Académique Documents

Professionnel Documents

Culture Documents

Introduction To RC Design: National Mission On Education Through Ict (MHRD, Govt of India)

Transféré par

Brajesh SumanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Introduction To RC Design: National Mission On Education Through Ict (MHRD, Govt of India)

Transféré par

Brajesh SumanDroits d'auteur :

Formats disponibles

INTRODUCTION TO RC DESIGN

DR. SUSHANTA CHAKRABORTY

NATIONAL MISSION ON EDUCATION THROUGH ICT

(MHRD, GOVT OF INDIA)

I N D I A N I N ST I T U T E O F T EC H N O LO GY

K H A R AG P U R 7 2 1 3 0 2 I N D I A

CONCRETE - Building Material for over 150 years

Advantage

Durability, specially resistance against water

Easy to cast in various size and shape

Excellent compressive bearing

Economic to use

Disadvantage

Remarkably weak in tension (1/10th of compressive

strength)

Basic Considerations in RC Design of Structures

Strength & Integrity

Ability to resist stresses due to environmental loading,

fire etc.

Stability

Against overturning, sliding and buckling

Serviceability

Adequate stiffness to counteract deflection, vibration

response, crack width etc.

Economics

Aesthetics

Goal of RC Design

To ensure ductile failure, instead of the sudden brittle failure

of plain concrete

concrete is embedded with steel bars (cuts across principal

tensile planes, i.e. across the potential tensile cracks), as if

stitching the (to be) separated concrete parts

Role of Structural Analysis in Design

Analysis problem

The geometric entities and material properties of a structure is

defined. It is desired to find out the stresses, deformations and

allowable load onto that member. The solutions are usually

unique.

Design problem

Explore the various combinations of geometric and material

properties which may fulfill the purpose in hand, e.g. to carry a

defined loading. There may be multiple or even infinite

possibilities.

Importance of Specifications and Standards

Actual construction practice needs supports from real

experimental or observational evidences, past records of

performances of similar structures.

Various Codes of Practices across the countries try to lay down

guidelines, for design and construct structures, supported by

empirical laws, collective observational records of experts.

These codes are updated periodically with respect to new

findings.

Importance of Specifications and Standards

The main functions of these codes are to bring valuable and

sophisticated information in the form of simple formulae and

charts, readable by nominally trained practicing engineers.

Apart from complying with any such code, the engineer must

ensure adequate technical supervision to ensure quality of

material used and appropriate construction techniques with

proper sequences.

The students must be introduced properly with the existence of

such professional ethics right at this moment

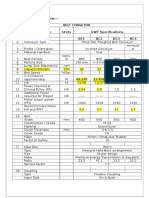

Code of Practise for Design

IS 456: 2000

Plain and Reinforced Concrete- Code of Practice

IS 875: 1987

Loading (other than earthquake)

IS 1893: 2002

Criteria for Earthquake Resistant Design of Structures

IS 13920: 1993

Ductile Detailing of Reinforced Concrete Structures Subjected to

Seismic Forces

SP16: 1980

Design Aids for Reinforced Concrete to IS 456: 1978

SP34: 1987

Handbook on Concrete Reinforcement and Detailing

Actual Stress Strain Behaviour of Concrete

Design Stress Strain Behaviour of Concrete in

Flexural Compression

Discussion of Design Stress Strain Curve

c= partial safety factor for concrete=1.5

The graph consists of an initial parabolic portion up to a

strain of 0.002 and a straight line up to the an ultimate strain

of 0.0035

Under uniform compression (not from flexure) the ultimate

strain is limited to 0.002 only.

For a combination of axial compression and flexure, the

ultimate strain is limited to a value between 0.002 and 0.0035

depending upon the location of neutral axis.

Actual Stress Strain Behaviour of Reinforcing Steel

Characteristic and Design Stress Strain Behaviour

of Reinforcing Steel

s= partial safety factor for steel=1.15

y 0.87

y

0.002

E

Discussion of Design Stress Strain Curve

s= partial safety factor for steel=1.15

For cold-worked type of steels (FE415 or Fe500) there is no

specific yield point.

