Académique Documents

Professionnel Documents

Culture Documents

Strength Calculation

Transféré par

Anonymous B1AOOsmRMiCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Strength Calculation

Transféré par

Anonymous B1AOOsmRMiDroits d'auteur :

Formats disponibles

2/88

- CONTENTS No. DESCRIPTION

PAGE

1. DESIGN DATA --------------------------------------------------------------- 3

2. SETTING SUMMARY ------------------------------------------------------------- 4 ~ 5

3. PRESSURE SUMMARY ------------------------------------------------------------ 6 ~ 7

4. HYDROSTATIC TEST PRESSURE --------------------------------------------------- 8 ~ 9

5. THICKNESS SUMMARY ----------------------------------------------------------- 10

6. NOZZLE SCHEDULE ------------------------------------------------------------- 11

7. NOZZLE SUMMARY -------------------------------------------------------------- 12

8. SHELL & HEAD ---------------------------------------------------------------- 13 ~ 23

9. NOZZLE NECK & REINFORCEMENT PAD & WRC107 ------------------------------------ 24 ~ 55

10. WEIGHT SUMMARY -------------------------------------------------------------- 56

11. SUPPORT SADDLE UNDER EXTERNAL LOAD (INCLUDED SEISMIC LOAD)------------------- 57 ~ 61

12. LIFTING LUG ----------------------------------------------------------------- 62 ~ 67

13. NOZZLE LOADS ---------------------------------------------------------------- 68 ~ 85

14. MANHOLE DAVIT --------------------------------------------------------------- 86 ~ 88

3/88

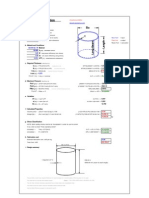

STRENGTH CALCULATION SHEET

FOR PRESSURE VESSEL

D E S I G N

D A T A

CODE

ASME SEC. VIII DIV.1 2007 ED. + 2009 ADD.

ITEM NO.

1041-D-042

ITEM NAME

GASOLIN 91/95/98 CLOSED DRAIN DRUM

CODE STAMP

YES (ASME U)

SIZE(mmxmm) 1300 I.D x 4000 TL TO TL

TYPE

H-SADDLE

SHELL SIDE

UNIT

GASOLINE

CAPACITY

5.5

M3

SPECIFIC GRAVITY

0.74

FLUID

INT.

3.5 (0.343)

KG/CM .G(Mpa)

EXT.

H.V

KG/CM2.G(Mpa)

0 (0)

KG/CM2.G(Mpa)

KG/CM2.G(Mpa)

SHOP

25.42 (2.493)

KG/CM2.G(Mpa)

FIELD

17.52 (1.718)

KG/CM2.G(Mpa)

87 / 87

45

13.48 (1.322)

KG/CM2.G(Mpa)

AT HAED

19.55 (1.917)

KG/CM2.G(Mpa)

AT HAED

M.D.M.T

P.W.H.T

NO

DESIGN

PRESSURE

OPERATING

PNEUM. TEST

HYDRO. TEST

TEMPERATURE

DESIGN (INT./EXT.)

OPERATING

M.A.W.P

HOT & CORRODED

M.A.P

NEW & COLD

M.A.E.P

2.64(0.259)

KG/CM .G(Mpa)

MM

RADIOGRAPHY (SHELL/HEAD)

SOPT / FULL

JOINT EFFICIENCY (SHELL/HEAD)

0.85 / 1.0

YES (BOOT HEAD ONLY)

INSULATION

NO

MM

FIRE PROOFING

NO

MM

WIND DESIGN

N/A

IBC 2009, (I=1.25, R=3, Sds:0.284, Sd1:0.075

2 :1 ELLIP

1150

TEST

FULL WATER

MM

SHELL

SA516-65N

HEAD

SA516-65N

CORROSION ALLOWANCE

STRESS RELIEF (HEAD)

SEISMIC DESIGN

TYPE OF HEAD

OPERATING

LIQUID LEVEL

MATERIAL

4/88

Settings Summary

COMPRESS Build 7010

Units: MKS

Datum Line Location: -38.00 mm from right seam

Design

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Design or Rating:

Get Thickness from Pressure

Minimum thickness:

6.0 mm + C.A

Design for cold shut down only:

No

Design for lethal service (full radiography required):

No

Design nozzles for:

Larger of MAWP or MAP

Corrosion weight loss:

100% of theoretical loss

UG-23 Stress Increase:

1.00

Skirt/legs stress increase:

1.0

Minimum nozzle projection:

192 mm

Yes

Juncture calculations for > 30 only:

Preheat P-No 1 Materials > 1.25" and <= 1.50" thick:

No

UG-37(a) shell tr calculation considers longitudinal stress: No

Butt welds are tapered per Figure UCS-66.3(a).

Hydro/Pneumatic Test

Shop Hydrotest at user defined pressure

Test liquid specific gravity: 1.00

Field Hydrotest Pressure:

1.3 times vessel MAWP

Wind load present @ field: 75% of design

Maximum stress during test: 90% of yield

Required Marking - UG-116

UG-116 (e) Radiography:

RT4

UG-116 (f) Postweld heat treatment: None

Code Cases\Interpretations

Use Code Case 2547:

No

Apply interpretation VIII-1-83-66: Yes

Apply interpretation VIII-1-86-175: Yes

Apply interpretation VIII-1-83-115: Yes

Apply interpretation VIII-1-01-37: Yes

No UCS-66.1 MDMT reduction:

No

No UCS-68(c) MDMT reduction: No

Disallow UG-20(f) exemptions:

No

UG-22 Loadings

UG-22 (a) Internal or External Design Pressure :

UG-22 (b) Weight of the vessel and normal contents under operating or test conditions:

UG-22 (c) Superimposed static reactions from weight of attached equipment (external loads):

UG-22 (d)(2) Vessel supports such as lugs, rings, skirts, saddles and legs:

UG-22 (f) Wind reactions:

UG-22 (f) Seismic reactions:

UG-22 (j) Test pressure and coincident static head acting during the test:

Note: UG-22 (b),(c) and (f) loads only considered when supports are present.

Yes

Yes

Yes

Yes

No

Yes

Yes

5/88

TABLE OF LOADING CASES AND LODE COMBINNATIONS

NOTES: 1.

6/88

Pressure Summary

Pressure Summary for Chamber bounded by RIGHT HEAD and LEFT HEAD

Identifier

P

T

Te

MAP

MAEP external

MDMT

Design Design (MAWP

2

2

2

kg/cm

)

(

kg/cm

)

(

kg/cm

)

( C)

2

( kg/cm ) ( C)

( C)

MDMT

Exemption

Impact

Tested

LEFT HEAD

3.5

87

13.48

19.55

4.22

87

-48

Note 1

No

Straight Flange on LEFT HEAD

3.5

87

19.72

25.8

2.64

87

-48

Note 2

No

SHELL

3.5

87

16.75

21.93

2.64

87

-48

Note 3

No

Straight Flange on RIGHT HEAD

3.5

87

19.72

25.8

2.64

87

-48

Note 2

No

RIGHT HEAD

3.5

87

13.48

19.55

4.22

87

-48

Note 1

No

BOOT SHELL

3.5

87

42.65

55.95

23.27

87

-105

Note 19

No

Straight Flange on BOOT HEAD

3.5

87

50.21

65.82

23.27

87

-105

Note 20

No

BOOT HEAD

3.5

87

41.86

57.44

19.19

87

-105

Note 11

No

SADDLE

3.5

87

13.48

N/A

N/A

N/A

N/A

N/A

N/A

INLET (A)

3.5

87

13.48

19.55

2.64

87

-48

Nozzle Note 4

No

Pad Note 5

No

OUTLET TO ATM (B2)

3.5

87

13.48

19.55

2.64

87

-48

Nozzle Note 6

No

Pad Note 7

No

PUMP OUT CONNECTION (B3)

3.5

87

13.48

19.55

2.64

87

-49

Note 8

No

Nozzle Note 9

No

Pad Note

10

No

BOOT SHELL (BOOT)

3.5

87

13.48

19.55

2.64

87

-48

DRAIN (D)

3.5

87

13.48

19.55

19.19

87

-49

Note 12

No

LEVEL TRANSMITTER (L1)

3.5

87

13.48

19.55

2.64

87

-48

Nozzle Note

13

No

Pad Note 7

LEVEL TRANSMITTER (L2)

3.5

87

13.48

19.55

2.64

87

-48

Nozzle Note

13

Pad Note 7

MANWAY (M1)

3.5

87

13.48

19.55

2.64

87

-47.83

No

No

No

Nozzle Note

14

No

Pad Note

15

No

Nozzle Note

16

No

PUMP CONNECTION NOZZLE

(M2)

3.5

NITROGEN CONNECTION (N1)

3.5

87

13.48

19.55

2.64

87

-49

Note 8

No

PRESSURE TRANSMITTER (P)

3.5

87

13.48

19.55

2.64

87

-49

Note 8

No

STEAM OUT (S)

3.5

87

13.48

19.55

2.64

87

-49

Note 17

No

TEMPERATURE

TRANSMITTER (T)

3.5

87

13.48

19.55

2.64

87

-49

Note 8

No

UTILITY CONNECTION (UC)

3.5

87

13.48

19.55

2.64

87

-48

Nozzle Note

18

No

87

13.48

19.55

2.64

87

-48

Pad Note 7

Pad Note 7

VESSEL VENT (V)

3.5

87

13.48

Chamber design MDMT is 7 C

Chamber rated MDMT is -47.83 C @ 13.48 kg/cm2

Chamber MAWP hot & corroded is 13.48 kg/cm2 @ 87 C

Chamber MAP cold & new is 19.55 kg/cm2 @ 21 C

Chamber MAEP is 2.64 kg/cm2 @ 87 C

Vacuum rings did not govern the external pressure rating.

19.55

2.64

87

-49

Note 8

No

No

No

7/88

Notes for MDMT Rating:

Note #

Exemption

Details

1.

Material impact test exemption temperature from Fig UCS-66M Curve D = -48 C

UCS-66 governing thickness = 9.75 mm

2.

