Académique Documents

Professionnel Documents

Culture Documents

Manufacturing Quality Plan: Manufacturer'S Name & Address

Transféré par

charzreeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Manufacturing Quality Plan: Manufacturer'S Name & Address

Transféré par

charzreeDroits d'auteur :

Formats disponibles

MANUFACTURING QUALITY PLAN

MANUFACTURER'S NAME & ADDRESS

MQP NO.

M/s G. K. ELECTRICALS, 6-A, F-SECTOR, INDUSTRIAL

ITEM : ISOLATOR

AREA, GOVINDPURA, BHOPAL

S.No.

Component operation

Type of check

& Description of test

RAW MATERIAL AND COMPONENTS CHECK

1

M.S. Channel & Bass Frame

a) Visual

b) Diamentional

c) Galvanising

Electrolytic Copper tubes, rods,

flate channel & special extrusion

a)Visual

b)Diamentional

c) Plating

d) Machenical Properties

e) Conductivity

Visual

measurment

Chamical

Quantum of

check by us

100%

10%

5%

REV. NO.

Ref. Document &

Acceptance norm

As per Approved drawing

GKE/MQP/02

0

DATE

16.08.2013

VALID UP TO

26.06.2014

Testing Agency

Remarks

(a), (b) Q. C.

Record

c manufacturer's TC

Record Review by

Customer at the time of

Inspection

(a), (b) Q. C. record

( c) (d) (e)

manufacturer's TC

Record Review by

Customer at the time of

Inspection

As per Approved drawing

(a), (b) Q. C.

Record

Record Review by

Customer at the time of

Inspection

As per Approved drawing

(a), (b) Q. C. Record

( c) (d) (e)

manufacturer's TC

Record Review by

Customer at the time of

Inspection

As per Approved drawing

Visual

measurment

Chamical

Test

Test

100%

10%

5%

one sample

one sample

Aluminium rods, tube, channel,

flate & special extrusion

a) Visual

b)Diamentional

Visual

measurment

100%

10%

GI Pipe tendum Pipe

a) Visual

b)Diamentional

c) Uniformity

d) Mass of Coting

e) Adhesion

Visual

measurment

Dip. Test

Strip Test

HammerTest

100%

10%

manufacturer's TC

manufacturer's TC

10

11

12

13

14

Stainless Steel Contact Springs

a)Diamentional

b) Spring Rate Measurment

c) Hardness

measurment

Mech. Test

Mech. Test

20%

one sample

one sample

Bearing Shaft Assembly

a) Visual

b) Diamentional

Visual

measurment

20%

20%

Moving Blade

a) Visual

b) Diamentional

c) Plating

Visual

measurment

Chamical

100%

10%

10%

Fixed Contact

a) Visual

b) Diamentional

c) Plating

Visual

measurment

Chamical

100%

10%

10%

Test on Mechanism

a) Visual

b) Diamentional

c) Operation test

Visual

measurment

Performance

100%

one sample

one sample

Terminal Connectors

a) Visual

b) Diamentional

Visual

measurment

100%

10%

MS Hardware

a) Visual

b) Diamentional

c) Galvanising

Visual

measurment

Chamical

10%

10%

5%

Calibration of measuring test equipment

a) Calibration

Record checking

100%

Broughtout Componant

a) Visual

Visual

Random

Name Plate Rating

a) Visual

Visual

10%

As per Approved drawing

(a) Q. C. Record

(b) ( c) manufacturer's

TC

Record Review by

Customer at the time of

Inspection

As per Approved drawing

(a), (b) Q. C. Record

Record Review by

Customer at the time of

Inspection

As per Approved drawing

(a), (b) Q. C.

Record

(c ) manufacturer's TC

Record Review by

Customer at the time of

Inspection

As per Approved drawing

(a), (b) Q. C.

Record

(c ) manufacturer's TC

Record Review by

Customer at the time of

Inspection

As per our design

Q.C Record

Record View

As per Approved drawing

(a), (b) Q. C. Record

Record Review by

Customer at the time of

Inspection

As per Approved drawing

(a), (b) Q. C. Record

(c )manufacturer's TC

Record Review by

Customer at the time of

Inspection

Periodicity of caliberation to

exeed 12 month

Caliberation

Record

Caliberation is

done from independent

laboratary

As per our design/requirement Q.C. Record

Record review

As per our design/drawing

Record review

Q.C Record

15

16

Isolator Assembly & Carried out

Routine Test

a) H.V. Dry Test

b) Milivolt Drop test

c) Operation test

d) Dimentional check

Acceptance Test

a) Visual Examination

b) Diamentional Checkup

c) H.V. Dry Test

d) Millivolt Drop Test

e) Operation test

f) Voltage test on control & Aux

Circuit

g) Hot dip Galvanized Test

Electrical

Electrical

Manual

Measurment

100%

100%

10%

100%

Visual

measurment

Electrical

Electrical

Manual

10%

5%

5%

5%

one sample

Electrical

Chemical Test

5%

one sample

As per IS: 9921

As per drawing

As per Approved drawing

QC Record /GKE

GKE

GKE

GKE

Record Review.

