Académique Documents

Professionnel Documents

Culture Documents

On Site Assessment Template

Transféré par

wentropremCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

On Site Assessment Template

Transféré par

wentropremDroits d'auteur :

Formats disponibles

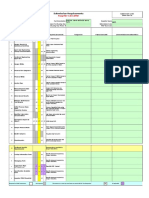

Supplier On-Site Assessment Instructions

Instructions 1. Obtain On-Site Assessment file from the Strategic Sourcing sharepoint site, under the Template section

located at:

http://cipt0283:83/sites/FuncComm/Sourc_Comm/Shared

%20Documents/Supplier_Onsite_Assessment.aspx

2. Send Audit Form form to selected supplier and ask to complete the self assessment and record the

findings in the "Supplier" column. All sections must be filled-out, regardless of applicability. Sections and

questions that do not apply will be identified with the "N/A" label.

3. Upon return of the completed assessment, the Commodity Manger reviews the data, requests any

clarifications, and then prepares for the Copper-led on-site evaluation.

4. The Commodity Leader assembles an appropriate audit team, ideally consisting of representatives from

Quality, Engineering, Materials, and Purchasing, and schedules the on-site assessment.

5. The team evaluates the supplier by asking the questions in the On-Site Assessment (tab Audit Form)

and scores each question based on the evidence observed. Scoring is recorded in the "Cooper" column of

the audit sheet in accordance with the Audit Scoring Definitions shown below.

6. At the completion of the assessment, scores are compiled for both the individual sections of the audit

and an overall result. These results are shown in the tab Scoring Summary.

7. A corective action sheet is included in the audit materials to address any deficiencies identified in the

audit. The sheet can also be used at the team's discrection to catalogue any other further reqired actions

related to sourcing decisions.

8. Complete the Recommendation section and save the file as, vendor name_assessment_MM_YYYY

9. Upload the completed assessment to the Strategic Sourcing sharepoint site using the "Upload the OnSite Assessment" feature.

10. Add comments in the sharepoint site indicating the final thoughts and recommendations.

Audit Scoring Definitions

Score

Segmentati

on

Strategic

Preferred

Maintain

Unacceptabl

e

No documentation

N/A

N/A

Not Required

Documentation

Full documentation

with no missing

requirements

Substantial

documentation with

some missing

requirements

Limited

documentation

Implementation

Results

Full execution. No

non-conformances

Evidence to support full understanding and

implementation

Execution evident

with limited nonconformances

Limited execution

with major nonconformances

No evidence of

implementation

Element required but no evidence of execution

or understanding

Not Required

Element not required

Evidence supports understanding of

requirement with partial execution

Limited evidence of requirement

Coper Industries

Document #3.0004

Issue Date: 11/06/2010

Revision: 003

Supplier On-Site Assessment

Supplier Score

Cooper Score

#DIV/0!

#DIV/0!

Supplier Information

Supplier Name:

Plant Location:

Vendor ID #:

Phone #:

Supplier Contact

Supplier E-Mail:

Audit Information

Division :

Commodity Fami

Product Type:

Audit Date:

Auditor Name:

Auditor E-Mail:

Auditor Phone:

Cooper Division:

1. Customer Satisfaction

Supplier Cooper

Observations / Evidence

There is a documented process for determining customer satisfaction, including

1.1 frequency of determination, delivered part quality, customer disruptions, field returns,

delivery performance, and customer notifications?

1.2

Metrics monitoring customer satisfaction that are related to supplier manufacturing are

understood and tracked.

1.3

There are projects and programs in place to improve customer satisfaction, with

corrective actions addressed, and a closed-loop review system progress

1.4

Customer dedicated service group with multifunctional team has been established for

key accounts

Customer Satisfaction Section Score: #DIV/0! #DIV/0!

2. Quality System

Supplier Cooper

Observations / Evidence

Do you have a quality system registered to a recognized standard, like

2.1

IS09000/TS16949?

2.2

There are quarterly Management Reviews to verify the effectiveness of the quality

system.

2.3

Each department has goals that are defined and measured and focus on the use quality

policy, objectives, audit results, analysis of data, corrective / preventive actions

Management regularly reviews the status of the Preventive Maintenence completion to

2.4 plan. Management reviews corrective action plans to ensure any backlog (past due)

maintenance has a plan to become current to the PM schedule.

2.5 Internal audit frequency is modified based on non-conformance trends.

2.6 Internal audits are available to verify that the quality system is being followed.

2.7

A formal business/manufacturing system is in place ( Capacity Planning, Shop Floor

Control, ERP, etc.)

2.8 Proactive notification of issues which could affect delivery or quality are documented and performed

Does the Supplier have a process for final product identification, including bar code, if

required.

