Académique Documents

Professionnel Documents

Culture Documents

II 1 Si Tech Introduction

Transféré par

HarshvardhanUpadhyay0 évaluation0% ont trouvé ce document utile (0 vote)

25 vues9 pagessilicon technology

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentsilicon technology

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

25 vues9 pagesII 1 Si Tech Introduction

Transféré par

HarshvardhanUpadhyaysilicon technology

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 9

Introduction - Chapter 1

INTRODUCTION - Chapter 1 in the Text

This course is basically about silicon chip fabrication,

the technologies used to manufacture ICs.

We will place a special emphasis on computer

simulation tools to help understand these processes

and as design tools.

These simulation tools are more sophisticated in some

technology areas than in others, but in all areas they

have made tremendous progress in recent years.

1960s and early 1990s integrated circuits.

Progress due to:

Feature size reduction - 0.7X/3 years (Moores Law).

Increasing chip size - 16% per year.

Creativity in implementing functions.

SILICON VLSI TECHNOLOGY

Fundamentals, Practice and Modeling

By Plummer, Deal and Griffin

2000 by Prentice Hall

Upper Saddle River, NJ.

Introduction - Chapter 1

Year of 1st DRAM

Shipment

Minimum Feature

Size

DRAM Bits/Chip

DRAM Chip Size

(mm2)

Microprocessor

Transistors/chip

Maximum Wiring

Levels

Minimum Mask

Count

Minimum Supply

Voltage (volts)

1997

1999

2003

2006

2009

2012

250 nm 180 nm 130 nm 100 nm 70 nm

50 nm

256M

280

1G

400

4G

560

16G

790

64G

1120

256G

1580

11M

21M

76M

200M

520M

1.40B

6-7

7-8

8-9

22

22/24

24

24/26

26/28

28

1.8-2.5 1.5-1.8 1.2-1.5 0.9-1.2 0.6-0.9 0.5-0.6

SIA NTRS (selected data). Updated ITRS available at

http://public.itrs.net/Files/1999_SIA_Roadmap/Home.htm

Feature Size

100 m

Integrated Circuit

History

10 m

1 m

0.25 in 1997

NTRS Roadmap

0.1 m

10 nm

Transition Region

Quantum Devices

1 nm

Atomic Dimensions

0.1 nm

1960

1980

2000

2020

2040

Year

History and future projections for minimum feature

size in silicon chips.

Device limits appear today to be 25 nm (250 )

channel lengths in MOS transistors.

SILICON VLSI TECHNOLOGY

Fundamentals, Practice and Modeling

By Plummer, Deal and Griffin

2000 by Prentice Hall

Upper Saddle River, NJ.

Introduction - Chapter 1

(Reprinted with permission of IBM.)

1990 IBM demo of scale lithography.

Technology appears to be capable of making

structures much smaller than currently known device

limits.

Historical Perspective

How did we get to todays planar technology?

(Reprinted with permission of Lucent Technologies).

Invention of the bipolar transistor - 1947, Bell Labs.

Shockleys creative failure methodology.

SILICON VLSI TECHNOLOGY

Fundamentals, Practice and Modeling

By Plummer, Deal and Griffin

2000 by Prentice Hall

Upper Saddle River, NJ.

Introduction - Chapter 1

N

N

Grown junction transistor technology of the 1950s.

In

In

P

N

N

Alloy junction technology of the 1950s.

SILICON VLSI TECHNOLOGY

Fundamentals, Practice and Modeling

By Plummer, Deal and Griffin

2000 by Prentice Hall

Upper Saddle River, NJ.

Introduction - Chapter 1

N

N

P

N

P

N

N

P

N

N

P

N

Double diffused transistor technology of the 1950s.

Si O2

P

N

P

P

N

The planar process (Hoerni - Fairchild, late 1950s).

SILICON VLSI TECHNOLOGY

Fundamentals, Practice and Modeling

By Plummer, Deal and Griffin

2000 by Prentice Hall

Upper Saddle River, NJ.

Introduction - Chapter 1

Light

Mask

Photoresist

Deposited Film

Substrate

Film deposition

Photoresist application

Exposure

Etch mask

Etching

Development

Resist removal

Basic lithography process which is central to todays

chip fabrication.

Lithographic process allows integration of multiple

devices side by side on a wafer.

SILICON VLSI TECHNOLOGY

Fundamentals, Practice and Modeling

By Plummer, Deal and Griffin

2000 by Prentice Hall

Upper Saddle River, NJ.

Introduction - Chapter 1

P+

P+

N+

N Well

N+

P Well

Schematic cross-section of a modern silicon IC.

(Reprinted with permission of Integrated Circuit Engineering.)

Actual cross-section of a modern microprocessor chip.

Note the multiple levels of metal and planarization.

SILICON VLSI TECHNOLOGY

Fundamentals, Practice and Modeling

By Plummer, Deal and Griffin

2000 by Prentice Hall

Upper Saddle River, NJ.

Introduction - Chapter 1

Computer Simulation Tools (TCAD)

Most of the basic technologies in silicon chip

manufacturing can now be simulated.

Simulation is now used for:

Designing new processes and devices.

