Académique Documents

Professionnel Documents

Culture Documents

tmpB2AD TMP

Transféré par

FrontiersDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

tmpB2AD TMP

Transféré par

FrontiersDroits d'auteur :

Formats disponibles

2227

Almuslet et. al./ Elixir Chem. Phys. 33 (2011) 2227-2230

Available online at www.elixirjournal.org

Chemical Physics

Elixir Chem. Phys. 33 (2011) 2227-2230

Graft copolymerization of acrylamide onto gum karaya using diode laser

(532nm)

Nafie A. AlMuslet(1), Elfatih Ahmed Hassan(2), Al Sayed Abd-El-Magied Al-Sherbini(3),Mohamed Gusm Alla Muhgoub(4).

1

Institute of Laser, Sudan University of Science &Technology, Khartoum / Republic of Sudan,

Faculty of Science, Sudan University of Science &Technology, Khartoum / Republic of Sudan.

3

National Institute of Laser Enhanced Sciences (NILES), Cairo University, Cairo / Egypt,

4

Faculty of Education, Alzaiem Alazhari University, Khartoum / Republic of Sudan.

A R TI C L E I N F O

A B ST R A C T

Art i c l e h i st ory :

Received: 19 February 2011;

Received in revised form:

18 March 2011;

Accepted: 27 March 2011;

Graft copolymerization of acrylamide (AAm) on Gum Karaya GK using diode laser (532

nm) was investigated. The results showed that, the optimum conditions to achieve efficient

graft copolymerization were: 60 minutes laser irradiation time and 0.5 gm of GK, 0.142 gm

of acrylamide (monomer). The percentage of graft efficiency and percentage of graft yield

were 28.00%, and 98.59%, respectively. The graft copolymers were characterized using

Fourier-transform

infrared

spectroscopy (FTIR),

X-ray diffraction

(XRD),

Thermogravimetric analysis (TGA) and Scanning Electron Microscope (SEM) which proved

a successful production of GK-g-AAm. Thus, Laser irradiation was found to be effective

and clean method for producing GK-g-AAm.

K ey w or d s

Polymerization by laser,

Graft copolymerization,

Laser in photochemistry,

Laser spectroscopy.

Introduction

Gum Karaya:

Scientific Name(s): Sterculia urens Roxb. Family:

Sterculiaceae. The gum also may be obtained from S. villosa, S.

tragacantha, or other species of Sterculia [1].

Common Name(s): Karaya, sterculia. In Sudan, and

elsewhere in Africa, gum karaya can be obtained from S.

setigera. The exudates from these three species are very similar

in chemical composition and physico-chemical characteristics.

Accordingly, in terms of current legal definitions of identity and

trade specifications, exudates from any Sterculia, or admixtures,

can be offered for sale. Sterculia setigera is a multi-purpose

savanna tree which spreads naturally in central and southern

Sudan. The species is the main source of the internationally

accepted, Gum Karaya in Sudan [2,3,4,5]. Traditionally, India is

the largest producer and exporter of karaya gum [6]. Increasing

amounts are exported by African countries. Currently the gum is

used in a variety of products, including cosmetics, hair sprays,

and lotions, to provide bulk [7].

Gum Karaya is a complex, partially acetylated

polysaccharide obtained as a calcium and magnesium salt. The

polysaccharide component of gum karaya has a high molecular

weight and is composed of galacturonic acid, beta-D-galactose,

glucuronic acid, L-rhamnose, and other residues [1,2,3]. The

quality of gum karaya depends on the thoroughness of impurity

removal. Food-grade gum is usually a white to pinkish gray

powder with a slight vinegar odor [2]. Pharmaceutical grades of

gum karaya may be almost clear or translucent [3].

Gum Karaya is not digested or absorbed systemically. It is

essentially inert and is not associated with any pharmacologic

activity. Gum Karaya has a number of applications in the food

industry. Medicinally, gum karaya is an effective bulk laxative

as gum particles absorb water and swell from 60 to 100 times

their original volume [6]. The mechanism of action is an

Tele:

E-mail addresses: mnmfa2008@yahoo.com

2011 Elixir All rights reserved

2011 Elixir All rights reserved.

increase in the volume of the gut contents. Gum Karaya should

be taken with plenty of fluid and it may take a few days for

effects to be noticeable. It also has been used as an adhesive for

dental fixtures and ostomy equipment, and as a base for salicylic

acid patches [8,9]. Some preliminary studies suggest that gums

may normalize blood sugar and plasma lipid levels [10], but this

has not been thoroughly investigated. The use of gum karaya as

a carrier for drugs with differing solubilities in aqueous medium

has been investigated [11,12].

Experimental part:

Materials:

Gum Karaya collected from South Kordfan region, Sudan

during season 2007 and was used after cleaning from park,

leaves and extraneous materials without further purification.

Also other materials were used such as:

Acrylamide, puriss, Ceric Ammonium Nitrate (CAN),

Nitric Acid (Molar Solution) and Ethanol, all were supplied

from purum (Fluka Co.).

Equipments:

The equipments used in this study were:

(1)- Diode laser with wavelength of 532 nm and Power of 200

mW, supplied from (USA).