Full design yield strength is assumed to be 0.87fy correspond

to the proof strain of 0.002

The design yield strain is to be taken as

y

y 0.87

0.002

E

Difference in Implementing Stress-strain Relation Of

The Concrete And Steel

The partial safety factor s for steel is applicable in inelastic

region only because,

the Modulus of elasticity is independent of yield strength.

Whereas,

The partial safety factor c for concrete is applicable in all the

stresses because,

the stress strain curve behaviour depends on the

characteristic strength of concrete.

DIFFERENT METHODS OF RC DESIGN

WORKING STRESS METHOD (WSM)

ULTIMATE LOAD METHOD (ULM)

LIMIT STATE METHOD (LSM)

Working Stress Method (WSM)

Linear elastic behaviour is assumed.

Permissible stresses are kept well below the material strength.

WSM is based on service load alone

Factor of Safety

= (Strength of the material)/(Permissible stresses)

Factor of safety remains same for all kind of loading.

The method is unable to depict the uncertainties associated

with different types of loading.

Ultimate Load Method (ULM)

Non-linear elastic behaviour may be assumed.

Permissible stresses are kept well below the material strength.

ULM is based on ultimate load alone

Load factor

= (Ultimate Load)/(Working Load)

Factor of safety is different for different kind of loading.

The method fails to fulfill serviceability condition.

LIMIT STATE METHOD (LSM)

Limit State Method (LSM) is to provide safety against ultimate

load and serviceability at working load.

Variations in loading, material properties, geometric entities

having varying degrees of uncertainties are incorporated using

Multiple Safety Factor format.

Partial factor of

safety for Material

Partial factor of

safety for load

The methodology actually is based on the probability of

failure in statistical terms and expressed as probability

density function of failure.

Probability Density

Probability Density Function of Failure

S = Load Effect

R = Resistance

Load or Resistance

Design Load & Design Strength

THE END

Vous aimerez peut-être aussi

- Final Book Word DocumentDocument209 pagesFinal Book Word DocumentNasreen KhanamPas encore d'évaluation

- Reinforced Concrete Buildings: Behavior and DesignD'EverandReinforced Concrete Buildings: Behavior and DesignÉvaluation : 5 sur 5 étoiles5/5 (1)

- (Unit) Title of The Chapter Name of FacilitatorDocument35 pages(Unit) Title of The Chapter Name of FacilitatorDipesh BasnetPas encore d'évaluation

- Refuerzo Por DuctilidadDocument5 pagesRefuerzo Por Ductilidad4630220Pas encore d'évaluation

- DCS Basic Lect1Document18 pagesDCS Basic Lect1Aman JhaPas encore d'évaluation

- Reinforced Concrete Ch2Document37 pagesReinforced Concrete Ch2Gaurav naddaPas encore d'évaluation

- Dr. Mirvat Bulbul-EnCE335 Fundamentals of Reinforced Concrete Design According ACI 318-05-Birzeit University, Palestinian جامعة بيرزيت هي جامعة فلسطينية (2011-2012)Document41 pagesDr. Mirvat Bulbul-EnCE335 Fundamentals of Reinforced Concrete Design According ACI 318-05-Birzeit University, Palestinian جامعة بيرزيت هي جامعة فلسطينية (2011-2012)Seifeldin Ali MarzoukPas encore d'évaluation

- ETABS & STAAD ComparisonDocument70 pagesETABS & STAAD Comparisonpido290% (1)

- Dhaarini ImplantDocument19 pagesDhaarini ImplantDhaarini SriPas encore d'évaluation

- Basic Concept Limit State Design Partial Factor of Safety Types of LoadingsDocument9 pagesBasic Concept Limit State Design Partial Factor of Safety Types of LoadingsRCdesign2012Pas encore d'évaluation

- Steel TankDocument14 pagesSteel TankYoussef Ben SmidaPas encore d'évaluation

- Performance Based Design Criteria For Steel MR FramesDocument12 pagesPerformance Based Design Criteria For Steel MR Framesbursuc2Pas encore d'évaluation

