Académique Documents

Professionnel Documents

Culture Documents

SM002 RevF 2005 Site Survey For Diesel Generator AMG Lowres

Transféré par

Ken VikstromTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

SM002 RevF 2005 Site Survey For Diesel Generator AMG Lowres

Transféré par

Ken VikstromDroits d'auteur :

Formats disponibles

Site surveys for synchronous generators for

diesel and gas engines, AMG 710 - 1600

SM002 EN REV F 2005

Service notes

A site survey should be performed if there is

insufficient information about the condition of

a generator. The survey is carried out during a

process shutdown, and the results are recorded

in a detailed report. This contains information

on the present condition of the generator and

the ambient conditions in which it operates, as

well as recommendations for any immediate

measures that could be taken in order to

maximize availability.

The objective is to create a long-term

systematic preventive maintenance program

that is based on the survey results and on the

product specific maintenance schedule.

Unique benefits

- Information about the actual system and

environmental conditions

- Assessment of the service material

required for preventive maintenance

- Understanding of maintenance resource

needs

- Useful pre-planning for preventive

maintenance

- Information for the long-term systematic

maintenance program

- Proposals for future generator development

- Evaluation of current maintenance

procedures

- Information about spare part and support

availability

SM002 EN REV F 2005

Actions on site

- Checking the maintenance history,

familiarization with the service philosophy

- Assessing the generators condition

- Inspection of the environment

- Checking documentation and spare part

availability

- Evaluating the competence of the

maintenance personnel

- Evaluating the generators performance

- Checking the AVR parameter settings

- Assessing the generators maintenance needs

- Short/long term upgrades and modifications

- Lifetime estimation

- Preventive maintenance kits

Preventive maintenance

In order to ensure optimum performance

over the entire lifetime of a generator, ABB

recommends that annual inspections and

regular preventive maintenance are carried out.

Copyright 2007 ABB. All rights reserved. Specifications subject to change without notice.

Service notes

Preparatory actions

- Studying the generators maintenance

history

- Checking details on the generator

- Preparing the reporting templates

- Evaluating the training needs (operation

and maintenance)

Reporting

- Statement about the generators condition

- List of recommended spare parts

- Recommendations for the next inspection or

maintenance

- Recommendations for corrective actions

(if necessary) or future generator

development

- Detailed record of inspections, faults and

defects fixed

- Photographs of the findings

- Statement about the lifecycle phase of the

generator to ensure spare part and support

availability

Printed in Finland.

Three stage process

ABB Oy

Machines, After Sales

PO Box 186

FIN-00381 Helsinki, Finland

Tel: +358 10 22 11

Fax: +358 10 2222 544

e-mail: aftersales.machines@fi.abb.com

www.abb.com/motors&generators

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- DNV Ru Ship Pt4ch10Document53 pagesDNV Ru Ship Pt4ch10Ken Vikstrom100% (1)

- DNV Ru Ship Pt2ch1Document50 pagesDNV Ru Ship Pt2ch1Ken VikstromPas encore d'évaluation

- Ix T7AM-CAN - Beijer ElectronicsDocument1 pageIx T7AM-CAN - Beijer ElectronicsKen VikstromPas encore d'évaluation

- DNV Ru Ship Pt4ch9Document60 pagesDNV Ru Ship Pt4ch9Ken VikstromPas encore d'évaluation

- DNV Ru Ship Pt4ch11Document15 pagesDNV Ru Ship Pt4ch11Ken VikstromPas encore d'évaluation

- DNV Ru Ship Pt4ch4Document102 pagesDNV Ru Ship Pt4ch4Ken VikstromPas encore d'évaluation

- DNV-RU-SHIP-Pt1Ch3 Part 1 General Regulations Chapter 3 Documentation and CertificationDocument8 pagesDNV-RU-SHIP-Pt1Ch3 Part 1 General Regulations Chapter 3 Documentation and CertificationKen VikstromPas encore d'évaluation

- DNV-RU-SHIP-Pt1Ch1 Part 1 General Regulations Chapter 1 General RegulationsDocument50 pagesDNV-RU-SHIP-Pt1Ch1 Part 1 General Regulations Chapter 1 General RegulationsKen VikstromPas encore d'évaluation

- DNV Ru Ship Pt4ch7Document140 pagesDNV Ru Ship Pt4ch7Ken VikstromPas encore d'évaluation

- DNV Ru Ship Pt4ch1Document35 pagesDNV Ru Ship Pt4ch1Ken VikstromPas encore d'évaluation

- Iso 8528 8 2016Document9 pagesIso 8528 8 2016Ken VikstromPas encore d'évaluation

- DNV Ru Ship Pt4ch5Document90 pagesDNV Ru Ship Pt4ch5Ken VikstromPas encore d'évaluation

- Iso 8528 9 Reciprocating Ic Engine Driven Alternating Current Generating Sets Part 9Document19 pagesIso 8528 9 Reciprocating Ic Engine Driven Alternating Current Generating Sets Part 9Ken VikstromPas encore d'évaluation

- Iso 8528 1 2018Document11 pagesIso 8528 1 2018Ayub Anwar M-Salih50% (2)

