Académique Documents

Professionnel Documents

Culture Documents

D PWT D6riii PDF

Transféré par

Dennis OlayaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

D PWT D6riii PDF

Transféré par

Dennis OlayaDroits d'auteur :

Formats disponibles

D

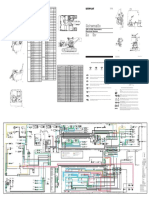

COMPONENT LIST

No.

Schematic

Location

Part

Number

Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

C-4

A-5

E-5

E-4

N/A

D-3

B-1

C-4

E-5

F-6

A-6

B-2

N/A

N/A

226-3902

235-5812

213-1308

263-9949

9G-5127

220-1418

238-1116

231-4166

220-1429

231-5969

231-5990

232-6207

241-5635

223-9039

POWER TRAIN OIL PUMP (3 SECTION)

POWER TRAIN OIL FILTERS

ELECTRONIC BRAKE CONTROL VALVE

LUBE DIST. / TC INLET RELIEF MANIFOLD

BREATHER

TORQUE CONVERTER OUTLET RELIEF VALVE

OIL COOLER

PUMP INLET SCREEN / HOUSING GP.

TRANSMISSION AR.

LEFT DRIVE / BRAKE GP.

RIGHT DRIVE / BRAKE GP.

TORQUE CONVERTER / HOUSING GP.

DIPSTICK

OIL FILL TUBE

The three-section gear-type power train oil pump (B) is

mounted to the front of the main case, at the upper right.

E-6

D-8

M

N

L2

L1

LB1

LB2

CL1

CL2

CL3

CL4

CL5

AA

BB

E-4

D-3

E-2

C-8

E-6

A-6

C-6

C-7

D-7

D-7

D-6

A-4

A-5

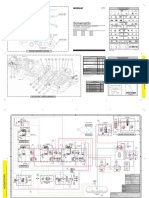

T/C SUPPLY PRESSURE

T/C OUTLET PRESSURE

FLYWHEEL LUBE PRESSURE

TRANS. LUBE PRESSURE

L BRAKE LUBE PRESSURE

R BRAKE LUBE PRESSURE

TRANS. CLUTCH 1 PRESSURE

TRANS. CLUTCH 2 PRESSURE

TRANS. CLUTCH 3 PRESSURE

TRANS. CLUTCH 4 PRESSURE

TRANS. CLUTCH 5 PRESSURE

PTO SAMPLING PORT (SOS)

PTO PRESSURE

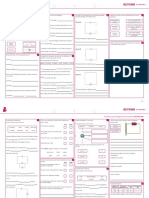

PRESSURE

COMPENSATION

LINE RESTRICTION

(VARIABLE)

SPRING

(ADJUSTABLE)

VARIABILITY

TWO POSITION

VALVE PORTS

The transmission and torque converter scavenge section

(H) of the power train oil pump draws approximately 125

L/min. (33 US gal./min.) from the torque divider case, and

the transmission case.

The scavenge oil is used for lubrication of the steering differential. The power train oil temperature sensor (I) provides main

sump oil temperature information to the Machine ECM. This is the temperature sensor that is considered when performing

power train calibrations, such as brake touch-ups and transmission clutch fill calibrations.

The torque converter inlet relief valve (J) and the lube

distribution manifold (L) are both contained in one

housing. Oil from the torque converter charging section

of the power train oil pump is supplied to the torque

converter inlet relief valve through the upper hose (K).

