Académique Documents

Professionnel Documents

Culture Documents

Rate of Biogas Production and Quality For Selected Mixtures of Livestock Wastes

Transféré par

ijaertTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Rate of Biogas Production and Quality For Selected Mixtures of Livestock Wastes

Transféré par

ijaertDroits d'auteur :

Formats disponibles

International Journal of Advanced Engineering Research and Technology (IJAERT) 353

Volume 3 Issue 11, November 2015, ISSN No.: 2348 8190

RATE OF BIOGAS PRODUCTION AND QUALITY FOR SELECTED

MIXTURES OF LIVESTOCK WASTES

G. M. N. Ngunjiri1*, P. M. Ndungu2. , D.M. Nyaanga1, R. M. Wambua1

1

Department of Agricultural Engineering, Egerton University, Kenya

2

Department of Industrial & Energy Engineering, Egerton University, Kenya

Abstract

This research was conducted at Egerton University, Njoro, Kenya. The main objective of the research was to

investigate the rate and quality of biogas generation of co-digesting cow dung with sheep droppings (CS) and cow

dung with chicken droppings (CC) compared to cow dung alone (CA). Mixture ratios of CS and CC studied were 9:1,

7:3, 1:1, 3:7 and 1:9. Generally, all mixture ratios of CS and CC showed improved biogas generation and quality

compared to CA. For the retention time of 28 days, the mixture ratio of 7:3 for CC and CS respectively, recorded the

highest biogas productions of 17.0 and 13.3 m3 compared to 6.0 m3 for CA. Methane content in the biogas for the

same ratios averaged 54% for CC and 58% for CS while it was 55% for CA. Significant improvement for biogas

quality was observed for CC and CS for the ratios 3:7 and 1:9 with methane contents above 64% for CC and above

62% for CS.

Key words: Substrate mixtures, biogas, percent methane content, cow dung, chicken and sheep droppings.

1. INTRODUCTION

Pure methane (CH4) has a calorific value of 2.167MJ/m3 while calorific value of biogas varies from 1.142 1. 643MJ

/m3 (FAO, 1997). Compared to the common liquid fossil fuels, 1.33 - 1.87; and 1.5 - 2.1 m3 of biogas, are equivalent

to one liter of petrol and diesel, respectively (Fulford, 2001). Biogas has an approximate specific gravity of 0.86 and

low flame speed factor. The flame is therefore unstable and will tend to lift off burners which are not properly

designed (ITDG, 2006).

Biogas is formed when bacteria anaerobically decompose organic materials such as; livestock droppings, farmyard

manure, organic waste materials, slaughter house waste and others. It is a mixture of about 60% methane and 35%

carbon dioxide with traces of other gases (Legget et al., 2006). Any anaerobic decomposition releases methane which

is a greenhouse gas and a major contributor to global warming problem (Legget et al., 2006 and Jenkins, 1999).

Biogas is a clean burning, colourless and odourless gas. It can be used for cooking, lighting, heating and running

engines for electricity generation. This has already been done on large scale in countries like China, India and Nepal

(Fulford, 2001 and Jawurek, 1987). Biogas programmes in Asian countries have had teething problems. Korea had

30,000 plants in 1979, but problems with poor gas production in Koreas cold winters reduced the impetus (GATE,

1999; Ravindranath and Hall, 1995). Thailand has had small biogas study programmes for many years but an adequate

supply of other fuels resulted in slow growth in the extension of biogas to rural areas (Fulford, 2001 and Teri, 1994).

Escalating cost of imported fuels encouraged Brazil, along with other South American nations to start bio-fuel and

biogas programmes. Between 1980 and 1985, Brazil built 7,530 biogas plants (ITDG, 2006 and Vanburgel and

FLorison, 2006).

Kenya has traditionally relied on imported petroleum to meet 75% of its commercial energy needs which drains a

significant proportion of foreign exchange (ITDG, 2006). The country was classified as a prospective fuel deficit area

(FAO, 1981). The status of energy in the country as at the year 2010 is that, 92% of electricity is generated using

renewable energy sources that is 72% hydroelectricity, 20% geothermal and 8% thermal diesel generated (Jellyfish,

2010). The country however, produces far less energy than its capacity. It is argued that because 60% to 90% of the

population is not connected to the national grid electricity, many people, especially in rural areas resort to firewood

and charcoal which is harmful to our environment because of loss of forest cover and desertification (Jellyfish, 2010).

