Académique Documents

Professionnel Documents

Culture Documents

8 Types of Production Systems Explained

Transféré par

Jyoti Nawlani0 évaluation0% ont trouvé ce document utile (0 vote)

377 vues6 pagesproduction management

Titre original

Types of Production System

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentproduction management

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

377 vues6 pages8 Types of Production Systems Explained

Transféré par

Jyoti Nawlaniproduction management

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 6

TYPES OF

PRODUCTION

SYSTEMS

Intermittent

Production

Project

Production

Job Shop

Production

Continuous

Production

Batch

Production

Mass

Production

Assembly

line

Production

Process

Production

Synthetic

Production

Analytical

Production

The types of production system are grouped under two categories.,

Intermittent production system, and

Continuous production system.

1. INTERMITTENT PRODUCTION SYSTEM

Intermittent means something that starts and stops at irregular intervals

In the intermittent production system, goods are produced based on customer's

orders.

These goods are produced on a small scale.

The flow of production is not continuous.

In this system, large varieties of products are produced.

These products are of different sizes.

The design of these products goes on changing. It keeps changing according to the

design and size of the product.

Therefore, this system is very flexible.

Example:

The work of a tailor is based on the number of orders he gets from his customers. The clothes are stitched

for every customer independently by the tailor as per one's measurement and size. Goods (stitched

clothes) are made on a limited scale and is proportional to the number of orders received from customers.

Here, stitching is not done on a continuous basis.

Production and Operations Management

Jyoti Nawlani

The types of intermittent production system include:

a. Project production flows,

b. Job shop production flows, and

c. Batch production flows.

a. PROJECT PRODUCTION FLOWS,

Single assignment job is there

Complex in nature

This system is for specific time period

Specific expenditure is there

All the operations are carried out in a fixed position layout

High customization

The sequence of operations is unique to each project

Products cannot be produced to stock because needs of next customer

unknown

Examples are: - ships, locomotives air crafts, roads, building, spacecrafts.

b. JOB-SHOP PRODUCTION

Job-shop production are characterised by manufacturing one or few quantity of

products designed and produced as per the specification of customers within

prefixed time and cost.

The distinguishing feature of this is low volume and high variety of products.

A job-shop comprises of general-purpose machines arranged into different

departments.

Each job demands unique technological requirements, demands processing on

machines in a certainsequence.

Production and Operations Management

Jyoti Nawlani

Use of general purpose machines and facilities.

Highly skilled operators who can take up each job as a challenge because of

uniqueness.

Large inventory of materials, tools, parts.

Detailed planning is essential for sequencing the requirements of each product,

capacities foreachwork centre and order priorities.

Advantages

1.Because of general purpose machines and facilities variety of products can be

produced.2. Operators will become more skilled and competent, as each job

gives themlearningopportunities.3. Full potential of operators can be utilized.

4. Opportunity exists for Creative methods and innovative ideas.

Limitations

1. Higher cost due to frequent set up changes.2. Higher level of inventory at all

levels and hence higher inventory cost. 3. Production planning is complicated.

4. Larger space requirements.

c. BATCH PRODUCTION

American Production and Inventory Control Society (APICS) defines Batch

Production as a form of manufacturing in which the job pass through the

functional departments in lots or batches and each lot may have a different

routing.

It is characterised by the manufacture of limited number of products

produced at regular intervals and stocked awaiting sales.

Plant and machinery are flexible.

Plant and machinery set up is used for the production of item in a batch and

change of set upis required for processing the next batch.

Manufacturing lead-time and cost are lower as compared to job order

production

Advantages

:1. Better utilisation of plant and machinery.2. Promotes functional

specialisation.3. Cost per unit is lower as compared to job order production.4.

Lower investment in plant and machinery.5. Flexibility to accommodate and

process number of products.6. Job satisfaction exists for operators.

Limitations:

1. Material handling is complex because of irregular and longer flows.2.

Production planning and control is complex. 3. Work in process inventory is

higher compared to continuous production.4. Higher set up costs due to

frequent changes in set up.

