Académique Documents

Professionnel Documents

Culture Documents

C6 TurtleDiagramProductManufacturingProcess产品制造过程乌龟图 En

Transféré par

BAlaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

C6 TurtleDiagramProductManufacturingProcess产品制造过程乌龟图 En

Transféré par

BAlaDroits d'auteur :

Formats disponibles

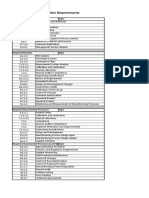

File: Turtle Diagram

Quality Systems ProcessTurtle Diagram

Product Manufacturing Procedure

Turtle Diagram Trial Version

Approaches

(Material/equipment/facility/necessary spare parts, etc.)

1. Equipment in perfect conditions, customer properties,

spare parts

2Computer, network, fax, printer

3Pens

Inputs

(External & internal customer opinions)

1 Customer order/production plan reviewed

2 Qualified raw/supporting materials, and

purchased or externally processed parts

3 Energies like water, power, and gas

4 Control plan, operation guidance, inspectin

guidance, product review standards, in-work

inspection standards for raw/supporting

materials, and purchased or externally

processed parts, and sealed samples

5 Record forms complied with control plans

6 People being trained and qualified for the

positions

Process Type No.: C6

Date of examination:

Page 1/1

Who

(Responsibility/skill matrix/qualification training/special training)

1 Production: production plan, marks, logistics plan, transportation tools,

warehouse management

2Tech: control plan for new product batch production, creation of operation guidance, technique

validation, creation of record book, change of techniques

3Factory technicians: reception of new product technical document, control plan for batch

products, change of operation guidance, technique validation, creation and change of record

forms, change of techniques, examination of technique disciplines, on-site SPC, quality

improvement, etc.

4Tech. Manager: review and approve new or changed technical documents.

5Factories: manufacture by plans; position requirements/staff qualifications/training requirements, plans;

validation of production preparation; maintenance of equipment; on-site logistics; marks and security. An

authorized person in the factory can order to terminate production.

6. QA: create inspection guidance, goods inspection, process inspection, final inspection, and

review of unqualified products.

Product Manufacturing

Procedure

How?

(Approach/special environment requirement/procedure/work specification/list/format)

1YGB-KPSNC-QM001-2004 Quality Manual

2YGB-KPSNC-QP7501-2004 Process Control Procedure

3YGB-KPSNC-QP8301-2004 Unqualified Product Control Procedure

4. In-Work Inspection Standards for Purchased/Externally Processed/Raw/SupportingMaterials

5 YGB-KPSNC-QP7502-2004 Equipment Management Control Procedure

6. YGB-KPSNC-QP7506-2004 Marks & Traceability Control Procedure

7YGZ-KPSNC-QT050 Standards for Techniques Validation

8YGZ-KPSNC-QT022 Examination of Technique Disciplines

Outputs

(Procedures & major points internal & external

customers expect)

1Products at different manufacturing statuses

2Products in the warehouse

Measurement

(Performance of process target)

1% of production plans completed

2% of qualified products, PPm

3Quality cost

4CpkMSACmk

5Customer satisfaction, and complaints

(performance is continuously improved)

Vous aimerez peut-être aussi

- C4 Turtle Diagram Process Design ProcessDocument1 pageC4 Turtle Diagram Process Design Processcao thanh quocPas encore d'évaluation

- Turtle For Process MapDocument0 pageTurtle For Process MapGhulam Mustafa100% (1)

- IATF 16949 2016 Mandatory ProcedureDocument1 pageIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- Summary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesDocument8 pagesSummary of New QMS Documents With References To ISO 9001 & IATF 16949 ClausesStephen Lim Kean Jin100% (2)

- TS ClausesDocument3 pagesTS Clausesgarvmonu100% (2)

- IATF 16949 2016 Gap ToolDocument353 pagesIATF 16949 2016 Gap ToolOziel Cardenas33% (6)