Material impact test exemption temperature from Fig UCS-66M Curve D = -47.63 C

Fig UCS-66.1M MDMT reduction = 17.8 C, (coincident ratio = 0.68269)

Rated MDMT is governed by UCS-66(b)(2)

UCS-66 governing thickness = 13 mm

3.

Material impact test exemption temperature from Fig UCS-66M Curve D = -47.63 C

Fig UCS-66.1M MDMT reduction = 17.7 C, (coincident ratio = 0.6834465)

Rated MDMT is governed by UCS-66(b)(2)

UCS-66 governing thickness = 13 mm

4.

Nozzle is impact tested to -48 C (UCS-66(g))

UCS-66 governing thickness = 11.11

mm.

5.

Pad impact test exemption temperature from Fig UCS-66M Curve D = -48 C

Fig UCS-66.1M MDMT reduction = 0.3 C, (coincident ratio = 0.99425)

Rated MDMT is governed by UCS-66(b)(2)

UCS-66 governing thickness = 11.11

mm.

6.

Nozzle is impact tested to -48 C (UCS-66(g))

UCS-66 governing thickness = 13 mm.

7.

Pad impact test exemption temperature from Fig UCS-66M Curve D = -47.63 C

Fig UCS-66.1M MDMT reduction = 18 C, (coincident ratio = 0.67837)

Rated MDMT is governed by UCS-66(b)(2)

UCS-66 governing thickness = 13 mm.

8.

Nozzle is impact tested to -49 C (UCS-66(g))

UCS-66 governing thickness = 13 mm.

9.

Nozzle is impact test exempt to -105 C per UCS-66(b)(3) (coincident ratio = 0.26452).

10.

Pad impact test exemption temperature from Fig UCS-66M Curve D = -47.63 C

Fig UCS-66.1M MDMT reduction = 17.8 C, (coincident ratio = 0.68273)

Rated MDMT is governed by UCS-66(b)(2)

11.

Material is impact test exempt to -105 C per UCS-66(b)(3) (coincident ratio =

0.32442)

12.

Flange rating governs: Flange impact tested to -49C (UCS-66(g))

13.

Nozzle is impact test exempt to -105 C per UCS-66(b)(3) (coincident ratio = 0.08208).

14.

Nozzle impact test exemption temperature from Fig UCS-66M Curve D = -47.63 C

Fig UCS-66.1M MDMT reduction = 0.2 C, (coincident ratio = 0.99643)

UCS-66 governing thickness = 13 mm.

15.

Pad impact test exemption temperature from Fig UCS-66M Curve D = -47.63 C

Fig UCS-66.1M MDMT reduction = 0.2 C, (coincident ratio = 0.99643)

UCS-66 governing thickness = 13 mm.

16.

Nozzle is impact test exempt to -105 C per UCS-66(b)(3) (coincident ratio = 0.2271).

17.

Nozzle is impact tested to -49 C (UCS-66(g))

18.

Nozzle is impact test exempt to -105 C per UCS-66(b)(3) (coincident ratio = 0.2314).

19.

Nozzle is impact test exempt to -105 C per UCS-66(b)(3) (coincident ratio = 0.26681).

20.

Nozzle is impact test exempt to -105 C per UCS-66(b)(3) (coincident ratio = 0.26657).

Design notes are available on the Settings Summary page.

UCS-66 governing thickness = 13 mm.

UG-84 provisions apply

UCS-66 governing thickness = 9.75 mm.

8/88

Hydrostatic Test

Shop test pressure determination for Chamber bounded by RIGHT HEAD and LEFT HEAD based on user defined pressure

Shop test gauge pressure is 25.42 kgf/cm2 at 21 C

The shop test is performed with the vessel in the horizontal position.

Local test Test liquid

Stress

Allowable

Stress

Identifier

pressure static head during test test stress excessive?

2

2

2

2

kgf/cm

kgf/cm

kgf/cm

kgf/cm

LEFT HEAD

25.61

0.19

1,536.589

2,211.763

No

Straight Flange on LEFT HEAD

25.61

0.19

1,293.253

2,211.763

No

SHELL

25.61

0.19

1,293.253

2,211.763

No

Straight Flange on RIGHT HEAD

25.61

0.19

1,293.253

2,211.763

No

RIGHT HEAD

25.61

0.19

1,536.589

2,211.763

No

BOOT SHELL

25.63

0.31

507.424

2,211.763

No

Straight Flange on BOOT HEAD

25.75

0.33

507.897

2,211.763

No

BOOT HEAD

25.76

0.34

524.513

2,211.763

No

BOOT SHELL (BOOT)

25.74

0.33

2,091.871

3,303.878

No

DRAIN (D)

25.78

0.36

535.158

3,303.878

No

INLET (A)

25.51

0.1

1,094.875

3,303.878

No

LEVEL TRANSMITTER (L1)

25.48

0.06

704.465

3,303.878

No

LEVEL TRANSMITTER (L2)

25.48

0.06

704.465

3,303.878

No

MANWAY (M1)

25.57

0.16

2,302.517

3,303.878

No

NITROGEN CONNECTION (N1)

25.48

0.06

1,385.442

3,303.878

No

OUTLET TO ATM (B2)

25.48

0.06

883.144

3,303.878

No

PRESSURE TRANSMITTER (P)

25.48

0.06

1,273.931

3,303.878

No

PUMP CONNECTION NOZZLE (M2) 25.48

0.06

1,625.341

3,303.878

No

PUMP OUT CONNECTION (B3)

25.48

0.06

1,273.931

3,303.878

No

STEAM OUT (S)

25.61

0.19

1,712.213

3,303.878

No

TEMPERATURE TRANSMITTER (T) 25.48

0.06

1,273.931

3,303.878

No

UTILITY CONNECTION (UC)

25.48

0.06

1,009.842

3,303.878

No

VESSEL VENT (V)

25.48

0.06

1,385.442

3,303.878

No

Notes:

(1) PL stresses at nozzle openings have been estimated using the method described in PVP-Vol. 399, pages 77-82.

(2) 1.5*0.9*Sy used as the basis for the maximum local primary membrane stress at the nozzle intersection PL.

(3) The zero degree angular position is assumed to be up, and the test liquid height is assumed to the top-most flange.

The test temperature of 21 C is warmer than the minimum recommended temperature of -30.83 C so the brittle fracture provision of UG99(h) has been met.

9/88

Corroded Hydrostatic Test

The shop test condition has not been investigated for the Chamber bounded by RIGHT HEAD and LEFT HEAD.

Field test pressure determination for Chamber bounded by RIGHT HEAD and LEFT HEAD based on MAWP per UG-99(b)

Field hydrostatic test gauge pressure is 17.52 kgf/cm2 at 21 C (the chamber MAWP = 13.48 kgf/cm2)

The field test is performed with the vessel in the horizontal position.

Local test Test liquid UG-99 UG-99

Stress

Allowable

Stress

Identifier

pressure static head stress pressure during test test stress excessive?

2

2

2

2

kgf/cm

kgf/cm

ratio

factor

kgf/cm

kgf/cm

LEFT HEAD (1)

17.71

0.2

1.30

1,542.216

2,211.763

No

Straight Flange on LEFT HEAD

17.71

0.2

1.30

1,165.511

2,211.763

No

SHELL

17.71

0.2

1.30

1,165.511

2,211.763

No

Straight Flange on RIGHT HEAD

17.71

0.2

1.30

1,165.511

2,211.763

No

RIGHT HEAD

17.71

0.2

1.30

1,542.216

2,211.763

No

BOOT SHELL

17.73

0.31

1.30

459.855

2,211.763

No

Straight Flange on BOOT HEAD

17.85

0.33

1.30

460.474

2,211.763

No

BOOT HEAD

17.86

0.34

1.30

505.26

2,211.763

No

BOOT SHELL (BOOT)

17.85

0.33

1.30

1,845.631

3,303.878

No

DRAIN (D)

17.88

0.36

1.30

533.717

3,303.878

No

INLET (A)

17.62

0.1

1.30

748.192

3,303.878

No

LEVEL TRANSMITTER (L1)

17.58

0.06

1.30

503.61

3,303.878

No

LEVEL TRANSMITTER (L2)

17.58

0.06

1.30

503.61

3,303.878

No

MANWAY (M1)

17.68

0.16

1.30

2,086.204

3,303.878

No

NITROGEN CONNECTION (N1)

17.58

0.06

1.30

1,269.584

3,303.878

No

OUTLET TO ATM (B2)

17.58

0.06

1.30

708.054

3,303.878

No

PRESSURE TRANSMITTER (P)

17.58

0.06

1.30

1,148.091

3,303.878

No

PUMP CONNECTION NOZZLE (M2) 17.58

0.06

1.30

1,632.783

3,303.878

No

PUMP OUT CONNECTION (B3)

17.58

0.06

1.30

1,148.091

3,303.878

No

STEAM OUT (S)

17.71

0.19

1.30

1,840.56

3,303.878

No

TEMPERATURE TRANSMITTER (T) 17.58

0.06

1.30

1,148.091

3,303.878

No

UTILITY CONNECTION (UC)

17.58

0.06

1.30

717.463

3,303.878

No

VESSEL VENT (V)

17.58

0.06

1.30

1,269.584

3,303.878

No

Notes:

(1) LEFT HEAD limits the UG-99 stress ratio.

(2) PL stresses at nozzle openings have been estimated using the method described in PVP-Vol. 399, pages 77-82.

(3) 1.5*0.9*Sy used as the basis for the maximum local primary membrane stress at the nozzle intersection PL.

(4) The zero degree angular position is assumed to be up, and the test liquid height is assumed to the top-most flange.

The test temperature of 21 C is warmer than the minimum recommended temperature of -30.83 C so the brittle fracture provision of UG99(h) has been met.