(2) -Fourier transform infrared spectrometer (FT-IR), model

Perkin Elmer 2000 FT-IR system supplied from (Perkin Elmer,

Norwalk, CT), using the KBr disk method (2 mg sample in 200

mg KBr). The scanning range was 500 to 4000 cm-1 and the

resolution was 1 cm-1.

(3) - X-ray Diffraction system attached with liquid nitrogen

cooled detector, model Brukur D 8 Advance (Germany),

equipped with a - goniometer under the following operation

conditions: 40 KV and 40 mA with CuK -radiation at

1.54056A. The relative intensity was recorded in the scattering

range (2) of 460,

(4) - Scanning Electron Microscope (SEM), supplied from JEOL

2228

Almuslet et. al./ Elixir Chem. Phys. 33 (2011) 2227-2230

(Japan) model 840 Ao,

(5) - Thermogravimetric analysis system (TGA) supplied from

Shimadzu (Japan) at a heating rate of 10C/min.

Methods:

(1) -Graft Copolymerization with Cerium 1V ammonium nitrate

(CAN):

The graft copolymerization of acrylamide onto Gum Karaya

was carried out under different reaction conditions and different

concentrations of the monomer to obtain the optimum condition

of graft copolymerization. In this study the graft

copolymerization method was done as follows:

0.5 gram of Gum Karay was dissolved in 75 mL of double

distilled water, then it was magnetically stirred under nitrogen

for 5 minutes, followed by the addition of required amount of

Cerium 1V ammonium nitrate (CAN) in molar nitric acid with

continuous stirring for 15 minutes to facilitate the formation of

free radical sites on the Gum Karaya chain followed by drop

wise addition of acrylamide.

The total volume was completed to 100 mL by distilled

water. Then the polymerization process was preceded at 30 o C

for 3 hours. After the solution was allowed to cool, the mixture

was washed with water and ethanol repeatedly to extract

homopolymer as well as unreacted monomer formed during the

grafting reaction. The grafted copolymer was dried under

vacuum oven at 40C to a constant weight.

Laser Induced Graft Copolymerization:

In this case the method was done as follows:

0.5 gram of Gum Karaya was dissolved in 75 mL of

distilled water, and then it was magnetically stirred under

nitrogen for 5 minutes. Diode laser was used, as initiator, to

irradiate the sample for 60 minutes. The acrylamide (monomer),

with concentration of 0.02 mol dm-3, was added. The total

volume was completed to 100 mL by distilled water. Then the

polymerization process was preceded at 30 o C for 3 hours.

The mixture was allowed to cool then solution was washed

with water and ethanol repeatedly to extract homopolymer as

well as unreacted monomer formed during the grafting reaction.

The final product was dried to a constant weight and its

percentage of grafting efficiency (%GE) and percentage of

grafting yield (%GY) were deduced according to the following

equations [13]:

% Graft Efficiency (%GE) = 100 (W2 W1) / W1

(1)

% Graft yield (%GY)

= 100 (W2 W1) / W3

(2)

where W1, W2 and W3 denote, the weights of the natural

polymer, graft copolymer and monomer, respectively.

Results and Discussion:

First of all graft copolymerization with Cerium 1V

ammonium nitrate (CAN) was carried out at different

concentrations of GK, different monomer concentrations at

different temperatures and the time required to complete the

reaction in order to obtain the optimum conditions for graft

copolymerization.

The deduced optimum conditions were 0.5 gm of GK, 0.142

gm of acrylamide (monomer) at 30oC and the time required to

complete the reaction was 3 hrs.

The percentage of graft yield at the optimum conditions was

97% and the percentage of graft efficiency was 27%, as shown

in fig.(1).

The apparent acceleration in the percentage of graft yield

and percentage of graft efficiency may be attributed to the gel

effect, resulting from an enhanced solubility of polyacrylamide

in the monomer.

Figure (1) Effect of reaction time on% graft efficiency and

% graft yield of GK-g-AAm (Acrylamide =0.020 mole dm-3,

CAN=0.91x10- in 100 ml solution.

The effect of exposure time of diode laser on percentage of

graft efficiency and percentage of graft yield of GK-g-AAm was

studied and illustrated in figure (2).

The graph is characterized by initial increases in percentage

of graft yield and percentage of graft efficiency with exposure

time of the laser up to a period of 60 minutes. With increasing

the irradiation time the percentage of graft efficiency and

percentage of graft yield decreases. The decrease in percentage

of graft yield and percentage of graft efficiency after 60 minutes

may be rationalized by partial hydrolysis and dissolution of the

grafted polymer chains. It is of interest to illustrate that the

percentage of graft efficiency and percentage of graft yield in

case of diode laser induced graft copolymerization were 28.00%

and 98.59%, respectively. Employing laser was an efficient

method for initiating graft copolymerization of Gum Karaya.

Fig. (2) Effect of diode laser exposure time on %GE and

%GY of GK-g-AAm (Acrylamide =0.020 mole dm-3, in 100

ml solution, time 3 hour and temp. 30 oC).

FTIR of GK-g-Acrylamide:

As maintained above the evidence of grafting has been

obtained during the graft copolymerization of different ratios of

acrylamide onto GK, from the increases in weight of the product

of the graft copolymer compared with the original substrate.

Also the evidence of grafting was observed among the infrared

spectra comparison between the substrate and graft copolymer.