Does the supplier obtain customer waiver (concession/deviation) prior to further

2.10 processing when the product/process is different from what is approved? And are

shipping containers properly identified when this occurs?

2.9

Quality System Section Score: #DIV/0! #DIV/0!

3. Business System

3.1

Observations / Evidence

A Customer-focused strategy has been developed and deployed to ensure business

portfolio diversity

Is there evidence and use of tools like Electronic Data Interface (EDI), Request For Quote

(RFQ), Advanced Planning and Scheduling (APS) ?

Have contingency plans been prepared to satisfy customer requirements in the event of

3.3 an emergency such as utility interruptions, labor shortages, key equipment failures, and

field returns?

3.2

3.4 Is there a process to address product liability / recall issues?

3.5

Does the supplier have a long-term plan for sustainability, including a system in place to

identify key business and product risks and opportunities?

Are the Purchase Orders reviewed for commitment to qty, price, delivery date, delivery

3.6 method, and any additional special requirements or instructions? If any differences

arises the differences are resolved prior to acceptance of the order.

3.7

Personnel performing specific tasks shall be qualified on the basis of appropriate

education, training, and/or experience.

Business System Section Score: #DIV/0! #DIV/0!

2of 8

Cooper Industries

Document #3.0004

Issue Date: 11/06/2010

Revision: 003

4. EHS and Risk Management

Observations / Evidence

An effective process for EHS is formally defined, well documented and understood with

4.1

systematic root cause investigation and tracked corrective actions for all EHS defects

4.2

A well documented and understood effective process is in place, that requires formal risk

assessment upon change or initial set-up of equipment.

4.3

Knowledge of each waste stream, final location, regulatory permit states of the disposal

site, and quantity involved.

4.4

Does the company comply with OSHA or other applicable safety and health regulations,

specifically in the use of Personal Protection Equipment?

4.5 Procedures in place for hazardous substance control

4.6 Emergency Action and Disaster Recovery Plans established and in place

4.7

All governing requirements are effectively in place (i.e. RoHS, EU REACH, WEEE) and all

materials are approved under applicable requirements, per Division, for the US.

EHS and Risk Management Section Score: #DIV/0! #DIV/0!

New Product related questions

Supplier Cooper

A formalized New Product Introduction process has been established for new

product

development

projects:and tollgates

- Process identifies

key milestones

- Includes evidence of training on the process

- Documented inputs/outputs for each critical phase

DESIGN RESPONSIBLE SUPPLIERS

New Product Development

Questions

5. New Product Development

Observations / Evidence

N/A

N/A

Do Not Assess- Roll-up Score

N/A

N/A

Do Not Assess- Roll-up Score

N/A

N/A

Do Not Assess- Roll-up Score

N/A

N/A

Do Not Assess- Roll-up Score

-Process shows evidence of Advanced Product Quality Planning techniques (APQP)

There is a process in place to ensure key elements of the Product Design and

Development

are performed:

- Engineering drawings

& spec.

- Design for Manufacturability and Assembly

- DFMEA

-Development of Prototypes

- Design review and verification

- Material spec.

- Drawing & spec changes

- Evidence of design validation testing and confirmation

Process in place to ensure key elements of the process design, development

and

validation

performed:

- Product

/ Processare

quality

review

- Floor Plan Layout

- Packaging standards and spec

- Preventive Maintenance Planning

- Process Capability Study

- Testing and Measurement

- Production validation testing

Capability with the Production Part Approval Process (PPAP)

Element #1: Part Submission Warrant (PSW)

Element #2: Design Records & Bubbled part print(s).

Element #6: Process Flow Diagrams

Element #7: Process FMEA

Element #8: Control Plan

Element #9: Measurement System Analysis Studies

Element #10: Dimensional Results

Element #11: Material, Performance Test Results

Element

Element

Element

Element

Element

#12: Initial Process Study (Cpk) Capability Studies

#13: Qualified Laboratory Documentation

#14: Appearance Approval Report

#17: Checking Aids Capability with the Production Part Approval Process

#18: Customer Specific Requirements

New Product Development Section Score: #DIV/0! #DIV/0!

6. Purchasing and Sub-Supplier Management

Supplier Cooper

Observations / Evidence

Purchase Order's are used to communicate product quality requirements to sub-suppliers

6.1 to ensure the requirements are understood and can be met. If any differences arises the

differences are resolved prior to acceptance of the order.

6.2

Other quality requirements are communicated to the sub-suppliers like social

responsibility

6.3 Product and capacity requirements are understood throughout the facility and value chai

6.4

An official sub-supplier management process has been established, in which the

suppliers' performance are monitored and evaluated regularly.

6.5

Is there a formal Sub-suppliers selection process with adequate review of the

performance metrics, business practices, and social responsibility

6.6

Sub-suppliers are required to follow a formal product qualification process and submit

warrants prior to final approval of the part.