Wood fuel (firewood and charcoal) is the largest form of primary energy consumed, accounting for 68% of total

energy needs in the country (MOE, 2006). In the year 2000, the wood fuel demand stood at 34.3 million tonnes

compared to established sustainable supply of 15 million tonnes, thereby indicating a deficit of 56% (MOE, 2006).

Demand was established to be growing at 2.7% per year, while sustainable supply was growing at a slower rate of 0.6

% (MOE, 2006). It is therefore necessary to search for other sources of energy. This study aims at establishing the

effects of selected livestock mixtures on the rate of biogas production and quality. Many Kenyan rural homesteads

own cattle, chicken, sheep and/or goats. The study therefore was conducted on various mixture ratios of cow dung and

www.ijaert.org

International Journal of Advanced Engineering Research and Technology (IJAERT) 354

Volume 3 Issue 11, November 2015, ISSN No.: 2348 8190

sheep droppings, CS; and, cow dung and chicken droppings, CC. Biogas production and quality for the mixtures were

compared to the production and quality of biogas from cow dung alone, CA.

Cheruiyot et al., (2009), studied the behaviour and performance of plastic biogas digesters using cow dung under

natural and greenhouse conditions and suggested further studies on a variety of substrates such as chicken waste, pig

waste, sheep and goat droppings or combinations of these. Laura and Idnani (1991) had found that the quantity and

quality of biogas was increased by addition of small amounts of cane sugar, urea or calcium carbonate to fresh

cowdung. Addition of urine also increased gas production over cowdung alone and the percentage of methane in the

biogas was raised from 54% to 70% by these additives.

A study of the effect of mixing pig manure and cowdung on biogas yield showed that co-digestion of cowdung with

pig manure increased the biogas yield as compared to pure samples of either pig or cowdung perhaps suggesting a

possibility of synergistic effect among the waste (Kasisira and Muyiiya, 2009). The maximum increase of almost

seven and three fold of pure cowdung and pig dung was respectively achieved when pig manure and cowdung were

mixed in proportions of 1:1. Inglis and Gooch (2007) studied the effects of co-digesting cow dung and food waste and

concluded that, Consistent feeding of small amounts of substrate appears to be a better strategy for mixed digesters

than larger amounts of influent over a shorter period of time. Another study conducted by Abadeyo et al., (2012) on

co-digesting cow dung waste and maize combs showed increased biogas and methane generation compared to cow

dung alone. There are indications that there could be synergistic effect in both quantity and quality of biogas when

cowdung is co-digested with other animal and plant wastes but the right ratios are unknown. It was therefore important

to find out if co-digesting cowdung with other substrates at ratios would increase biogas quantity and quality.

The rate of biogas production and proportion of methane to carbon dioxide in any digestible biomass depends on

substrate and may be predicted by equation 7:-

Where the subscripts x, y and z are numbers used to balance the atoms in the equation for the respective elements.

Measuring the methane content in the biogas and the volume of the gas produced per unit of organic matter of the

substrate including the total solids (TS) and volatile solids (VS) indicates the state of digestion process.

Typical gas composition for carbohydrate feedstocks are 55% methane, 40% carbon dioxide and 5% trace gases

while for fats the gas contains as much as 68% methane (Mursec et al., 2009). Biogas contains combustible and noncombustible gases. Table 1, shows the biogas yield of some domestic animals waste.