INFINITE POSITION

PRESSURE

PILOT

CONTROLLED

ROTATING SHAFTS

FLOW

TEMPERATURE

UNIDIRECTIONAL

BIDIRECTIONAL

FLUID STORAGE RESERVOIRS

D6R Series III Track-Type Tractor

Power Train System

GJB1-UP

WCB1-UP

HDC1-UP

RFC1-UP

TBC1-UP

JEK1-UP

HCD1-UP

HKE1-UP

WRG1-UP

MTJ1-UP

SHUTTLE

SPRING

LOADED

BASIC

SYMBOL

MEASUREMENT

VENTED

RETURN ABOVE FLUID LEVEL

PRESSURIZED

RETURN BELOW FLUID LEVEL

COMBINATION CONTROLS

DMK1-UP

LGP1-UP

JDL1-UP

DLM1-UP

LFM1-UP

EXL1-UP

DPS1-UP

EXW1-UP

GMT1-UP

MRT1-UP

SOLENOID

SOLENOID

or MANUAL

SERVO

SOLENOID and

PILOT or MANUAL

SOLENOID

and PILOT

DETENT

THERMAL

MANUAL CONTROL SYMBOLS

PUSH-PULL LEVER

GENERAL MANUAL

MANUAL SHUTOFF

PUSH BUTTON

PEDAL

SPRING

PILOT CONTROL SYMBOLS

RELEASED PRESSURE

EXTERNAL RETURN

REMOTE SUPPLY PRESSURE

INTERNAL RETURN

SIMPLIFIED

CROSSING AND JOINING LINES

ACCUMULATORS

The torque converter inlet relief valve is installed in the

housing. Excess oil flows past the inlet relief valve into

the main sump through a port in the front of the case, and

behind the housing. Oil flow to the torque converter inlet

is through the hose on the right (N).

CHECK VALVES

P T

SHIFTED POSITION

The power train oil pump draws oil for the torque

converter charging circuit and for the transmission

charging circuit from a screened suction manifold that

connects to the pump at the pump inlet (E).

The transmission charging section (G) of the power train

oil pump supplies approximately 54 L/min. (14.3 US

gal./min.) of oil to the transmission and brakes circuit.

FOUR-WAY

THREE-WAY

AB

P T

NORMAL POSITION

ATTACHMENT

LINE RESTRICTION

VARIABLE and PRESSURE

COMPENSATED

TWO-WAY

THREE POSITION

PUMP: VARIABLE and

PRESSURE COMPENSATED

2-SECTION PUMP

HYDRAULIC

PNEUMATIC

ENERGY TRIANGLES

VALVES

VALVE ENVELOPES

ONE POSITION

B

P

LINE RESTRICTION

(FIXED)

RESTRICTION

CONTROL VALVES

Description

C-1

CONTROL VALVES

SPRING

FLUID CONDITIONER

AB

Tap Locations

ER1

MAIN AUX.

ENGINE SPEED

TRANS. GEAR

P/T OIL TYPE

PTO SUMP OIL TEMP

BRAKE PRESSURE

TRANS. MAIN RELIEF

BASIC COMPONENT SYMBOLS

PUMP or MOTOR

The torque converter inlet relief valve and the lube

distribution manifold are both incorporated into one

housing (D). These two components are mounted to the

left front of the main case, near the bottom.

Schematic

Location

FLUID POWER SYMBOLS

The electronic brake valve (C) is located on top of the main

case, to the left of center.

The torque converter charging section (F) of the power

train oil pump supplies approximately 145 L/min. (38.3 US

gal./min.) of oil to the torque converter circuit for operation

of the torque converter and for lubrication purposes.

Tap

Number

RENR7954-01

June 2006

The screened main suction manifold (A) for the power train

oil pump is located at the right front of the main case, near

the bottom.

SPRING LOADED

GAS CHARGED

LINES CROSSING

HYDRAULIC PUMPS

FIXED

DISPLACEMENT

Cooled oil from the power train oil cooler is directed to the

lube distribution manifold (L) through the hose on the left

(M). The smaller hose (P) is the line leading to the remote

pressure test port for torque converter inlet pressure

( M ). This remote pressure test port is located inside the

front compartment on the right fender

HYDRAULIC AND PNEUMATIC CYLINDERS

SINGLE ACTING

LINES JOINING

FIXED

DISPLACEMENT

VARIABLE DISPLACEMENT

NON-COMPENSATED

UNIDIRECTIONAL

UNIDIRECTIONAL

BIDIRECTIONAL

BIDIRECTIONAL

DOUBLE ACTING

INTERNAL PASSAGEWAYS

HYDRAULIC MOTORS

VARIABLE DISPLACEMENT

NON-COMPENSATED

INTERNAL

SUPPLY PRESSURE

COMPLETE

FLOW IN ONE

DIRECTION

PARALLEL

FLOW

CROSS

FLOW

FLOW ALLOWED IN

EITHER DIRECTION

Printed in U.S.A.