6.7 Material Compliance (Internal and External Verification) is in place and utilized

Purchasing and Sub-Supplier Management Section Score: #DIV/0! #DIV/0!

3of 8

Cooper Industries

Document #3.0004

Issue Date: 11/06/2010

Revision: 003

7. Production Control and Planning

Supplier Cooper

Observations / Evidence

7.1 Is evidence of Statistical Process Control being used to evaluate the production

processes, where applicable.

7.2 Utilization of product control plans with inspection requirements and identification of key

product/process characteristics

7.3 Process set up verification is used and documented

7.4 The supplier has and maintains a system for traceability on individual product or batches

as

required.

7.5 Inspections based on appropriate sampling plans and are sufficient to detect product

nonconformance. Do the inspection items on the inspection plan meet Customer

requirement?

7.6

Supplier has a strategy for receiving inspection. If incoming quality inspections are

made, there is evidence of the specification and compliance to the specification. If no

incoming inspections are made, there is a rationale for qualifying sub-suppliers.

7.7 Is there evidence of in-process checks, including final inspection, to validate the

manufacturing process and the packaging requirements?

Production Control and Planning Section Score: #DIV/0! #DIV/0!

8. Change Management

Supplier Cooper

Observations / Evidence

8.1 An effective change control process is formally defined, well documented and

understood. Strict advance customer notification process is followed, prior to executing

the change.

8.2 A formal drawing and change control system exists and manufacturing and inspection

have access to adequate and up-to-date drawings.

8.3 Does the supplier have a process to assure the timely review, distribution and

implementation of all customer engineering standards/specifications and changes

including a record of the date on which each change is implemented in production

8.4 Is there a process to ensure parts, product, and materials comply with environment and

regulatory requirements

Change Management Section Score: #DIV/0! #DIV/0!

9. Inventory Control and Housekeeping

Supplier Cooper

Observations / Evidence

Is there a warehouse management system in place that uses formal inventory control

9.1

systems like First in First Out (FIFO) and 5S?

9.2 Is the warehouse temperature and humidity conditions appropriately controlled?

The supplier has continuous improvement plans for plant cleanliness, housekeeping,

9.3 ergonomics, and working conditions. There is evidence that the supplier management

team is following continuous improvement plans.

9.4

Finished and released product/containers are properly labeled and identified to signify

acceptance status

9.5

Supplier takes measures to minimize foreign material, chips, debris, contamination,

excessive oil, etc. where part quality can be negatively affected.

Inventory Control and Housekeeping Section Score: #DIV/0! #DIV/0!

10. Corrective Action and Control of Non-Conforming Product

Supplier Cooper

Observations / Evidence

10.1 A corrective action procedure exists and is followed for internal, in-process quality issues

10.2 A corrective action procedure exists and is followed for supplier incoming quality

problems

10.3 A corrective action procedure exists and is followed for customer complaints.

10.4 Problem solving is done in cross-functional teams, using a disciplined problem solving

process (e.g. 8D or 7D) with the appropriate problem solving tools to eliminate root

cause and prevent recurrence?

10.5 Root Cause analysis and corrective action response are completed within agreed upon

time frame.

10.6 Nonconforming material is identified and controlled to prevent its use or shipment to

customers in receiving, in-process, outgoing and customer returns

10.7 Returned material is analyzed for determination of cause for rejection and initiation of

corrective action

10.8

Are the issues identified down to the product/process root cause

10.9 Incoming Quality Operator follows a reaction plan if raw material or purchased part is

found to be out of specification.

10.10

Reworked material is re-qualified prior to use or shipment

Corrective Action and Control of Non-Conforming Product Section Score: #DIV/0! #DIV/0!

11. Continuous Improvement

Supplier Cooper

Observations / Evidence

11.1 Does the supplier use management reviews to guide and track continuous improvement

projects.

11.2 The

supplier maintains a prioritized action plan for continuous improvement as it relates

to product and process characteristic variation.

11.3 The supplier maintains a prioritized action plan for continuous improvement as it relates

to cost reduction and productivity enhancement initiatives, including lead time reduction.

11.4 The supplier maintains a prioritized action plan for continuous improvement as it relates

to the evaluation of the effectiveness of the quality systems.

Continuous Improvement Section Score: #DIV/0! #DIV/0!

4of 8

Cooper Industries

Document #3.0004

Issue Date: 11/06/2010

Revision: 003

12. Measurement and Test

Supplier Cooper

Observations / Evidence

12.1 Does the supplier have a formal Measurement Systems Analysis program in place that

includes calibration standards for all gages and test equipment?

12.2 Does the supplier evaluate the impact on the product when an out-of calibration issue is

identified? Reaction plans are identified and followed.