Production and Operations Management

Jyoti Nawlani

2. CONTINUOUS PRODUCTION SYSTEM

Continuous means something that operates constantly without any irregularities or

frequent halts.

In the continuous production system, goods are produced constantly as per

demand forecast.

Goods are produced on a large scale for stocking and selling.

They are not produced on customer's orders.

Here, the inputs and outputs are standardized along with the production process

and sequence.

Example:

The production system of a food industry is purely based on the demand forecast.

Here, a large-scale production of food takes place. It is also a continuous

production.

.

The types of continuous production system include:

a. Mass production flows, and

b. Process production flows.

Advantages

Production and Operations Management

Jyoti Nawlani

1. Standardisation of product and process sequence.2. Higher rate of production with

reduced cycle time.3. Higher capacity utilisation due to line balancing.4. Manpower is

not required for material handling as it is completely automatic.5. Person with limited

skills can be used on the production line.6. Unit cost is lower due to high volume of

production.

Limitations :

1. Flexibility to accommodate and process number of products does not exist.2. Very

high investment for setting flow lines.3. Product differentiation is limited

a. MASS PRODUCTION AND ASSEMBLYLINE PRODUCTION

Manufacture of discrete parts or assemblies using a continuous process are called

Mass Production.

This production system is justified by very large volume of production.

The machines are arranged in a line or product layout. Product and process

standardisation exists and all outputs follow the same path.

Mass Production is characterised by

1. Standardisation of product and process sequence.2. Dedicated special purpose

machines having higher production capacities and output rates.3. Large volume of

products.4. Shorter cycle time of production.5. Lower in process inventory.6.

Perfectly balanced production lines.7. Flow of materials, components and parts is

continuous and without any back tracking.8. Production planning and control is

easy.9. Material handling can be completely automatic.

Advantages

1.Higher rate of production with reduced cycle time.2. Higher capacity utilisation

due to line balancing.3. Less skilled operators are required.4. Low process

inventory.5. Manufacturing cost per unit is low.

Limitations:

1. Breakdown of one machine will stop an entire production line.2. Line layout

needs major change with the changes in the product design.3. High investment in

production facilities.4. The cycle time is determined by the slowest operation

c. PROCESS PRODUCTION

Process production is characterized by the manufacture of a single product . The

flexibility of such plants is almost zero as only one type of product can be

produced in the plant

Examples are refineries, petrol, kerosene, and diesel oil.

Production and Operations Management

Jyoti Nawlani

Characteristics of Process Production

i.

ii.

iii.

iv.

v.

Special purpose machines and equipments are used

Material handling is highly mechanized In this manufacturing cycle time is

almost zero.

The whole plant is like one large machine where materials are entered at the

one end.

Labor required is having semi skilled workmen and skilled technicians are

required

Supervision in this type of production is high

There are two types of Process Production

1. Analytical Process: Here raw material is broken down into its component

parts. Ex: Crude oil inrefinery is broken down into individual fractions like

Kerosene. Petrol, Naptha etc.

2. Synthetic Process: Mixing of two or more parts of materials to form a

finishesd product like soap.

Production and Operations Management

Jyoti Nawlani

Vous aimerez peut-être aussi

- Production SystemDocument5 pagesProduction SystemPratiksinh VaghelaPas encore d'évaluation

- Types of Production SystemsDocument5 pagesTypes of Production Systemsjgkonnully92% (12)

- Process SelectionDocument39 pagesProcess Selectionajit88ak100% (1)

- Cost Accounting Short QuestionsDocument5 pagesCost Accounting Short QuestionsMalika HaiderPas encore d'évaluation

- Production Information SystemDocument9 pagesProduction Information Systemamitjhaime50% (2)

- Types of Production Systems ExplainedDocument4 pagesTypes of Production Systems ExplainedDemi DelizoPas encore d'évaluation