10/88

Component

Identifier

Material

Thickness Summary

Diameter Length Nominal t Design t Total Corrosion Joint

(mm)

(mm)

(mm)

(mm)

(mm)

E

Load

LEFT HEAD

SA-516 65 1,300 ID

334.75

9.75*

5.33

1.00

External

Straight Flange on LEFT HEAD

SA-516 65 1,300 ID

38

13

8.14

1.00

External

SHELL

SA-516 65 1,300 ID

3,924

13

8.14

0.85

External

Straight Flange on RIGHT HEAD SA-516 65 1,300 ID

38

13

8.14

1.00

External

RIGHT HEAD

SA-516 65 1,300 ID

334.75

9.75*

5.33

1.00

External

BOOT SHELL

SA-516 65 500 ID

1,321

13

4.89

0.85

External

BOOT HEAD

SA-516 65 500 ID

136.05

11.05*

3.9

1.00

External

Straight Flange on BOOT HEAD

SA-516 65 500 ID

38

13

4.89

1.00

External

Nominal t:

Design t:

Joint E:

*

Vessel wall nominal thickness

Required vessel thickness due to governing loading + corrosion

Longitudinal seam joint efficiency

Head minimum thickness after forming

Load

internal:

external:

Wind:

Seismic:

Circumferential stress due to internal pressure governs

External pressure governs

Combined longitudinal stress of pressure + weight + wind governs

Combined longitudinal stress of pressure + weight + seismic governs

11/88

Nozzle Schedule

Materials

Nozzle

mark

Service

Size

Nozzle

Impact Norm

Fine

Grain

Pad

Impact Norm

Fine

Grain

Flange

A(DN200)

INLET

8" Sch 80

(XS) DN

200

SA-333 6

Wld &

smls pipe

No

No

No

SA516

65

No

Yes

Yes

WN A350

LF2 Cl.1

Class 150

B1(DN50)

(BY

OTHERS)

PUMP OUTLET

2" Sch 160

DN 50

SA-333 6

Wld &

smls pipe

No

No

No

SA516

65

No

Yes

Yes

WN A350

LF2 Cl.1

Class 300

B2(DN 250)

OUTLET TO ATM

10" Sch 80

DN 250

SA-333 6

Wld &

smls pipe

No

No

No

SA516

65

No

Yes

Yes

WN A350

LF2 Cl.1

Class 150

B3(DN50)

PUMP OUT

CONNECTION

42.90

IDx17.55

SA-350

LF2 Cl 1

No

Yes

Yes

N/A

N/A

N/A

N/A

LWN A350

LF2 Cl.1

Class 150

BOOT

BOOT SHELL

500.00

IDx13.00

SA-516 65 No

Yes

Yes

SA516

65

No

Yes

Yes

N/A

D(DN50)

DRAIN

50.80

IDx13.60

SA-350

LF2 Cl 1

No

Yes

Yes

N/A

N/A

N/A

N/A

LWN A350

LF2 Cl.1

Class 150

L1(DN100)

LEVEL

TRANSMITTER

4" Sch 120

DN 100

SA-333 6

Wld &

smls pipe

No

No

No

SA516

65

No

Yes

Yes

WN A350

LF2 Cl.1

Class 300

L2(DN100)

LEVEL

TRANSMITTER

4" Sch 120

DN 100

SA-333 6

Wld &

smls pipe

No

No

No

SA516

65

No

Yes

Yes

WN A350

LF2 Cl.1

Class 300

M1(DN600)

MANWAY

583.60

IDx13.00

SA-516 65 No

Yes

Yes

SA516

65

No

Yes

Yes

WN A350

LF2 Cl.1

Class 150

M2(DN450)

PUMP

CONNECTION

NOZZLE

431.20

IDx13.00

SA-516 65 No

Yes

Yes

SA516

65

No

Yes

Yes

WN A350

LF2 Cl.1

Class 150

N1(DN50)

NITROGEN

CONNECTION

50.80

IDx13.60

SA-350

LF2 Cl 1

No

Yes

Yes

N/A

N/A

N/A

N/A

LWN A350

LF2 Cl.1

Class 150

P(DN50)

PRESSURE

TRANSMITTER

50.80

IDx16.65

SA-350

LF2 Cl 1

No

Yes

Yes

N/A

N/A

N/A

N/A

LWN A350

LF2 Cl.1

Class 300

S(DN50)

STEAM OUT

42.90

IDx17.55

SA-350

LF2 Cl 1

No

Yes

Yes

N/A

N/A

N/A

N/A

LWN A350

LF2 Cl.1

Class 150

T(DN50)

TEMPERATURE

TRANSMITTER

42.90

IDx20.60

SA-350

LF2 Cl 1

No

Yes

Yes

N/A

N/A

N/A

N/A

LWN A350

LF2 Cl.1

Class 300

UC(DN150)

UTILITY

CONNECTION

6" Sch 80

(XS) DN

150

SA-333 6

Wld &

smls pipe

No

No

No

SA516

65

No

Yes

Yes

WN A350

LF2 Cl.1

Class 150

V(DN50)

VESSEL VENT

50.80

IDx13.60

SA-350

LF2 Cl 1

No

Yes

Yes

N/A

N/A

N/A

N/A

LWN A350

LF2 Cl.1

Class 150

12/88

Nozzle Summary

Nozzle

mark

A(DN200)

tn:

Req tn:

Nom t:

Design t:

User t:

Aa:

Ar:

Corr:

*

OD

(mm)

Reinforcement

Shell

Pad

tn

Req tn A ? A ?

Corr

1

2

(mm) (mm)

Nom t Design t User t Width

tpad (mm)

(mm)

(mm)

(mm) (mm) (mm)

219.08 12.7

Yes Yes 9.75*

9.75

82.21

13

136.9

B2(DN 250) 273.05 15.09 11.18

Yes Yes 13

9.82

118.48

13

182.2

B3(DN50)

78

17.55 7.8

Yes Yes 13

N/A

N/A

N/A

Exempt

BOOT

526

13

9.83

Yes Yes 13

9.82

222

13

165.7

D(DN50)

78

13.6

6.66

Yes Yes 11.05* N/A

N/A

N/A

Exempt

L1(DN100)

114.3

11.13 9.45

Yes Yes 13

9.82

47.85

13

275.2

L2(DN100)

114.3

11.13 9.45

Yes Yes 13

9.82

47.85

13

275.2

M1(DN600) 609.6

13

9.73

Yes Yes 9.75*

9.75

220.2

13

111.2

M2(DN450) 457.2

13

9.78

Yes Yes 13

9.82

206.4

13

173.5

N1(DN50)

78

13.6

7.8

Yes Yes 13

N/A

N/A

N/A

Exempt

P(DN50)

84.1

16.65 7.8

Yes Yes 13

9.78

N/A

N/A

242.0

S(DN50)

78

17.55 7.8

Yes Yes 9.75*

N/A

N/A

N/A

Exempt

T(DN50)

84.1

20.6

Yes Yes 13

N/A

N/A

N/A

Exempt

UC(DN150) 168.28 10.97 10.54

Yes Yes 13

9.82

65.86

13

188.2

V(DN50)

Yes Yes 13

N/A

N/A

N/A

Exempt

78

13.6

11.1

Aa/Ar

(%)

7.8

7.8

Nozzle thickness

Nozzle thickness required per UG-45/UG-16

Vessel wall thickness

Required vessel wall thickness due to pressure + corrosion allowance per UG-37

Local vessel wall thickness (near opening)

Area available per UG-37, governing condition

Area required per UG-37, governing condition

Corrosion allowance on nozzle wall

Head minimum thickness after forming

13/88

LEFT HEAD

ASME Section VIII, Division 1, 2007 Edition, A09 Addenda Metric

Component:

Ellipsoidal Head

Material Specification:

SA-516 65 (II-D Metric p.14, ln. 35)

Material impact test exemption temperature from Fig UCS-66M Curve D = -48 C

UCS-66 governing thickness = 9.75 mm

Internal design pressure: P = 3.5 kgf/cm2 @ 87 C

External design pressure: Pe = 0.5 kgf/cm2 @ 87 C

Static liquid head:

Ps= 0.0853 kgf/cm2 (SG=0.74, Hs=1153 mm Operating head)

Pth= 0.1948 kgf/cm2 (SG=1, Hs=1950 mm Horizontal test head)

Corrosion allowance:

Inner C = 3 mm

Outer C = 0 mm

Design MDMT = 7C

No impact test performed

Rated MDMT = -48C

Material is normalized

Material is produced to fine grain practice

PWHT is not performed

Do not Optimize MDMT / Find MAWP

Radiography:

Category A joints Head to shell seam -

Full UW-11(a) Type 1

Spot UW-11(a)(5)(b) Type 1

corr = 102.3 kg

new = 145.2 kg

Estimated weight*:

Capacity*:

new = 338 liters

corr = 343.8 liters

* includes straight flange

Inner diameter

= 1300 mm

Minimum head thickness

= 9.75 mm

Head ratio D/2h

= 2 (new)

Head ratio D/2h

= 1.9909 (corroded)

Straight flange length Lsf

= 38 mm

Nominal straight flange thickness tsf = 13 mm

Results Summary

The governing condition is external pressure.

Minimum thickness per UG-16

= 1.5 mm + 3 mm = 4.5 mm

Design thickness due to internal pressure (t)

= 4.79 mm

Design thickness due to external pressure (te)

= 5.33 mm

Maximum allowable working pressure (MAWP) = 13.48 kgf/cm2

Maximum allowable pressure (MAP)

= 19.55 kgf/cm2

Maximum allowable external pressure (MAEP)

= 4.22 kgf/cm2

K

(Corroded)=

(1/6)*[2 + (D / (2*h))2]

K

=

(1/6)*[2 + (1,306 / (2*328))2]

=

0.993917

K

(New) =

(1/6)*[2 + (D / (2*h))2]

K

=

(1/6)*[2 + (1,300 / (2*325))2]

=

1

Design thickness for internal pressure, (Corroded at 87 C) Appendix 1-4(c)

t

=

P*D*K / (2*S*E - 0.2*P) + Corrosion

=

3.59*1,306*0.993917 / (2*1,305.236*1 - 0.2*3.59) + 3

=

4.78 mm

The head internal pressure design thickness is 4.79 mm.