Table 1: Methane yield from some domestic animals waste

Animal

Typical gas yield/Kg)

CH4 %

CO2 %

of manure

Cattle

200-350lts

57.4

36.5

Poultry

550 -650lts

70.0

30.0

Pig

400-500lts

65.0

35.0

(Adopted from Abdulkareem, 2005)

Thermal content

MJ/m3

23

28

26

2. MATERIALS AND METHODS

Experimental set up

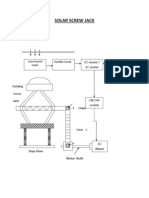

The digesters consisted of 11 units which served to produce gas from the substrates. Figure 1 shows the schematic

diagram of the experimental set up. The basic set up consisted of a 20 liter plastic container, 5 liter displacement bottle

and a measuring conical flask all connected through rubber and capillary tubes. At the top of the experimental digester

a plastic cork with a well fitting capillary tube was used to close the outlet. The lid was then sealed using reinforced

plastic resin. The well fitting plastic and capillary tubes were used to connect the digester via a release valve to the 5

liter displacement bottle filled with water to capacity. The displacement bottle was then connected through one of the

capillary and plastic tubing to the graduated conical flask. Eleven units of digesters were each filled with 13.3 liters of

the respective substrates. All substrates were diluted with water to a consistency of about 11% total solids. The

substrates mixtures for each digester were thoroughly mixed by a handle rotated by hand to make them homogenous.

Biogas production:

Biogas yield was measured daily using the displacement method. A five-liter plastic bottle was filled with water to

capacity and connected to a graduated conical flask for each treatment (digester). The pressure of the gas from the

www.ijaert.org

International Journal of Advanced Engineering Research and Technology (IJAERT) 355

Volume 3 Issue 11, November 2015, ISSN No.: 2348 8190

digester forced water to flow from the plastic bottle into the conical flask graduated in milliliters. A valve placed in

between the digester and the displacement bottle was open for gas measurement at a specific time and closed after all

the gas for each day was exhausted. The volume of water displaced represented the volume of gas generated in one

day for each treatment (Plate 1).

Figure 1: Schematic representation of the experimental set up

Plate 1: Experimental set up showing biogas collection system

Quality of biogas:

Biogas composition was determined on the 17th day of the retention period for each substrate. A gas chromatograph,

GC, as shown on Plate 2 was used to analyze the gas. The procedure involved extracting gas samples using syringes

from the experimental digesters and injecting the same into the chromatograph. The carrier gas (nitrogen) in the

chromatograph then swept the gas sample injected into the capillary column packed with the stationary phase. The

column has high boiling point and interacts with the sample while separating it into various components. The gases

with least affinity for stationary phase were exited first. The separated gaseous compound was then carried into the

detector unit known as the flame ionization detector (FID). The FID identified the various gaseous compounds present

in the sample according to their retention times. The monitoring unit (a computer) then picked up the detected gases.

Plate 2: Gas chromatograph

www.ijaert.org

International Journal of Advanced Engineering Research and Technology (IJAERT) 356

Volume 3 Issue 11, November 2015, ISSN No.: 2348 8190

Presence of methane in the biogas was also subjectively tested by lighting the gas released which burned easily on the

burner. It was however not possible to quantify the composition of gases using this method. In this case, it can be

concluded that, the gas contained more than 50% methane since it burned with ease (Fulford, 2001).

Data analysis:

Analysis of variance was run for the biogas yields and quality. An F-test was used for hypothesis testing at 95%

confidence level. The F-values, for the parameters studied, were obtained by dividing the mean squares of gas yields

by the error mean squares. The calculated F-values were compared with tabulated/critical F-values to decide whether

to accept the alternative hypothesis of difference or the null hypothesis. If the null hypothesis was not rejected the

analysis was concluded but if the null hypothesis was rejected then a t-test was used to determine Fishers least

significance difference. Scatter points of mean gas yields were plotted for the corresponding time in (days) of the

observations and a polynomial regression fitted to predict how well the coefficient of determination (r 2) explained the

trend.

3. RESULTS AND DISCUSSIONS

Biogas Production

The weekly daily means gas produced by the mixture ratios for cow dung to chicken droppings, cow dung to sheep

droppings and cow dung alone are shown in Table 2. They ranged from 236 to 1,104 ml/day, 243 to 814ml/day for CC

and CS respectively and that of cow dung alone ranged from 202 to 398ml/day. From the table, it is evident that

weekly gas production was highest and significantly different ( < 0.05) on the third week for all mixture ratios. The

results also indicate a general increase in total gas produced by the mixture ratios in comparison with cow dung alone.

