Académique Documents

Professionnel Documents

Culture Documents

T-FLEX Analysis Brochure

Transféré par

icadCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

T-FLEX Analysis Brochure

Transféré par

icadDroits d'auteur :

Formats disponibles

T-FLEX Analysis

offers a wide spectrum of specialized analysis tools to

help engineers virtually test and analyze complicated

parts and assemblies. It employs the finite element

method for performing static, frequency, buckling,

thermal, optimization, fatigue and other analysis. T-FLEX

Analysis shows how a model will perform under real-world

conditions before it is built.

Associative Model high stresses. Various structural loads and restraints can be

specified including force, pressure, gravity, rotational load,

The CAE model is fully associative to the design model, since it bearing force, torque, prescribed displacement, temperature,

uses native T-FLEX CAD geometry. T-FLEX Analysis ensures etc.

that the very latest design information is available for

simulation without the need for any time-consuming geometry

translation or data re-creation. Design changes made in a model

are automatically updated for analysis calculations.

Meshing is automatic and completely adaptive to even the most

complex model geometry.

User Interface

Complete integration with T-FLEX CAD means that T-FLEX

Analysis users can perform design analysis, simulation and

optimization directly from their T-FLEX CAD user interface. T-

FLEX Analysis utilizes the T-FLEX CAD Model Tree,

Properties dialog boxes, command and menu structure, and

many of the same mouse and keyboard commands, so anyone

who can design a part in T-FLEX CAD can analyze it without

having to learn a new interface.

Frequency Analysis

Area of Application

Frequency Analysis determines a part's natural frequencies and

Quick and inexpensive analysis often reveals non intuitive the associated mode shapes. It can determine if a part resonates

solutions and benefits engineers by providing them with a better at the frequency of an attached, power-driven device, such as a

understanding of product characteristics. Whether used in the motor. While resonance in structures must typically be avoided

mechanical, electromechanical, aerospace, transportation, or damped, engineers may choose to exploit resonance in other

power, medical or construction industries, T-FLEX Analysis applications. The typical applications include acoustical

can help to shorten development time, reduce testing costs, speaker design, aerospace structure design, bridge and overpass

improve product quality, increase profitability, and cut time to architecture, construction equipment design, musical

market. instrument study, robotic system analysis, rotating machinery

and turbine design, vibrating conveyor optimization and others.

Structural Static Analysis

Structural analysis capabilities enable engineers to perform

static stress analyses of parts and assemblies under various Buckling Analysis

loading conditions. Static studies calculate displacements,

reaction forces, strains, stresses, and factor of safety Critical buckling load analysis examines the geometric stability

distribution. Static analysis can help you avoid failure due to of models under primarily axial load. It helps avoid failure due

design, resulting in the best possible product for minimum cost.

Because your designs may have hundreds of variable parameters

with complex interrelationships, finding an optimal design

through manual iterations is hit-or-miss at best. T-FLEX Analysis

relieves the burden of improving product designs by automating

the iterative process of comparing performance against

specifications.

Frequency Response Analysis

to buckling which refers to sudden large displacements and can be

catastrophic if it occurs in the normal use of most products.

Buckling analysis provides the lowest buckling load which is of

interest and is usually used in such applications as automotive

frame design, column design, infrastructure design, safety factor

determination, transmission tower design, vehicle skin design and

others.

Thermal Analysis

Frequency response analysis determines the steady-state operation

of a machine, vehicle or process equipment design subjected to

continuous harmonic loading. As compared to linear transient

stress analyses, frequency response analysis provides an easy,

quick method in which the only inputs are a constant frequency and

amplitude. For example, this analysis type could be used to

determine the vibration effects of a washing machine with an

unbalanced load or a bent wheel on a vehicle.

Fatigue Analysis

Repeated loading and unloading weakens objects over time even

when the induced stresses are considerably less than the allowable

stress limits. Fatigue analysis is vital for products such as steel

rails, beams and girders, which can experience mechanical failure

under repeated or otherwise varying loads that never reach a level

sufficient to cause failure in a single application. T-FLEX Analysis

Capabilities for simulating thermal effects include steady-state simulates fatigue-based failure and lets users design for durability

and transient heat transfer analysis. Thermal studies calculate by subjecting a product to cyclic applications of stress in order to

temperatures, temperature gradients, and heat flow based on heat determine its endurance limit and thereby ensure safety.

generation, conduction, convection, and radiation conditions.

Thermal analysis can help you avoid undesirable thermal Analysis Results (Post Processing)

conditions like overheating and melting.

T-FLEX Analysis provides a comprehensive range of post

Optimization processing operations with animation, various plots, lists, and

graphs depending on the study and result types. The special

Designing and producing innovative products that meet reporting command helps you document your studies quickly and

performance criteria is a goal of every manufacturer. Using systematically by generating Internet-ready reports. The reports

optimization techniques, engineers can improve a proposed are structured to describe all aspects of the study.

Top Systems

127055, p.o.b. #133, Moscow, Russia

tflex@topsystems.ru

www.tflex.com

T-FLEX CAD, T-FLEX Analysis are trademarks of Top Systems.

All other logos, trademarks or service marks used herein are

the property of their respective owners.

Copyright © 2006 Top Systems, All rights reserved.