12.3 Adequate calibration intervals have been established, which are determined by the type

of equipment, frequency of use and the occurrence of deviation. The calibration records

are maintained.

12.4 If the measuring devices are calibrated internally, a qualified internal calibrator is a

must. The calibrating methods and instructions for internally-calibrated devices shall be

documented.

gages / standards are traceable to a recognized national / international standard.

12.5 Master

(for example: NIST)

12.6 Calibration status readily available to operators. The expiration date of the calibration is

shown.

12.7 The appropriate precision of the gage based upon print tolerances is determined.

Measurement and Test Section Score: #DIV/0! #DIV/0!

13. Process Walk

Supplier Cooper

Observations / Evidence

13.1 Process work instructions are documented, up-to-date, available to operators, and are

being followed.

13.2 Setup and operating parameters are documented and utilized as specified.

13.3 Required tools and inspection equipment are identified for each operation and are

utilized as specified.

13.4 Each setup is qualified prior to the start of production as required and critical parameters

are identified, reviewed and approved.

13.5 Repaired production tooling is qualified prior to production use and results documented.

13.6 Are 6S (Safety, Sort, Set in order, Shine, Standardize and Sustain) activities evident

through the facility including ongoing activities to sustain the accomplishments.

13.7 Material identification, acceptance status, and control of non-conforming material is

maintained throughout the manufacturing process and while product is in storage.

13.8 There are control plans that exist for each part number/process, that include

the following:

- Standard for approval and rejection

- Signature and date

- Reaction plans for out of control conditions

- Characteristics to be inspected and/or tested

- Engineering revision level

- Sample size and frequency of observations

- Methodology and tools to be used for inspection and/or test

All inspections are completed, per the control plan, before inventory (stores) or shipping

and include records of appropriate product characteristics.

N/A

N/A

Do Not Assess- Roll-up Score

N/A

N/A

Do Not Assess- Roll-up Score

Are the basic statistical methods widely used to measure the process / product, such as

checklist, histogram, trends chart and etc., where applicable.

Where statistical methods are utilized for control of key characteristics and process

parameters

- Evaluate how they are chosen

- Define what are the statistical methods used

- Determine if the appropriate level of control is established

13.9 Where the Process Control Plan calls for SPC,

- Is the data properly recorded?

- Does the data make sense and are reasonable control limits shown?

- Are out of control points noted with the corrective action taken?

- Does the manufacturing process demonstrate the required capability or performance?

Process Walk Section Score: #DIV/0! #DIV/0!

5of 8

Cooper Industries

Document #3.0004

Issue Date: 11/06/2010

Revision: 003

Supplier On-Site Assessment

Corrective Action Form

Supplier Information

Supplier Name:

Plant Location:

0

0

Vendor ID #:

Phone #:

0

0

Supplier Contact

Supplier E-Mail:

Division :

Commodity Fami

Product Type:

Audit Date:

0

0

0

0

Auditor Name:

Auditor E-Mail:

Auditor Phone:

Cooper Division:

0

0

0

0

Audit Information

No.

Item

Non-Conformance

Corrective Action

Responsibilit

Due DateVerification Date and Comments

y

1

2

3

4

5

6

7

8

9

10

11

12

13

6of 8

Cooper Industries

Document #3.0004

Issue Date: 11/06/2010

Revision: 003

ments

7of 8

Cooper Industries

Document #3.0004

Issue Date: 11/06/2010

Revision: 003

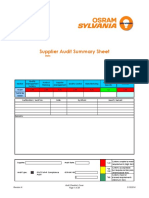

Supplier On-Site Assessment Summary

#DIV/0!

#DIV/0!

Supplier Score

Cooper Score

Supplier Information

Supplier Name:

Vendor ID #:

Plant Location:

Phone #:

Supplier Contact:

Supplier E-Mail:

Division :

Commodity Family

Product Type:

Audit Date:

Audit Information

Auditor Name

Auditor E-Mail

Auditor Phone

Cooper Divisi

0

0

0

0

0

0

0

Initial (Self) Assessment Summary

Points

Section

TotaPossible Percentage

Customer Satisfaction

0l

0

#DIV/0!

Quality System

0

0

#DIV/0!

Business System

0

0

#DIV/0!

Customer

Process

Walk Satisfaction

Quality System

EHS and Risk Management

0

0

#DIV/0!

Measure and Test

100%Business System

New Product Development

0

0

#DIV/0!

50%

Purchasing and Sub-Suplier

Continuous Improvement

0

0

#DIV/0!

0% EHS and Risk Management

Management

Production Control and Planning

0

0

#DIV/0!

Corrective Action and Non-Conforming Prod.

New Product Development

Change Management

0

0

#DIV/0!

Inventory Control and Housekeeping

Purchasing and Sub-Suplier Management Inventory Control and Housekeeping

0

0

#DIV/0!