- Demand Forecasting Methods PPT MBADocument20 pagesDemand Forecasting Methods PPT MBAkeshmuPas encore d'évaluation

- Recent Trends in OmDocument3 pagesRecent Trends in OmSathiyan HR50% (2)

- Production & Operation ManagementDocument13 pagesProduction & Operation Managementmadhvendra99Pas encore d'évaluation

- Scope of financial management and its objectivesDocument4 pagesScope of financial management and its objectivesgosaye desalegnPas encore d'évaluation

- Efficient Facility Layout DesignDocument6 pagesEfficient Facility Layout DesignOckouri BarnesPas encore d'évaluation

- Continuous vs Intermittent ProductionDocument7 pagesContinuous vs Intermittent ProductionLilselosa Anthonette Gonzales50% (2)

- The Four Supply Chain EnablersDocument13 pagesThe Four Supply Chain EnablersBrendon Nyaude0% (1)

- Types of Manufacturing SystemDocument23 pagesTypes of Manufacturing SystemVishal ChoudharyPas encore d'évaluation

- Unit 3: Managerial EconomicsDocument29 pagesUnit 3: Managerial Economicsarjun singh100% (1)

- Value Analysis and Material ManagementDocument9 pagesValue Analysis and Material Managementsimply_cooolPas encore d'évaluation

- Demand ForecastingDocument16 pagesDemand Forecastingkarteek_arPas encore d'évaluation

- Manufacturing & Non-Manufacturing OperationsDocument6 pagesManufacturing & Non-Manufacturing OperationsSNEHA ARAVIND 16BCF050Pas encore d'évaluation

- Factors for Deducting Employee Remuneration Under Tax PlanningDocument3 pagesFactors for Deducting Employee Remuneration Under Tax PlanningashurebelPas encore d'évaluation

- Inter Process ProfitsDocument10 pagesInter Process ProfitsKella Pradeep100% (1)

- Unit I Introduction To Operations ManagementDocument60 pagesUnit I Introduction To Operations Management2arunagiri0% (1)

- Mis Notes As Per Kannur University Syllabus Module 1Document17 pagesMis Notes As Per Kannur University Syllabus Module 1ROSEMARYPas encore d'évaluation

- Methods and Types of CostingDocument2 pagesMethods and Types of CostingCristina Padrón PeraltaPas encore d'évaluation

- Operation Research First Unit Notes For Bba 4th SemDocument16 pagesOperation Research First Unit Notes For Bba 4th SemRavi Patel78% (9)

- Factors affecting production planning and controlDocument7 pagesFactors affecting production planning and controlharshdeep mehtaPas encore d'évaluation

- Operational Management 1Document10 pagesOperational Management 1Aditya Agrawal50% (2)

- Understanding Integrated vs Non-Integrated Accounting SystemsDocument20 pagesUnderstanding Integrated vs Non-Integrated Accounting Systemsrabi_kungle0% (1)

- SCM Question BankDocument2 pagesSCM Question BankKalpesh Patil0% (1)

- Plant Layout Operation ManagementDocument7 pagesPlant Layout Operation ManagementKAPIL VARSHNEYPas encore d'évaluation

- Types of LayoutDocument19 pagesTypes of Layoutmuneerpp100% (5)

- Learning ObjectivesDocument10 pagesLearning ObjectivesShraddha MalandkarPas encore d'évaluation

- MCQ OSCM Unit 2 PDFDocument13 pagesMCQ OSCM Unit 2 PDFbhupesh joshiPas encore d'évaluation

- Work StudyDocument70 pagesWork StudyNinad100% (3)

- 5 - Marginal CostingDocument9 pages5 - Marginal Costing9897856218Pas encore d'évaluation

- Production FunctionDocument35 pagesProduction Functionrinky_trivedi100% (1)

- Optimize Operations with the Right LayoutDocument6 pagesOptimize Operations with the Right LayoutwearematalabiPas encore d'évaluation

- Management Accounting NotesDocument72 pagesManagement Accounting NotesALLU SRISAIPas encore d'évaluation