This shows that mixing of the substrates improved the population of bacteria and growth conditions. It is an indication

of availability of an optimum mixture level where the conditions are favorable.

Table 2: Weekly daily mean gas production (ml/day) for the different mixture ratios

Week

Ratio

9:1

7:3

5:5

3:7

1:9

CC

CS

CC

CS

CC

CS

CC

CS

CC

CS

1

0d

0d

0d

0d

0d

0d

0d

0d

0d

0d

c

b

b

c

c

b

b

b

a

2

324

352

761

403

240

254 304

243

615

403c

a

a

a

a

a

a

a

a

b

3

612

438

1,104

814

653

483 496

586

399

637a

b

b

c

b

b

a

a

a

c

4

433

448

574

505

409

491 581

571

236

590b

lsd

95.5

29.8

95.5

29.8

95.5

29.8 95.5 29.8 95.5

29.8

Means with the same superscript in the same column are not significantly different ( < 0.05)

Key: CC= Cow dung to Chicken droppings; CS = Cow dung to Sheep droppings

10:0

CA

0d

202b

398a

267b

29.8

The cumulative total means of gas produced for the entire hydraulic retention period (28 days) for each mixture ratio

are presented in Table 3.

The highest gas production per retention period was by 17.00 m3 for the ratio 7:3 of CC compared to 6.04 m3 for cow

dung alone (CA). The lowest was by 8.52 m3 for the ratio 9:1 of CS. The mean daily gas produced was between

0.34m3 to 0.61m3 for the CC, and varied from 0.31 m3 to 0.48 m3 for the CS, while that for CA was 0.22m3. Table 4

shows, the maximum daily gas production (ml/day) for the mixture ratios.

Table 3: Daily and Total gas production (m3) per retention time (28days)

Mixture

Ratio

9:1

7:3

1:1

3:7

1:9

CC

Total

10.37

17.00

9.52

11.54

9.56

Daily

0.37

0.61

0.34

0.41

0.34

SC

Total

8.52

13.29

8.85

9.87

11.74

Daily

0.31

0.48

0.32

0.35

0.42

1:0

6.04

0.22

6.04

0.22

Table 4: Maximum daily gas production (ml/day) for the mixtures CC and CS

Mixture

Ratio

1:9

7:3

1:1

3:7

1:9

CC

674

1,223

680

714

860

CS

521

854

555

638

692

www.ijaert.org

Mean

10.67

0.38

9.72

0.35

1:0

454

454

International Journal of Advanced Engineering Research and Technology (IJAERT) 357

Volume 3 Issue 11, November 2015, ISSN No.: 2348 8190

The daily variation of gas produced for each mixture ratios (CC, CS & CA) showed significant differences at < 0.05

for each day. The results also show that, the ratio 7:3 of CC had the highest gas production of 1,223 ml/day. The

highest mean gas production for CS was 854 ml/day for the ratio 7:3 and the lowest was 454 ml/day for the ratio 1:0

(CA). This showed a similar pattern in gas production for both mixtures with increase in chicken or sheep droppings.

This suggests that there is a certain mixture level at which the conditions are optimum for enhancing maximum gas

production as earlier noted.

Figures 1 and 2 show the daily variation of gas produced for some mixture ratios. The variation shows respective peak

values are obtained followed by a general decline. There are noticeable subsidiary oscillations in the gas produced for

some ratios. This could be due to breakdown of easily digestible materials such as fats, sugars and carbohydrates

while the lower gas produced could be due to less digestible materials such as cellulose and lignin.

The scatter lines for the ratios 7:3 and 1:9 follow the same pattern though the ratio 1:9 was at a much lower level than

the ratio 7:3. This suggest similar pattern in the bacteria activity of the substrates for both the ratios. The results agree

with the findings of Maramba (1978) and Chowdhurry (1987), who observed that, there are two regions of higher rate

of biogas production at short times of at least 22 days, and lower production at longer times of 32 days.

