Académique Documents

Professionnel Documents

Culture Documents

Anaerobic Baffled Reactor (ABR)

Transféré par

Anastasya Putri SafinaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Anaerobic Baffled Reactor (ABR)

Transféré par

Anastasya Putri SafinaDroits d'auteur :

Formats disponibles

11/23/2015

AnaerobicBaffledReactor(ABR)

Anaerobic Baffled Reactor (ABR)

Published on SSWM (http://www.sswm.info/)

Anaerobic Baffled Reactor (ABR)

Compiledby:

Eawag(SwissFederalInstituteof

AquaticScienceandTechnology),

DorotheeSpuhler(seecon

internationalgmbh)

An anaerobic baffled reactor (ABR) is an improved [879Septic Tank]

with a series of baffles under which the [noecompendium]grey,

black or the industrial [/noecompendium]wastewater is forced to

flow[noecompendium] under and offer the baffles from the inlet to

the outlet[/noecompendium]. The increased contact time with the

active biomass (sludge) results in improved treatment. [no

ecompendium]ABRs are robust and can treat a wide range of wastewater, but both remaining sludge and

effluents still need further treatment in order to be reused or discharged properly. [/noecompendium]

In

Out

Blackwater, Greywater, Brownwater, (Faecal Sludge) Fertigation Water, Biogas, Compost/Biosolids

[noecompendium]

Introduction

Anaerobic baffled reactors (ABR) are septic tanks that have been upgraded with a series of baffles along the

treatment chamber. [/noecompendium]The upflow chambers provide enhanced removal and digestion of

organic matter.[noecompendium] As septic tanks, ABRs are based on a physical treatment (settling) and a

biological treatment (anaerobic digestion).

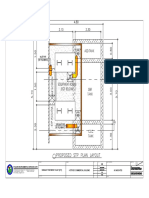

Schematic of the Anaerobic Baffled Reactor. Source: TILLEY et al. (2014).

An ABR consists of a tank and alternating hanging and standing baffles that compartmentalise the reactors and force

liquid to flow up and down from one compartment to the next, enabling an enhanced contact between the fresh

http://www.sswm.info/print/848?tid=934

1/7

11/23/2015

AnaerobicBaffledReactor(ABR)

wastewater entering the reactor and the residual sludge, containing the microorganisms responsible for anaerobic

digestion of the organic pollutants. The compartmentalised design separates the solids retention time from the

hydraulic retention time, making it possible to anaerobically treat wastewater at short retention times of only some

hours (EPA 2006). Solids high treatment rates are high, while the overall sludge production is characteristically low

(FOXON et al. 2004). They are simple to build and simple to operate, as well as very robust to hydraulic and organic

shock loading (SASSE 1998). Yet, both sludge and effluent still need further treatment.

DecentralizedWastewaterManagementatAdarshCollegeBadalapurMaharashtraIndia. Source:SUSANA2010

ABRs are suitable for a wide range of wastewater, including highstrength industrial wastewater, but its efficiency

increases with higher organic load. Therefore, ABRs are particularly suited for influents with a high percentage of

nonsettleable suspended solids and a narrow COD/BOD ratio (SASSE 1998). ABRs are typically applied in DEWATS,

usually in combination with several other treatment steps. A typical DEWATS could be a five component system of

first three anaerobic steps consisting of a biogas settler; an ABR and an anaerobic filter; followed by an aerobic

treatment unit such as a constructed wetland (FreeWater Surface CV, Horizontal Subsurface Flow CV or Vertical Flow

CV) and a maturation pond (WHO 2009).[/noecompendium] BOD may be reduced by up to 90%, which is far superior to

its removal in a conventional Septic Tank.

DesignConsiderations

[noecompendium]ABRs are a combination of the principles of septic tanks, moving bed reactors and upflow

anaerobic sludge blanket reactors. The difference to MBRs and UASBs lies in the fact that it is not necessary

for the sludge blanket to float; and that effluent retention is not necessary since a part of the active sludge

that is washed out from one chamber is trapped in the next (SASSE 1998). [/noecompendium]The majority of

settleable solids are removed in a sedimentation chamber in front of the actual ABR. Smallscale standalone

units typically have an integrated settling compartment, but primary sedimentation can also take place in a

separate Settler or another preceding technology (e.g., existing Septic Tanks). Designs without a settling

compartment are of particular interest for (Semi) Centralized Treatment plants that combine the ABR with

other technologies, or where prefabricated, modular units are used.