- Ppu 300Document75 pagesPpu 300Ken VikstromPas encore d'évaluation

- Tas 331DG 4921220036Document4 pagesTas 331DG 4921220036Ken VikstromPas encore d'évaluation

- Iso 8528 7 2017Document9 pagesIso 8528 7 2017Ken VikstromPas encore d'évaluation

- Asc 4 Commissioning Guidelines 4189341077 UkDocument59 pagesAsc 4 Commissioning Guidelines 4189341077 UkKen VikstromPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Learn With Facebook - Digital-Skills-Modules-Combined-04-24 PDFDocument182 pagesLearn With Facebook - Digital-Skills-Modules-Combined-04-24 PDFMostesarePas encore d'évaluation

- Reading V - Customs and Warehouse ServicesDocument3 pagesReading V - Customs and Warehouse ServicesRous TobarPas encore d'évaluation

- Word SmartDocument189 pagesWord SmartSmeeta Prasai0% (1)

- IELTS Advantage Speaking and Listening SkillsDocument122 pagesIELTS Advantage Speaking and Listening SkillsAlba Lucía Corrales Reina100% (8)

- Contrastive and Error AnalysisDocument22 pagesContrastive and Error AnalysisAan SafwandiPas encore d'évaluation

- Chapter 12 Quiz 1Document4 pagesChapter 12 Quiz 1joycePas encore d'évaluation

- Faith Heminger Critical Self ReflectionDocument5 pagesFaith Heminger Critical Self Reflectionapi-385782224Pas encore d'évaluation

- Curriculum Map Physical Education 6-8Document7 pagesCurriculum Map Physical Education 6-8Levine Del VallePas encore d'évaluation

- Morshed Mannan - Single - WebDocument72 pagesMorshed Mannan - Single - WebManuu VilardoPas encore d'évaluation

- Letter of Inquiry RegardingDocument10 pagesLetter of Inquiry RegardingPradyumn Kumar ShuklaPas encore d'évaluation

- Maintenance Supervisor or Maintenance Technician or Mechanic orDocument2 pagesMaintenance Supervisor or Maintenance Technician or Mechanic orapi-77711996Pas encore d'évaluation

- Masters Degree Thesis For Educational ManagementDocument39 pagesMasters Degree Thesis For Educational ManagementJohn Bryan Aldovino100% (2)

- Levinas - The Levinas ReaderDocument313 pagesLevinas - The Levinas Readerzbiralec100% (3)

- How Can Smes Effectively Implement The CSR Agenda: Kelompok 5Document21 pagesHow Can Smes Effectively Implement The CSR Agenda: Kelompok 5Vitha MasyitaPas encore d'évaluation

- Alabama Uniform Concealed Carry ActDocument29 pagesAlabama Uniform Concealed Carry ActLuke_McCoy_2863Pas encore d'évaluation

- SB 864Document2 pagesSB 864Sinclair Broadcast Group - EugenePas encore d'évaluation

- Whitehead and BiosemioticsDocument22 pagesWhitehead and BiosemioticsJ PPas encore d'évaluation

- Corrective and Preventive Action - WikipediaDocument20 pagesCorrective and Preventive Action - WikipediaFkPas encore d'évaluation

- Conejo Top AttractionsDocument2 pagesConejo Top AttractionsDemnal55Pas encore d'évaluation

- Drill To Win 12 Months To Better Brazillian Jiu Jitsu - 8zggktb PDFDocument2 pagesDrill To Win 12 Months To Better Brazillian Jiu Jitsu - 8zggktb PDFAdarsh More100% (1)

- FMS Information Bulletin 2008Document52 pagesFMS Information Bulletin 2008meenana100% (2)

- Mid Term Defense Updated SlidesDocument31 pagesMid Term Defense Updated SlidesRojash ShahiPas encore d'évaluation

- Why Small Retailers Endure in Latin AmericaDocument16 pagesWhy Small Retailers Endure in Latin AmericaAhmed SamirPas encore d'évaluation

- Hiscox Appetite GuideDocument4 pagesHiscox Appetite GuideAmlan Kumar SahuPas encore d'évaluation

- Operating InstructionsDocument3 pagesOperating InstructionsShami MudunkotuwaPas encore d'évaluation

- Sleeping PodsDocument1 pageSleeping PodsSamrin ZeyaPas encore d'évaluation

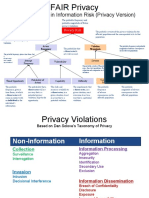

- Factor Analysis in Information Risk (Privacy Version)Document8 pagesFactor Analysis in Information Risk (Privacy Version)Otgonbayar TsengelPas encore d'évaluation

- Sam Selvon The Lonely LondonersDocument59 pagesSam Selvon The Lonely LondonersAndy LinPas encore d'évaluation

- Tourism Engagement Co-Creating Well-Bein PDFDocument349 pagesTourism Engagement Co-Creating Well-Bein PDFMariana ValcacioPas encore d'évaluation

- AOT Traffic Report-2018Document252 pagesAOT Traffic Report-2018Egsiam SaotonglangPas encore d'évaluation