- List of Mandatory Documents Required by IATF 16949-2016Document3 pagesList of Mandatory Documents Required by IATF 16949-2016Oscar Solis MartirPas encore d'évaluation

- IQA IATF ChecksheetDocument37 pagesIQA IATF ChecksheetSumeet Rathee100% (5)

- Iatf ActivitiesDocument6 pagesIatf ActivitiesWizard tube and Engineered componentPas encore d'évaluation

- Appendix 25 VDA 6 3 Process AuditDocument12 pagesAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (1)

- T2 VSA With RequirementDocument8 pagesT2 VSA With RequirementSandeep K Malhotra100% (3)

- Copy of APQP Check List - Ford (Blank)Document9 pagesCopy of APQP Check List - Ford (Blank)feiraluremaPas encore d'évaluation

- IATF 16949 DocumenDocument1 pageIATF 16949 Documenpunitg_2Pas encore d'évaluation

- Advanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial StageDocument6 pagesAdvanced Product Quality Planning Timing Chart: Plan and Define Programme - PP Trial Stagerajesh sharma100% (2)

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- IATF 16949 List of Mandatory DocumentsDocument2 pagesIATF 16949 List of Mandatory DocumentsLuis Alejandro60% (5)

- With What (Infrastructure) With Who (Personnel) Risk Assessment ModelDocument3 pagesWith What (Infrastructure) With Who (Personnel) Risk Assessment Model80ALLA86i100% (2)

- Contract Review Turtle (WIP 9-14-05)Document1 pageContract Review Turtle (WIP 9-14-05)api-3852736100% (2)

- Clausul IATFDocument8 pagesClausul IATFAhmad ZainuddinPas encore d'évaluation

- IATF Implementation Plan and Co-Ordinator RolesDocument3 pagesIATF Implementation Plan and Co-Ordinator RolesKumaravel50% (2)

- Pecb Iatf 16949 Lead Auditor Exam Preparation GuideDocument14 pagesPecb Iatf 16949 Lead Auditor Exam Preparation GuideR.BALASUBRAMANI100% (1)

- Blank Turtle DiagramDocument1 pageBlank Turtle Diagrammrtelephone1100% (2)

- System Audit RequirementDocument37 pagesSystem Audit Requirementavinashbatra171% (7)

- Quality Manual: Subject: Procedure For PFMEADocument3 pagesQuality Manual: Subject: Procedure For PFMEAPk Nimiwal100% (3)

- IATF Additional Requirement LocationsDocument6 pagesIATF Additional Requirement LocationsSudhagar50% (2)

- 11.process Turtile DiagramDocument20 pages11.process Turtile DiagrammuthuselvanPas encore d'évaluation

- IATF 16949 QMS Requirements MatrixDocument1 pageIATF 16949 QMS Requirements MatrixJOECOOL67100% (5)

- Turtle Diagram PPAPDocument1 pageTurtle Diagram PPAPDL50% (2)

- APQP Supplier ProcedureDocument20 pagesAPQP Supplier ProcedurepharmatonPas encore d'évaluation

- HF-0467 - Product Audit Report - C - 2015-08-06Document44 pagesHF-0467 - Product Audit Report - C - 2015-08-06Enis SirbegovicPas encore d'évaluation

- QAF12 Process Audit Rev 09Document4 pagesQAF12 Process Audit Rev 09ukavathekarPas encore d'évaluation

- Iatf Process Audit Check Sheet FormatDocument14 pagesIatf Process Audit Check Sheet FormatPuspavathi S Rama NaiduPas encore d'évaluation

- Red Bin Analysis FormatDocument1 pageRed Bin Analysis FormatPRABHAT RANJAN100% (1)

- APQP Check ListDocument17 pagesAPQP Check ListmdjeckelPas encore d'évaluation

- Required Doc For IATFDocument3 pagesRequired Doc For IATFAbhayPas encore d'évaluation

