étoiles5/5 (1)

- Do-It-Yourself Technical Analysis Simplified by Trained AccountantD'EverandDo-It-Yourself Technical Analysis Simplified by Trained AccountantPas encore d'évaluation

- Force Control - FMS ArticleDocument3 pagesForce Control - FMS ArticleGodwin RichmondPas encore d'évaluation

- The Supply Chain Television ChannelDocument42 pagesThe Supply Chain Television ChannelGodwin RichmondPas encore d'évaluation

- 0009009Document12 pages0009009srilankanonlinePas encore d'évaluation

- 5j GM1927 84 Drill Deep Worksheet 12 Oct 04Document2 pages5j GM1927 84 Drill Deep Worksheet 12 Oct 04jesusmemPas encore d'évaluation

- 2015 Eng Career Fair Employer List 09-18-2015 1Document14 pages2015 Eng Career Fair Employer List 09-18-2015 1Godwin RichmondPas encore d'évaluation

- Ie 6490Document4 pagesIe 6490Godwin RichmondPas encore d'évaluation

- SyllabusDocument6 pagesSyllabusGodwin RichmondPas encore d'évaluation

- 0009009Document12 pages0009009srilankanonlinePas encore d'évaluation

- Lecture - 3 Slides ImportantDocument19 pagesLecture - 3 Slides ImportantGodwin RichmondPas encore d'évaluation

- Control Charts for Attributes Monitoring with p-Chart ExampleDocument26 pagesControl Charts for Attributes Monitoring with p-Chart ExampleBurcu Gözde Bilol100% (1)

- Mtech Iem 2013Document12 pagesMtech Iem 2013Jaykrishnan GopalakrishnanPas encore d'évaluation

- Checking The Reliability of A Linear-Programming Based Approach Towards Detecting Community Structures in NetworksDocument17 pagesChecking The Reliability of A Linear-Programming Based Approach Towards Detecting Community Structures in NetworksGodwin RichmondPas encore d'évaluation

- Problem Solving: Developing Life SkillsDocument25 pagesProblem Solving: Developing Life SkillsAakash KamblePas encore d'évaluation

- Or Project Based On Linear ProgrammingDocument6 pagesOr Project Based On Linear ProgrammingdawncpainPas encore d'évaluation

- Selection Graph LPDocument1 pageSelection Graph LPGodwin RichmondPas encore d'évaluation

- Cuban Michigan Dinner MenuDocument2 pagesCuban Michigan Dinner MenuGodwin RichmondPas encore d'évaluation

- Slowsmenu June2014Document4 pagesSlowsmenu June2014Godwin RichmondPas encore d'évaluation

- WSU IE7325 Supply Chain ManagementDocument5 pagesWSU IE7325 Supply Chain ManagementGodwin RichmondPas encore d'évaluation

- NDS 64720 Efficacy of Sorghum Peanut Blend and Corn Soy Blend Plus in 081314Document10 pagesNDS 64720 Efficacy of Sorghum Peanut Blend and Corn Soy Blend Plus in 081314Godwin RichmondPas encore d'évaluation

- 5S TPS - NewDocument23 pages5S TPS - NewGodwin Richmond100% (1)

- Harvest 01Document37 pagesHarvest 01venkateshPas encore d'évaluation

- Time Study Format 147Document17 pagesTime Study Format 147Godwin Richmond100% (1)

- FMEA TemplateDocument28 pagesFMEA Templatevin_araujoPas encore d'évaluation

- 2015 Eng Career Fair Employer List 09-18-2015 1Document14 pages2015 Eng Career Fair Employer List 09-18-2015 1Godwin RichmondPas encore d'évaluation

- Project Management TipsDocument10 pagesProject Management TipsNelson Aguirre BravoPas encore d'évaluation

- Cool WipesDocument7 pagesCool WipesGodwin RichmondPas encore d'évaluation

- Case Study 3. Cool Wipes Excel SheetDocument14 pagesCase Study 3. Cool Wipes Excel SheetGodwin Richmond20% (5)

- Cool WipesDocument7 pagesCool WipesGodwin RichmondPas encore d'évaluation

- Michigan Driving BookletDocument154 pagesMichigan Driving BookletGodwin RichmondPas encore d'évaluation

- CHM4943 Wastewater TreatmentDocument7 pagesCHM4943 Wastewater TreatmentUsman GhaniPas encore d'évaluation