- Designing A Steel Trusses To EC3Document20 pagesDesigning A Steel Trusses To EC3NL ChanPas encore d'évaluation

- Bracing and SWDocument13 pagesBracing and SWJagadeesh SundaramPas encore d'évaluation

- Chapter 1Document8 pagesChapter 1Saker MohamedPas encore d'évaluation

- Two Marks Ce8501Document12 pagesTwo Marks Ce8501myidmaranPas encore d'évaluation

- Detailed Study and Execution Work in Post Tension SlabsDocument87 pagesDetailed Study and Execution Work in Post Tension Slabsrahulgehlot20080% (1)

- Reinforced Concrete: oDocument5 pagesReinforced Concrete: oEngr AtaUllahPas encore d'évaluation

- CHAPTER 6 Serviceability CriteriaDocument9 pagesCHAPTER 6 Serviceability CriteriaLittleRedPas encore d'évaluation

- Design Criteria For RCCDocument7 pagesDesign Criteria For RCCAtifkhan132Pas encore d'évaluation

- دورة التصميم الانشائي الكاملةDocument249 pagesدورة التصميم الانشائي الكاملةAlsayed DiabPas encore d'évaluation

- Introduction To Structural Steel DesignDocument95 pagesIntroduction To Structural Steel DesignicpertacortaPas encore d'évaluation

- DRC Two MarksDocument26 pagesDRC Two MarksVenkatesh GRmPas encore d'évaluation

- Hospital Building ProjectDocument58 pagesHospital Building ProjectAnonymous yM5XLR694% (18)

- Chapter 1 - Introduction To Steel SectionDocument24 pagesChapter 1 - Introduction To Steel SectionAhmad Ubaidillah Abdul RaniPas encore d'évaluation

- PPT On Design PhilosphiesDocument21 pagesPPT On Design PhilosphiesAshish GuptaPas encore d'évaluation

- Review of Design PhilosophyDocument6 pagesReview of Design PhilosophyNambiyanna DavanagerePas encore d'évaluation

- Mahesh Tandon PDFDocument57 pagesMahesh Tandon PDFhavmanyfriendsPas encore d'évaluation

- Lecture On Limit State Design by Manish BhutaniDocument27 pagesLecture On Limit State Design by Manish BhutaniTarunPas encore d'évaluation

- Module - 1 Introduction: Advantages and Disadvantages of Steel Structures, Limit State Method Limit State ofDocument12 pagesModule - 1 Introduction: Advantages and Disadvantages of Steel Structures, Limit State Method Limit State of2BA19CV059 Rakshita SarangmathPas encore d'évaluation

- Design of Industrial Steel Building by Limit State MethodDocument11 pagesDesign of Industrial Steel Building by Limit State MethodbharathikrishnaPas encore d'évaluation

- Document From Chithu BabuDocument134 pagesDocument From Chithu BabuAE AMBALAPARA GPPas encore d'évaluation

- Lect 4 REG 371 2016Document73 pagesLect 4 REG 371 2016Säbrinä ShukrìPas encore d'évaluation

- Design of Concrete Structures: DR Sandip A VasanwalaDocument18 pagesDesign of Concrete Structures: DR Sandip A VasanwalaSaket ThakkarPas encore d'évaluation

- Shear Wall Design For Seismic ProtectionDocument7 pagesShear Wall Design For Seismic ProtectionshreeshlkoPas encore d'évaluation

- IS: 800 - Indian Code of Practice For Construction in Steel: Comparison With International CodesDocument49 pagesIS: 800 - Indian Code of Practice For Construction in Steel: Comparison With International CodesARYA100% (1)

- 18 Mahdi GharibDocument14 pages18 Mahdi GharibYCPas encore d'évaluation

- UNIT-1: Reinforced Cement ConcreteDocument18 pagesUNIT-1: Reinforced Cement ConcreteMohammad Aatif Matoo NyXScllFvhPas encore d'évaluation

- INSDAG Presentation On Fatigue in Steel StructureDocument28 pagesINSDAG Presentation On Fatigue in Steel StructureNIBEDITA DEYPas encore d'évaluation