Figure (3) presents the FTIR of Gum Karaya, acrylamide and

Gum Karaya grafted AAm. The figure shows the main vibration

bands of unmodified Gum Karaya, acrylamide and GK-g-AAm,

respectively. The Gum Karaya showed a broad absorption band

at 3420 cm1. This band is a characteristic of the glucosidic ring

and might due to the stretching vibration of OH, a small peak at

2933 cm1, attributed to the CH stretching vibration. In case of

acrylamide the recorded infrared spectra in the same regions

shows bands at 3359, 3187 cm-1 ascribed to the antisymmetric

and symmetric NH stretching, respectively. In addition the

bands at 3035 and 2812cm-1 were attributed to the symmetric

stretching of C-H2 and vibration of stretching C-H. In case of

acrylamide, the recorded spectrum in the same regions indicated

the bands at 3359, 3187 cm-1 that are ascribed to the

antisymmetric and symmetric NH stretching, respectively.

In addition, the bands at 3035 and 2812cm-1 are attributed to

Almuslet et. al./ Elixir Chem. Phys. 33 (2011) 2227-2230

the symmetric stretching of C-H2 and vibration of stretching vCH. When Gum Karaya was grafted by acrylamide the FTIR

spectra of the grafted copolymerized product showed the same

absorption band as in case of Gum Karaya. It is of interest that

new peaks are observed at 2497 cm-1and 2336 cm-1 in case of

GK-g-AAm. These new peaks may be due to the vibrational

symmetric stretching of CH2 and vibrational stretching CH,

respectively suggesting the existence of grafting. In the region

between 2000-1500 cm-1, the FTIR of GK showed two peaks at

1731 cm-1 and 1610 cm-1 which attributed to the C=O stretching

and C=C stretching respectively.

In case of acrylamide the peaks between 1672 cm-11610 cm1

are due to the C=O, the C=C stretching and in plan bending of(

N H2, C-H2). In the same region the spectra of GK-g-AAm,

showed shift of the position of the absorption band from 1610

cm-1 for GK to 1634 cm-1 and from 1731 cm-1 for GK to 1740

cm-1. In case of GK-g-AAm this shift also evidence of grafting.

The peaks at 1740 cm-1 and 1634 cm-1 are assigned to C=O , C-O

and N-H2 deformation ( N-H2) respectively.

In the domain of 1500-500 cm-1, the FTIR of Gum Karaya

showed peak at 1521 cm-1 due to C=C stretch and a weak band

at 1432 cm-1 assigned to symmetric CO2 stretch while for AAm

the peak observed at 1428 cm-1 is due to C-N stretching. In the

same region, the peaks at (1521, 1423 cm-1) were disappeared in

case of GK-g-AAm.

This might be due to the grafting. Acrylamide was shows

two peaks at 1350 cm-1 and 1281 cm-1 while GK-g-AAm has

peaks at 1323 cm-1 and 1285 cm-1 assigned to OH bending

vibration and C-O antisymmetric and symmetric stretching

vibration, respectively. The strong peaks from 1200900 cm-1

are the finger print of carbohydrates.

These peaks are observed in case of GK and GK-g-AAm,

while disappeared for AAm which has four absorption peaks at

1138,1048 , 988 and 961 cm-1 due to the rocking of NH2, C-H2,

in plan bending of C-H and (wagging trans of CH=CH ,

wagging of CH2), respectively. Within the range of 900-500 cm1

, the FTIR of acrylamide showed absorption bands at 840, 817

cm-1 and other bands observed from 700-500 cm-1.

These peaks are assigned to (C-C), (torsion) (NCC) +

(CCC), (bending) (NH2) + (CH2 and (NH2) + (CH2),

respectively. In the same domain the Gum Karaya showed weak

peaks assigned to CCO, COC, symmetrical and asymmetrical

ring breathing vibration. After graft copolymerization the

product showed that the peak at 882 cm-1, 853 cm-1 and 817 cm1

( (C-C)) decrease in case of acrylamide while the other peak at

817 cm-1 is not observed. It is also observed that there are three

new peaks at 670 cm-1 to 611 cm-1 and 580 cm-1 in case of

grafted Gum Karaya which are not existed in case of both AAm

and GK. This indicated that Gum Karaya was grafted with

acrylamide.

X-ray Diffraction (XRD) of GK and Gum Karaya-gAcrylamide:

Fig. (4-a,b) illustrated the powder X-ray diffractograms

obtained for natural GK, before and after grafting, respectively.

The XRD pattern shows the amorphous nature of GK. From

figure (4a), the maximum intensity is at 2 = 20o which well

agreed with values reported in literatures. The observed peak

corresponds to 2 = 19.895o, has the average grain length

estimated to d-space = 4.4375Ao. The XRD pattern provides an

interesting feature of intensity distribution. After carrying out

the graft copolymerization of GK by acrylamide, the peak of the

distribution was shifted considerably to 2 = 20.79o which has

the average grain length estimated to d-space = 4.267Ao in

comparison to the Gum Karaya. On the other hand fig.(4b)

shows that the grafting decreases the intensity of the

corresponding peak. The graft copolymer becomes almost

amorphous. The grafting of acrylamide is taken place randomly

along the GK chain, giving rise to a random copolymer. This

will efficiently destroyed the regularity of the packing of the

original GK chains, which results in the formation of amorphous

copolymer.