- Required Documents For IATF - 16949Document5 pagesRequired Documents For IATF - 16949Rajesh Sahasrabuddhe0% (1)

- S ApqpDocument15 pagesS ApqpIram ChaviraPas encore d'évaluation

- Turtle DiagramDocument22 pagesTurtle DiagramVikas0% (1)

- ISO 9001 Process Audit Turtle DiagramDocument1 pageISO 9001 Process Audit Turtle DiagramJoel Alcantara100% (3)

- Supplier Audit Check Sheet For New & NON ISO SupplierDocument7 pagesSupplier Audit Check Sheet For New & NON ISO SupplierManoj Kaushik100% (1)

- TurtlesDocument15 pagesTurtlesshobhit2310100% (4)

- Iatf Gap Analysis ToolDocument100 pagesIatf Gap Analysis ToolKumaravel100% (3)

- Clause Map - IATF 16949:2016 To ISO/TS 16949:2009Document5 pagesClause Map - IATF 16949:2016 To ISO/TS 16949:2009Navnath TamhanePas encore d'évaluation

- APQP ProcedureDocument9 pagesAPQP ProcedurePk Nimiwal100% (4)

- Procedure For NPD HandoverDocument1 pageProcedure For NPD HandoverTushar Wagh100% (1)

- Turtle Diagram (Calibration)Document1 pageTurtle Diagram (Calibration)semaphore689% (9)

- Automotive Process Approach Audit For IATF 16949 - 2016Document4 pagesAutomotive Process Approach Audit For IATF 16949 - 2016isolongPas encore d'évaluation

- Manufacturing Audit ChecklistDocument8 pagesManufacturing Audit Checklistgksp100% (1)

- Iso Iatf Quality System Manual PDFDocument53 pagesIso Iatf Quality System Manual PDFKrishnamoorthyPas encore d'évaluation

- Product Audit Check SheetDocument3 pagesProduct Audit Check SheetLakshmanan Venkatesan100% (8)

- SMT Generic Control PlanDocument3 pagesSMT Generic Control PlanPedro Lopez Rodriguez100% (1)

- Apqp Status LogDocument1 pageApqp Status Logsathyabalaraman67% (3)

- Assessment Manual ExamDocument19 pagesAssessment Manual ExamSaurabhPas encore d'évaluation

- Layout Inspection Report XH5DR June 20 2012Document17 pagesLayout Inspection Report XH5DR June 20 2012nathiven100% (1)

- Audit Check List All Elements ISO TS 16949Document80 pagesAudit Check List All Elements ISO TS 16949irad_cota88% (16)

- Manufacturing Process Validation - NewDocument34 pagesManufacturing Process Validation - Newavrahamharris100% (1)

- Validation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyDocument26 pagesValidation: Presented To: Prof. H.S. Keerthy Department of Pharmaceutics Mallige College of PharmacyAfdal Naim100% (1)

- Cosmetic GMP Implementation Part 6Document23 pagesCosmetic GMP Implementation Part 6Anonymous yBhOAi5UH100% (1)

- Procedure For ProductionDocument7 pagesProcedure For ProductionSharif Khan100% (1)

- Batch Records HandoDocument39 pagesBatch Records HandoNiranjan SinghPas encore d'évaluation

- Experiments (Tutorial)Document24 pagesExperiments (Tutorial)BAlaPas encore d'évaluation

- HSE Hazard Identification SheetDocument1 pageHSE Hazard Identification SheetBAlaPas encore d'évaluation

- Excel Tool Process Audit Services VDA 6.3 2016 en V1.0Document12 pagesExcel Tool Process Audit Services VDA 6.3 2016 en V1.0Roberto Barbosa100% (1)

- External Issue RegisterDocument1 pageExternal Issue RegisterBAlaPas encore d'évaluation