Typical inflows range from 2 to 200 m3 per day. Critical design parameters include a hydraulic retention time

(HRT) between 48 to 72 hours, upflow velocity of the wastewater below 0.6 m/h and the number of upflow

chambers (3 to 6). The connection between the chambers can be designed either with vertical pipes or baffles.

Accessibility to all chambers (through access ports) is necessary for maintenance. Usually, the biogas produced

in an ABR through anaerobic digestion is not collected because of its insufficient amount. The tank should be

vented to allow for controlled release of odorous and potentially harmful gases.[noecompendium]

The reactor always starts with a settling chamber for larger solids and impurities (SASSE 1998) followed by a

series of at least 2 (MOREL & DIENER 2006), sometimes up to 5 (SASSE 1998) upflow chambers. The

wastewater enters the chambers at the bottom and needs to pass through the sludge to move up and to the

next compartment. Thereby particles settle against the upstream (SASSE 1998). As the wastewater passes

through the sludge, intensive contact between the active biomass in the resident sludge and newly incoming

wastewater occurs. To equally distribute the entering liquid in the chambers, they should be designed as

relatively short compartments (< 75 cm of length and < 50% to 60% of the height, SASSE 1998). To retain any

possible scum formed in the upflow chamber, the outlets of each tank as well as the final outlet should be

http://www.sswm.info/print/848?tid=934

2/7

11/23/2015

AnaerobicBaffledReactor(ABR)

placed slightly below the liquid surface (SASSE 1998).

The upflow velocity is the most crucial parameter for dimensioning, especially with high hydraulic loading. It

should not exceed 2.0 m/h (SASSE 1998; MOREL & DIENER 2006). Based on a given HRT, the upflow velocity

increases in direct relation to the reactor height. Therefore, the reactor height cannot serve as a variable

parameter to design the reactor for the required HRT. The limited upstream velocity results in large but

shallow tanks. It is for this reason that the baffled reactor is not economical for larger plants (SASSE 1998).

The organic load should be below 3 kg COD/m3/day. Higher loadingrates are possible with higher temperature

and for easily degradable substrates (SASSE 1998).

During the anaerobic digestion, biogas is produced, which can be recovered and reused in the kitchen or for

driving pumps and other equipment when necessary. Methane concentration increases steadily from the first

compartment to the last (WANG et al. 2004). The methane producing activity of anaerobic sludge in different

compartments depends on the substrate, which suggests that the proper anaerobic consortium in each separate

compartment develops in accordance to the substrate available and the specific environmental conditions

(WANG et al. 2004). The use of the produced biogas in the kitchen might be the most realistic and easiest way

to reuse the biogas in decentralised systems. If the gas is not recovered, the tanks need to be vented to

prevent the release of the potentially harmful gases (TILLEY et al. 2008).

To increase the treatment efficiency (especially regarding pathogens), the last chamber may be an anaerobic

filter (WSP 2008).[/noecompendium]

[noecompendium]

Treatment performance

Construction of different toilet blocks connected to two prefabricated fibreglass reactor comprising a settling chamber, an aerobic

baffled reactor and a final anaerobic filter unit. Source: BORDA (2009)[/noecompendium]

[noecompendium]Treatment performance of ABRs is in the range of 65% to 90% COD (Chemical Oxygen

Demand) removal, corresponding to about 70% to 95% of BOD (Biological Oxygen Demand) (SASSE 1998; MOREL

& DIENER 2006; BORDA 2008). This is far superior to that of a conventional septic tank (30 to 50 %, UNEP

2004). The majority of the settleable solids are removed in the sedimentation chamber at the beginning of the

ABR, which typically represents 50 % of the total volume of TSS (TILLEY et al. 2008). The special design also

allows for an enhanced treatment of nonsettleable solids and a Total Suspended Solids (TSS) removal of up to

90% can be achieved (SINGH 2008). The tanks put in series also help to digest substances that are difficult to

degrade, predominantly in the rear part, after easily degradable matters have been digested in the front part

already (SASSE 1998). Consequently, recycling of effluent would have a slightly negative effect on treatment

quality. ABRs can be designed for a daily inflow in a range of some m3/day up to several hundreds of m3/day

(FOXON et al. 2004; TILLEY et al. 2008). The Hydraulic Retention Time (HRT) in ABRs is relatively short and

http://www.sswm.info/print/848?tid=934

3/7

11/23/2015

AnaerobicBaffledReactor(ABR)

varies from only a few hours up to two or three days (FOXON et al. 2004; MOREL & DIENER 2006; TILLEY et al.