- Production and Operations Management Notes PDFDocument103 pagesProduction and Operations Management Notes PDFYashPas encore d'évaluation

- Editing Coding Tabulation of DataDocument18 pagesEditing Coding Tabulation of DataAshi GuptaPas encore d'évaluation

- Plant LayoutDocument15 pagesPlant LayoutVaibhav Vithoba Naik89% (9)

- Cost Accounting MCQs and ProblemsDocument5 pagesCost Accounting MCQs and ProblemsEnbathamizhanPas encore d'évaluation

- Cost Sheet Breakdown: Materials, Labor, ExpensesDocument17 pagesCost Sheet Breakdown: Materials, Labor, Expenses9986212378Pas encore d'évaluation

- Principles of Management Series Test 1 Question PaperDocument1 pagePrinciples of Management Series Test 1 Question PaperKailas Sree Chandran0% (1)

- Various Inventory Costs: - Holding / - Ordering Costs - Purchase Costs - Total CostDocument28 pagesVarious Inventory Costs: - Holding / - Ordering Costs - Purchase Costs - Total CostAditya Dashputre100% (2)

- Inventory Management PPT 1st Review I MDocument11 pagesInventory Management PPT 1st Review I Maavula kalyaniPas encore d'évaluation

- Meaning Research MethodsDocument3 pagesMeaning Research MethodsBasappaSarkar100% (1)

- Decisions Involving Alternate ChoicesDocument20 pagesDecisions Involving Alternate Choicesnaveenpimg1990100% (1)

- AshrulDocument58 pagesAshrulNilabjo Kanti Paul100% (2)

- A Study On VED Analysis Done at SRI IYYAN TEXTILE MILL PVT LTD, CoimbatoreDocument25 pagesA Study On VED Analysis Done at SRI IYYAN TEXTILE MILL PVT LTD, CoimbatoreKrishna Murthy APas encore d'évaluation

- Two Marks-On U IDocument20 pagesTwo Marks-On U ISaravanan Shanmugam0% (3)

- Product Operation Management PPT (Unit 1&2)Document110 pagesProduct Operation Management PPT (Unit 1&2)Sudhir Singh100% (2)

- DepartmentDocument21 pagesDepartmentnitin100% (1)

- Cost SheetDocument29 pagesCost Sheetnidhisanjeet0% (1)

- Unit - 4 Demand Forecasting: 4.0 ObjectivesDocument8 pagesUnit - 4 Demand Forecasting: 4.0 ObjectivesParth ThakkarPas encore d'évaluation

- Demand ForecastingDocument21 pagesDemand ForecastingPrasanth Shanmugam100% (2)

- Management Function Behaviour AssignmentDocument21 pagesManagement Function Behaviour AssignmentAnand75% (4)

- (EFM) Ecomonics For Manager-SEM-I-GTUDocument109 pages(EFM) Ecomonics For Manager-SEM-I-GTUkeyurPas encore d'évaluation

- On GradingDocument58 pagesOn Gradingkumar1992prashantPas encore d'évaluation

- Om2 TPSDocument21 pagesOm2 TPSharischarmPas encore d'évaluation

- Classifying Production Systems: Job Shop, Batch, Mass & ContinuousDocument3 pagesClassifying Production Systems: Job Shop, Batch, Mass & ContinuousSamir GokarnPas encore d'évaluation

- Davies Paints Philippines FINALDocument5 pagesDavies Paints Philippines FINALAnonymous 0zrCNQPas encore d'évaluation

- MGT 101Document13 pagesMGT 101MuzzamilPas encore d'évaluation

- American Bible Society Vs City of Manila 101 Phil 386Document13 pagesAmerican Bible Society Vs City of Manila 101 Phil 386Leomar Despi LadongaPas encore d'évaluation

- Transformation of The Goddess Tara With PDFDocument16 pagesTransformation of The Goddess Tara With PDFJim Weaver100% (1)