- Scope CC 3390Document6 pagesScope CC 3390BAlaPas encore d'évaluation

- Standard Operating Procedure Index - Food Hygiene & SafetyDocument1 pageStandard Operating Procedure Index - Food Hygiene & SafetyBAlaPas encore d'évaluation

- Int Cal WRKDocument16 pagesInt Cal WRKBAlaPas encore d'évaluation

- Sample Collection Procedure (HM)Document1 pageSample Collection Procedure (HM)BAlaPas encore d'évaluation

- FSSCDocument2 pagesFSSCBAlaPas encore d'évaluation

- DocumentDocument90 pagesDocumentBAlaPas encore d'évaluation

- Mobile Devices Policy 2015 FinalDocument30 pagesMobile Devices Policy 2015 FinalBAlaPas encore d'évaluation

- 1436Document7 pages1436BAlaPas encore d'évaluation

- Z Score Altman Z Score TemplateDocument2 pagesZ Score Altman Z Score TemplateIbrahimKariadiPas encore d'évaluation

- 442Document54 pages442BAlaPas encore d'évaluation

- Stakeholder AnalysisDocument4 pagesStakeholder AnalysisBAlaPas encore d'évaluation

- MRM AgendaDocument2 pagesMRM AgendaBAlaPas encore d'évaluation

- FM ENV 015 Land Development and Buildings - Envtal MGTDocument29 pagesFM ENV 015 Land Development and Buildings - Envtal MGTBAlaPas encore d'évaluation

- Sample RecordsDocument2 pagesSample RecordsBAlaPas encore d'évaluation

- Supreme Court To Centre - Pet Coke, Furnace Oil Main Causes of Pollution in Delhi-NCR, Must Be Banned - Mail Today, News - India TodayDocument4 pagesSupreme Court To Centre - Pet Coke, Furnace Oil Main Causes of Pollution in Delhi-NCR, Must Be Banned - Mail Today, News - India TodayBAlaPas encore d'évaluation

- Stress Management PolicyDocument12 pagesStress Management PolicyBAla100% (1)

- Layer Process AuditDocument8 pagesLayer Process AuditBAlaPas encore d'évaluation

- 5095Document2 pages5095BAlaPas encore d'évaluation

- 2417Document5 pages2417BAlaPas encore d'évaluation

- Issue RegisterDocument2 pagesIssue RegisterBAla100% (1)

- Axter General Solar PV Inspection and Routine Maintenance GuideDocument4 pagesAxter General Solar PV Inspection and Routine Maintenance GuideBAlaPas encore d'évaluation

- 2b. Publicly Available SMETA CAPR Template 10112015Document11 pages2b. Publicly Available SMETA CAPR Template 10112015BAlaPas encore d'évaluation

- OM-UK-0511 SolarDocument6 pagesOM-UK-0511 SolarCarlos BenavidesPas encore d'évaluation

- C 012760Document14 pagesC 012760BAlaPas encore d'évaluation

- 5095Document2 pages5095BAlaPas encore d'évaluation

- Wheel Alignment SpecificationsDocument15 pagesWheel Alignment SpecificationsBAla0% (1)

- Project Management - Chapter 2Document27 pagesProject Management - Chapter 2Sara Younes100% (1)

- Group 1 BSA 2Y1-2: Operations ManagementDocument45 pagesGroup 1 BSA 2Y1-2: Operations ManagementAi Eleanor ScarlettPas encore d'évaluation

- FAHM 2018 Programme v4Document16 pagesFAHM 2018 Programme v4Aviation Events InternationalPas encore d'évaluation

- Course Title:: AnnexureDocument6 pagesCourse Title:: AnnexureGeetika RajputPas encore d'évaluation

- E-Logistics and E-Supply Chain Management: Applications For Evolving BusinessDocument21 pagesE-Logistics and E-Supply Chain Management: Applications For Evolving BusinessRUCHI RATANPas encore d'évaluation

- Project Deliverables in Website DesignDocument12 pagesProject Deliverables in Website Designarevazhagun FueldigiPas encore d'évaluation