Maximum allowable working pressure, (Corroded at 87 C) Appendix 1-4(c)

P

=

2*S*E*t / (K*D + 0.2*t) - Ps

=

2*1,305.236*1*6.75 / (0.993917*1,306 +0.2*6.75) - 0.09

=

13.48 kgf/cm2

The maximum allowable working pressure (MAWP) is 13.48 kgf/cm2.

Maximum allowable pressure, (New at 21 C) Appendix 1-4(c)

P

=

2*S*E*t / (K*D + 0.2*t) - Ps

=

2*1,305.236*1*9.75 / (1*1,300 +0.2*9.75) - 0

=

19.55 kgf/cm2

The maximum allowable pressure (MAP) is 19.55 kgf/cm2.

Design thickness for external pressure, (Corroded at 87 C) UG-33(d)

Equivalent outside spherical radius (Ro)

Ro

=

Ko*Do

=

0.8869*1,319.5

=

1,170.26 mm

A

=

=

=

0.125 / (Ro / t)

0.125 / (1,170.26 / 2.33)

0.000249

14/88

From Table CS-2 Metric:B=251.1281 kgf/cm2

Pa

=

=

=

B / (Ro / t)

251.1281 / (1,170.26 / 2.33)

0.5 kgf/cm2

t

=

2.33 mm + Corrosion = 2.33 mm + 3 mm = 5.33 mm

Check the external pressure per UG-33(a)(1) Appendix 1-4(c)

t

=

1.67*Pe*D*K / (2*S*E - 0.2*1.67*Pe) + Corrosion

=

1.67*0.5*1,306*0.993917 / (2*1,305.236*1 - 0.2*1.67*0.5) + 3

=

3.42 mm

The head external pressure design thickness (te) is 5.33 mm.

Maximum Allowable External Pressure, (Corroded at 87 C) UG-33(d)

Equivalent outside spherical radius (Ro)

Ro

=

Ko*Do

=

0.8869*1,319.5

=

1,170.26 mm

A

=

=

=

0.125 / (Ro / t)

0.125 / (1,170.26 / 6.75)

0.000721

From Table CS-2 Metric:B=731.1995 kgf/cm2

Pa

=

=

=

B / (Ro / t)

731.1995 / (1,170.26 / 6.75)

4.2177 kgf/cm2

Check the Maximum External Pressure, UG-33(a)(1) Appendix 1-4(c)

P

=

2*S*E*t / ((K*D + 0.2*t)*1.67) - Ps2

=

2*1,305.236*1*6.75 / ((0.993917*1,306 +0.2*6.75)*1.67) - 0

=

8.12 kgf/cm2

The maximum allowable external pressure (MAEP) is 4.22 kgf/cm2.

% Extreme fiber elongation - UCS-79(d)

EFE =

(75*t / Rf)*(1 - Rf / Ro)

=

(75*13 / 227.5)*(1 - 227.5 / )

=

4.2857%

The extreme fiber elongation does not exceed 5%.

15/88

Straight Flange on LEFT HEAD

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Component:

Straight Flange

Material specification:

SA-516 65 (II-D Metric p. 14, ln. 35)

Material impact test exemption temperature from Fig UCS-66M Curve D = -47.63 C

Fig UCS-66.1M MDMT reduction = 17.8 C, (coincident ratio = 0.68269)

Rated MDMT is governed by UCS-66(b)(2)

UCS-66 governing thickness = 13 mm

Internal design pressure: P = 3.5 kg/cm2 @ 87 C

External design pressure: Pe = 0.5 kg/cm2 @ 87 C

Static liquid head:

Ps = 0.09 kg/cm2 (SG = 0.74, Hs = 1153 mm,Operating head)

Pth = 0.19 kg/cm2 (SG = 1, Hs = 1950 mm, Horizontal test head)

Corrosion allowance

Inner C = 3 mm

Outer C = 0 mm

Design MDMT = 7 C

No impact test performed

Rated MDMT = -48 C

Material is normalized

Material is produced to Fine Grain Practice

PWHT is not performed

Full UW-11(a) Type 1

Radiography:

Longitudinal joint Circumferential joint Spot UW-11(a)(5)b Type 1

Estimated weight New = 16 kg

corr = 12.3 kg

Capacity

New = 50.44 liters corr = 50.9 liters

ID

= 1,300 mm

Length Lc = 38 mm

t

= 13 mm

Design thickness, (at 87 C) UG-27(c)(1)

t

= P*R / (S*E - 0.60*P) + Corrosion

= 3.59*653 / (1,305.24*1.00 - 0.60*3.59) + 3

= 4.8 mm

Maximum allowable working pressure, (at 87 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t) - Ps

= 1,305.24*1.00*10 / (653 + 0.60*10) - 0.09

= 19.72 kg/cm2

Maximum allowable pressure, (at 21 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t)

= 1,305.24*1.00*13 / (650 + 0.60*13)

= 25.8 kg/cm2

External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 4,218.67 / 1,326 = 3.1815

Do / t = 1,326 / 5.14

= 258.1652

From table G:

A = 0.000096

From table CS-2 Metric: B = 96.8122 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*96.81 / (3*(1,326 / 5.14))

= 0.5 kg/cm2

Design thickness for external pressure Pa = 0.5 kg/cm2

ta

= t + Corrosion = 5.14 + 3 = 8.14 mm

Maximum Allowable External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 4,218.67 / 1,326 = 3.1815

Do / t = 1,326 / 10

= 132.5965

From table G:

A = 0.000260

From table CS-2 Metric: B = 262.6607 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*262.66 / (3*(1,326 / 10))

= 2.64 kg/cm2

% Extreme fiber elongation - UCS-79(d)

EFE =

(50*t / Rf)*(1 - Rf / Ro)

=

(50*13 / 656.5)*(1 - 656.5 / )

=

0.9901%

The extreme fiber elongation does not exceed 5%.

16/88

SHELL

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Component:

Cylinder

Material specification:

SA-516 65 (II-D Metric p. 14, ln. 35)

Material impact test exemption temperature from Fig UCS-66M Curve D = -47.63 C

Fig UCS-66.1M MDMT reduction = 17.7 C, (coincident ratio = 0.6834465)

Rated MDMT is governed by UCS-66(b)(2)

UCS-66 governing thickness = 13 mm

Internal design pressure: P = 3.5 kg/cm2 @ 87 C

External design pressure: Pe = 0.5 kg/cm2 @ 87 C

Static liquid head:

Ps = 0.09 kg/cm2 (SG = 0.74, Hs = 1153 mm,Operating head)

Pth = 0.19 kg/cm2 (SG = 1, Hs = 1950 mm, Horizontal test head)

Corrosion allowance

Inner C = 3 mm

Outer C = 0 mm

Design MDMT = 7 C

No impact test performed

Rated MDMT = -48 C

Material is normalized

Material is produced to Fine Grain Practice

PWHT is not performed

Spot UW-11(b) Type 1

Radiography:

Longitudinal joint Left circumferential joint Spot UW-11(a)(5)b Type 1

Right circumferential joint Spot UW-11(a)(5)b Type 1

Estimated weight New = 1,596.5 kg

corr = 1,231 kg

Capacity

New = 5,208.42 liters corr = 5,256.6 liters

ID

= 1,300 mm

Length Lc = 3,924 mm

t

= 13 mm

Design thickness, (at 87 C) UG-27(c)(1)

t

= P*R / (S*E - 0.60*P) + Corrosion

= 3.59*653 / (1,305.24*0.85 - 0.60*3.59) + 3

= 5.12 mm

Maximum allowable working pressure, (at 87 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t) - Ps

= 1,305.24*0.85*10 / (653 + 0.60*10) - 0.09

= 16.75 kg/cm2

Maximum allowable pressure, (at 21 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t)

= 1,305.24*0.85*13 / (650 + 0.60*13)

= 21.93 kg/cm2

External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 4,218.67 / 1,326 = 3.1815

Do / t = 1,326 / 5.14

= 258.1652

From table G:

A = 0.000096

From table CS-2 Metric: B = 96.8122 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*96.81 / (3*(1,326 / 5.14))

= 0.5 kg/cm2

Design thickness for external pressure Pa = 0.5 kg/cm2

ta

= t + Corrosion = 5.14 + 3 = 8.14 mm

Maximum Allowable External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 4,218.67 / 1,326 = 3.1815

Do / t = 1,326 / 10

= 132.5965

From table G:

A = 0.000260

From table CS-2 Metric: B = 262.6607 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*262.66 / (3*(1,326 / 10))

= 2.64 kg/cm2

% Extreme fiber elongation - UCS-79(d)

EFE =

(50*t / Rf)*(1 - Rf / Ro)

=

(50*13 / 656.5)*(1 - 656.5 / )

=

0.9901%

The extreme fiber elongation does not exceed 5%.

17/88

Straight Flange on RIGHT HEAD

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Component:

Straight Flange

Material specification:

SA-516 65 (II-D Metric p. 14, ln. 35)

Material impact test exemption temperature from Fig UCS-66M Curve D = -47.63 C

Fig UCS-66.1M MDMT reduction = 17.8 C, (coincident ratio = 0.68269)

Rated MDMT is governed by UCS-66(b)(2)

UCS-66 governing thickness = 13 mm

Internal design pressure: P = 3.5 kg/cm2 @ 87 C

External design pressure: Pe = 0.5 kg/cm2 @ 87 C

Static liquid head:

Ps = 0.09 kg/cm2 (SG = 0.74, Hs = 1153 mm,Operating head)

Pth = 0.19 kg/cm2 (SG = 1, Hs = 1950 mm, Horizontal test head)

Corrosion allowance

Inner C = 3 mm

Outer C = 0 mm

Design MDMT = 7 C

No impact test performed

Rated MDMT = -48 C

Material is normalized

Material is produced to Fine Grain Practice

PWHT is not performed

Full UW-11(a) Type 1

Radiography:

Longitudinal joint Circumferential joint Spot UW-11(a)(5)b Type 1

Estimated weight New = 16 kg

corr = 12.3 kg

Capacity

New = 50.44 liters corr = 50.9 liters

ID

= 1,300 mm

Length Lc = 38 mm

t

= 13 mm

Design thickness, (at 87 C) UG-27(c)(1)

t

= P*R / (S*E - 0.60*P) + Corrosion

= 3.59*653 / (1,305.24*1.00 - 0.60*3.59) + 3

= 4.8 mm

Maximum allowable working pressure, (at 87 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t) - Ps

= 1,305.24*1.00*10 / (653 + 0.60*10) - 0.09

= 19.72 kg/cm2

Maximum allowable pressure, (at 21 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t)

= 1,305.24*1.00*13 / (650 + 0.60*13)

= 25.8 kg/cm2

External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 4,218.67 / 1,326 = 3.1815

Do / t = 1,326 / 5.14

= 258.1652

From table G:

A = 0.000096

From table CS-2 Metric: B = 96.8122 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*96.81 / (3*(1,326 / 5.14))

= 0.5 kg/cm2

Design thickness for external pressure Pa = 0.5 kg/cm2

ta

= t + Corrosion = 5.14 + 3 = 8.14 mm

Maximum Allowable External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 4,218.67 / 1,326 = 3.1815

Do / t = 1,326 / 10

= 132.5965

From table G:

A = 0.000260

From table CS-2 Metric: B = 262.6607 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*262.66 / (3*(1,326 / 10))

= 2.64 kg/cm2

% Extreme fiber elongation - UCS-79(d)

EFE =

(50*t / Rf)*(1 - Rf / Ro)

=

(50*13 / 656.5)*(1 - 656.5 / )

=

0.9901%

The extreme fiber elongation does not exceed 5%.