- Seismic Drift Performance-Based Design Optimization of Reinforced Concrete BuildingsDocument14 pagesSeismic Drift Performance-Based Design Optimization of Reinforced Concrete BuildingsxelmerxPas encore d'évaluation

- Lists of Notations: Dept. of Civil Engg. Sait 2018-2019Document50 pagesLists of Notations: Dept. of Civil Engg. Sait 2018-2019Arunesh KumarPas encore d'évaluation

- Performance Criteria For MR Steel Frames in Seismic Zones: Daniel Grecea, Florea Dinu, Dan DubinaDocument11 pagesPerformance Criteria For MR Steel Frames in Seismic Zones: Daniel Grecea, Florea Dinu, Dan DubinaMazen Al-arsanPas encore d'évaluation

- PRS ReviewerDocument9 pagesPRS ReviewerRose Diana DecenaPas encore d'évaluation

- ICSBOCDocument9 pagesICSBOCAyman ShamaPas encore d'évaluation

- Fracture and Fatigue Control in Steel Structures PDFDocument14 pagesFracture and Fatigue Control in Steel Structures PDFMarcoPas encore d'évaluation

- IJCRT2210458Document24 pagesIJCRT2210458omar heshamPas encore d'évaluation

- Steel Lecture 2 - Design Loads, ASD Vs LRFDDocument55 pagesSteel Lecture 2 - Design Loads, ASD Vs LRFDSana'a AamirPas encore d'évaluation

- The Comparative Study On Analysis Results of Multi-Storeyed Commercial Building (G+12) by STAAD - Pro and ETABS Chapter-1Document10 pagesThe Comparative Study On Analysis Results of Multi-Storeyed Commercial Building (G+12) by STAAD - Pro and ETABS Chapter-1rajaPas encore d'évaluation

- Chapter 1 - Introduction To RCDocument46 pagesChapter 1 - Introduction To RCMazliah Zainal AbidinPas encore d'évaluation

- Chapter 6Document27 pagesChapter 6EDWARD T CHENJERAIPas encore d'évaluation

- Atde 43 Atde230712Document7 pagesAtde 43 Atde230712MdPas encore d'évaluation

- CE6505 Design of RC ElementsDocument30 pagesCE6505 Design of RC ElementsKarna RPas encore d'évaluation

- Review On Comparative Analysis of SymmetricalDocument9 pagesReview On Comparative Analysis of SymmetricalIJRASETPublicationsPas encore d'évaluation

- Seismic Design Requirements and Construction Challenges of Lifeline Essential and Critical BridgesDocument44 pagesSeismic Design Requirements and Construction Challenges of Lifeline Essential and Critical BridgesJack JackPas encore d'évaluation

- Stiffness Optimization Technique For 3D Tall Steel Building Frameworks Under Multiple Lateral LoadingsDocument7 pagesStiffness Optimization Technique For 3D Tall Steel Building Frameworks Under Multiple Lateral LoadingskarolPas encore d'évaluation

- Unit 14: Aircraft Structutal Integrity Outcome 1Document19 pagesUnit 14: Aircraft Structutal Integrity Outcome 1Rezve AhmedPas encore d'évaluation

- Steel Structures Design Based on Eurocode 3D'EverandSteel Structures Design Based on Eurocode 3Évaluation : 3 sur 5 étoiles3/5 (1)

- Introduction to Design of Building StructuresD'EverandIntroduction to Design of Building StructuresÉvaluation : 4 sur 5 étoiles4/5 (22)

- Design of Steel Structures: Materials, Connections, and ComponentsD'EverandDesign of Steel Structures: Materials, Connections, and ComponentsPas encore d'évaluation

- Catalogo Gres Aragon 2021Document10 pagesCatalogo Gres Aragon 2021horseatilasPas encore d'évaluation

- Notes ACI 318Document53 pagesNotes ACI 318Mostafa AbdellaPas encore d'évaluation

- NCDE RYD NBS XX SP A K40 Demountable Ceiling Construction C1Document10 pagesNCDE RYD NBS XX SP A K40 Demountable Ceiling Construction C1johnPas encore d'évaluation