45

40

Intensity (counts/sec)

2229

35

30

25

20

15

10

5

10

20

30

40

50

60

Fig (4-a,b) XRD of (a)Gum Karaya Gum and (b) Karaya-gAcrylamide.

Scanning Electron Microscope (SEM) of GK and GK-gAcrylamide:

Morphological examination of the fine powder of Gum

Arabic and grafted copolymerized was carried out using SEM

type (JEOL-840) by making a thin film of desirable size on

copper grids and coated with gold. The surface topography of

the GK-g-AAm studied by SEM and compared with the GK.

The exterior surface of the GK-g-AAm appears as

heterogeneous rocky surface and clearly different from that of

the parent GK, which has rocky shape of smooth surface with

different sizes. Hence, the surface evidence supports the grafting

of AAm onto the GK, as shown in Fig.( 5-a,b).

GK

Optical Density (O.D)

100

AAm

50

GK-g-AAm

0

4000

3500

3000

2500

2000

1500

1000

-1

Wavelength (cm )

Figure (3) FTIR spectra of GK, Acrylamide, and GK-gAcrylamide in the range from 4000 to 500 cm-1.

Figure (5-a,b) Typical SEM images of (a) Gum

Karaya before grafting and (b) GK-g- AAm.

Thermogravimetric Analysis (TGA):

(1) - Gum Karaya-g-Acrylamide:

In this study TGA was done on the dried samples in air with

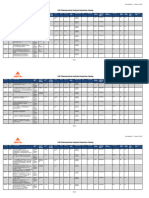

a heating rate of 10 C/min. Figure (6-a,b) and table (1)

illustrate the details of thermal behavior according to the

primary thermograms and derivative thermograms for Gum

Karaya and Gum Karaya-g-Acrylamide. The samples showed

2230

Almuslet et. al./ Elixir Chem. Phys. 33 (2011) 2227-2230

first a small weight loss (15%) up to 250C and (9%) up

to249C for GK and GK-g-AAm, respectively. The early minor

weight loss in samples is attributed to desorption of moisture as

hydrogen bound water to the saccharide structure. This is not

unexpected taking into account the hydrophilic nature of the

composite constituents. It should be noted that the thermogram

of the Gum Karaya exhibited three stages, the first stage is

attributed to desorption of moisture as hydrogen bound water to

the gum structure while the second and third stages of TGA

curve are probably due to molecular degradation and

decomposition reactions of GK. It was observed that the weight

loss was slower in the case of the graft copolymer indicating that

the graft copolymer is more thermally stable than the GK.

(Weight loss%)x10

10

GK-g-AAm

GK

6

4

100

200

300

400

500

600

700

800

Temperature( C)

Figure (6-a,b) TGA curves of a) Gum Karaya

before grafting and (b) GK-g- AAm.

Acknowledgment:

The authors would like to express their appreciation to the

staff of National Institute of Laser Enhanced Science (NILES) Cairo University, Egypt, for their invaluable assistance and

guidance during practical work.

We also acknowledge institute of laser and faculty of

Science - Sudan University of Science &Technology, Khartoum

for their assistance.

References:

1. Tyler VE. Pharmacognosy. Philadelphia, PA: Lea & Febiger;

1981.

2. Leung AY. Encyclopedia of Common Natural Ingredients

Used In Food, Drugs, and Cosmetics. New York, NY: J. Wiley

and Sons; 1980.

3. Morton JF. Major Medicinal Plants. Springfield, IL: CC

Thomas;1977.

4. Evans WC. Trease and Evans' Pharmacognosy. 13th ed.

London,England:BailliereTindall;1989.

5. Osol A, Farrar GE Jr, eds. The Dispensatory of the United

States of America. 25th ed. Philadelphia, PA: J.B. Lippincott

Co.; 1955.

6. Verbeken D, Dierckx S, Dewettinck K. Exudate gums:

occurrence, production, and applications. Appl Microbiol

Biotechnol.2003;63:10-21.

7. Der Marderosian AH, Liberti LE. Natural Product Medicine.

Philadelphia,PA:G.F.StickleyCo.;1988.

8. Meier P, Seiler WO, Stahelin HB. Bulk-forming agents as

laxatives in geriatric patients [in German]. Schweiz Med

Wochenschr.1990;120:314-317.

9. Bart BJ, Biglow J, Vance JC, Neveaux JL. Salicylic acid in

karaya gum patch as a treatment for verruca vulgaris. J Am

Acad Dermatol.1989;20:74-76.

10. Behall KM. Effect of soluble fibers on plasma lipids, glucose

tolerance and mineral balance. Adv Exp Med Biol. 1990; 270:716.

11. Wilson M, Harvey W. Prevention of bacterial adhesion to

dentureacrylic.JDent.1989;17:166-170.

12. Munday DL, Cox PJ. Compressed xanthan and karaya gum

matrices: hydration, erosion and drug release mechanisms. Int J

Pharm.2000; 203:179-192.

13. Eromosele, I.C. (1994), Graft Coplymerization of acrylo

nitrile onto Cotton Cellulose by potassium permanganate-thio

acetamide redox system, J. Appli. Polym. Sci, 51, 1817-1821.