18/88

RIGHT HEAD

ASME Section VIII, Division 1, 2007 Edition, A09 Addenda Metric

Component:

Ellipsoidal Head

Material Specification:

SA-516 65 (II-D Metric p.14, ln. 35)

Material impact test exemption temperature from Fig UCS-66M Curve D = -48 C

UCS-66 governing thickness = 9.75 mm

Internal design pressure: P = 3.5 kgf/cm2 @ 87 C

External design pressure: Pe = 0.5 kgf/cm2 @ 87 C

Static liquid head:

Ps= 0.0853 kgf/cm2 (SG=0.74, Hs=1153 mm Operating head)

Pth= 0.1948 kgf/cm2 (SG=1, Hs=1950 mm Horizontal test head)

Corrosion allowance:

Inner C = 3 mm

Outer C = 0 mm

Design MDMT = 7C

No impact test performed

Rated MDMT = -48C

Material is normalized

Material is produced to fine grain practice

PWHT is not performed

Do not Optimize MDMT / Find MAWP

Radiography:

Category A joints Head to shell seam -

Full UW-11(a) Type 1

Spot UW-11(a)(5)(b) Type 1

corr = 115.5 kg

new = 164.2 kg

Estimated weight*:

Capacity*:

new = 338 liters

corr = 343.8 liters

* includes straight flange

Inner diameter

= 1300 mm

Minimum head thickness

= 9.75 mm

Head ratio D/2h

= 2 (new)

Head ratio D/2h

= 1.9909 (corroded)

Straight flange length Lsf

= 38 mm

Nominal straight flange thickness tsf = 13 mm

Results Summary

The governing condition is external pressure.

Minimum thickness per UG-16

= 1.5 mm + 3 mm = 4.5 mm

Design thickness due to internal pressure (t)

= 4.79 mm

Design thickness due to external pressure (te)

= 5.33 mm

Maximum allowable working pressure (MAWP) = 13.48 kgf/cm2

Maximum allowable pressure (MAP)

= 19.55 kgf/cm2

Maximum allowable external pressure (MAEP)

= 4.22 kgf/cm2

K

(Corroded)=

(1/6)*[2 + (D / (2*h))2]

K

=

(1/6)*[2 + (1,306 / (2*328))2]

=

0.993917

K

(New) =

(1/6)*[2 + (D / (2*h))2]

K

=

(1/6)*[2 + (1,300 / (2*325))2]

=

1

Design thickness for internal pressure, (Corroded at 87 C) Appendix 1-4(c)

t

=

P*D*K / (2*S*E - 0.2*P) + Corrosion

=

3.59*1,306*0.993917 / (2*1,305.236*1 - 0.2*3.59) + 3

=

4.78 mm

The head internal pressure design thickness is 4.79 mm.

Maximum allowable working pressure, (Corroded at 87 C) Appendix 1-4(c)

P

=

2*S*E*t / (K*D + 0.2*t) - Ps

=

2*1,305.236*1*6.75 / (0.993917*1,306 +0.2*6.75) - 0.09

=

13.48 kgf/cm2

The maximum allowable working pressure (MAWP) is 13.48 kgf/cm2.

Maximum allowable pressure, (New at 21 C) Appendix 1-4(c)

P

=

2*S*E*t / (K*D + 0.2*t) - Ps

=

2*1,305.236*1*9.75 / (1*1,300 +0.2*9.75) - 0

=

19.55 kgf/cm2

The maximum allowable pressure (MAP) is 19.55 kgf/cm2.

Design thickness for external pressure, (Corroded at 87 C) UG-33(d)

Equivalent outside spherical radius (Ro)

Ro

=

Ko*Do

=

0.8869*1,319.5

=

1,170.26 mm

A

=

=

0.125 / (Ro / t)

0.125 / (1,170.26 / 2.33)

19/88

0.000249

From Table CS-2 Metric:B=251.1281 kgf/cm2

Pa

=

=

=

B / (Ro / t)

251.1281 / (1,170.26 / 2.33)

0.5 kgf/cm2

t

=

2.33 mm + Corrosion = 2.33 mm + 3 mm = 5.33 mm

Check the external pressure per UG-33(a)(1) Appendix 1-4(c)

t

=

1.67*Pe*D*K / (2*S*E - 0.2*1.67*Pe) + Corrosion

=

1.67*0.5*1,306*0.993917 / (2*1,305.236*1 - 0.2*1.67*0.5) + 3

=

3.42 mm

The head external pressure design thickness (te) is 5.33 mm.

Maximum Allowable External Pressure, (Corroded at 87 C) UG-33(d)

Equivalent outside spherical radius (Ro)

=

Ko*Do

Ro

=

0.8869*1,319.5

=

1,170.26 mm

A

=

=

=

0.125 / (Ro / t)

0.125 / (1,170.26 / 6.75)

0.000721

From Table CS-2 Metric:B=731.1995 kgf/cm2

Pa

=

=

=

B / (Ro / t)

731.1995 / (1,170.26 / 6.75)

4.2177 kgf/cm2

Check the Maximum External Pressure, UG-33(a)(1) Appendix 1-4(c)

P

=

2*S*E*t / ((K*D + 0.2*t)*1.67) - Ps2

=

2*1,305.236*1*6.75 / ((0.993917*1,306 +0.2*6.75)*1.67) - 0

=

8.12 kgf/cm2

The maximum allowable external pressure (MAEP) is 4.22 kgf/cm2.

% Extreme fiber elongation - UCS-79(d)

EFE =

(75*t / Rf)*(1 - Rf / Ro)

=

(75*13 / 227.5)*(1 - 227.5 / )

=

4.2857%

The extreme fiber elongation does not exceed 5%.

20/88

BOOT SHELL

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Component:

Cylinder

Material specification:

SA-516 65 (II-D Metric p. 14, ln. 35)

Material is impact test exempt to -105 C per UCS-66(b)(3) (coincident ratio = 0.26681)

Internal design pressure: P = 3.5 kg/cm2 @ 87 C

External design pressure: Pe = 0.5 kg/cm2 @ 87 C

Static liquid head:

Ps = 0.18 kg/cm2 (SG = 0.74, Hs = 2484 mm,Operating head)

Pth = 0.05 kg/cm2 (SG = 1, Hs = 500 mm, Horizontal test head)

Ptv = 0.13 kg/cm2 (SG = 1, Hs = 1321 mm, Vertical test head)

Corrosion allowance

Inner C = 3 mm

Outer C = 0 mm

Design MDMT = 7 C

No impact test performed

Rated MDMT = -105 C

Material is normalized

Material is produced to Fine Grain Practice

PWHT is not performed

Radiography:

Longitudinal joint Spot UW-11(b) Type 1

Top circumferential joint Spot UW-11(a)(5)b Type 1

Bottom circumferential joint Spot UW-11(a)(5)b Type 1

Estimated weight New = 216.8 kg

corr = 167.7 kg

Capacity

New = 259.38 liters corr = 265.64 liters

ID

= 500 mm

Length Lc = 1,321 mm

t

= 13 mm

Design thickness, (at 87 C) UG-27(c)(1)

t

= P*R / (S*E - 0.60*P) + Corrosion

= 3.68*253 / (1,305.24*0.85 - 0.60*3.68) + 3

= 3.84 mm

Maximum allowable working pressure, (at 87 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t) - Ps

= 1,305.24*0.85*10 / (253 + 0.60*10) - 0.18

= 42.65 kg/cm2

Maximum allowable pressure, (at 21 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t)

= 1,305.24*0.85*13 / (250 + 0.60*13)

= 55.95 kg/cm2

External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 1,401.67 / 526 = 2.6648

Do / t = 526 / 1.89

= 278.9025

From table G:

A = 0.000104

From table CS-2 Metric: B = 104.5883 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*104.59 / (3*(526 / 1.89))

= 0.5 kg/cm2

Design thickness for external pressure Pa = 0.5 kg/cm2

ta

= t + Corrosion = 1.89 + 3 = 4.89 mm

Maximum Allowable External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 1,401.67 / 526 = 2.6648

Do / t = 526 / 10

= 52.5986

From table G:

A = 0.001238

From table CS-2 Metric: B = 918.0742 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*918.07 / (3*(526 / 10))

= 23.27 kg/cm2

% Extreme fiber elongation - UCS-79(d)

EFE =

(50*t / Rf)*(1 - Rf / Ro)

=

(50*13 / 256.5)*(1 - 256.5 / )

=

2.5341%

The extreme fiber elongation does not exceed 5%.