- 0 - Dist Officers List 20.03.2021Document4 pages0 - Dist Officers List 20.03.2021srimanraju vbPas encore d'évaluation

- PersonalEditionInstallation6 XDocument15 pagesPersonalEditionInstallation6 XarulmozhivarmanPas encore d'évaluation

- Electrical Energy Audit and SafetyDocument13 pagesElectrical Energy Audit and SafetyRam Kapur100% (1)

- Peugeot ECU PinoutsDocument48 pagesPeugeot ECU PinoutsHilgert BosPas encore d'évaluation

- Stores & Purchase SopDocument130 pagesStores & Purchase SopRoshni Nathan100% (4)

- Philippine LiteratureDocument75 pagesPhilippine LiteratureJoarlin BianesPas encore d'évaluation

- Samuel Johnson Short Fiction Analysis - EssayDocument2 pagesSamuel Johnson Short Fiction Analysis - EssayATRI BHATTACHARYYAPas encore d'évaluation

- Static pile load test using kentledge stackDocument2 pagesStatic pile load test using kentledge stackHassan Abdullah100% (1)

- API Technical Document 10656Document19 pagesAPI Technical Document 10656NazmulPas encore d'évaluation

- Dinie Zulkernain: Marketing Executive / Project ManagerDocument2 pagesDinie Zulkernain: Marketing Executive / Project ManagerZakri YusofPas encore d'évaluation

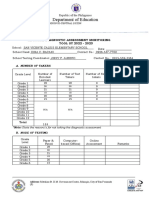

- Regional Diagnostic Assessment Report SY 2022-2023Document3 pagesRegional Diagnostic Assessment Report SY 2022-2023Dina BacaniPas encore d'évaluation

- On Site and Off Site Emergency PlanningDocument12 pagesOn Site and Off Site Emergency Planningyogeshwaran N100% (1)

- GST English6 2021 2022Document13 pagesGST English6 2021 2022Mariz Bernal HumarangPas encore d'évaluation

- Aerial Hijacking and The International LawDocument14 pagesAerial Hijacking and The International LawAnonymous vUVxDQPas encore d'évaluation

- 1.introduction To IESL B PaperDocument47 pages1.introduction To IESL B PaperGayan IndunilPas encore d'évaluation

- Attestation Process ChecklistDocument2 pagesAttestation Process Checklistkim edwinPas encore d'évaluation

- Social Media Audience Research (To Use The Template, Click The "File" Tab and Select "Make A Copy" From The Drop-Down Menu)Document7 pagesSocial Media Audience Research (To Use The Template, Click The "File" Tab and Select "Make A Copy" From The Drop-Down Menu)Jakob OkeyPas encore d'évaluation

- MNC diversity factors except expatriatesDocument12 pagesMNC diversity factors except expatriatesGanesh Devendranath Panda100% (1)

- English For Informatics EngineeringDocument32 pagesEnglish For Informatics EngineeringDiana Urian100% (1)

- Name Designation Division/Section Telephone Head Office: New DelhiDocument6 pagesName Designation Division/Section Telephone Head Office: New DelhiHarshaditya Singh ChauhanPas encore d'évaluation

- UNIT 4 Lesson 1Document36 pagesUNIT 4 Lesson 1Chaos blackPas encore d'évaluation

- Immersion-Reviewer - Docx 20240322 162919 0000Document5 pagesImmersion-Reviewer - Docx 20240322 162919 0000mersiarawarawnasahealingstagePas encore d'évaluation

- Chapter 2Document16 pagesChapter 2golfwomann100% (1)

- The Call of CthulhuDocument15 pagesThe Call of CthulhuCerrüter LaudePas encore d'évaluation

- Aznar V CitibankDocument3 pagesAznar V CitibankDani LynnePas encore d'évaluation

- Compounding & Reduplication: Forms and Analysis Across LanguagesDocument23 pagesCompounding & Reduplication: Forms and Analysis Across LanguagesUtari ListiyaniPas encore d'évaluation