Figure 1: Daily variation of gas produced for mixture ratios CC and CA

Figure 2: Daily variation of gas produced for the mixture ratios CS and CA

www.ijaert.org

International Journal of Advanced Engineering Research and Technology (IJAERT) 358

Volume 3 Issue 11, November 2015, ISSN No.: 2348 8190

The findings are further confirmed by the results obtained for the gas production to reach the peak for each mixture

ratio as shown in Table 5. The gas production for the mixture ratios of cow dung to chicken droppings indicate that the

peak production was achieved between the 13th and the 21st day. The ones for cow dung to sheep droppings indicate

that the peak production was achieved between the 20th and the 23rd day. This implies that the mixture and ratios of

CC had more easily digestible materials and at shorter time periods than that of CS.

Table 5: Time taken (days) for the Mixture ratios to reach the peak gas production

Mixture

Ratio

1:9

7:3

1:1

3:7

1:9

CC

21

14

19

18

13

CS

23

20

23

23

23

1:0

20

20

Quality of Biogas:

The results of gas quality for each of the substrate mixture ratio are indicated in Table 6. The quality of biogas is

determined by the composition of gases which is mainly a mixture of Methane (CH 4); 40-70%, carbon dioxide (CO2)

30-60% and trace gases; of 1-5% (Hoetz et al., 2006). The mean values of methane from the ratios of CC ranged from

57 to 65%.

Table 6: Composition of Biogas from CC and CS substrate mixture at different ratios

Ratio

CC

CS

CH4

CO2

Trace gases

CH4

CO2

Trace gases

1:0

55.0g

38.7a

6.3

55.0c

38.7a

6.3

9:1

57.2e

34.5c

8.3

55.8c

34.6c

9.6

g

c

b

c

7:3

54.4

34.8

6.0

58.2

33.9

8.0

1:1

61.0c

34.2c

5.0

59.2b

34.0c

6.8

3:7

63.7a

32.1d

3.9

62.2a

32,2d

5.5

1:9

65.4a

32.0d

2.6

62.6a

32.3d

5.1

LSD

1.95

2.41

1.35

2.44

Means in the same column followed by the same letter are not significantly different, < 0.05

These values are lower than those reported in the literature for poultry of 70% (Table 1). Percent methane observed for

cow dung alone was 55%. The variation in methane content may be as a result of mixing of the two substrates which

may have enhanced the gas content. The methane content for cow dung to sheep droppings averaged from 56 to 63%.

These values were lower than that of sheep droppings alone of 64% and higher than that of cow dung alone. The

apparent difference may be attributed to the mixing of the two substrates as reported earlier. It was difficult to make

the system air tight; this may have contributed to dilution of the biogas, hence the lower methane content. Stucky

(1983) has reported that the content of methane in the biogas is affected by temperature as well as pressure and

oxidation state of the carbon in the substrate. These parameters may also have played part in the apparent differences

since they were not controlled.

Conclusions and Recommendations:

The study was primarily conducted to study the effects of the rate of biogas production and quality for selected

livestock waste mixtures. It was observed that, biogas production and quality for mixture ratios of cow dung with

chicken droppings (CC) and cow dung with sheep droppings (CS) averaged higher than for cow dung alone (CA).

Biogas yield for CC and CS were 0.41m3/day and 0.38m3/day compared to 0.22m3/day for CA. The results obtained in

the research showed that, methane content in the biogas for the mixture ratios averaged 61% and 60% for CC and CS

respectively, while that of CA was 55%. From the foregoing therefore, it can be concluded that, mixing cow dung with

chicken droppings and with sheep droppings improved both the quantity and quality of biogas generated. These

findings also compare well with those of Kasisira and Muyiiya, (2009); Inglis and Gooch (2007); and Abadeyo et al.,

(2012); who respectively, reported improved biogas production on co-digestion of cow dung with pig manure; cow

dung and food waste; and cow dung with maize cobs.

This research considered mixing of only cow dung with chicken and sheep droppings one at a time. It did not consider

using other wastes or mixtures of more than two wastes. It is thus recommended that, further research could be done to

study biogas production of cow dung with other substrates of animal and plant origin such as pig waste, tea waste,

www.ijaert.org

International Journal of Advanced Engineering Research and Technology (IJAERT) 359

Volume 3 Issue 11, November 2015, ISSN No.: 2348 8190

coffee waste, water hyacinth and wheat husks to mention but a few. Also, further research could be conducted using

mixtures of more than two substrates.