Table (1) Thermogravimetric data obtained during heating rate at

10 C/min under nitrogen atmosphere of GK and GK-g-AAm.

Sample

GK

GK-g-AAm

Number of stage

1

2

3

1

2

Temperature range (oC)

50-250

250-400

400-700

50-249

300-700

Weight loss (%)

15

65

20

9

81

Vous aimerez peut-être aussi

- Immobilization of Urease On (HEMA IA) Hydrogel Prepared by Gamma RadiationDocument9 pagesImmobilization of Urease On (HEMA IA) Hydrogel Prepared by Gamma RadiationGoh Kek BoonPas encore d'évaluation

- A Single Novel PVC Membrane For Dual Determination of Sul - 2015 - Arabian JournDocument6 pagesA Single Novel PVC Membrane For Dual Determination of Sul - 2015 - Arabian JournEwo50 NewPas encore d'évaluation

- Synthesis and Characterization of Agar SDocument12 pagesSynthesis and Characterization of Agar SQuế NghiPas encore d'évaluation

- The Heterogenation of Melamine and Its Catalytic Activity: Applied Catalysis A: GeneralDocument7 pagesThe Heterogenation of Melamine and Its Catalytic Activity: Applied Catalysis A: GeneralJimmy NelsonPas encore d'évaluation

- Food Chemistry: Vural Go Kmen, Hamide Z. S SS EnyuvaDocument8 pagesFood Chemistry: Vural Go Kmen, Hamide Z. S SS EnyuvaPradhana AdiputraPas encore d'évaluation

- Gelation Properties of Flaxseed GumDocument9 pagesGelation Properties of Flaxseed GumAntares1973Pas encore d'évaluation

- Sonolytic Degradation of High-Molecular Weight Amylose by Graphene Oxide NanoparticlesDocument4 pagesSonolytic Degradation of High-Molecular Weight Amylose by Graphene Oxide NanoparticleserpublicationPas encore d'évaluation

- Eco Friendly Extraction and Characterization of Cellulose From Oil Plam Empty Fruit BunchesDocument12 pagesEco Friendly Extraction and Characterization of Cellulose From Oil Plam Empty Fruit BunchesJair Fajrdo LopezPas encore d'évaluation

- SPE 164135 Mechanical and Thermal Stability of Polyacrylamide-Based Microgel Products For EORDocument11 pagesSPE 164135 Mechanical and Thermal Stability of Polyacrylamide-Based Microgel Products For EORLeopold Roj DomPas encore d'évaluation

- (En) Evaluation of Optimal Conditions For Crude Palm Oil Bleaching On Locally Prepared Activated Carbon Using Rsm-Ga and A Hybrid Ann-GaDocument15 pages(En) Evaluation of Optimal Conditions For Crude Palm Oil Bleaching On Locally Prepared Activated Carbon Using Rsm-Ga and A Hybrid Ann-GaAli MulhakimPas encore d'évaluation

- Polymers For Advanced Techs - December 1995 - Saraydin - Acrylamide Maleic AcidDocument8 pagesPolymers For Advanced Techs - December 1995 - Saraydin - Acrylamide Maleic AcidQuế NghiPas encore d'évaluation

- Synthesis and Characterization of Biodegradable Starch-Polyacrylamide Graft Copolymers Using Starches With Different MicrostructuresDocument7 pagesSynthesis and Characterization of Biodegradable Starch-Polyacrylamide Graft Copolymers Using Starches With Different MicrostructuresLina Maria RodriguezPas encore d'évaluation

- Cellulose Acetate Production by Acetylation of Cellulose Derived From Date Palm FrondsDocument10 pagesCellulose Acetate Production by Acetylation of Cellulose Derived From Date Palm FrondsOmar AzougaghPas encore d'évaluation

- Preformulation, Characterization, and in Vitro Release Studies of Caffeine-Loaded Solid Lipid NanoparticlesDocument11 pagesPreformulation, Characterization, and in Vitro Release Studies of Caffeine-Loaded Solid Lipid NanoparticlesJunior GonzalesPas encore d'évaluation

- Preprint 99-3: SME Annual Meeting March 1-3, 1999, Denver, ColoradoDocument5 pagesPreprint 99-3: SME Annual Meeting March 1-3, 1999, Denver, ColoradoGustavo Gabriel JimenezPas encore d'évaluation

- Crude Oil Wax, Emulsion and AsphalteneDocument30 pagesCrude Oil Wax, Emulsion and AsphalteneĐinh Tiên HoàngPas encore d'évaluation

- Chemical and Spectral Characterization of Cell Wall Polysaccharide of Gracilaria Edulis (Gmelin) SilvaDocument5 pagesChemical and Spectral Characterization of Cell Wall Polysaccharide of Gracilaria Edulis (Gmelin) SilvaWin ArigaPas encore d'évaluation

- Nano Alumina Sulfuric AcidDocument4 pagesNano Alumina Sulfuric AcidTahseen AlHattabPas encore d'évaluation

- 439 Asd 2Document15 pages439 Asd 2Luthfi Iza mahendraPas encore d'évaluation

- NST SynopsisDocument3 pagesNST SynopsisRaisul IslamPas encore d'évaluation

- Synthesis of Hydrogel Film Based On Carrageenan Extracted FromDocument9 pagesSynthesis of Hydrogel Film Based On Carrageenan Extracted FromIstiqomahPas encore d'évaluation