2006 Caterpillar

All Rights Reserved

Power Train Oil Pump 1

TWO

POSITION

THREE

POSITION

INFINITE

POSITIONING

Electrical Symbols Table

Q

AA

BB

Hydraulic Symbols (Electrical)

Transmission Charge

Circuit Accumulator

CL1 CL2 CL3

CL4 CL5 P

L1

10

LB1

Transducer

(Fluid)

L1

12

CL4

CL5

CL3

CL2

Transmission Lube

Temperature Sensor

Transducer

(Gas / Air)

Pressure Switch

(Adjustable)

Pressure Switch

CL1

Generator

Electric Motor

Electrical Wire

Temperature Switch

Electrical Symbols (Electrical)

T

L1

Pressure

Symbol

Temperature

Symbol

Flow

Symbol

Level

Symbol

CL4

ECPC XMSN

Clutch Valves

CL5

Wire Number Identification Codes

M

CL3

11

LB2

AA

13 14

Opening the front door of the forward compartment on the right fender gains access to the power train oil filter (S). This spin-on type canister

contains a replaceable 6-micron filter element. The filter base contains a filter bypass switch (R). This is a normally open switch that is held closed

by the filter bypass valve spool. The bypass valve opens, allowing the switch to open, when the difference in pressure between the filter inlet and

the filter outlet becomes great enough (approximately 50 psi). The switch is monitored by the Caterpillar Monitoring System and alerts the operator

to the filter bypass condition.

Transmission Lube

Temperature Sensor

CL1

5 13 14

Electrical Schematic Example

Opening the top door of the forward compartment on the right fender gains access to the combination power train oil fill tube and dipstick (Q).

CL2

Transmission Housing

CL1 CL2 CL3

CL4 CL5 P

L1

The filter base also contains the power train oil sampling (AA) and a pressure test port (BB) for the transmission charging circuit. The pressure test

port is situated downstream from the filter. The power train oil sampling port is situated upstream, or before the filter.

AA

Located at the rear of the machine, on top of the the transmission case are the following service points:

Also located in the forward compartment on the right fender and inboard from the power train oil filter canister are the following service points:

1. Transmission main relief pressure test port (P)

2. Transmission lube pressure test port (L1)

3. Transmission lube temperature sensor

(T). remote power train breather

(M). remote pressure test port for torque converter inlet pressure

(N). remote pressure test port for torque converter outlet pressure

Current Standard

Current Standard

Harness identification code

This example indicates

wire 135 in harness "AG".

Wire

Circuit Number

Identification

Wire Color

325-AG135 PK-14

325-PK

Circuit Identification

Number

Wire Color

Wire Gauge

Previous Standard

Wire Color

Wire

Pressure test ports for each of the five transmission clutches remain on the transmission cover. These pressure test ports

are:

325-PK-14

Power Train Oil Filter Group 2

(CL1). Transmission clutch (reverse clutch)

(CL2). Transmission clutch (forward clutch)

(CL3). Transmission clutch (speed 3)

(CL5). Transmission clutch (speed 1)

(CL4). Transmission clutch (speed 2)

Hydraulic Schematic Example

B

Circuit Number

Identification

Wire Gauge

(EXAMPLE VALVE)

Clutch engagement pressure calibrations are no longer required, with the common top pressure strategy. Proper

adjustment of the transmission main relief valve will set the proper pressure for the operation of all five transmission

clutches and the brakes. It is still necessary to perform transmission clutch fill calibrations and to perform brake touch-up

calibrations.