2008).

[/noecompendium]

[ecompappropriateness]

HealthAspects/Acceptance

Under normal operating conditions, users do not come in contact with the influent or effluent. Effluent, scum

and sludge must be handled with care as they contain high levels of pathogenic organisms. The effluent

contains odorous compounds that may have to be removed in a further polishing step. Care should be taken to

design and locate the facility such that odours do not bother community members.[noecompendium]

In general, the quality of ABR effluents has been shown to consistently meet guidelines for irrigation regarding

the removal of organics (e.g. COD or BOD) for reuse in agriculture, but not for discharge to surface water

(FOXON et al. 204). The effluents do also contain high amounts of nutrients, ammonia and phosphorus and

these nutrients may be regarded as a resource from an agricultural point of view (FOXON et al. 2004). The

problem is though, that pathogen removal is generally not satisfactory for the reuse in agriculture and when,

only very restricted reuse is recommended.

Costsconsiderations

Septic tank are generally low cost. However, the costs vary depending on the availability of materials and

economy of scale (EAWAG/SANDEC 2008). In any case, ABRs have a high potential to be used in DEWATS. As

they do not require any electricity and are simple to construct and operate, they are generally cheaper than

more mechanical, centralised technology options. ABRs can be constructed with locally available material.

However, expert design is required.[/noecompendium]

Operation&Maintenance

An ABR requires a startup period of several months to reach full treatment capacity since the slow growing

anaerobic biomass first needs to be established in the reactor. To reduce startup time, the ABR can be

inoculated with anaerobic bacteria, e.g., by adding fresh cow dung or septic tank sludge. The added stock of

active bacteria can then multiply and adapt to the incoming wastewater. [noecompendium]In principle, it is

advantageous to start with a quarter of the daily flow and then slightly increase loading rates over three

months, allowing the bacteria enough time to multiply before suspended solids are washed out (SASSE 1998).

As a long start up time is required for the anaerobic digestion of the sludge, the ABR technology should not be

used when the need for a treatment system is immediate (TILLEY et al. 2008). [/noecompendium]Because of

the delicate ecology, care should be taken not to discharge harsh chemicals into the ABR.

Scum and sludge levels need to be monitored to ensure that the tank is functioning well. Process operation in

general is not required, and maintenance is limited to the removal of accumulated sludge and scum every 1 to

3 years[noecompendium] (EAWAG/SANDEC 2008)[/noecompendium]. This is best done using a Motorized

Emptying and Transport technology[noecompendium] or a Humanpowered Emptying and Transport

Technology to avoid that humans get in contact with the sludge and are exposed to health risks (TILLEY et al.

2008)[/noecompendium]. The desludging frequency depends on the chosen pretreatment steps, as well as on

the design of the ABR. [noecompendium]When emptying the tanks, it is vital that some active sludge is left in

each of the compartments to maintain a stable treatment process (SASSE 1998).[/noecompendium]

ABR tanks should be checked from time to time to ensure that they are watertight.

[noecompendium]

AtaGlance

Working Principle

Vertical baffles in the tank force the presettled wastewater to flow under and over

the baffles guaranteeing contact between wastewater and resident sludge and allowing

an enhanced anaerobic digestion of suspended and dissolved solids; at least 1

http://www.sswm.info/print/848?tid=934

4/7

11/23/2015

AnaerobicBaffledReactor(ABR)

sedimentation chamber and 25 upflow chambers.

Community (and household) level; For presettled domestic or (highstrength)

Capacity/Adequacy industrial wastewater of narrow COD/BOD ration. Typically integrated in DEWATS

systems; Not adapted for areas with high groundwater table or prone to flooding.

Performance

70 95% BOD; 80% 90% TSS; Low pathogen reduction.

HRT: 1 to 3 days

Costs

Generally lowcost; depending on availability of materials and economy of scale.

Selfhelp

Compatibility

Requires expert design, but can be constructed with locally available material.

O&M

Should be checked for water tightness, scum and sludge levels regularly; Sludge needs

to be dug out and discharged properly (e.g. in composting or drying bed); needs to be

vented.

Reliability

High resistance to shock loading and changing temperature, pH or chemical

composition of the influent; requires no energy.