- Swelling of Superabsorbant Kim 26 6-8-0110 8Document13 pagesSwelling of Superabsorbant Kim 26 6-8-0110 8Alesam44bPas encore d'évaluation

- Full TextDocument8 pagesFull TextGopal ChavanPas encore d'évaluation

- Structural and Rheological Characteristics of Alginate From Sargassum Cristaefolium Extracted by Twin Screw ExtruderDocument17 pagesStructural and Rheological Characteristics of Alginate From Sargassum Cristaefolium Extracted by Twin Screw Extrudersugiono sugionoPas encore d'évaluation

- Immobilized Amylase ArticleDocument6 pagesImmobilized Amylase ArticleHarish Ramani ChandranPas encore d'évaluation

- Original Paper: Jin-Sheng Sun, Wei-Chao Du, Xiao-Lin Pu, Zhuan-Zheng Zou, Bo-Bo ZhuDocument10 pagesOriginal Paper: Jin-Sheng Sun, Wei-Chao Du, Xiao-Lin Pu, Zhuan-Zheng Zou, Bo-Bo ZhuAnand aashishPas encore d'évaluation

- Evaluation For Collagen Products For Cosmetic ApplicationDocument15 pagesEvaluation For Collagen Products For Cosmetic ApplicationDumy DumiterrPas encore d'évaluation

- Lee Et Al 2005Document9 pagesLee Et Al 2005Hyejin Yeni PatmawatiPas encore d'évaluation

- ZeolitDocument7 pagesZeolitIndra WahyuPas encore d'évaluation

- Food Chemistry: G Okhan Demirel, K Ursßat O Guz Yaykasßlı, Ahmet YasßarDocument4 pagesFood Chemistry: G Okhan Demirel, K Ursßat O Guz Yaykasßlı, Ahmet YasßaroscarPas encore d'évaluation

- Development of A Solid Phase Microextraction Protocol For The GC-MS Citral DegradationDocument8 pagesDevelopment of A Solid Phase Microextraction Protocol For The GC-MS Citral DegradationcarlosPas encore d'évaluation

- TLR 2023 088 AhmedDocument24 pagesTLR 2023 088 AhmeddavorPas encore d'évaluation

- Agar Extraction Process For Gracilaria CliftoniiDocument7 pagesAgar Extraction Process For Gracilaria CliftoniiAdaPas encore d'évaluation

- tmp93D TMPDocument8 pagestmp93D TMPFrontiersPas encore d'évaluation

- Effects of Soaking On Yield and Quality of Agarwood OilDocument8 pagesEffects of Soaking On Yield and Quality of Agarwood OilNilamdeen Mohamed ZamilPas encore d'évaluation

- Shells 3Document8 pagesShells 3Donna HayesPas encore d'évaluation

- SPE-182836-MS Simulation of Ionic Liquid Flooding For Chemical Enhance Oil Recovery Using CMG STARS SoftwareDocument14 pagesSPE-182836-MS Simulation of Ionic Liquid Flooding For Chemical Enhance Oil Recovery Using CMG STARS SoftwareVeronicaPas encore d'évaluation

- Terje MahanDocument15 pagesTerje MahanErikaPas encore d'évaluation

- Purification of Crude Glycerol From Transesterific PDFDocument11 pagesPurification of Crude Glycerol From Transesterific PDFesiPas encore d'évaluation

- Vinicius Rossa, Production of Solketal Using Acid Zeolites As CatalystsDocument18 pagesVinicius Rossa, Production of Solketal Using Acid Zeolites As Catalystsnysa arientikaPas encore d'évaluation

- Bioresources.: Optimized Conditions For Graft Copolymerization of Poly (Acrylamide) Onto Rubberwood FibreDocument11 pagesBioresources.: Optimized Conditions For Graft Copolymerization of Poly (Acrylamide) Onto Rubberwood Fibredeni.sttnPas encore d'évaluation

- Flocculation of Kaolinite Suspensions in Water by Coconut Cream CaseinDocument7 pagesFlocculation of Kaolinite Suspensions in Water by Coconut Cream CaseinNadia MandasariPas encore d'évaluation

- Seawater Desalination Using Smart Polyacrylic Acid Hydrogel in Haqel-Tabuk, Kingdom of Saudi Arabia (Ksa)Document8 pagesSeawater Desalination Using Smart Polyacrylic Acid Hydrogel in Haqel-Tabuk, Kingdom of Saudi Arabia (Ksa)TJPRC PublicationsPas encore d'évaluation

- Palm Stearin GuavaDocument8 pagesPalm Stearin GuavaAhmad ZiaurrahmanPas encore d'évaluation

- Double Bypasses Soxhlet Apparatus For Extraction of Piperine From Piper NigrumDocument4 pagesDouble Bypasses Soxhlet Apparatus For Extraction of Piperine From Piper Nigrumpurnama sariPas encore d'évaluation

- Albay RakDocument6 pagesAlbay Rakhayder1920Pas encore d'évaluation

- KalalehDocument10 pagesKalalehCarlos Ruben Suarez GavidiaPas encore d'évaluation

- 517 PDFDocument6 pages517 PDFsyedt4140Pas encore d'évaluation

- Preparation of A Novel Magnetic Geopolymer/ Zero-Valent Iron Composite With Remarkable Adsorption Performance Towards Aqueous Acid Red 97Document15 pagesPreparation of A Novel Magnetic Geopolymer/ Zero-Valent Iron Composite With Remarkable Adsorption Performance Towards Aqueous Acid Red 97basselPas encore d'évaluation