REFERENCES

[1] Adebayo, A.O., Jekayinfa, S.O. and Linke, B. (2012). Effect of Co-Digestion on biogas Production-A case study

of Cow Slurry with Maize Cob. Paper presented at the 2012 ASABE Annual International Meeting held at Dallas,

Texas (July 29 August 1, 2012)

[2] Abdulkreem, A. S. (2005). Refining biogas produced from biomass,an alternative to cooking gas. Leonardo

journal of sciences, Issue 7; pp1-8

[3] Cheruiyot, P.K., Ngunjiri, G.M.N., Ndiema, M.C., Chemelil, R and Wambua, M (2009). Effect of ground

insulation and Greenhouse micoenvironment on the rate and quality of biogas production. Botswana Jounal of

Technology; Vol 18, No. 2; pp 1 11

[4] Chowdhurry, R. (1987). Kinetics of anaerobic digestion, comparing performance of batch and semi - continuous

systems; M. phil. Thesis, University of Reading

[5] FAO (Food and Agricultural Organization). (1997). Renewable biological systems for alternative Sustainable

energy production: Agricultural Services Bulletin No.128; Rome

[6] FAO (Food and Agricultural Organization). (1981). Map of fuel wood situation in the Developing. Countries

.Global survey carried out by FAOs Forestry Department

[7] Fulford, D. (2001). Running a Biogas Programme Handbook, ITDG publication London.

[8] GATE (Deutsches Zentrum fur Entwicklungstechnologien). (1999). Biogas technology in Orissa, India.

Eschborn, German

[9] Hoerz, T., Kramco, P., Klingler, B. (2006). Information and advisory service on Appropriate Technology (ISAT);

German Agency for Technical Co-operation

[10] Inglis, F.S. and Gooch A.C. (2007). Biogas Production Fluctuations Associated with Feeding Frequency for a

Mixed Digester. Paper presented at the Sixth International Dairy Housing Conference Proceeding 16-18 June 2007,

(Minneapolis, Minnesota, USA): ASABE Publication Number 701P0507e

[11] ITDG (Intermediate Technology Development Group). (2006). Biogas and Liquid Biofuels; Technical brief

publication Britain

[12] Jenkins, J. (1999). The Humanure Hand Book. Guide to composting human manure Chelsea Green Publishing,

New yolk, USA

[13] Jellyfish, C. B. (2010). Future green for Kenya. < http://laketurkanawindpower.com Accessed on 15/12/2010

[14] Jawurek, H., Lane, W and Rallis, J. (1987). Biogas/Petrol dual Fueling of SI Engine for Third World Use

Biomass

[15] Kasisra, L. L. and Muyiira, D. (2009). Batch co-digestion of multi-component Agro-wastes; Agricultural

Engineering International; The CIGR Journal; Vol.X1,80,19

[16] Laura, R.D and Idnani, M. A. (1991). Increased production of biogas from cowdung by adding other

Agricultural waste: Material Journal of science; Vol 11; 286 -289

[17] Legget, J., Graves, R. and Lanyon, E. (2006). Biogas Production and Odor Reduction From Manure;

Agricultural and biological Engineering Department, College of Agricultural Sciences, Pennsylvania State University,

USA.

[18] Maramba, F. D. (1978). Biogas and waste recycling, the Philippines experience; Liberty Flour Mills Inc., Metro

Manila, Philippines

[19] Mursec, B., Vindis, P., Janzecovic, M., Brus, M and Cus, F. (2009). Analysis of different substrates for

processing into biogas: Journal of achievement and Manufacturing Engineering 37/2 652-659

[20] Ravindranath, N. H. and Hall, D. O. (1995). Biomass, Energy and Environment: A Developing country

perspective from India; Oxford University Press

[21] Stuckey, D.C. (1983). Biogas in developing countries; A critical appraisal in proceedings of Third International