- Bottom Up and Top BottomDocument7 pagesBottom Up and Top BottomJonah Dave VegaPas encore d'évaluation

- 05 - Build Crate ChairDocument4 pages05 - Build Crate ChairMartin GyurikaPas encore d'évaluation

- Soil Cement Tank (Theory)Document13 pagesSoil Cement Tank (Theory)sumitPas encore d'évaluation

- Wind Load On The RoofDocument14 pagesWind Load On The RoofHussein HasenPas encore d'évaluation

- Module 4Document22 pagesModule 4Bhong Vicencio BacaltosPas encore d'évaluation

- Tank Dismantling ProcedureDocument24 pagesTank Dismantling ProcedureRemmo S Ardiansyah100% (5)

- Indiabulls Realtech LimitedDocument5 pagesIndiabulls Realtech LimitedSagar MankarPas encore d'évaluation

- Hawa MahalDocument2 pagesHawa MahalAnnabeth100% (1)

- Detail Section 2: Reflected Ground Ceiling Plan 1 A4 Reflected Second Ceiling Plan 2 A4Document1 pageDetail Section 2: Reflected Ground Ceiling Plan 1 A4 Reflected Second Ceiling Plan 2 A4JAN WESLEY MORIDOPas encore d'évaluation

- CRC JoyousDocument37 pagesCRC Joyousmanish tomarPas encore d'évaluation

- June 2016 Ale Past Board Exam: RefresherDocument51 pagesJune 2016 Ale Past Board Exam: RefresherKaren Mae MaravillaPas encore d'évaluation

- Surface Preparation Guide: Back To TopDocument2 pagesSurface Preparation Guide: Back To TopJustin MichaelPas encore d'évaluation

- Supplement On Container Inspection and Repair Gray Areas 2ndDocument23 pagesSupplement On Container Inspection and Repair Gray Areas 2ndDr-moustafa Elafandy100% (1)

- 2 Topic 1 Taking Off WallDocument24 pages2 Topic 1 Taking Off WallaremyulPas encore d'évaluation

- Summarecon Makassar: Type XLDocument51 pagesSummarecon Makassar: Type XLzaidPas encore d'évaluation

- STEEL Building Construction and Technology 5Document155 pagesSTEEL Building Construction and Technology 5dudenology92% (12)

- TamrielData ChangelogDocument25 pagesTamrielData ChangelogTheFancy PotatoPas encore d'évaluation

- Revised Data SheetDocument11 pagesRevised Data Sheetbashok20Pas encore d'évaluation

- The Concise Guide To The Identification of Insect Attack and Fungal Decay of TimberDocument37 pagesThe Concise Guide To The Identification of Insect Attack and Fungal Decay of Timbercarl2005Pas encore d'évaluation

- Module 15 - UNIT III - PolymersDocument12 pagesModule 15 - UNIT III - PolymersJhess GaliciaPas encore d'évaluation

- Laboratory Report 2 - de LunaDocument7 pagesLaboratory Report 2 - de LunaAgent PPas encore d'évaluation

- 11 FCM WizardDocument63 pages11 FCM Wizardkom1984Pas encore d'évaluation

- Asce 7-22 CH 13 - For PCDocument50 pagesAsce 7-22 CH 13 - For PCsharethefilesPas encore d'évaluation

- Rules RegulationsDocument10 pagesRules Regulationsapi-42073675Pas encore d'évaluation

- Government of Andhra Pradesh: Common Schedule of Rates As Per A.P. Revised Standard Data For The Year 2022-23)Document846 pagesGovernment of Andhra Pradesh: Common Schedule of Rates As Per A.P. Revised Standard Data For The Year 2022-23)Charan Teja Chowdary50% (2)

- Painting Procedure - Rev.1Document30 pagesPainting Procedure - Rev.1didi sudiPas encore d'évaluation

- Construction Method (Outline Narrative Description)Document8 pagesConstruction Method (Outline Narrative Description)EzPas encore d'évaluation