- Oriental Journal of Chemistry 28 (3) 1091-1098Document8 pagesOriental Journal of Chemistry 28 (3) 1091-1098Noureddine BarkaPas encore d'évaluation

- Use of Rice Straw and Radiation-Modified Maize Starch/acrylonitrile in The Treatment of WastewaterDocument12 pagesUse of Rice Straw and Radiation-Modified Maize Starch/acrylonitrile in The Treatment of Wastewaterdeni.sttnPas encore d'évaluation

- Gel Characteristic of Surimi Added With HydrocolloidsDocument6 pagesGel Characteristic of Surimi Added With HydrocolloidsWahyu MuhammadPas encore d'évaluation

- Structural Characterization of Cellulose ObtainedDocument5 pagesStructural Characterization of Cellulose ObtainedRezza MarcellaPas encore d'évaluation

- Ge 2019 GranulDocument10 pagesGe 2019 GranulRestu KusumawardaniPas encore d'évaluation

- Isolation Characterization and Molecular Weight Determination of Collagen From Marine Sponge Spirastrella Inconstans (Dendy)Document8 pagesIsolation Characterization and Molecular Weight Determination of Collagen From Marine Sponge Spirastrella Inconstans (Dendy)Paulo JuniorPas encore d'évaluation

- Aniagor2020 - Relational Description of An Adsorption System Based On IsothermDocument26 pagesAniagor2020 - Relational Description of An Adsorption System Based On Isothermco.aniagorPas encore d'évaluation

- Fuels, Chemicals and Materials from the Oceans and Aquatic SourcesD'EverandFuels, Chemicals and Materials from the Oceans and Aquatic SourcesFrancesca M. KertonPas encore d'évaluation

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsD'EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsPas encore d'évaluation

- Corrosion and Fouling Control in Desalination IndustryD'EverandCorrosion and Fouling Control in Desalination IndustryPas encore d'évaluation

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesD'EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesPas encore d'évaluation

- tmpCE8C TMPDocument19 pagestmpCE8C TMPFrontiersPas encore d'évaluation

- tmpEFCC TMPDocument6 pagestmpEFCC TMPFrontiersPas encore d'évaluation

- Tmp1a96 TMPDocument80 pagesTmp1a96 TMPFrontiersPas encore d'évaluation

- tmp6F0E TMPDocument12 pagestmp6F0E TMPFrontiersPas encore d'évaluation

- tmpF178 TMPDocument15 pagestmpF178 TMPFrontiersPas encore d'évaluation

- tmp80F6 TMPDocument24 pagestmp80F6 TMPFrontiersPas encore d'évaluation

- tmp3CAB TMPDocument16 pagestmp3CAB TMPFrontiersPas encore d'évaluation

- tmpFFE0 TMPDocument6 pagestmpFFE0 TMPFrontiersPas encore d'évaluation

- tmpE7E9 TMPDocument14 pagestmpE7E9 TMPFrontiersPas encore d'évaluation

- tmpE3C0 TMPDocument17 pagestmpE3C0 TMPFrontiersPas encore d'évaluation

- Tmpa077 TMPDocument15 pagesTmpa077 TMPFrontiersPas encore d'évaluation

- tmpF407 TMPDocument17 pagestmpF407 TMPFrontiersPas encore d'évaluation

- tmpF3B5 TMPDocument15 pagestmpF3B5 TMPFrontiersPas encore d'évaluation

- tmp6382 TMPDocument8 pagestmp6382 TMPFrontiersPas encore d'évaluation

- tmp37B8 TMPDocument9 pagestmp37B8 TMPFrontiersPas encore d'évaluation

- tmp72FE TMPDocument8 pagestmp72FE TMPFrontiersPas encore d'évaluation

- tmpC0A TMPDocument9 pagestmpC0A TMPFrontiersPas encore d'évaluation

- tmp8B94 TMPDocument9 pagestmp8B94 TMPFrontiersPas encore d'évaluation

- tmp9D75 TMPDocument9 pagestmp9D75 TMPFrontiersPas encore d'évaluation

- tmp60EF TMPDocument20 pagestmp60EF TMPFrontiersPas encore d'évaluation

- tmp998 TMPDocument9 pagestmp998 TMPFrontiersPas encore d'évaluation

- tmpD1FE TMPDocument6 pagestmpD1FE TMPFrontiersPas encore d'évaluation

- tmp4B57 TMPDocument9 pagestmp4B57 TMPFrontiersPas encore d'évaluation

- tmpA0D TMPDocument9 pagestmpA0D TMPFrontiersPas encore d'évaluation

- tmpC30A TMPDocument10 pagestmpC30A TMPFrontiersPas encore d'évaluation

- tmp2F3F TMPDocument10 pagestmp2F3F TMPFrontiersPas encore d'évaluation

- Tmp75a7 TMPDocument8 pagesTmp75a7 TMPFrontiersPas encore d'évaluation

- tmpB1BE TMPDocument9 pagestmpB1BE TMPFrontiersPas encore d'évaluation

- tmp27C1 TMPDocument5 pagestmp27C1 TMPFrontiersPas encore d'évaluation

- tmp3656 TMPDocument14 pagestmp3656 TMPFrontiersPas encore d'évaluation

- GENERAL CHEMISTRY For First Years of Faculties of Science, Medicine and Pharmacy Part 1Document102 pagesGENERAL CHEMISTRY For First Years of Faculties of Science, Medicine and Pharmacy Part 1Mufaddal KaderbhaiPas encore d'évaluation