21/88

Straight Flange on BOOT HEAD

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Component:

Straight Flange

Material specification:

SA-516 65 (II-D Metric p. 14, ln. 35)

Material is impact test exempt to -105 C per UCS-66(b)(3) (coincident ratio = 0.26657)

Internal design pressure: P = 3.5 kg/cm2 @ 87 C

External design pressure: Pe = 0.5 kg/cm2 @ 87 C

Static liquid head:

Ps = 0.19 kg/cm2 (SG = 0.74, Hs = 2522 mm,Operating head)

Pth = 0.05 kg/cm2 (SG = 1, Hs = 500 mm, Horizontal test head)

Ptv = 0.14 kg/cm2 (SG = 1, Hs = 1359 mm, Vertical test head)

Corrosion allowance

Inner C = 3 mm

Outer C = 0 mm

Design MDMT = 7 C

No impact test performed

Rated MDMT = -105 C

Material is normalized

Material is produced to Fine Grain Practice

PWHT is not performed

Radiography:

Longitudinal joint Full UW-11(a) Type 1

Circumferential joint Spot UW-11(a)(5)b Type 1

Estimated weight New = 6.2 kg

corr = 4.8 kg

New = 7.46 liters corr = 7.64 liters

Capacity

ID

= 500 mm

Length Lc = 38 mm

t

= 13 mm

Design thickness, (at 87 C) UG-27(c)(1)

t

= P*R / (S*E - 0.60*P) + Corrosion

= 3.69*253 / (1,305.24*1.00 - 0.60*3.69) + 3

= 3.72 mm

Maximum allowable working pressure, (at 87 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t) - Ps

= 1,305.24*1.00*10 / (253 + 0.60*10) - 0.19

= 50.21 kg/cm2

Maximum allowable pressure, (at 21 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t)

= 1,305.24*1.00*13 / (250 + 0.60*13)

= 65.82 kg/cm2

External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 1,401.67 / 526 = 2.6648

Do / t = 526 / 1.89

= 278.9025

From table G:

A = 0.000104

From table CS-2 Metric: B = 104.5883 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*104.59 / (3*(526 / 1.89))

= 0.5 kg/cm2

Design thickness for external pressure Pa = 0.5 kg/cm2

ta

= t + Corrosion = 1.89 + 3 = 4.89 mm

Maximum Allowable External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 1,401.67 / 526 = 2.6648

Do / t = 526 / 10

= 52.5986

From table G:

A = 0.001238

From table CS-2 Metric: B = 918.0742 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*918.07 / (3*(526 / 10))

= 23.27 kg/cm2

% Extreme fiber elongation - UCS-79(d)

EFE =

(50*t / Rf)*(1 - Rf / Ro)

=

(50*13 / 256.5)*(1 - 256.5 / )

=

2.5341%

The extreme fiber elongation does not exceed 5%.

22/88

BOOT SHELL

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

Component:

Cylinder

Material specification:

SA-516 65 (II-D Metric p. 14, ln. 35)

Material is impact test exempt to -105 C per UCS-66(b)(3) (coincident ratio = 0.26681)

Internal design pressure: P = 3.5 kg/cm2 @ 87 C

External design pressure: Pe = 0.5 kg/cm2 @ 87 C

Static liquid head:

Ps = 0.18 kg/cm2 (SG = 0.74, Hs = 2484 mm,Operating head)

Pth = 0.05 kg/cm2 (SG = 1, Hs = 500 mm, Horizontal test head)

Ptv = 0.13 kg/cm2 (SG = 1, Hs = 1321 mm, Vertical test head)

Corrosion allowance

Inner C = 3 mm

Outer C = 0 mm

Design MDMT = 7 C

No impact test performed

Rated MDMT = -105 C

Material is normalized

Material is produced to Fine Grain Practice

PWHT is not performed

Radiography:

Longitudinal joint Spot UW-11(b) Type 1

Top circumferential joint Spot UW-11(a)(5)b Type 1

Bottom circumferential joint Spot UW-11(a)(5)b Type 1

Estimated weight New = 216.8 kg

corr = 167.7 kg

Capacity

New = 259.38 liters corr = 265.64 liters

ID

= 500 mm

Length Lc = 1,321 mm

t

= 13 mm

Design thickness, (at 87 C) UG-27(c)(1)

t

= P*R / (S*E - 0.60*P) + Corrosion

= 3.68*253 / (1,305.24*0.85 - 0.60*3.68) + 3

= 3.84 mm

Maximum allowable working pressure, (at 87 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t) - Ps

= 1,305.24*0.85*10 / (253 + 0.60*10) - 0.18

= 42.65 kg/cm2

Maximum allowable pressure, (at 21 C) UG-27(c)(1)

P

= S*E*t / (R + 0.60*t)

= 1,305.24*0.85*13 / (250 + 0.60*13)

= 55.95 kg/cm2

External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 1,401.67 / 526 = 2.6648

Do / t = 526 / 1.89

= 278.9025

From table G:

A = 0.000104

From table CS-2 Metric: B = 104.5883 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*104.59 / (3*(526 / 1.89))

= 0.5 kg/cm2

Design thickness for external pressure Pa = 0.5 kg/cm2

ta

= t + Corrosion = 1.89 + 3 = 4.89 mm

Maximum Allowable External Pressure, (Corroded & at 87 C) UG-28(c)

L / Do = 1,401.67 / 526 = 2.6648

Do / t = 526 / 10

= 52.5986

From table G:

A = 0.001238

From table CS-2 Metric: B = 918.0742 kg/cm2

Pa

= 4*B / (3*(Do / t))

= 4*918.07 / (3*(526 / 10))

= 23.27 kg/cm2

% Extreme fiber elongation - UCS-79(d)

EFE =

(50*t / Rf)*(1 - Rf / Ro)

=

(50*13 / 256.5)*(1 - 256.5 / )

=

2.5341%

The extreme fiber elongation does not exceed 5%.

23/88

0.000249

From Table CS-2 Metric:B=251.128 kgf/cm2

Pa

=

=

=

B / (Ro / t)

251.128 / (450.81 / 0.9)

0.5 kgf/cm2

t

=

0.9 mm + Corrosion = 0.9 mm + 3 mm = 3.9 mm

Check the external pressure per UG-33(a)(1) Appendix 1-4(c)

t

=

1.67*Pe*D*K / (2*S*E - 0.2*1.67*Pe) + Corrosion

=

1.67*0.5*506*0.984468 / (2*1,305.236*1 - 0.2*1.67*0.5) + 3

=

3.16 mm

The head external pressure design thickness (te) is 3.9 mm.

Maximum Allowable External Pressure, (Corroded at 87 C) UG-33(d)

Equivalent outside spherical radius (Ro)

=

Ko*Do

Ro

=

0.8635*522.1

=

450.81 mm

A

=

=

=

0.125 / (Ro / t)

0.125 / (450.81 / 8.05)

0.002232

From Table CS-2 Metric:B=1,074.4119 kgf/cm2

Pa

=

=

=

B / (Ro / t)

1,074.412 / (450.81 / 8.05)

19.1862 kgf/cm2

Check the Maximum External Pressure, UG-33(a)(1) Appendix 1-4(c)

P

=

2*S*E*t / ((K*D + 0.2*t)*1.67) - Ps2

=

2*1,305.236*1*8.05 / ((0.984468*506 +0.2*8.05)*1.67) - 0

=

25.18 kgf/cm2

The maximum allowable external pressure (MAEP) is 19.19 kgf/cm2.

% Extreme fiber elongation - UCS-79(d)

EFE =

(75*t / Rf)*(1 - Rf / Ro)

=

(75*13 / 91.5)*(1 - 91.5 / )

=

10.6557%

The extreme fiber elongation exceeds 5 percent. Heat treatment per UCS-56 may be required. See UCS-79(d)(4) or (5).

24/88

BOOT SHELL (BOOT)

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

tw(lower) =

Leg41 =

tw(upper) =

Leg42 =

Dp =

te =

Note: round inside edges per UG-76(c)

Located on:

SHELL

0.086 kgf/cm2

Liquid static head included:

Nozzle material specification:

SA-516 65 (II-D Metric p. 14, ln. 35) (normalized)

Nozzle longitudinal joint efficiency:

1

Pad material specification:

SA-516 65 (II-D Metric p. 14, ln. 35) (normalized)

Pad diameter:

970 mm

Nozzle orientation:

180

13 mm

Local vessel minimum thickness:

Nozzle center line offset to datum line: 2,400 mm

End of nozzle to shell center:

1,984 mm

Nozzle inside diameter, new:

500 mm

Nozzle nominal wall thickness:

13 mm

Nozzle corrosion allowance:

3 mm

Projection available outside vessel, Lpr: 1,321 mm

Pad is split:

No

Reinforcement Calculations for Internal Pressure

UG-37 Area Calculation Summary (cm2)

For P = 13.56 kgf/cm2 @ 87 C

The opening is adequately reinforced

A

A

required available

23.0315

42.8057

A1

A2

A3

8.0271 3.6781 --

A5

UG-45 Nozzle Wall

Thickness Summary (mm)

The nozzle passes UG-45

A

welds

treq

tmin

30.2903 0.8103 9.83

13

UG-41 Weld Failure Path Analysis Summary (kgf)

All failure paths are stronger than the applicable weld loads

Weld load Weld load Path 1-1 Weld load Path 2-2 Weld load Path 3-3

W

W1-1

strength

W2-2

strength

W3-3

strength

24,966

82,502

171,504

8,469

231,111

85,112

177,255

UW-16 Weld Sizing Summary

Weld description

Required weld Actual weld

size (mm)

size (mm)

Status

Nozzle to pad fillet (Leg41)

6.3

weld size is adequate

Pad to shell fillet (Leg42)

weld size is adequate

13

weld size is adequate

Nozzle to pad groove (Upper) 7

13 mm

9 mm

13 mm

10 mm

970 mm

13 mm

25/88

Check the opening per Appendix 1-7

Area required within 75 percent of the limits of reinforcement

= 2 / 3*A = (2 / 3)*34.5473 = 23.0315 cm2

Area that is within 75 percent of the limits of reinforcement is:

A1 = larger of 1.269 or

=

(2*limits - d)*(E1*t - F*tr) - 2*tn*(E1*t - F*tr)*(1 - fr1)

=

(2*379.5 - 506)*(1*10 - 1*6.83) - 2*10*(1*10 - 1*6.83)*(1 - 1)

=

8.0271 cm2

=

=

=

A5

Area =

=

=

(Dp - d - 2*tn)*te*fr4

(759 - 506 - 2*10)*13*1

30.2903 cm2

A1 + A2 + A3 + A41 + A42 + A43 + A5

8.0271 + 3.6781 + 0 + 0.8103 + 0 + 0 + 30.2903

42.8057 cm2

The area placement requirements of Appendix 1-7 are satisfied.