Symposium on anaerobic digestion; Boston, USA

[22] Teri, N (1994). Biogas, a source of rural employment; Tata Energy Research Institute;

http://www.ee.tata.en.si/2004/systems/pdf; Accessed on 10/23/2014

[23] Vanburgel, M. and Florison, O. P. (2006). Biogas and others in natural gas operation; 23rd world gas

conference proceedings, Amsterdam

www.ijaert.org

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Engine System FundamentalsDocument17 pagesEngine System FundamentalsJha PuiPas encore d'évaluation

- Neutral GroundingDocument9 pagesNeutral Groundingmspd2003Pas encore d'évaluation

- Advancement in Knitted Structure For Industrial Applications - A ReviewDocument8 pagesAdvancement in Knitted Structure For Industrial Applications - A ReviewijaertPas encore d'évaluation

- Siemens Gas Turbine SGT 500 Crude OilDocument10 pagesSiemens Gas Turbine SGT 500 Crude Oilgeverett2765Pas encore d'évaluation

- Induction MotorDocument44 pagesInduction MotorCalvert Wong100% (1)

- Smart GridDocument20 pagesSmart GridPrabir Kumar PatiPas encore d'évaluation

- Presentation Sustainable Buildings and Green MarketsDocument32 pagesPresentation Sustainable Buildings and Green MarketsVeenoyPas encore d'évaluation

- PTI Energy PolicyDocument52 pagesPTI Energy PolicyPTI Official100% (9)

- Electric Power CablesDocument6 pagesElectric Power CablesVENKATESAN RPas encore d'évaluation

- MUJ PSA Assignment-I Power System Analysis (EEE1505)Document7 pagesMUJ PSA Assignment-I Power System Analysis (EEE1505)Denish Gupta0% (1)

- Physics Project On Dual Axis Solar TrackerDocument10 pagesPhysics Project On Dual Axis Solar TrackerDanish AhamedPas encore d'évaluation

- Advanced Power Electronic For Wind-Power Generation Buffering (TH., Alejandro Montenegro León)Document194 pagesAdvanced Power Electronic For Wind-Power Generation Buffering (TH., Alejandro Montenegro León)bubulescuPas encore d'évaluation

- Academic Writing Skills Level2 Students Book Unit1 Sample PagesDocument8 pagesAcademic Writing Skills Level2 Students Book Unit1 Sample PagesAlexandru BalaucaPas encore d'évaluation

- Detection of Melanoma Using Asymmetric FeaturesDocument7 pagesDetection of Melanoma Using Asymmetric FeaturesijaertPas encore d'évaluation

- Simulation and Analysis of LLC Resonant Converter Using Closed Loop PI ControllerDocument3 pagesSimulation and Analysis of LLC Resonant Converter Using Closed Loop PI ControllerijaertPas encore d'évaluation

- Geological/survey of Clay MaterialDocument9 pagesGeological/survey of Clay MaterialijaertPas encore d'évaluation

- A Review On Ceramics and Its Economic EmpowermentDocument4 pagesA Review On Ceramics and Its Economic EmpowermentijaertPas encore d'évaluation

- Changes in The Physical State of Ceramics Materials Brought About by The Removal of Free WaterDocument5 pagesChanges in The Physical State of Ceramics Materials Brought About by The Removal of Free WaterijaertPas encore d'évaluation

- Design of Robust Type-2 Fuzzy Logic Power System Stabilizer Using Hopf BifurcationsDocument5 pagesDesign of Robust Type-2 Fuzzy Logic Power System Stabilizer Using Hopf BifurcationsijaertPas encore d'évaluation

- A Review On Synthesis, Characterization and Applications of Silica ParticlesDocument7 pagesA Review On Synthesis, Characterization and Applications of Silica ParticlesijaertPas encore d'évaluation

- Characterization of Ezzodo Clay Deposit For Its Industrial PotentialsDocument8 pagesCharacterization of Ezzodo Clay Deposit For Its Industrial PotentialsijaertPas encore d'évaluation

- Feature Selection Approach For Intrusion Detection System Based On Pollination AlgorithmDocument5 pagesFeature Selection Approach For Intrusion Detection System Based On Pollination AlgorithmijaertPas encore d'évaluation