GKE

GKE

GKE

GKE

GKE

Routine/Acceptance carried

out at G. K. Electricals

works by customer

rep./inspecting officer as

per your specification/

GKE

IS- 9921 Part 4

GKE

LEGENDS

QC- Quality control

M- Manufacturer

TC- Test certificate

GKE- G.K. Electricals

for G.K.Electricals

Vous aimerez peut-être aussi

- VDR - Farabi Paraffin Derivative ComplexDocument7 pagesVDR - Farabi Paraffin Derivative ComplexcharzreePas encore d'évaluation

- Directional OvercurrentDocument1 pageDirectional OvercurrentcharzreePas encore d'évaluation

- Mal-Function of Electrical Equipment at SuvliDocument1 pageMal-Function of Electrical Equipment at SuvlicharzreePas encore d'évaluation

- 1.15.3.-LTR 393-Wrmsp-Suv-15Document1 page1.15.3.-LTR 393-Wrmsp-Suv-15charzreePas encore d'évaluation

- Question: What Are The Effects of Switching Transients and Are Suppressors Necessary?Document4 pagesQuestion: What Are The Effects of Switching Transients and Are Suppressors Necessary?charzreePas encore d'évaluation

- Cable Sizing NotepadDocument1 pageCable Sizing NotepadcharzreePas encore d'évaluation

- Generator Reactive PowerDocument1 pageGenerator Reactive PowercharzreePas encore d'évaluation

- K-E-161226-01 Necessity of DG Fuel at All PSDocument2 pagesK-E-161226-01 Necessity of DG Fuel at All PScharzreePas encore d'évaluation

- HarmonicsDocument2 pagesHarmonicscharzreePas encore d'évaluation

- Detuned Reactor StudyDocument3 pagesDetuned Reactor StudycharzreePas encore d'évaluation

- LTR Draft To Ortex - Ground Fault of Incoming Cable in Kizil RavatDocument2 pagesLTR Draft To Ortex - Ground Fault of Incoming Cable in Kizil RavatcharzreePas encore d'évaluation

- Harmonic FilterDocument2 pagesHarmonic FiltercharzreePas encore d'évaluation

- Mal-Function of Electrical Equipment at SuvliDocument1 pageMal-Function of Electrical Equipment at SuvlicharzreePas encore d'évaluation

- Mal-Function of Electrical Equipment at SuvliDocument1 pageMal-Function of Electrical Equipment at SuvlicharzreePas encore d'évaluation

- The Residual Voltage That Is Developed Is Equal To Three Times The Zero Sequence VoltageDocument2 pagesThe Residual Voltage That Is Developed Is Equal To Three Times The Zero Sequence VoltagecharzreePas encore d'évaluation

- Furkat PT FuseDocument1 pageFurkat PT FusecharzreePas encore d'évaluation

- Star Delta Capacitor LocationDocument2 pagesStar Delta Capacitor LocationcharzreePas encore d'évaluation

- Setting List (LV 7A-7037)Document34 pagesSetting List (LV 7A-7037)charzreePas encore d'évaluation

- How To Select A Pump-By Majid HamedyniaDocument72 pagesHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- Capacitive BreakingDocument1 pageCapacitive BreakingcharzreePas encore d'évaluation

- QuestionsDocument1 pageQuestionscharzreePas encore d'évaluation

- Symmetrical Components ZmudaDocument2 pagesSymmetrical Components ZmudacharzreePas encore d'évaluation

- Neutral Voltage ShiftDocument3 pagesNeutral Voltage ShiftcharzreePas encore d'évaluation

- The Temperature High Fault Has Occurred in 2 NoDocument2 pagesThe Temperature High Fault Has Occurred in 2 NocharzreePas encore d'évaluation

- Assembly InstructionsDocument11 pagesAssembly InstructionscharzreePas encore d'évaluation

- Intake Pump LOP Terminal DetailsDocument1 pageIntake Pump LOP Terminal DetailscharzreePas encore d'évaluation

- How To Resize Pictures To Fit Cells in ExcelDocument7 pagesHow To Resize Pictures To Fit Cells in ExcelcharzreePas encore d'évaluation

- MS-Excel, Understanding Variables, Conditions & Loops in Excel VBA - A Demo Application UsDocument22 pagesMS-Excel, Understanding Variables, Conditions & Loops in Excel VBA - A Demo Application UscharzreePas encore d'évaluation

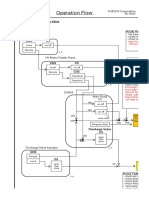

- BP-0000 Operation Flow (Master) - 20140217aDocument32 pagesBP-0000 Operation Flow (Master) - 20140217acharzreePas encore d'évaluation

- Booster Pump LOPDocument1 pageBooster Pump LOPcharzreePas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- IPC and WHMA Standards Supporting The Automotive and Wire Harness Industries - C.GonzalezDocument52 pagesIPC and WHMA Standards Supporting The Automotive and Wire Harness Industries - C.GonzalezJoao BrandtPas encore d'évaluation