- Lesson 2.5 - Self-InspectionDocument3 pagesLesson 2.5 - Self-InspectionMark Harold GonzalesPas encore d'évaluation

- Business Analyst Preview PDFDocument20 pagesBusiness Analyst Preview PDFRuchi MarwahPas encore d'évaluation

- Chapter 9 MH Systems DesignDocument19 pagesChapter 9 MH Systems DesignKhánh Đoan Lê ĐìnhPas encore d'évaluation

- Human Resource Management in Standard Chartered BankDocument23 pagesHuman Resource Management in Standard Chartered BankFahad Bhuiyan100% (3)

- Daimler AG's Code of Ethics: English DeutschDocument16 pagesDaimler AG's Code of Ethics: English DeutschHenry KarlPas encore d'évaluation

- BSBRSK301Document35 pagesBSBRSK301Vineet Kumar100% (1)

- Curriculum Master ASTP: Classroom/ Private Workload (H) ECTS 12Document1 pageCurriculum Master ASTP: Classroom/ Private Workload (H) ECTS 12aafreen sayyadPas encore d'évaluation

- U.S. State Department Telephone DirectoryDocument52 pagesU.S. State Department Telephone DirectoryLeakSourceInfoPas encore d'évaluation

- Scope and Importance of Personal SellingDocument9 pagesScope and Importance of Personal SellingArun Kumar SatapathyPas encore d'évaluation

- Integrated Planning Process With Local Special Bodies and Advisory CouncilsDocument3 pagesIntegrated Planning Process With Local Special Bodies and Advisory CouncilsDann Marr100% (1)

- Dynamics 365 Training and Certification Guide NetCom LearningDocument25 pagesDynamics 365 Training and Certification Guide NetCom LearningHamza AlouiPas encore d'évaluation

- Chapter 6 - Inventory Control ModelsDocument40 pagesChapter 6 - Inventory Control ModelsAbo FawazPas encore d'évaluation

- Security Management Standard - Physical Asset Protection ANSI - ASIS PAP AMERICAN NATIONAL STANDARD - 1 - 部分2Document20 pagesSecurity Management Standard - Physical Asset Protection ANSI - ASIS PAP AMERICAN NATIONAL STANDARD - 1 - 部分2安靖Pas encore d'évaluation

- PfizerDocument3 pagesPfizerGracia Catalina Pinero100% (1)

- Competence Matrix.Document1 pageCompetence Matrix.JOAI BITANAPas encore d'évaluation

- PAWIM-F-004 Risk Registry Template R10 V2Document3 pagesPAWIM-F-004 Risk Registry Template R10 V2Joynilenge LavadorPas encore d'évaluation

- Logistics and Supply Chain Management 0Document5 pagesLogistics and Supply Chain Management 0srinivasPas encore d'évaluation

- Penjelasan Penggunaan Monsson SIMDocument43 pagesPenjelasan Penggunaan Monsson SIMAde Rizki FauziPas encore d'évaluation

- Chapter 5 QuizDocument8 pagesChapter 5 Quizjoyce nacutePas encore d'évaluation

- Chapter 10 - MGT From Islamic PerspectivesDocument21 pagesChapter 10 - MGT From Islamic PerspectivesAngelinePas encore d'évaluation

- EPR001-Energy Review and Assessment For Significant Energy UseDocument3 pagesEPR001-Energy Review and Assessment For Significant Energy UseArvind YadavPas encore d'évaluation

- ImcDocument20 pagesImcJay KoliPas encore d'évaluation

- Format of Integration PaperDocument31 pagesFormat of Integration PaperGwen BrossardPas encore d'évaluation

- Pranjita Kalita Mayuri Mandot Yogesh Poswal Nishang Sukhadia PrabhatDocument17 pagesPranjita Kalita Mayuri Mandot Yogesh Poswal Nishang Sukhadia Prabhatyogesh7703Pas encore d'évaluation