Engine Oil Cooler

The transmission charge circuit accumulator is mounted

beneath the fuel tank and located above the transmission

case.

11 10

LB1 LB2

12

This accumulator is pre-charged to approximately 1724

kPa (250 psi). It is used to help maintain transmission

charge circuit pressure for short periods of time, such as

when transmission clutches are filling (shifts) or at other

times when the pressure in the transmission charging

circuit may become too low (cold oil, low idle, etc.).

Power Train

Oil Cooler

CL4

Right Side

CL5

CL3

CL2

ECPC XMSN

Clutch Valves

Transmission Charge

Circuit Accumulator

Left Side

Below and to the rear of the engine

oil cooler is the oil-to-water type

power train oil cooler.

CL1

Component and Tap Locations

Transmission Group 9

Power Train Oil Cooler 7

24 Page

BB

RENR7954-01

AA

L1

LB1

CLUTCH/BRAKES

LEFT BRAKE

PRESSURE PORT

10

9

CL4

CL5

CL3

CL1

CL2

4

BRAKE

LUBE

L2

EB BRAKE VALVE

FLYWHEEL

HOUSING

B

PROPORTIONAL

VALVE

XMSN LUBE

3

MAIN

RELIEF

2ND

3RD

1ST

CL4

CL3

CL5

ENGINE

IMPLEMENT

PUMP

PROPORTIONAL

VALVE

DIFF STEER

BEVEL & TRANSFER

GEAR LUBE

P

PROPORTIONAL

VALVE

PROPORTIONAL

VALVE

C9

XL, XW, LGP 200 NET HP

STD 185 NET HP

AT 1850 RPM

TORQUE

CONVERTER

ECPC XMSN

CLUTCH VALVES

PROPORTIONAL

VALVE

PROPORTIONAL

VALVE

VENT LINE

CL2

CL1

FWD

REV

ER1

PTO TEMP.

SENSOR

SUCTION SCREEN

L1

24 Page, Color 2

RENR7954-01

TRANS. LUBE

TEMP. SENSOR

DRIVESHAFT

SCREEN

SCAV

SCAVENGE OUTPUT AND

DIFF STEER LUBE

TRANSMISSION

CONTROL VALVE

TRANS

T/C

C

12

POWERTRAIN

OIL COOLER

7

B

BRAKE

LUBE

11

AA

RIGHT BRAKE

PRESSURE PORT

CLUTCH/BRAKES

LB2

LINE PATTERNS

BB

NOTES:

(A) TRANSMISSION AND CONVERTER SCAVENGE PUMP

(B) TRANSMISSION CHARGE PUMP

(C) TORQUE CONVERTER CHARGE PUMP

Pressure Line

Pilot / Load Sensing Pressure

Drain / Return Lines

HYDRAULIC CIRCUIT COLOR DESCRIPTIONS

Component Group

Brakes.

Supply Line.

Drain / Return Line.

Attachment

Transmission Charge Pump.

Transmission and Torqueconverter Scavenge Pump

Torque Converter Charge Pump and Powertrain Oil Cooler

Air Line

CALLOUTS

YY

Taps (Pressure, Sampling,Sensor) by letter

52

Components by number

THIS SCHEMATIC IS FOR THE D6R TRACK-TYPE TRACTOR

PART #: 270-8369 CHG 01

Components are shown installed on a fully operable machine with the key and engine

off and transmission shifter in neutral.