- Persimmon Fruit Enhanced Quality Characteristics and Antioxidant Potential of BeerDocument7 pagesPersimmon Fruit Enhanced Quality Characteristics and Antioxidant Potential of BeerAlexandre PimentelPas encore d'évaluation

- 7 Sco Cum-Pcmbt-1 (Paper-B) Key Exam DT 21-07-2023Document4 pages7 Sco Cum-Pcmbt-1 (Paper-B) Key Exam DT 21-07-2023Samit KambalapallyPas encore d'évaluation

- Mechanical Characterization of MMT Nano Clay/Epoxy/ Basalt Fiber CompositesDocument6 pagesMechanical Characterization of MMT Nano Clay/Epoxy/ Basalt Fiber CompositesArpan BhandariPas encore d'évaluation

- Week 5 - Learning ActivitiesDocument4 pagesWeek 5 - Learning ActivitiesChuchai Isla Y AbadPas encore d'évaluation

- QB - DPT I - Fund. of Polymer ScienceDocument9 pagesQB - DPT I - Fund. of Polymer ScienceAryank mishraPas encore d'évaluation

- Certificate of Analysis - Certified Reference Material Certipur Sulfur ICP Standard 1000 MG/L SDocument2 pagesCertificate of Analysis - Certified Reference Material Certipur Sulfur ICP Standard 1000 MG/L SAndresOchoaPas encore d'évaluation

- Degradación Básica NafazolinaDocument7 pagesDegradación Básica NafazolinaLauryPas encore d'évaluation

- PFD Write UpDocument2 pagesPFD Write UpZeeshan WaheedPas encore d'évaluation

- Reactions of Halogens (As Aqueous Solutions)Document4 pagesReactions of Halogens (As Aqueous Solutions)Priya KumarPas encore d'évaluation

- Laetrile Amygdalinor Vitamin B17Document7 pagesLaetrile Amygdalinor Vitamin B17Isna NurhidayatiPas encore d'évaluation

- Clase 9Document35 pagesClase 9EdinberSPPas encore d'évaluation

- Chapter 2-Phenol FormaldehydesDocument32 pagesChapter 2-Phenol Formaldehydesaslı aslanPas encore d'évaluation

- 10 - StoichiometryDocument23 pages10 - StoichiometryBenedict LarocoPas encore d'évaluation

- Am Am Charla 2011Document10 pagesAm Am Charla 2011Raul Diaz TorresPas encore d'évaluation

- Pelletization Studies On A Beneficiated Magnetite ConcentrateDocument7 pagesPelletization Studies On A Beneficiated Magnetite ConcentrateravibelavadiPas encore d'évaluation

- Ansi C135.14-1979Document2 pagesAnsi C135.14-1979gestordecomprasPas encore d'évaluation

- General Biology Osmosis LabDocument8 pagesGeneral Biology Osmosis Labapi-350453759Pas encore d'évaluation

- Common Ion Effect (1.0)Document9 pagesCommon Ion Effect (1.0)Kuldipsinh ZalaPas encore d'évaluation

- Class-12 Holiday Homework (2023-24)Document17 pagesClass-12 Holiday Homework (2023-24)EmmReelsPas encore d'évaluation

- Redox Reactions - Shobhit NirwanDocument12 pagesRedox Reactions - Shobhit NirwanAadarsh PandeyPas encore d'évaluation

- Math Sectional 1Document55 pagesMath Sectional 1jsaab2692Pas encore d'évaluation

- Towards Dense Single-Atom Catalysts For Future Automotive ApplicationsDocument13 pagesTowards Dense Single-Atom Catalysts For Future Automotive ApplicationsAdriano Aj-formataçãoPas encore d'évaluation

- Solutions For Edr 1 Probs PDFDocument4 pagesSolutions For Edr 1 Probs PDFArfel Marie FuentesPas encore d'évaluation

- HUBUNGAN STRUKTUR, Ikatan Kimia Dan Aktivitas Fisiologis CompleteDocument67 pagesHUBUNGAN STRUKTUR, Ikatan Kimia Dan Aktivitas Fisiologis Completedatin suhaellaPas encore d'évaluation

- Standard Operating Procedure - OxidizersDocument5 pagesStandard Operating Procedure - OxidizersMishel Mijares100% (1)

- 8.0 Froth Flotation 02.04.2020 PDFDocument11 pages8.0 Froth Flotation 02.04.2020 PDFMabvuto Banda the son of the Consuming firePas encore d'évaluation

- Rammed Earth Technical Data 1Document6 pagesRammed Earth Technical Data 1Amrit NarkarPas encore d'évaluation

- Waste Management: Thomas H. Christensen, Valentina BisinellaDocument17 pagesWaste Management: Thomas H. Christensen, Valentina BisinellaclaudiacarranzafPas encore d'évaluation

- ROTH Hydraulics Technical InfoDocument28 pagesROTH Hydraulics Technical InfoSerge BordagePas encore d'évaluation