The opening is not within the size range defined by 1-7(b)(1)(a) and (b) so it is exempt from the requirements of 1-7(b)(2),(3) and (4).

Rn / R ratio does not exceed 0.7 so a U-2(g) analysis is not required per 1-7(b)(1)(c).

% Extreme fiber elongation - UCS-79(d)

EFE =

(50*t / Rf)*(1 - Rf / Ro)

=

(50*13 / 256.5)*(1 - 256.5 / )

=

2.5341%

The extreme fiber elongation does not exceed 5%.

Reinforcement Calculations for MAP

UG-37 Area Calculation Summary (cm2)

For P = 19.55 kgf/cm2 @ 21 C

The opening is adequately reinforced

A

A

required available

49.1185

81.4051

A1

A2

A3

15.8813 5.9935 --

UG-45 Nozzle Wall

Thickness Summary (mm)

The nozzle passes UG-45

A

welds

A5

treq

tmin

57.72 1.8103 8.33

13

UG-41 Weld Failure Path Analysis Summary (kgf)

All failure paths are stronger than the applicable weld loads

Weld load Weld load Path 1-1 Weld load Path 2-2 Weld load Path 3-3

W

W1-1

strength

W2-2

strength

W3-3

strength

44,460

85,524

193,161

13,292

255,050

89,936

201,195

UW-16 Weld Sizing Summary

Required weld Actual weld

size (mm)

size (mm)

Weld description

Status

Nozzle to pad fillet (Leg41)

6.3

weld size is adequate

Pad to shell fillet (Leg42)

6.5

weld size is adequate

Nozzle to pad groove (Upper) 9.1

13

Reinforcement Calculations for External Pressure

UG-37 Area Calculation Summary (cm2)

For Pe = 2.64 kgf/cm2 @ 87 C

The opening is adequately reinforced

A

A

A1

required available

16.8671

34.2748

--

A2

A3

3.1742 --

A5

weld size is adequate

UG-45 Nozzle Wall

Thickness Summary (mm)

The nozzle passes UG-45

A

welds

30.2903 0.8103 6.65

UG-41 Weld Failure Path Analysis Summary

Weld strength calculations are not required for external pressure

UW-16 Weld Sizing Summary

treq

tmin

13

26/88

Weld description

Required weld Actual weld

size (mm)

size (mm)

Status

Nozzle to pad fillet (Leg41)

6.3

weld size is adequate

Pad to shell fillet (Leg42)

weld size is adequate

13

weld size is adequate

Nozzle to pad groove (Upper) 7

Check the opening per Appendix 1-7

Area required within 75 percent of the limits of reinforcement

= 2 / 3*A = (2 / 3)*25.3006 = 16.8671 cm2

Area that is within 75 percent of the limits of reinforcement is:

A1 = larger of 0 or

(2*limits - d)*(E1*t - F*tr) - 2*tn*(E1*t - F*tr)*(1 - fr1)

=

=

(2*379.5 - 506)*(1*10 - 1*10) - 2*10*(1*10 - 1*10)*(1 - 1)

=

0 cm2

A5

=

=

=

Area =

=

=

(Dp - d - 2*tn)*te*fr4

(759 - 506 - 2*10)*13*1

30.2903 cm2

A1 + A2 + A3 + A41 + A42 + A43 + A5

0 + 3.1742 + 0 + 0.8103 + 0 + 0 + 30.2903

34.2748 cm2

The area placement requirements of Appendix 1-7 are satisfied.

27/88

INLET (A)

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

tw(lower) =

Leg41 =

tw(upper) =

Leg42 =

Dp =

te =

Note: round inside edges per UG-76(c)

Located on:

Liquid static head included:

Nozzle material specification:

Nozzle longitudinal joint efficiency:

Nozzle description:

Pad material specification:

Pad diameter:

Flange description:

Bolt Material:

Flange rated MDMT:

(UG-84 provisions apply)

(Flange impact tested to -49C (UCS-66(g)))

Liquid static head on flange:

ASME B16.5 flange rating MAWP:

ASME B16.5 flange rating MAP:

ASME B16.5 flange hydro test:

Gasket Description:

PWHT performed:

Circumferential joint radiography:

Nozzle orientation:

Calculated as hillside:

Local vessel minimum thickness:

End of nozzle to datum line:

Nozzle inside diameter, new:

Nozzle nominal wall thickness:

Nozzle corrosion allowance:

Opening chord length:

Projection available outside vessel, Lpr:

Projection available outside vessel to flange face, Lf:

Distance to head center, R:

Pad is split:

Reinforcement Calculations for Internal Pressure

UG-37 Area Calculation Summary (cm2)

For P = 13.48 kgf/cm2 @ 87 C

The opening is adequately reinforced

A

A

required available

A1

A2

A3

A5

RIGHT HEAD

0.0074 kgf/cm2

SA-333 6 Wld & smls pipe (II-D Metric p. 14, ln.

8)

1

8" Sch 80 (XS) DN 200

SA-516 65 (II-D Metric p. 14, ln. 35) (normalized)

400 mm

8 inch Class 150 WN A350 LF2 Cl.1

SA-320 L7M Bolt <= 64 (II-D Metric p. 348, ln.

31)

-49C

0.0074 kgf/cm2

18.45 kgf/cm2 @ 87C

19.99 kgf/cm2 @ 21C

30.59 kgf/cm2 @ 21C

Flexitallic Spiral Wound CGI 316L S.S.

No

Full UW-11(a) Type 1

0

Yes

9.75 mm

-550 mm

193.68 mm

12.7 mm

3 mm

214.96 mm

147.84 mm

249.44 mm

400 mm

No

UG-45 Nozzle Wall

Thickness Summary (mm)

The nozzle passes UG-45

A

welds

treq

tmin

9.75 mm

9 mm

13 mm

10 mm

400 mm

13 mm

28/88

14.5286

25.6288

0.0826 2.6684 --

21.3733 1.5045 9.71

11.11

UG-41 Weld Failure Path Analysis Summary (kgf)

All failure paths are stronger than the applicable weld loads

Weld load Weld load Path 1-1 Weld load Path 2-2 Weld load Path 3-3

W

W1-1

strength

W2-2

strength

W3-3

strength

18,865

33,344

67,055

5,717

83,906

34,920

62,621

UW-16 Weld Sizing Summary

Weld description

Required weld Actual weld

size (mm)

size (mm)

Status

Nozzle to pad fillet (Leg41)

6.3

weld size is adequate

Pad to shell fillet (Leg42)

3.38

weld size is adequate

13

weld size is adequate

Nozzle to pad groove (Upper) 6.79

29/88

OUTLET TO ATM (B2)

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

tw(lower) =

Leg41 =

tw(upper) =

Leg42 =

Dp =

te =

Note: round inside edges per UG-76(c)

Located on:

Liquid static head included:

Nozzle material specification:

Nozzle longitudinal joint efficiency:

Nozzle description:

Pad material specification:

Pad diameter:

Flange description:

Bolt Material:

Flange rated MDMT:

(UG-84 provisions apply)

(Flange impact tested to -49C (UCS-66(g)))

Liquid static head on flange:

ASME B16.5 flange rating MAWP:

ASME B16.5 flange rating MAP:

ASME B16.5 flange hydro test:

Gasket Description:

PWHT performed:

Circumferential joint radiography:

Nozzle orientation:

Local vessel minimum thickness:

Nozzle center line offset to datum line:

End of nozzle to shell center:

Nozzle inside diameter, new:

Nozzle nominal wall thickness:

Nozzle corrosion allowance:

Projection available outside vessel, Lpr:

Projection available outside vessel to flange face, Lf:

Pad is split:

Reinforcement Calculations for Internal Pressure

UG-37 Area Calculation Summary (cm2)

For P = 13.48 kgf/cm2 @ 87 C

The opening is adequately reinforced

A

A

required available

17.0113

42.8271

A1

A2

A3

7.9439 4.9258 --

A5

SHELL

0 kgf/cm2

SA-333 6 Wld & smls pipe (II-D Metric p. 14, ln.

8)

1

10" Sch 80 DN 250

SA-516 65 (II-D Metric p. 14, ln. 35) (normalized)

510 mm

10 inch Class 150 WN A350 LF2 Cl.1

SA-320 L7M Bolt <= 64 (II-D Metric p. 348, ln.

31)

-49C

0 kgf/cm2

18.45 kgf/cm2 @ 87C

19.99 kgf/cm2 @ 21C

30.59 kgf/cm2 @ 21C

Flexitallic Spiral Wound CGI 316L S.S.