Main strengths

Strong resistance; built from local material; biogas can be recovered.

Main weakness

Long startup phase.

[/noecompendium]

Applicability

This technology is easily adaptable and can be applied at the household level, in small neighbourhoods[no

ecompendium] as DEWATS[/noecompendium] or even in bigger catchment areas[noecompendium]

(preferably with a transport system such as a [1577simplified sewer] or a [3664solidsfree sewer] system in

place)[/noecompendium]. It is most appropriate where a relatively constant amount of blackwater and

greywater is generated. A (semi) centralized ABR is appropriate when there is a preexisting Conveyance

technology, such as a [1577Simplified Sewer].[noecompendium] ABRs in DEWATS are also suited for industrial

wastewaters.

Up to several hundreds of m3/day can be treated. However, a good community organisation is required to

ensure that the ABR is used and maintained properly. The effluent is not fully treated and must be disposed of

properly or sent to secondary treatment (EAWAG/SANDEC 2008).[/noecompendium]

This technology is suitable for areas where land may be limited since the tank is most commonly installed

underground and requires a small area. However, a vacuum truck should be able to access the location

because the sludge must be regularly removed (particularly from the settling compartment).[no

ecompendium] Also, it should not be installed in areas with a high groundwater table or prone to flooding as

infiltration will affect the treatment efficiency and contaminate the groundwater.

BORDA has developed prefabricated ABRs made out of fibreglass and including anaerobic filters as a final step

for emergency sanitation (BORDA 2009). Even though startup of the ABR takes several months, these pre

fabricated models are rapidly constructed and can consist in a longterm solution once the startup phase is

completed. Therefore, such prefabricated models might also find more and more application for other than

emergency situations.

Fibreglass is available and affordable in nearly all parts of the world and fibreglass

constructions can be built quickly and well in advance of need (BORDA 2009). However, one should keep in

mind, that the startup of ABR generally requires at least three month.[/noecompendium]

ABRs can be installed in every type of climate, although the efficiency is lower in colder climates. They are

not efficient at removing nutrients and pathogens. The effluent usually requires further treatment.

Advantages

Resistant to organic and hydraulic shock loads

No electrical energy is required

http://www.sswm.info/print/848?tid=934

5/7

11/23/2015

AnaerobicBaffledReactor(ABR)

Low operating costs

Long service life

High reduction of BOD

Low sludge production; the sludge is stabilized

Moderate area requirement (can be built underground)

Simple to operate

Disadvantages

Long startup phase

Requires expert design and construction

Low reduction of pathogens and nutrients

Effluent and sludge require further treatment and/or appropriate discharge

Needs strategy for faecal sludge management (effluent quality rapidly deteriorates if sludge is not

removed regularly)

Needs water to flush

Clear design guidelines are not available yet

References

BACHMANN, A.; BEARD, V. L.; MCCARTY, P. L. (1985): Performance Characteristics of the Anaerobic Baffled Reactor. In: Water Research

19, 99106. London: IWA Publishing.

BARBER, W.P.; STUCKEY D.C. (1999): The use of the anaerobic baffled reactor (ABR) for wastewater treatment A review. In: Wat. Res

33, 7.

BORDA (Editor) (2009): EmSan Emergency Sanitation. An innovative & rapidly installable solution to improve hygiene and health in

emergency situations. (= Concept Note). Bremen: Bremen Overseas Research and Development Association . URL [Accessed:

26.03.2010]. PDF

EAWAG/SANDEC (Editor) (2008): Sanitation Systems and Technologies. Lecture Notes . (= Sandec Training Tool 1.0, Module 4).

Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries

(SANDEC). PDF

FOXON, K. M.; BUCKLEY, C. A.; BROUCKAERT, C. J.; DAMA, P.; MTEMBU, Z.; RODDA, N.; SMITH, M.; PILLAY, S.; ARJUNG, N.;

LALBAHADUR, T.; BUX, F. (2006): Evaluation of the Anaerobic Baffled Reactor for Sanitation in Dense Periurban Settlements. (= WRC

Report No 1248/01/06). Pretoria: Water Research Commission. URL [Accessed: 21.08.2014]. PDF