Exploring the limits of semiconductor

devices and technology (R&D).

Centering manufacturing processes.

Solving manufacturing problems (what-if?)

Simulation of an advanced local oxidation process.

Simulation of photoresist exposure.

SILICON VLSI TECHNOLOGY

Fundamentals, Practice and Modeling

By Plummer, Deal and Griffin

2000 by Prentice Hall

Upper Saddle River, NJ.

Introduction - Chapter 1

Summary of Key Ideas

ICs are widely regarded as one of the key components

of the information age.

Basic inventions between 1945 and 1970 laid the

foundation for today's silicon industry.

For more than 30 years, "Moore's Law" (a doubling

of chip complexity every 2-3 years) has held true.

CMOS has become the dominant circuit technology

because of its low DC power consumption, high

performance and flexible design options.

Future projections suggest these trends will continue

through at least 2010 and likely beyond.

Computer simulation tools have been widely used for

device, circuit and system design for many years. New

tools are now being used for technology design as well.

Chapter 1 also contains some review information on

semiconductor materials and basic semiconductor

devices for students who have not studied this

material or who wish to review these areas. These

topics will be useful in later chapters of the text.

SILICON VLSI TECHNOLOGY

Fundamentals, Practice and Modeling

By Plummer, Deal and Griffin

2000 by Prentice Hall

Upper Saddle River, NJ.

Vous aimerez peut-être aussi

- E ReceiptDocument1 pageE ReceiptHarshvardhanUpadhyayPas encore d'évaluation

- J 08 14 IiDocument16 pagesJ 08 14 IiJay KartaPas encore d'évaluation

- Syllabi GATE2017 PDFDocument73 pagesSyllabi GATE2017 PDFAnkit Kumar AJPas encore d'évaluation

- Current Affairs Pocket PDF - August 2016 by AffairsCloudDocument45 pagesCurrent Affairs Pocket PDF - August 2016 by AffairsCloudSurya Srinivas VinjarapuPas encore d'évaluation

- How To Create BootableCDsDocument2 pagesHow To Create BootableCDsgarv_sk9Pas encore d'évaluation

- Ep 2339757 A1 20110629 (En)Document1 pageEp 2339757 A1 20110629 (En)HarshvardhanUpadhyayPas encore d'évaluation

- Research MethadologyDocument36 pagesResearch MethadologykaleemmibPas encore d'évaluation

- Education Net Syallabus PDFDocument23 pagesEducation Net Syallabus PDFrajputkhan1Pas encore d'évaluation

- Seminar Report DSPDocument34 pagesSeminar Report DSPwmallanPas encore d'évaluation

- Test Your C-Skills (Yashwant Kanitkar)Document144 pagesTest Your C-Skills (Yashwant Kanitkar)Kamlesh KumarPas encore d'évaluation

- Human Detector and Counter Using Raspberry 2017Document7 pagesHuman Detector and Counter Using Raspberry 2017HarshvardhanUpadhyayPas encore d'évaluation

- Syllabi GATE2017 PDFDocument73 pagesSyllabi GATE2017 PDFAnkit Kumar AJPas encore d'évaluation

- Alam2016 PDFDocument9 pagesAlam2016 PDFHarshvardhanUpadhyayPas encore d'évaluation

- FE Credit System SyllabusDocument36 pagesFE Credit System SyllabusHarshvardhanUpadhyayPas encore d'évaluation

- Current Affairs Pocket PDF - August 2016 by AffairsCloud PDFDocument45 pagesCurrent Affairs Pocket PDF - August 2016 by AffairsCloud PDFHarshvardhanUpadhyayPas encore d'évaluation

- Alam 2016Document9 pagesAlam 2016HarshvardhanUpadhyayPas encore d'évaluation

- Examiners Information: Sr. No. Class (E.g. FE SE) Branch Name of The Subject College Name and CodeDocument2 pagesExaminers Information: Sr. No. Class (E.g. FE SE) Branch Name of The Subject College Name and CodeHarshvardhanUpadhyayPas encore d'évaluation

- BEST Question Bank - Digital ElectronicsDocument157 pagesBEST Question Bank - Digital Electronicsabhinav_pundir0% (1)

- SE SYLLABUSDocument36 pagesSE SYLLABUSHarshvardhanUpadhyayPas encore d'évaluation

- Teaching PlanDocument3 pagesTeaching PlanHarshvardhanUpadhyayPas encore d'évaluation

- Memory SystemsDocument20 pagesMemory Systemsaakasha2Pas encore d'évaluation

- Wave Theory and Antenna Course File T.E. E&TC Semester IIDocument1 pageWave Theory and Antenna Course File T.E. E&TC Semester IIHarshvardhanUpadhyayPas encore d'évaluation

- Cache OrganizationDocument23 pagesCache OrganizationHarshvardhanUpadhyayPas encore d'évaluation

- Question Bank Computer Architecture and Organization: Unit 1Document2 pagesQuestion Bank Computer Architecture and Organization: Unit 1swayam_choukseyPas encore d'évaluation

- Cache Organization 2Document22 pagesCache Organization 2HarshvardhanUpadhyayPas encore d'évaluation