- Method Statement For Roof CoveringDocument6 pagesMethod Statement For Roof CoveringCalvin OhPas encore d'évaluation

- SG Qa 09 PDFDocument49 pagesSG Qa 09 PDFAnuj DeoPas encore d'évaluation

- ISO-20695-2020 - Hasta Pag 9Document15 pagesISO-20695-2020 - Hasta Pag 9Videos VideosPas encore d'évaluation

- Inspection and Testing PlanDocument7 pagesInspection and Testing PlanStephen David Gozun50% (2)

- Inspection and Test Plan FOR Filter Separator/CoalescerDocument6 pagesInspection and Test Plan FOR Filter Separator/Coalescersumit kumarPas encore d'évaluation

- ISO-CASCO - ISO-IEC 17020, Conformity Assessment - Requirements For The Operation of Various Types of Bodies Performing InspectionDocument37 pagesISO-CASCO - ISO-IEC 17020, Conformity Assessment - Requirements For The Operation of Various Types of Bodies Performing InspectionKatherine chirinosPas encore d'évaluation

- Split Unit InstallationDocument33 pagesSplit Unit Installationsree100% (1)

- Strategic Cost Management Final SessionDocument29 pagesStrategic Cost Management Final SessionMeena RamachandranPas encore d'évaluation

- EDG Electrical Test Checklist 2Document26 pagesEDG Electrical Test Checklist 2En FaizulPas encore d'évaluation

- Questionnaire QMDocument80 pagesQuestionnaire QMapi-3781101100% (3)

- Risk Based InspectionDocument66 pagesRisk Based Inspectionmurali67% (6)

- Part V (Wet Riser and Sprinkler System) PDFDocument123 pagesPart V (Wet Riser and Sprinkler System) PDFjra909089% (9)

- International Shore Connections For Marine FireDocument2 pagesInternational Shore Connections For Marine FireMeleti Meleti Meletiou100% (1)

- The Tamil Nadu Factories Rules, 1950Document380 pagesThe Tamil Nadu Factories Rules, 1950Kirthika RajaPas encore d'évaluation

- Assignment No.1 Title-Case Study Based Assignment On Method StudyDocument4 pagesAssignment No.1 Title-Case Study Based Assignment On Method Studyshreyas mithariPas encore d'évaluation

- Steels For Shipbuilding and Offshore StructuresDocument7 pagesSteels For Shipbuilding and Offshore Structuresmihalikj2190Pas encore d'évaluation

- Phased Array Applications - OnDT Canada (V1)Document19 pagesPhased Array Applications - OnDT Canada (V1)vrapciudorianPas encore d'évaluation

- 0 Civil Engineering Sevices ClassificationDocument7 pages0 Civil Engineering Sevices ClassificationPzynae FlorentinoPas encore d'évaluation

- Independence PrincipleDocument10 pagesIndependence PrincipleMich Ducul100% (1)

- SPE-KSA-614-MS, Keys To Successful Brownfield Engineering ExecutionDocument16 pagesSPE-KSA-614-MS, Keys To Successful Brownfield Engineering ExecutionAtef MoussaPas encore d'évaluation

- Curriculam Vitae: Oil & Gas IndustriesDocument9 pagesCurriculam Vitae: Oil & Gas IndustriesGanesan RamamoorthyPas encore d'évaluation

- D.T.D.900AA: Ministry of Defence Defence Procurement Agency, ADRP2 Abbey Wood Bristol BS34 8JHDocument24 pagesD.T.D.900AA: Ministry of Defence Defence Procurement Agency, ADRP2 Abbey Wood Bristol BS34 8JHSatyendra PandeyPas encore d'évaluation

- Win-Qa-105 (Lab Quality System)Document1 pageWin-Qa-105 (Lab Quality System)suchig84537Pas encore d'évaluation

- BTM2133-Chapter 1 IntroductionDocument26 pagesBTM2133-Chapter 1 IntroductionAswaja313Pas encore d'évaluation

- Special Inspection Manual Empennage and Associated StructureDocument16 pagesSpecial Inspection Manual Empennage and Associated StructureLeoPas encore d'évaluation

- Project: Baladna Dairy Farm Phase-2: Inspection and Test PlanDocument3 pagesProject: Baladna Dairy Farm Phase-2: Inspection and Test PlanMelih SENTURK100% (1)

- HQDM101015174-1 Certificat de ConformiteDocument2 pagesHQDM101015174-1 Certificat de Conformitetarek.amirechePas encore d'évaluation

- Automotive Assembly Course Outline With DetailsDocument6 pagesAutomotive Assembly Course Outline With Detailsasim qamarPas encore d'évaluation

- Division of Rizal District of Cainta II San Juan Elementary SchoolDocument4 pagesDivision of Rizal District of Cainta II San Juan Elementary SchoolJoel T. FernandezPas encore d'évaluation