FOXON, K.M.; PILLAY, S.; LALBAHADUR, T.; RODDA, N.; HOLDER, F.; BUCKLEY, C.A. (2004): The anaerobic baffled reactor (ABR) An

appropriate technology for onsite sanitation. In: Water SA 30, 5. PDF

GUTTERER, B.; SASSE, L.; PANZERBIETER, T.; RECKERZGEL, T.; ULRICH, A. (Editor); REUTER, S. (Editor); GUTTERER, B. (Editor) (2009):

Decentralised Wastewater Treatment Systems (DEWATS) and Sanitation in Developing Countries. Loughborough University (UK): Water

Engineering and Deveopment Centre (WEDC). URL [Accessed: 20.03.2014]. PDF

MOREL, A.; DIENER, S. (2006): Greywater Management in Low and MiddleIncome Countries, Review of Different Treatment Systems for

Households or Neighbourhoods. (= SANDEC Report No. 14/06). Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG),

Department of Water and Sanitation in Developing Countries (SANDEC). URL [Accessed: 19.05.2010]. PDF

SANIMAS (Editor) (2005): Informed Choice Catalogue. pdf presentation. BORDA and USAID. PDF

SASSE, L. ; BORDA (Editor) (1998): DEWATS. Decentralised Wastewater Treatment in Developing Countries. Bremen: Bremen Overseas

Research and Development Association (BORDA). PDF

SINGH, S.; HABERLA, R.; MOOG, O.; SHRESTA, R.R.; SHRESTA, P.; SHRESTA, R. (2009): Performance of an Anaerobic Baffled Reactor and

Hybrid Constructed Wetland treating highstrength Wastewater in Nepal A model for DEWATS . In: Ecological Engineering 35, 654660.

STUCKEY, D. C.; H. H. P. Fang (Editor) (2010): Anaerobic Baffled Reactor (ABR) for Wastewater Treatment. In: H. H. P. Fang (Editor)

(2010): Environmental Anaerobic Technology. London.

SUSANA (Editor) (2010): Decentralized Wastewater Management at Adarsh College Badalapur, Maharashtra, India. Factsheet. (= SuSanA

Factsheet). Eschborn: Sustainable Sanitation Alliance (SuSanA). URL [Accessed: 12.01.2011]. PDF

TILLEY, E.; ULRICH, L.; LUETHI, C.; REYMOND, P.; ZURBRUEGG, C. (2014): Compendium of Sanitation Systems and Technologies. 2nd

Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag). URL [Accessed:

28.07.2014]. PDF

TILLEY, E.; LUETHI, C.; MOREL, A.; ZURBRUEGG, C.; SCHERTENLEIB, R. (2008): Compendium of Sanitation Systems and Technologies.

Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (EAWAG) and Water Supply and Sanitation

Collaborative Council (WSSCC). URL [Accessed: 15.02.2010]. PDF

http://www.sswm.info/print/848?tid=934

6/7

11/23/2015

AnaerobicBaffledReactor(ABR)

See document in FRENCH

U.S. EPA (Editor) (2006): Emerging Technologies for Biosolids Management. (= EPA 832R, 5/6). United States Environmental Protection

Agency, Office of Wastewater Management. PDF

WANG, J.; HUANG, Y.; ZHAO, X. (2004): Performance and Characteristics of an Anaerobic Baffled Reactor. In: Bioresource Technology

93, 205208.

WHO (Editor) (2009): Ecosan Expert Training Course for the Introduction of Ecological Sanitation in Bhutan. (= Training Course Report).

Geneva: World Health Organisation. URL [Accessed: 12.01.2011]. PDF

WSP (Editor) (2008): Technology Options for Urban Sanitation in India. A Guide to DecisionMaking. pdf presentation. New Delhi: Water

and Sanitation Program (WSP). URL [Accessed: 26.03.2010]. PDF

For further readings, case studies, awareness raising material, training material, important weblinks or

the related powerpoint presentation, see www.sswm.info/category/implementationtools/wastewater

treatment/hardware/semicentralisedwastewatertreatments8

http://www.sswm.info/print/848?tid=934

7/7

Vous aimerez peut-être aussi

- Uasb/egsb Applications For Industrial Wastewater TreatmentDocument10 pagesUasb/egsb Applications For Industrial Wastewater Treatmentalberto_03Pas encore d'évaluation

- UASB Upflow Anaerobic Sludge Blanket Process V2Document18 pagesUASB Upflow Anaerobic Sludge Blanket Process V2Khang TrầnPas encore d'évaluation