Vous aimerez peut-être aussi

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- T-FLEX CAD BrochureDocument4 pagesT-FLEX CAD Brochureicad100% (1)

- Mathcad Tutorial Introduction & Examples - CADDIT AustraliaDocument40 pagesMathcad Tutorial Introduction & Examples - CADDIT Australiaicad100% (2)

- Inside ProgeCAD 2009Document200 pagesInside ProgeCAD 2009meholakoPas encore d'évaluation

- VariCAD 2D 3D Light Industrial and Mechanical CAD SystemDocument178 pagesVariCAD 2D 3D Light Industrial and Mechanical CAD Systemicad100% (4)

- T-FLEX CAD BrochureDocument4 pagesT-FLEX CAD Brochureicad100% (1)

- progeCAD IntelliCAD DWG Drafting CAD Software FeaturesDocument2 pagesprogeCAD IntelliCAD DWG Drafting CAD Software Featuresicad100% (2)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Sho001 Nap Ifc M2 06 RCM DR SS 5001 03 0aDocument1 pageSho001 Nap Ifc M2 06 RCM DR SS 5001 03 0aMohanad EldarerPas encore d'évaluation

- Ce 5355Document2 pagesCe 5355ragunas tatyaPas encore d'évaluation

- Light Timber Steel Frame Structure ManualDocument132 pagesLight Timber Steel Frame Structure ManualDinesh Poudel100% (1)

- BridgeDocument12 pagesBridgesoumyakuriakosePas encore d'évaluation

- Approved College Exam Board, College of Engineering, Science and Technology Graduation List For December 2020Document4 pagesApproved College Exam Board, College of Engineering, Science and Technology Graduation List For December 2020EloniPas encore d'évaluation

- Commissioning Process Plant ModelDocument21 pagesCommissioning Process Plant ModelLuis EnriquePas encore d'évaluation

- Dr. Nahed Sobhi Dr. Nahed SobhiDocument20 pagesDr. Nahed Sobhi Dr. Nahed Sobhijaga_desh86Pas encore d'évaluation

- Commissioning and Qualification 2Document0 pageCommissioning and Qualification 2venki_beePas encore d'évaluation

- Teleprotection Systems For 220 KV Ohl With Three Ends: Florin BALASIU, Gheorghe MORARUDocument3 pagesTeleprotection Systems For 220 KV Ohl With Three Ends: Florin BALASIU, Gheorghe MORARUMihaelaPas encore d'évaluation

- Transformer REFDocument4 pagesTransformer REFs_banerjeePas encore d'évaluation

- R961006855 EHTG-Flyer USD WebDocument2 pagesR961006855 EHTG-Flyer USD Webmarc271986Pas encore d'évaluation

- Modern Finnish Wooden TownDocument6 pagesModern Finnish Wooden TownChechu MenendezPas encore d'évaluation

- Culvert ThicknessDocument23 pagesCulvert ThicknessNilaAbubakarPas encore d'évaluation

- Gaddhsumit Sumit-GaddhDocument2 pagesGaddhsumit Sumit-GaddhSumit GaddhPas encore d'évaluation

- Effect of Technological Advancement in Quantity Surveying On Cost Labour and Time Performance of Construction Projects in AbujaDocument11 pagesEffect of Technological Advancement in Quantity Surveying On Cost Labour and Time Performance of Construction Projects in AbujaDwayne ChimaPas encore d'évaluation

- (05225) - Calculation of Reinforced Concrete Buildings With Sap2000 PDFDocument63 pages(05225) - Calculation of Reinforced Concrete Buildings With Sap2000 PDFJohn Chiv0% (1)

- Deped K To 12 Technology and Livelihood Education - PlumbingDocument8 pagesDeped K To 12 Technology and Livelihood Education - Plumbingyachiru12175% (4)

- ACI 350 3 06 Appendix BRev00 29 Sep 2013Document11 pagesACI 350 3 06 Appendix BRev00 29 Sep 2013Ghencea Adrian100% (2)

- Master Thesis Topics in Industrial EngineeringDocument5 pagesMaster Thesis Topics in Industrial Engineeringpbfbkxgld100% (1)

- The Ecat Magazine 1.0 (By Uet Tribune)Document55 pagesThe Ecat Magazine 1.0 (By Uet Tribune)Anonymous n7eRdoKiiv100% (1)

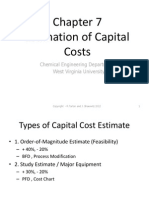

- Chapter 7 - Capital Cost EstimationDocument35 pagesChapter 7 - Capital Cost EstimationSyafiq IzzuddinPas encore d'évaluation

- Canam Deck CertificationsDocument2 pagesCanam Deck CertificationsIlonaBartoshPas encore d'évaluation

- BS EN 10034-1993 Structural Steel I and H Sections - Tolerances On Shape and Dimensions PDFDocument14 pagesBS EN 10034-1993 Structural Steel I and H Sections - Tolerances On Shape and Dimensions PDFsouravrobinPas encore d'évaluation

- 4 Code Requeriments For Nuclear Safety Related Concrete StructuresDocument89 pages4 Code Requeriments For Nuclear Safety Related Concrete StructuresRavi Teja Polisetti0% (1)

- Shaft DesignDocument37 pagesShaft DesignFarah HumaPas encore d'évaluation

- Typical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BDocument4 pagesTypical Sizes and Shapes of Concrete Masonry Units: TEK 2-1BfostbarrPas encore d'évaluation

- Jasco Beam ManualDocument32 pagesJasco Beam Manualxyzhyn100% (2)

- Multidirectional Ringlock Scaffolding: - Catalogue & Parts ListDocument8 pagesMultidirectional Ringlock Scaffolding: - Catalogue & Parts ListIng JJ SPPas encore d'évaluation

- BP 2632 GBDocument24 pagesBP 2632 GBالمهندسوليدالطويلPas encore d'évaluation

- Manoj Raj P R - Uae - UpdatedDocument4 pagesManoj Raj P R - Uae - UpdatedMano LazyboyPas encore d'évaluation