Production

Change Management

Control and Planning

Corrective Action and Non-Conforming

0

0

#DIV/0!

Prod.

Continuous Improvement

0

0

#DIV/0!

Measure and Test

0

0

#DIV/0!

Process Walk

0

0

#DIV/0!

Score

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

Final (Cooper) Assessment Summary

Points

Section

TotaPossible Percentage

Customer Satisfaction

0l

0

#DIV/0!

Quality System

0

0

#DIV/0!

Business System

0

0

#DIV/0!

Customer

Process

Walk Satisfaction

Quality System

EHS and Risk Management

0

0

#DIV/0!

Measure and Test

Business System

New Product Development

0

0

#DIV/0!

Purchasing and Sub-Supplier

0

0

#DIV/0!

Continuous Improvement

EHS and Risk Management

Management

Production Control and Planning

0

0

#DIV/0!

Corrective Action and Non-Conforming Prod.

New Product Development

Change Management

0

0

#DIV/0!

Inventory Control and Housekeeping

Purchasing and Sub-Supplier Management Inventory Control and Housekeeping

0

0

#DIV/0!

Production

Change Management

Control and Planning

Corrective Action and Non-Conforming

0

0

#DIV/0!

Prod.

Continuous Improvement

0

0

#DIV/0!

Measure and Test

0

0

#DIV/0!

Process Walk

0

0

#DIV/0!

Score

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

On-Site Assessment Scoring

Overall Score

Segmentation

All Green

>79%

Level 1- Strategic

60-79%

Level 2 - Preferred

40-59%

Level 3 - Maintain

< 39% Level 4 -

Description

Current Supplier: Supplier is currently performing at a Level 1 - Recommend strongly

New Supplier: Performance is consistent with Level 1 performance - Recommend strongly

Current Supplier: Not currently performing at a Level 1 but has the potential with minimal

improvements. Existing business can continue and the supplier can be considered for new business Recommend with Corrective Actions

New Supplier: Has the potential to perform at a Level 1 with minimal improvements required Recommend with Corrective Actions

Current Supplier: Corrective actions are needed for the supplier to improve performance. During

this time, business can continue upon review of corrective actions - Not Recommended - Source

with Risk

New Supplier: Significant corrective actions needed to bring the performance to an acceptable level

- Not Recommended - Source with Risk

Current Supplier: Performance not consistent with minimum Cooper standards. Not

Recommended for New Business. A corrective action plan must be provided and

implemented within 60 days. Failure wil result in alternative site sourcing

Non-Performing

New Supplier: No new business will be awarded. Not Recommended - Do Not Source

On-Site Assessment

Cooper Industries

Document # 3.0004

Issue Date: 11/06/2010

Revision: 003

Vous aimerez peut-être aussi

- Supplier Audit Checklist NewDocument7 pagesSupplier Audit Checklist NewsigmasundarPas encore d'évaluation

- Monitoring and Assessment Quality Objectives - Form - Admin.2Document3 pagesMonitoring and Assessment Quality Objectives - Form - Admin.2Vanny Joyce BaluyutPas encore d'évaluation

- New Process Qualification Check ListDocument7 pagesNew Process Qualification Check Listccocos7182Pas encore d'évaluation

- Checklists For Vendors AuditDocument7 pagesChecklists For Vendors AuditDeepak GargPas encore d'évaluation

- 741 Supplier EvalutionDocument3 pages741 Supplier EvalutionPrakashRaiPas encore d'évaluation

- Temecula Quality Plating AS9100 REV C MANUALDocument13 pagesTemecula Quality Plating AS9100 REV C MANUALHoang TanPas encore d'évaluation

- ISO ChecklistDocument36 pagesISO ChecklistDhinakaran100% (1)

- ISO Audit ChecklistDocument21 pagesISO Audit Checklistsharafudheen_s100% (1)

- Process Capability Plan FormDocument4 pagesProcess Capability Plan FormMani Rathinam RajamaniPas encore d'évaluation

- Supplier Pre-Assessment Questionnairevendor Evaluation Form: Document No. Revision 0Document12 pagesSupplier Pre-Assessment Questionnairevendor Evaluation Form: Document No. Revision 0Priyank Srivastava100% (1)

- Departmental Wise Measurable Master - 2Document13 pagesDepartmental Wise Measurable Master - 2VenkatesanPas encore d'évaluation

- Procedure For Supplires EvaluationDocument3 pagesProcedure For Supplires EvaluationShiraz Khan100% (1)

- Supplier Selection & Evaluation TemplateDocument5 pagesSupplier Selection & Evaluation Templatek9pup100% (1)

- Supplier EvaluationDocument6 pagesSupplier Evaluationnithi_123100% (1)