- Design Criteria SBRDocument8 pagesDesign Criteria SBRranbeer41100% (1)

- Anaerobic Baffled Reactor (ABR) - SSWM PDFDocument9 pagesAnaerobic Baffled Reactor (ABR) - SSWM PDFAnonymous gqtnY7iRk1Pas encore d'évaluation

- Anaerobic Digestion and Wastewater Treatment SystemsDocument26 pagesAnaerobic Digestion and Wastewater Treatment SystemsRoberto SusePas encore d'évaluation

- Anaerobic ReactorsDocument21 pagesAnaerobic ReactorsManish Kumar GhoraPas encore d'évaluation

- Visit ReportDocument9 pagesVisit Reportrohit Sharma100% (1)

- Efficiency Comparison of Various Sewage Treatment Plants in BangaloreDocument36 pagesEfficiency Comparison of Various Sewage Treatment Plants in BangalorePRETTY MARY100% (1)

- Ankit Akela Minor ProjectDocument34 pagesAnkit Akela Minor ProjectAnkit TuranPas encore d'évaluation

- Trickling FilterDocument7 pagesTrickling FilterTasirmistPas encore d'évaluation

- Rotating Biological ContactorDocument17 pagesRotating Biological Contactormikelycan100% (2)

- AOPs A Critical Review PDFDocument54 pagesAOPs A Critical Review PDFM S MahtabPas encore d'évaluation

- Anaerobic Treatment and Biogas (Short)Document61 pagesAnaerobic Treatment and Biogas (Short)Dinda SyafidahPas encore d'évaluation

- 7-Trickling Filter F11Document31 pages7-Trickling Filter F11Jon Bisu Debnath100% (1)

- Tutorial 5Document4 pagesTutorial 5Pratik Babu GhimirePas encore d'évaluation

- ENVI Trickling FiltersDocument23 pagesENVI Trickling FiltersbaBy daBy AnNetTePas encore d'évaluation

- SBR DesignDocument10 pagesSBR DesignQuốc TuyênPas encore d'évaluation

- Oxidation Ditch PresentationDocument12 pagesOxidation Ditch PresentationAngelina PranotoPas encore d'évaluation

- Concept of Zero DischargeDocument4 pagesConcept of Zero DischargeShesharam Chouhan67% (3)

- Activated Sludge ProcessDocument10 pagesActivated Sludge ProcessSai Raghava Rajeev100% (1)

- Sample WW QuestionsDocument10 pagesSample WW QuestionsKrishna Kumar MeenaPas encore d'évaluation

- Water Supply EngineeringDocument3 pagesWater Supply EngineeringSujan SinghPas encore d'évaluation

- Biological Wastewater Treatment III - MBR Processes R1Document26 pagesBiological Wastewater Treatment III - MBR Processes R1NUR ASYIQIN BINTI AZAHARPas encore d'évaluation

- SBR Asbr SBBRDocument10 pagesSBR Asbr SBBRThanh LanPas encore d'évaluation

- Project Report On Extended Aeration and Step AerationDocument38 pagesProject Report On Extended Aeration and Step AerationHakim Asif Haider100% (2)

- Rapid Sand FiltrationDocument16 pagesRapid Sand FiltrationNurul ShafinazPas encore d'évaluation

- Aerated Lagoon: Types of Aerated Lagoons or BasinsDocument4 pagesAerated Lagoon: Types of Aerated Lagoons or BasinsRaajiv MenonPas encore d'évaluation

- Grit ChamberDocument29 pagesGrit Chamberazcomp100% (1)

- Attached GrowthDocument42 pagesAttached GrowthDini AryantiPas encore d'évaluation

- Treatment of Industrial Waste Water and Process Water With Membrane Processes and Membrane Bio ReactorsDocument52 pagesTreatment of Industrial Waste Water and Process Water With Membrane Processes and Membrane Bio ReactorsturtlemethodPas encore d'évaluation

- Sewage Treatment WorksheetDocument18 pagesSewage Treatment WorksheetRemedanPas encore d'évaluation

- Activated Sludge Calcs With ExcelDocument22 pagesActivated Sludge Calcs With ExcelsahatPas encore d'évaluation

- Pptonfab MBBR 130616081952 Phpapp01Document18 pagesPptonfab MBBR 130616081952 Phpapp01TAREK ALMAHDY100% (3)