No

Full UW-11(a) Type 1

0

13 mm

3,600 mm

1,200 mm

242.87 mm

15.09 mm

3 mm

435.4 mm

537 mm

No

UG-45 Nozzle Wall

Thickness Summary (mm)

The nozzle passes UG-45

A

welds

29.2109 0.7465 9.78

treq

tmin

13.2

13 mm

9 mm

13 mm

10 mm

510 mm

13 mm

30/88

UG-41 Weld Failure Path Analysis Summary (kgf)

All failure paths are stronger than the applicable weld loads

Weld load Weld load Path 1-1 Weld load Path 2-2 Weld load Path 3-3

W

W1-1

strength

W2-2

strength

W3-3

strength

12,771

45,531

92,971

10,313

118,043

48,440

92,664

UW-16 Weld Sizing Summary

Weld description

Required weld Actual weld

size (mm)

size (mm)

Status

Nozzle to pad fillet (Leg41)

6.3

weld size is adequate

Pad to shell fillet (Leg42)

weld size is adequate

13

weld size is adequate

Nozzle to pad groove (Upper) 8.46

31/88

PUMP OUT CONNECTION (B3)

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

tw(lower) =

Leg41 =

Leg43 =

hnew =

Note: round inside edges per UG-76(c)

Located on:

Liquid static head included:

Nozzle material specification:

Nozzle longitudinal joint efficiency:

Flange description:

Bolt Material:

Flange rated MDMT:

(UG-84 provisions apply)

(Flange impact tested to -49C (UCS-66(g)))

Liquid static head on flange:

ASME B16.5 flange rating MAWP:

ASME B16.5 flange rating MAP:

ASME B16.5 flange hydro test:

Gasket Description:

PWHT performed:

Nozzle orientation:

Local vessel minimum thickness:

Nozzle center line offset to datum line:

End of nozzle to shell center:

Nozzle inside diameter, new:

Nozzle nominal wall thickness:

Nozzle corrosion allowance:

Projection available outside vessel, Lpr:

Internal projection, hnew:

Projection available outside vessel to flange face, Lf:

Reinforcement Calculations for Internal Pressure

SHELL

0 kgf/cm2

SA-350 LF2 Cl 1 (II-D Metric p. 18, ln. 15)

(normalized)

1

2 inch Class 150 LWN A350 LF2 Cl.1

SA-320 L7M Bolt <= 64 (II-D Metric p. 348, ln. 31)

-49C

0 kgf/cm2

18.45 kgf/cm2 @ 87C

19.99 kgf/cm2 @ 21C

30.59 kgf/cm2 @ 21C

Flexitallic Spiral Wound CGI 316L S.S.

No

0

13 mm

1,600 mm

1,200 mm

42.9 mm

17.55 mm

3 mm

517.95 mm

50 mm

537 mm

UG-45 Nozzle Wall

Thickness Summary (mm)

The nozzle passes UG-45

UG-37 Area Calculation Summary (cm2)

For P = 13.48 kgf/cm2 @ 87 C

A

required

A

available

A1

A2

A3

A5

A

welds

treq

This nozzle is exempt from area calculations per UG-36(c)(3)(a) 7.8

UG-41 Weld Failure Path Analysis Summary

The nozzle is exempt from weld strength calculations per UW-15(b)(2)

UW-16 Weld Sizing Summary

tmin

17.55

13 mm

9 mm

9 mm

50 mm

32/88

Weld description

Required weld

Actual weld

throat size (mm) throat size (mm)

Nozzle to shell fillet (Leg41) 6

6.3

This opening does not require reinforcement per UG-36(c)(3)(a)

Status

weld size is adequate

33/88

DRAIN (D)

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

tw(lower) = 11.05 mm

Leg41 = 9 mm

Note: round inside edges per UG-76(c)

Located on:

Liquid static head included:

Nozzle material specification:

Nozzle longitudinal joint efficiency:

Flange description:

Bolt Material:

Flange rated MDMT:

(UG-84 provisions apply)

(Flange impact tested to -49C (UCS-66(g)))

Liquid static head on flange:

ASME B16.5 flange rating MAWP:

ASME B16.5 flange rating MAP:

ASME B16.5 flange hydro test:

Gasket Description:

PWHT performed:

Nozzle orientation:

Calculated as hillside:

Local vessel minimum thickness:

End of nozzle to datum line:

Nozzle inside diameter, new:

Nozzle nominal wall thickness:

Nozzle corrosion allowance:

Projection available outside vessel, Lpr:

Projection available outside vessel to flange face, Lf:

Distance to head center, R:

Reinforcement Calculations for Internal Pressure

BOOT HEAD

0.1965 kgf/cm2

SA-350 LF2 Cl 1 (II-D Metric p. 18, ln. 15)

(normalized)

1

2 inch Class 150 LWN A350 LF2 Cl.1

SA-320 L7M Bolt <= 64 (II-D Metric p. 348, ln. 31)

-49C

0.2109 kgf/cm2

18.45 kgf/cm2 @ 87C

19.99 kgf/cm2 @ 21C

30.59 kgf/cm2 @ 21C

Flexitallic Spiral Wound CGI 316L S.S.

No

0

No

11.05 mm

0 mm

50.8 mm

13.6 mm

3 mm

176.43 mm

195.48 mm

0 mm

UG-45 Nozzle Wall

Thickness Summary (mm)

The nozzle passes UG-45

UG-37 Area Calculation Summary (cm2)

For P = 13.67 kgf/cm2 @ 87 C

A

required

A

available

A1

A2

A3

A5

A

welds

This nozzle is exempt from area calculations per UG-36(c)(3)(a) 5.61

UG-41 Weld Failure Path Analysis Summary

The nozzle is exempt from weld strength calculations per UW-15(b)(2)

treq

tmin

13.6

34/88

UW-16 Weld Sizing Summary

Weld description

Required weld

Actual weld

throat size (mm) throat size (mm)

Nozzle to shell fillet (Leg41) 5.63

6.3

This opening does not require reinforcement per UG-36(c)(3)(a)

Status

weld size is adequate

35/88

NITROGEN CONNECTION (N1)

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

tw(lower) = 13 mm

Leg41 = 9 mm

Note: round inside edges per UG-76(c)

Located on:

Liquid static head included:

Nozzle material specification:

Nozzle longitudinal joint efficiency:

Flange description:

Bolt Material:

Flange rated MDMT:

(UG-84 provisions apply)

(Flange impact tested to -49C (UCS-66(g)))

Liquid static head on flange:

ASME B16.5 flange rating MAWP:

ASME B16.5 flange rating MAP:

ASME B16.5 flange hydro test:

Gasket Description:

PWHT performed:

Nozzle orientation:

Local vessel minimum thickness:

Nozzle center line offset to datum line:

End of nozzle to shell center:

Nozzle inside diameter, new:

Nozzle nominal wall thickness:

Nozzle corrosion allowance:

Projection available outside vessel, Lpr:

Projection available outside vessel to flange face, Lf:

Reinforcement Calculations for Internal Pressure

SHELL

0 kgf/cm2

SA-350 LF2 Cl 1 (II-D Metric p. 18, ln. 15)

(normalized)

1

2 inch Class 150 LWN A350 LF2 Cl.1

SA-320 L7M Bolt <= 64 (II-D Metric p. 348, ln. 31)

-49C

0 kgf/cm2

18.45 kgf/cm2 @ 87C

19.99 kgf/cm2 @ 21C

30.59 kgf/cm2 @ 21C

Flexitallic Spiral Wound CGI 316L S.S.

No

0

13 mm

200 mm

1,200 mm

50.8 mm

13.6 mm

3 mm

517.95 mm

537 mm

UG-45 Nozzle Wall

Thickness Summary (mm)

The nozzle passes UG-45

UG-37 Area Calculation Summary (cm2)

For P = 13.48 kgf/cm2 @ 87 C

A

required

A

available

A1

A2

A3

A5

A

welds

treq

This nozzle is exempt from area calculations per UG-36(c)(3)(a) 7.8

UG-41 Weld Failure Path Analysis Summary

The nozzle is exempt from weld strength calculations per UW-15(b)(2)

UW-16 Weld Sizing Summary

tmin

13.6

36/88

Weld description

Required weld

Actual weld

throat size (mm) throat size (mm)

Nozzle to shell fillet (Leg41) 6

6.3

This opening does not require reinforcement per UG-36(c)(3)(a)

Status

weld size is adequate

37/88

UTILITY CONNECTION (UC)

ASME Section VIII Division 1, 2007 Edition, A09 Addenda Metric

tw(lower) =

Leg41 =

tw(upper) =

Leg42 =

Dp =

te =

Note: round inside edges per UG-76(c)

Located on:

Liquid static head included:

Nozzle material specification:

Nozzle longitudinal joint efficiency:

Nozzle description:

Pad material specification:

Pad diameter:

Flange description:

Bolt Material:

Flange rated MDMT:

(UG-84 provisions apply)

(Flange impact tested to -49C (UCS-66(g)))

Liquid static head on flange:

ASME B16.5 flange rating MAWP:

ASME B16.5 flange rating MAP:

ASME B16.5 flange hydro test:

Gasket Description:

PWHT performed:

Circumferential joint radiography:

Nozzle orientation:

Local vessel minimum thickness:

Nozzle center line offset to datum line:

End of nozzle to shell center:

Nozzle inside diameter, new:

Nozzle nominal wall thickness:

Nozzle corrosion allowance:

Projection available outside vessel, Lpr:

Projection available outside vessel to flange face, Lf:

Pad is split:

Reinforcement Calculations for Internal Pressure

UG-37 Area Calculation Summary (cm2)

For P = 13.48 kgf/cm2 @ 87 C

The opening is adequately reinforced

A

A

required available

10.4183

26.421

A1

A2

A3

4.8593 3.2793 --

A5

SHELL

0 kgf/cm2

SA-333 6 Wld & smls pipe (II-D Metric p. 14, ln.

8)

1

6" Sch 80 (XS) DN 150

SA-516 65 (II-D Metric p. 14, ln. 35) (normalized)

300 mm

6 inch Class 150 WN A350 LF2 Cl.1

SA-320 L7M Bolt <= 64 (II-D Metric p. 348, ln.

31)

-49C

0 kgf/cm2

18.45 kgf/cm2 @ 87C

19.99 kgf/cm2 @ 21C

30.59 kgf/cm2 @ 21C

Flexitallic Spiral Wound CGI 316L S.S.

No

Full UW-11(a) Type 1

0

13 mm

3,100 mm

1,200 mm

146.33 mm

10.97 mm

3 mm

448.1 mm

537 mm

No

UG-45 Nozzle Wall

Thickness Summary (mm)

The nozzle passes UG-45

A

welds

17.1236 1.1587 9.22

treq

tmin

9.6

13 mm

9 mm

13 mm

10 mm

300 mm

13 mm

38/88

UG-41 Weld Failure Path Analysis Summary (kgf)

All failure paths are stronger than the applicable weld loads

Weld load Weld load Path 1-1 Weld load Path 2-2 Weld load Path 3-3

W

W1-1

strength

W2-2

strength

W3-3

strength

7,873

28,143

47,048