- Design of Goods & Services: Tanweer Ascem KharralDocument10 pagesDesign of Goods & Services: Tanweer Ascem KharralHadeed GulPas encore d'évaluation

- Portland Traffic Crash Report 2021Document11 pagesPortland Traffic Crash Report 2021KGW NewsPas encore d'évaluation

- Me 6401 Kom - Uti Ans KeyDocument11 pagesMe 6401 Kom - Uti Ans Keylogeshboy007100% (1)

- 2003 VW Jetta Wiring DiagramsDocument123 pages2003 VW Jetta Wiring DiagramsmikePas encore d'évaluation

- Common Sense Renewed R. C. ChristianDocument276 pagesCommon Sense Renewed R. C. Christianwarhed76100% (3)

- Wiper & Washer Circuit PDFDocument1 pageWiper & Washer Circuit PDFluis eduardo corzo enriquezPas encore d'évaluation

- Caterpillar FAPT Presentation PDFDocument18 pagesCaterpillar FAPT Presentation PDFJuniOrs RiVeraPas encore d'évaluation

- Mahamrityunjaya MantraDocument8 pagesMahamrityunjaya MantraBalakrishnan KannanPas encore d'évaluation

- Olympian Generator Brochure 26-200 KvaDocument7 pagesOlympian Generator Brochure 26-200 KvaJawad RazaPas encore d'évaluation

- Section 09 - Traction Electrification SystemDocument47 pagesSection 09 - Traction Electrification SystemAbu Monsur Ali100% (1)

- Comp7 - Answer Key - Dec. Exam - 1st SetDocument2 pagesComp7 - Answer Key - Dec. Exam - 1st SetHazel Joy LusellaPas encore d'évaluation

- Greek MathemaDocument6 pagesGreek MathemaSebastian GhermanPas encore d'évaluation

- Strategic Capacity ManagementDocument36 pagesStrategic Capacity ManagementRahul KhannaPas encore d'évaluation

- CPE PRACTICE TEST 2 READINGDocument4 pagesCPE PRACTICE TEST 2 READINGHong Anh0% (1)

- Case CX210B Mine Crawler Excavator Tier 3 Parts Manual PDFDocument701 pagesCase CX210B Mine Crawler Excavator Tier 3 Parts Manual PDFJorge Martinez100% (3)

- Solving Problems Involving Kinds of Propotion StudentDocument18 pagesSolving Problems Involving Kinds of Propotion StudentJohn Daniel BerdosPas encore d'évaluation

- SoalDocument2 pagesSoalmaria_diyah4312Pas encore d'évaluation

- GPS Navigator: ModelDocument99 pagesGPS Navigator: ModelMain UddinPas encore d'évaluation

- Papaya Burger - Chapter 1 6Document129 pagesPapaya Burger - Chapter 1 6Nicole Velasco NuquiPas encore d'évaluation

- FH400 73158464 Pca-6.140Document431 pagesFH400 73158464 Pca-6.140IgorGorduz100% (1)

- Operator Identities 2Document3 pagesOperator Identities 2jasmonPas encore d'évaluation

- Djoko The Indonesian Mineral Mining Sector Prospects and ChallengesDocument42 pagesDjoko The Indonesian Mineral Mining Sector Prospects and ChallengesUmesh ShanmugamPas encore d'évaluation

- Application of Operations Research in Banking FinanceDocument13 pagesApplication of Operations Research in Banking FinanceInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- Civil Engineering Set 2Document13 pagesCivil Engineering Set 2Dev ThakurPas encore d'évaluation

- The Indonesian Food Processing Industry (Final)Document48 pagesThe Indonesian Food Processing Industry (Final)patalnoPas encore d'évaluation

- (MITSUBISHI) Manual de Taller Mitsubishi Montero 2002Document21 pages(MITSUBISHI) Manual de Taller Mitsubishi Montero 2002wnsdPas encore d'évaluation

- CSS9 TQ PT 3rd4thDocument8 pagesCSS9 TQ PT 3rd4thJevan Hope BaltazarPas encore d'évaluation

- BT Word FormsDocument11 pagesBT Word FormsNguyên TrungPas encore d'évaluation

- Anatomy Mckinley PPT Chapter 1Document65 pagesAnatomy Mckinley PPT Chapter 1Rosa AlcantarPas encore d'évaluation