- Optimization of Gear To Improve Performance of GearboxDocument4 pagesOptimization of Gear To Improve Performance of Gearboxijaert100% (1)

- Comparative Study of End Moments Regarding Application of Rotation Contribution Method (Kani's Method) & Moment Distribution Method For The Analysis of Viaduct FrameDocument5 pagesComparative Study of End Moments Regarding Application of Rotation Contribution Method (Kani's Method) & Moment Distribution Method For The Analysis of Viaduct FrameijaertPas encore d'évaluation

- Structural Optimization of Composite Railway SleepersDocument6 pagesStructural Optimization of Composite Railway SleepersijaertPas encore d'évaluation

- Analysis of Gable Frame StructureDocument7 pagesAnalysis of Gable Frame Structureijaert50% (2)

- Comparative Analysis On Partial Replacement of Cement by Metakaolin and Fine Aggregate by Granite PowderDocument5 pagesComparative Analysis On Partial Replacement of Cement by Metakaolin and Fine Aggregate by Granite PowderijaertPas encore d'évaluation

- Behaviour of Concrete Partially Replacement of Cement by Steatite and Polypropylene FibreDocument4 pagesBehaviour of Concrete Partially Replacement of Cement by Steatite and Polypropylene FibreijaertPas encore d'évaluation

- ARPAE AeroMINEs 2018 SANDDocument2 pagesARPAE AeroMINEs 2018 SANDJofi001Pas encore d'évaluation

- V.Senthil Me WWW - Chennaituitions.in: Page 1 of 6Document6 pagesV.Senthil Me WWW - Chennaituitions.in: Page 1 of 6saranyakathiravan100% (1)

- Water Turbines PDFDocument146 pagesWater Turbines PDFMuhammad IrfanPas encore d'évaluation

- Tank Mounted Compressors LiteratureDocument2 pagesTank Mounted Compressors LiteratureRoger AklPas encore d'évaluation

- EEE259 Electrical Drives and Controls QBDocument10 pagesEEE259 Electrical Drives and Controls QBkannanchammyPas encore d'évaluation

- Geography Grade 8 2nd Term SOS - 2022-23Document2 pagesGeography Grade 8 2nd Term SOS - 2022-23mohammad abdurehmanPas encore d'évaluation

- Renewable Energy Research Report PDFDocument31 pagesRenewable Energy Research Report PDFOmar AwalePas encore d'évaluation

- dfc3000 Product Specifications1Document2 pagesdfc3000 Product Specifications1api-249329561Pas encore d'évaluation

- 250 MW Fuel Cell PlantDocument2 pages250 MW Fuel Cell PlantGomolemoGumzNtlailanePas encore d'évaluation

- Fiamm Res2 Datasheet EngDocument2 pagesFiamm Res2 Datasheet EngsyPas encore d'évaluation

- Solar Screw JackDocument6 pagesSolar Screw JackJeevan Landge PatilPas encore d'évaluation

- DS LT 110eu June 2004Document2 pagesDS LT 110eu June 2004Anicas AniffPas encore d'évaluation

- Integrated Resource Plan For St. Lucia, Bermuda-Energy-Summit, 11-2017Document30 pagesIntegrated Resource Plan For St. Lucia, Bermuda-Energy-Summit, 11-2017Detlef LoyPas encore d'évaluation

- GEI90368 F 1Document8 pagesGEI90368 F 1Fahim KazmiPas encore d'évaluation

- Cav PDFDocument6 pagesCav PDFshandediaz1600Pas encore d'évaluation

- On Developments On Solar Cookers 160213040826Document10 pagesOn Developments On Solar Cookers 160213040826Vishal KundalPas encore d'évaluation

- Prism 3 RWDocument201 pagesPrism 3 RWPhuongThuy Dang ThiPas encore d'évaluation

- The Low-Cost Vertical Axis Wind Turbine Project AnDocument13 pagesThe Low-Cost Vertical Axis Wind Turbine Project Anpomoc.pri.izradi.radaPas encore d'évaluation