- Supplier Audit Checklist: Explanation of Audit Value Ratings PointsDocument17 pagesSupplier Audit Checklist: Explanation of Audit Value Ratings Pointsjaxf001Pas encore d'évaluation

- Form QP 07-2 Supplier Evaluation Questionnaire - REV 0Document3 pagesForm QP 07-2 Supplier Evaluation Questionnaire - REV 0Charles Bill Eldredge100% (1)

- 7.4.1 Procedure Supplier Selection With FlowchartDocument3 pages7.4.1 Procedure Supplier Selection With FlowchartBharath50% (4)

- PSI First Article Inspection ReportDocument3 pagesPSI First Article Inspection ReportwentropremPas encore d'évaluation

- Corrective Action ProcedureDocument1 pageCorrective Action ProcedureZharel AhmadPas encore d'évaluation

- QMS of The Company As Per IsoDocument62 pagesQMS of The Company As Per IsogalavaPas encore d'évaluation

- Flexible Supplier Scorecard TemplateDocument3 pagesFlexible Supplier Scorecard TemplateantonyPas encore d'évaluation

- Supplier Evaluation and Approval - Disapproval PGP2001ADocument6 pagesSupplier Evaluation and Approval - Disapproval PGP2001ASayed AbbasPas encore d'évaluation

- Contract Review FormatDocument1 pageContract Review Formatsuresh kumarPas encore d'évaluation

- Sample Updated IQA Check Sheet.Document16 pagesSample Updated IQA Check Sheet.ashwaniPas encore d'évaluation

- ProQC ExampleReport Initial Supplier EvaluationDocument12 pagesProQC ExampleReport Initial Supplier EvaluationMohammad Faraz Akhter100% (1)

- SOP 006 Rev - NC Calibration & Verification of EquipmentDocument5 pagesSOP 006 Rev - NC Calibration & Verification of EquipmentmeongPas encore d'évaluation

- LSAI SQA Manual FileDocument39 pagesLSAI SQA Manual FileSivakumar L100% (1)

- Scar 201164448Document4 pagesScar 201164448tonierlandaPas encore d'évaluation

- Supplier Audit Check ListDocument6 pagesSupplier Audit Check ListShalinMishraPas encore d'évaluation

- Supplier QuestionnaireDocument17 pagesSupplier QuestionnairepuneetoguptaPas encore d'évaluation

- Supplier Performance Measure Rating SystemDocument12 pagesSupplier Performance Measure Rating SystemPaulo Lindgren0% (1)

- Submission Requirements: Supplier ChecklistDocument19 pagesSubmission Requirements: Supplier ChecklistSivakumar LPas encore d'évaluation

- Vendor Qualification ProcedureDocument2 pagesVendor Qualification ProcedurePrem Goel80% (10)

- 9001.2015 Quality Manual Ver. 3Document3 pages9001.2015 Quality Manual Ver. 3Vasu RajaPas encore d'évaluation

- Master Auditing Document Draft With Secondary Responses - SQF Level IIDocument95 pagesMaster Auditing Document Draft With Secondary Responses - SQF Level IIFloreid100% (1)

- 85-04, The BW Preventive Action Register.: Purpose and ScopeDocument2 pages85-04, The BW Preventive Action Register.: Purpose and Scopedanaka007Pas encore d'évaluation

- FRM-MR-01 Management Review Sept 03Document6 pagesFRM-MR-01 Management Review Sept 03Ranjit RoyPas encore d'évaluation

- Supplier Rating ProcedureDocument4 pagesSupplier Rating ProcedureAmine Chahi100% (1)

- AE-QA-09 - Master List of Instrument Cum Calibration PlanDocument3 pagesAE-QA-09 - Master List of Instrument Cum Calibration PlanKarthi ThiyagarajanPas encore d'évaluation

- ISO 9001-2015 Supplier Audit ChecklistDocument11 pagesISO 9001-2015 Supplier Audit ChecklistUlviyye Cavid-Umid Elesgerova100% (1)

- Risk & Opportunities Analysis PDFDocument2 pagesRisk & Opportunities Analysis PDFpremnath RPas encore d'évaluation

- Procedure Manual FinalDocument41 pagesProcedure Manual FinalMandleshwar PrasadPas encore d'évaluation

- Form - Supplier Quality Survey - Rev 0Document3 pagesForm - Supplier Quality Survey - Rev 0Selvaraj SimiyonPas encore d'évaluation

- Duramedical SDN BHD: Oral Dam Manufacturing & Quality Control, Description & Process Flow ChartDocument5 pagesDuramedical SDN BHD: Oral Dam Manufacturing & Quality Control, Description & Process Flow ChartYap Jian JiePas encore d'évaluation

- SOP For Training Procedure For Quality Control - Pharmaceutical GuidelinesDocument2 pagesSOP For Training Procedure For Quality Control - Pharmaceutical Guidelinesnbpgr gmoPas encore d'évaluation