- CS20120200012 16027405Document8 pagesCS20120200012 16027405HarshvardhanUpadhyayPas encore d'évaluation

- 8086 Microprocessors & Peripherals OverviewDocument31 pages8086 Microprocessors & Peripherals OverviewAbdul Qadeer100% (4)

- Photolithography Part1Document80 pagesPhotolithography Part1HarshvardhanUpadhyayPas encore d'évaluation

- Shree Ramchandra College of Engineering, LONIKAND, PUNE - 412 216Document1 pageShree Ramchandra College of Engineering, LONIKAND, PUNE - 412 216HarshvardhanUpadhyayPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Angel Turns 18 Debut ScriptDocument2 pagesAngel Turns 18 Debut ScriptChristian Jorge Lenox100% (1)

- The Experience of God Being Consciousness BlissDocument376 pagesThe Experience of God Being Consciousness BlissVivian Hyppolito100% (6)

- Limiting and Excess Reactants Lesson PlanDocument3 pagesLimiting and Excess Reactants Lesson Planapi-316338270100% (3)

- ThumbDocument32 pagesThumbdhapraPas encore d'évaluation

- D2 Pre-Board Prof. Ed. - Do Not Teach Too Many Subjects.Document11 pagesD2 Pre-Board Prof. Ed. - Do Not Teach Too Many Subjects.Jorge Mrose26Pas encore d'évaluation

- Revised Answer Keys for Scientist/Engineer Recruitment ExamDocument5 pagesRevised Answer Keys for Scientist/Engineer Recruitment ExamDigantPas encore d'évaluation

- Fiegel Kutter Idriss PDFDocument1 pageFiegel Kutter Idriss PDFAvaPas encore d'évaluation

- Proceedings of The 2012 PNLG Forum: General AssemblyDocument64 pagesProceedings of The 2012 PNLG Forum: General AssemblyPEMSEA (Partnerships in Environmental Management for the Seas of East Asia)Pas encore d'évaluation

- Residential Water Piping Installation GuideDocument28 pagesResidential Water Piping Installation GuideMunir RasheedPas encore d'évaluation

- Resume John BunkerDocument8 pagesResume John BunkerJohn BunkerPas encore d'évaluation

- A Business Development PlanDocument90 pagesA Business Development PlanRishabh Sarawagi100% (1)

- The Revival Strategies of Vespa Scooter in IndiaDocument4 pagesThe Revival Strategies of Vespa Scooter in IndiaJagatheeswari SelviPas encore d'évaluation

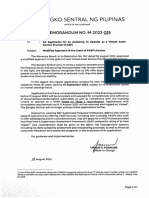

- BSP Memorandum No. M-2022-035Document1 pageBSP Memorandum No. M-2022-035Gleim Brean EranPas encore d'évaluation

- CFA三级百题 答案Document163 pagesCFA三级百题 答案vxm9pctmrrPas encore d'évaluation

- Buckling of Thin Metal Shells 58Document1 pageBuckling of Thin Metal Shells 58pawkomPas encore d'évaluation

- Otis, Elisha Graves REPORTDocument7 pagesOtis, Elisha Graves REPORTrmcclary76Pas encore d'évaluation

- 150 Most Common Regular VerbsDocument4 pages150 Most Common Regular VerbsyairherreraPas encore d'évaluation

- Jharkhand VAT Rules 2006Document53 pagesJharkhand VAT Rules 2006Krushna MishraPas encore d'évaluation

- GST Project ReportDocument29 pagesGST Project ReportHENA KHANPas encore d'évaluation

- Thompson Industrial Products Inc Is A DiversifiedDocument4 pagesThompson Industrial Products Inc Is A DiversifiedKailash KumarPas encore d'évaluation

- The Voice of PLC 1101Document6 pagesThe Voice of PLC 1101The Plymouth Laryngectomy ClubPas encore d'évaluation

- 15-8377 - 3521 Calandria Communications L. Rivera PDFDocument20 pages15-8377 - 3521 Calandria Communications L. Rivera PDFRecordTrac - City of OaklandPas encore d'évaluation

- Concept of Intestate SuccessionDocument9 pagesConcept of Intestate SuccessionBodhiratan BarthePas encore d'évaluation

- Lesson 1 Intro - LatinDocument11 pagesLesson 1 Intro - LatinJohnny NguyenPas encore d'évaluation

- Unit 3 Test A Test (Z Widoczną Punktacją)Document4 pagesUnit 3 Test A Test (Z Widoczną Punktacją)Kinga WojtasPas encore d'évaluation

- Compatibility Testing: Week 5Document33 pagesCompatibility Testing: Week 5Bridgette100% (1)

- Mar 2021Document2 pagesMar 2021TanPas encore d'évaluation

- Vdoc - Pub Parrys Valuation and Investment TablesDocument551 pagesVdoc - Pub Parrys Valuation and Investment TablesWan Rosman100% (1)

- PeripheralDocument25 pagesPeripheralMans FansPas encore d'évaluation

- ENTH 311 Course Video ReflectionDocument2 pagesENTH 311 Course Video ReflectionJeshua ItemPas encore d'évaluation