- Deliverable-1.10 Guideline Design Granular Sludge ReactorDocument19 pagesDeliverable-1.10 Guideline Design Granular Sludge ReactorCatalina Nicoleta RoscaPas encore d'évaluation

- Rotating Biological ContactorDocument10 pagesRotating Biological ContactorDr. Akepati Sivarami Reddy100% (1)

- MBBR SystemDocument7 pagesMBBR SystemThanneeru Naga Raju100% (1)

- ELMITVALLI 2005 Treatment of Municipal Wastewater in Upflow Anaerobic Sludge Blanket UASB ReactorDocument32 pagesELMITVALLI 2005 Treatment of Municipal Wastewater in Upflow Anaerobic Sludge Blanket UASB ReactorKuswandi AndiPas encore d'évaluation

- Conceptual Design of A Wastewater Treatment Plant of CotorroDocument8 pagesConceptual Design of A Wastewater Treatment Plant of CotorroAndresPas encore d'évaluation

- Design of Upflow Anaerobic Sludge Blanket For Mapua Institute of TechnologyDocument59 pagesDesign of Upflow Anaerobic Sludge Blanket For Mapua Institute of TechnologyNguyễnThịBíchPhượngPas encore d'évaluation

- Assignment 1Document3 pagesAssignment 1Victor Megong JakiPas encore d'évaluation

- Sewage Treatment PlantDocument34 pagesSewage Treatment PlantJohn Paul Paro100% (3)

- Grit ChambersDocument28 pagesGrit ChambersmkkPas encore d'évaluation

- Sedimentation Sanitary Engineering-Lecture4-2003Document41 pagesSedimentation Sanitary Engineering-Lecture4-2003motuz adamPas encore d'évaluation

- Imhoff TankDocument17 pagesImhoff Tankfandinisty100% (1)

- Chapter 8 - Activated Sludge PDFDocument12 pagesChapter 8 - Activated Sludge PDFRieskaYuniarPas encore d'évaluation

- DBDocument25 pagesDBAbhijit MondalPas encore d'évaluation

- Anaerobic FilterDocument7 pagesAnaerobic FilterdlunaonePas encore d'évaluation

- Lecture 12 - Waste Water Treatment MethodsDocument41 pagesLecture 12 - Waste Water Treatment MethodsUsman KhalidPas encore d'évaluation

- Iare Ce Iwwt Lecture Notes 2Document101 pagesIare Ce Iwwt Lecture Notes 2SHEKHARPas encore d'évaluation

- Case Study Fujifilm MBR v01Document2 pagesCase Study Fujifilm MBR v01كرم عمروPas encore d'évaluation

- Design Aspects Drinking Water Treatment.Document32 pagesDesign Aspects Drinking Water Treatment.Milton Alexander Rivera TorresPas encore d'évaluation

- Conversion Table For Wastewater TreatmentDocument5 pagesConversion Table For Wastewater TreatmentAG-Metal /Tretman Otpadnih Voda/Wastewater TreatmentPas encore d'évaluation

- Anaerobic Treatment (PPT) - (Part - I) 19-03-2013Document24 pagesAnaerobic Treatment (PPT) - (Part - I) 19-03-2013Gaurav Tanwer100% (1)

- Activated Sludge DesignDocument21 pagesActivated Sludge DesignChokri ChakiirPas encore d'évaluation

- Activated Sludge ProblemDocument3 pagesActivated Sludge ProblemCamille LeiPas encore d'évaluation

- Activated Sludge MathDocument21 pagesActivated Sludge MathJR Zuniga100% (1)

- Slide GateDocument1 pageSlide GateFortaengineering FortaenviroPas encore d'évaluation

- Indo-Swm Based On GisDocument213 pagesIndo-Swm Based On GisAndre Suito100% (1)

- GBR Rsau BGRDocument2 pagesGBR Rsau BGRAnastasya Putri SafinaPas encore d'évaluation

- List of Water Treatment CompanyDocument4 pagesList of Water Treatment CompanyAnastasya Putri Safina0% (1)

- Perhitungan Bore PileDocument11 pagesPerhitungan Bore PileAri Mulya100% (4)

- Engineer's ReportDocument9 pagesEngineer's ReportEyz Cabueños100% (1)

- Calculation For Activated Sludge Process PDFDocument6 pagesCalculation For Activated Sludge Process PDFvinoohmPas encore d'évaluation