- Supplier Audit ChecklistDocument28 pagesSupplier Audit Checklist88No1FanPas encore d'évaluation

- Master List of DocumentsDocument2 pagesMaster List of DocumentsAnkita Agrawal100% (2)

- Sta-P08-02 Non Conforming ProductDocument6 pagesSta-P08-02 Non Conforming ProductAnonymous B7pghhPas encore d'évaluation

- IMS IS9001 IATF16949 ISO 14001 Certifcation Road MapDocument2 pagesIMS IS9001 IATF16949 ISO 14001 Certifcation Road Mapukavathekar0% (1)

- Manufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)Document5 pagesManufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)khmorteza100% (1)

- Supplier Process Audit Checklist TemplateDocument8 pagesSupplier Process Audit Checklist TemplateYang LishengPas encore d'évaluation

- Audit ChecklistDocument6 pagesAudit ChecklistApoloTrevinoPas encore d'évaluation

- Form - Scar LogDocument18 pagesForm - Scar LogHarie BongkyPas encore d'évaluation

- Purchase and Supplier Related Process-Bought Out Parts / Job WorksDocument18 pagesPurchase and Supplier Related Process-Bought Out Parts / Job WorksBhuwan ChopraPas encore d'évaluation

- Guidance On INTERNAL AUDITSDocument7 pagesGuidance On INTERNAL AUDITSdhir.ankurPas encore d'évaluation

- Manufacturing Process Audit Checklist: Reference DocumentsDocument4 pagesManufacturing Process Audit Checklist: Reference DocumentsAri Rosyadi100% (1)

- Chemical Compatibility ChartDocument13 pagesChemical Compatibility ChartManuel Mendez GomezPas encore d'évaluation

- Procedure - Outsourced ProcessesDocument1 pageProcedure - Outsourced Processesmgamal1080Pas encore d'évaluation

- QA/QC Management Philosophy: 1. Quality Control Plan - ProcessDocument6 pagesQA/QC Management Philosophy: 1. Quality Control Plan - ProcessSimon ChangPas encore d'évaluation

- Internal Audit Checksheet EMS-OHSASDocument32 pagesInternal Audit Checksheet EMS-OHSASwentropremPas encore d'évaluation

- GN-11 Declaration of Conformity TemplateDocument1 pageGN-11 Declaration of Conformity TemplateIstu PataiPas encore d'évaluation

- Bend AllowanceDocument2 pagesBend AllowancewentropremPas encore d'évaluation

- Metric FastenersDocument5 pagesMetric FastenerswentropremPas encore d'évaluation

- 2.5 SLMTA Receipt Checklist v1Document2 pages2.5 SLMTA Receipt Checklist v1wentropremPas encore d'évaluation

- Bolt Torque SpecsDocument2 pagesBolt Torque SpecswentropremPas encore d'évaluation

- What Is The Best Way To Clean Aluminum Before WeldingDocument1 pageWhat Is The Best Way To Clean Aluminum Before WeldingwentropremPas encore d'évaluation

- ISO Standards On WeldingDocument6 pagesISO Standards On WeldingwentropremPas encore d'évaluation

- Astm b210mDocument13 pagesAstm b210mwentropremPas encore d'évaluation

- Staff Suggestion FormDocument1 pageStaff Suggestion FormwentropremPas encore d'évaluation

- Internal Audit Checksheet EMS-OHSASDocument32 pagesInternal Audit Checksheet EMS-OHSASRambir KaushikPas encore d'évaluation

- Your Company Name: Suggestion SheetDocument2 pagesYour Company Name: Suggestion Sheetwentroprem100% (1)

- Ultrasonic Testing FormulasDocument4 pagesUltrasonic Testing FormulasNavneet Singh100% (1)

- Quality Management System Audit Checklist: Department: Email: Locations Sampled: Phone: Fax: NameDocument7 pagesQuality Management System Audit Checklist: Department: Email: Locations Sampled: Phone: Fax: NamewentropremPas encore d'évaluation

- Stand RdsDocument23 pagesStand RdswentropremPas encore d'évaluation

- Page - of - : (A Copy of This Report Is To Remain at Job-Site. Use Additional Sheets If Necessary.)Document7 pagesPage - of - : (A Copy of This Report Is To Remain at Job-Site. Use Additional Sheets If Necessary.)wentropremPas encore d'évaluation

- Book TotDocument39 pagesBook TotwentropremPas encore d'évaluation

- PSI First Article Inspection ReportDocument3 pagesPSI First Article Inspection ReportwentropremPas encore d'évaluation

- Sample of Welding Quality ManualDocument5 pagesSample of Welding Quality ManualwentropremPas encore d'évaluation

- Fine-Grain Structural Steels, Normalised Rolled: Mechanical PropertiesDocument2 pagesFine-Grain Structural Steels, Normalised Rolled: Mechanical PropertieswentropremPas encore d'évaluation

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremPas encore d'évaluation

- WWW Iso-9001-Checklist Co UkDocument13 pagesWWW Iso-9001-Checklist Co UkAnonymous y7o7pjW8Pas encore d'évaluation

- Project Quality Plan For South GhawarDocument48 pagesProject Quality Plan For South Ghawarmoytabura96Pas encore d'évaluation

- Ifs GMP Checklist Pac enDocument9 pagesIfs GMP Checklist Pac enCevdet BEŞENPas encore d'évaluation

- QCP - 1 - NotesDocument18 pagesQCP - 1 - NotesJinendraabhi100% (8)

- Wqa Ver 8Document64 pagesWqa Ver 8BudiePas encore d'évaluation

- NonConformities 02Document3 pagesNonConformities 02sheerazaliPas encore d'évaluation

- Checklist of Mandatory Documents Required by ISO IEC 17025 2017 EN PDFDocument14 pagesChecklist of Mandatory Documents Required by ISO IEC 17025 2017 EN PDFkheng chanbormeiPas encore d'évaluation

- ISO 29001 - Correlation Matrices ISO 29001Document12 pagesISO 29001 - Correlation Matrices ISO 29001ValentinPas encore d'évaluation

- ISO CD 29991 v.3 2012-05Document19 pagesISO CD 29991 v.3 2012-05MajdAbbasPas encore d'évaluation

- AI Root Cause AnalysisDocument27 pagesAI Root Cause AnalysisAsuman100% (1)

- Leadership in TQM at Madami Pa HahaDocument11 pagesLeadership in TQM at Madami Pa HahaPristine ChamomilePas encore d'évaluation

- Iso 34Document38 pagesIso 34Judy MillánPas encore d'évaluation

- Reduction of High Maintenance Costs by Noah Olela Abong'oDocument20 pagesReduction of High Maintenance Costs by Noah Olela Abong'oNABONGO2Pas encore d'évaluation

- Public Doc ServletDocument16 pagesPublic Doc ServletMariyappanPas encore d'évaluation

- ISO 9001 - 2015 Documentation ToolkitDocument2 pagesISO 9001 - 2015 Documentation Toolkiteman100% (1)

- HACCP GMP Certification Criteria PDFDocument32 pagesHACCP GMP Certification Criteria PDFanon_417835525Pas encore d'évaluation

- CSD-Tesla-BMS-0000051 Rev 6 Supplier Handbook July 14,2016Document48 pagesCSD-Tesla-BMS-0000051 Rev 6 Supplier Handbook July 14,2016Kevin HuynhPas encore d'évaluation

- ISO 9001-2015 Supplier Audit ChecklistDocument20 pagesISO 9001-2015 Supplier Audit ChecklistReshe Ramchandra100% (4)

- 8D Corrective Action ProcedureDocument3 pages8D Corrective Action ProcedureANTONIO MARTINEZPas encore d'évaluation

- Check List IOSA SEC Remote 1Document19 pagesCheck List IOSA SEC Remote 1arief rachmanPas encore d'évaluation

- PE 005-3 (PICS GMP Guide For Blood Establishments)Document25 pagesPE 005-3 (PICS GMP Guide For Blood Establishments)William ChandraPas encore d'évaluation

- Supplier Audit Checklist: Explanation of Audit Value Ratings PointsDocument17 pagesSupplier Audit Checklist: Explanation of Audit Value Ratings Pointsjaxf001Pas encore d'évaluation

- Gap Analysis Vda Vs TsDocument4 pagesGap Analysis Vda Vs TsSeval GünaltayPas encore d'évaluation

- Sub-Tier Control GuideDocument10 pagesSub-Tier Control GuideJHBernardoPas encore d'évaluation

- CQI-8 Layered Process Audit GuidelineDocument7 pagesCQI-8 Layered Process Audit GuidelineLotfi RaboudiPas encore d'évaluation

- Ashutosh Tiwari: Irnferno926Document2 pagesAshutosh Tiwari: Irnferno926ashu926Pas encore d'évaluation

- TQM Final ReportDocument19 pagesTQM Final ReportfaryalPas encore d'évaluation

- Validated Assessment Process (VAP) OverviewDocument42 pagesValidated Assessment Process (VAP) OverviewMtzCarlosPas encore d'évaluation

- Catálogo de Peças Monroe-2016 PDFDocument115 pagesCatálogo de Peças Monroe-2016 PDFfdntinocoPas encore d'évaluation

- Common Work Instructions For Directorate - 26082022Document12 pagesCommon Work Instructions For Directorate - 26082022snigdhaprajapati955Pas encore d'évaluation