- STP 1Document1 pageSTP 1Angel RoaringPas encore d'évaluation

- Techno-Commercial Offer 10 KLD Etp TM Vrindavan GroupDocument9 pagesTechno-Commercial Offer 10 KLD Etp TM Vrindavan GroupTech MongerPas encore d'évaluation

- Tannery Industry 2Document7 pagesTannery Industry 2kavya1811Pas encore d'évaluation

- Iwwt - Question BankDocument10 pagesIwwt - Question BankGopinath MPas encore d'évaluation

- Poor Raw Water Clarifier Preformance - Floating Floc - FlatDocument1 pagePoor Raw Water Clarifier Preformance - Floating Floc - Flatja23gonzPas encore d'évaluation

- 3.isolation Hospital (IIYW) PDFDocument2 pages3.isolation Hospital (IIYW) PDFSandeepan ChowdhuryPas encore d'évaluation

- Rapid Sand FiltrationDocument4 pagesRapid Sand FiltrationMuzamil Maqbool RatherPas encore d'évaluation

- EE-II Midterm Set-A 15Document2 pagesEE-II Midterm Set-A 15DrShrikant JahagirdarPas encore d'évaluation

- Wartsila Water Systems MBRDocument4 pagesWartsila Water Systems MBRIvo Tadej GrmajPas encore d'évaluation

- Biological Wastewater Treatment - Principles Modelling and DesignDocument103 pagesBiological Wastewater Treatment - Principles Modelling and DesignNguyen Phuc Pham78% (9)

- Septic Tank Standard PHDocument2 pagesSeptic Tank Standard PHKenneth D. PacadaPas encore d'évaluation

- Introduction To Water Pollution and Water Quality Standards: By: Hem Raj Pandeya (074BME616)Document39 pagesIntroduction To Water Pollution and Water Quality Standards: By: Hem Raj Pandeya (074BME616)Abhishek KarnPas encore d'évaluation

- Septic System: Owner'S ManualDocument16 pagesSeptic System: Owner'S ManualKeith SagalowPas encore d'évaluation

- Nikkiso Dialysis Machines PDFDocument2 pagesNikkiso Dialysis Machines PDFenricolamPas encore d'évaluation

- Waste Water Process PDFDocument27 pagesWaste Water Process PDFFauzan AzmiPas encore d'évaluation

- Anaerobic Suspended and Attached Growth Biological Treatment ProcessesDocument26 pagesAnaerobic Suspended and Attached Growth Biological Treatment ProcessesJerome MilitarPas encore d'évaluation

- KVLRT3-MRCBGK-GS05-ESH-NCR-000147 - Sewage Overflow at P11-16Document3 pagesKVLRT3-MRCBGK-GS05-ESH-NCR-000147 - Sewage Overflow at P11-16Pembaca SenyapPas encore d'évaluation

- Sewage Treatment Plant (STP) - Module 2Document21 pagesSewage Treatment Plant (STP) - Module 2diana bunaganPas encore d'évaluation

- General Inspection FormDocument1 pageGeneral Inspection FormBernadette Lou LasinPas encore d'évaluation

- Final Calculation For Grey WaterDocument1 pageFinal Calculation For Grey WaterSushil GuptaPas encore d'évaluation

- Greater Kegalle Water Treatment PlantDocument9 pagesGreater Kegalle Water Treatment PlantRanjithPas encore d'évaluation

- CH 9 - Attached Growth ProcessDocument30 pagesCH 9 - Attached Growth Processxuantra92100% (1)

- POME Digestate Foam TreatmentDocument21 pagesPOME Digestate Foam TreatmentDhani AviantoPas encore d'évaluation

- How To Design Clarifier For Primary Treatment of Water Treatment PlantDocument6 pagesHow To Design Clarifier For Primary Treatment of Water Treatment PlantJon BallesteroPas encore d'évaluation

- Scinor® SMT600-P23: Pressurized Ultrafiltration ModuleDocument2 pagesScinor® SMT600-P23: Pressurized Ultrafiltration ModuleDiegoMarinPas encore d'évaluation

- Floccin Brochure 2012 PDFDocument6 pagesFloccin Brochure 2012 PDFRavindra S. JalukarPas encore d'évaluation

- List of References in The Food & Beverage Industry Christ Holland B.VDocument3 pagesList of References in The Food & Beverage Industry Christ Holland B.VariefmailPas encore d'évaluation

- ETPDocument28 pagesETPParvee K NakwalPas encore d'évaluation