Refer to the appropriate Service Manual for Troubleshooting, Specifications and Systems Operations

Vous aimerez peut-être aussi

- D6R Series III Track Type Tractor Power Train SystemDocument2 pagesD6R Series III Track Type Tractor Power Train SystemIH Medrano78% (9)

- Parts Manual D6H - 1 PDFDocument48 pagesParts Manual D6H - 1 PDFBudi Prayitno100% (2)

- Syllabus 330C SystemsDocument1 pageSyllabus 330C SystemsDANIEL VARGAS RODRIGUEZPas encore d'évaluation

- Fill Time For The Transmision Clutch - CalibrateDocument8 pagesFill Time For The Transmision Clutch - CalibrateTarwedi Tartor100% (1)

- Cat 140MDocument28 pagesCat 140MWicca GenesisPas encore d'évaluation

- D 8 TDocument2 pagesD 8 TAlberjose Sanchez RuizPas encore d'évaluation

- 428c esQUEMA HIDRAULICODocument2 pages428c esQUEMA HIDRAULICOJuniOrs RiVera100% (1)

- Electrical - BB International PDFDocument480 pagesElectrical - BB International PDFedelmolina100% (3)

- Mobile Jammer Using Ic555Document86 pagesMobile Jammer Using Ic555mounica453672% (32)

- Diagrama Hidraulico 777FDocument4 pagesDiagrama Hidraulico 777Ffabioalbor100% (1)

- 785d HydraulicDocument2 pages785d HydraulicSainbayr SainaaPas encore d'évaluation

- Starting Parts 777DDocument4 pagesStarting Parts 777DGerald BoyPas encore d'évaluation

- 140k Compliance FinalDocument29 pages140k Compliance FinalAGEGNEHU17Pas encore d'évaluation

- Engine Performance - Test - Engine Speed: Testing and AdjustingDocument2 pagesEngine Performance - Test - Engine Speed: Testing and AdjustingDANIEL VARGAS RODRIGUEZ100% (1)

- Performance Test D8R (9EM)Document6 pagesPerformance Test D8R (9EM)ahmad ruyaniPas encore d'évaluation

- Engine Performance - Test - Engine Speed: 320D and 323D Excavators Hydraulic SystemDocument3 pagesEngine Performance - Test - Engine Speed: 320D and 323D Excavators Hydraulic SystemEm sulistio100% (1)

- Electronic Control System ComponentsDocument4 pagesElectronic Control System ComponentsThein Htoon lwinPas encore d'évaluation

- D6R II Systems OperationDocument7 pagesD6R II Systems OperationBaron KasoziPas encore d'évaluation

- 12H - Specs0Document5 pages12H - Specs0Marco OlivettoPas encore d'évaluation

- CalibrationsDocument4 pagesCalibrationsalondra9520Pas encore d'évaluation

- 740B Articulated Truck Brake and Hoist SystemDocument5 pages740B Articulated Truck Brake and Hoist SystemRajan Mullappilly100% (1)

- Main Relief 302.5Document11 pagesMain Relief 302.5Yudi setiawanPas encore d'évaluation

- RENR9980RENR9980 07 SIS - DesbloqueadoDocument13 pagesRENR9980RENR9980 07 SIS - DesbloqueadoArturo AndPas encore d'évaluation

- System Operation Steering 950FDocument20 pagesSystem Operation Steering 950FEsteban MunaresPas encore d'évaluation

- 950F Frenos OperacionDocument19 pages950F Frenos OperacionChrissz Noxd50% (2)

- 1 Main Hydraulic SystemDocument6 pages1 Main Hydraulic SystemZawminhtunPas encore d'évaluation

- 330D L Excavator Electronic Control System DocumentationDocument3 pages330D L Excavator Electronic Control System DocumentationMiguel Angel Garrido CardenasPas encore d'évaluation

- Cat Rope ShowelDocument2 pagesCat Rope ShowelGanapati HegdePas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document24 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Eckard GuendelPas encore d'évaluation

- Injector Solenoid Circuit - Test: TroubleshootingDocument13 pagesInjector Solenoid Circuit - Test: TroubleshootingGolbert GolbiPas encore d'évaluation

- CAT 769c Valvula de Control de Transmision 1Document28 pagesCAT 769c Valvula de Control de Transmision 1Taller Pahr100% (1)

- Bell 1706C Plus System ChecksDocument12 pagesBell 1706C Plus System ChecksLeonPas encore d'évaluation

- Valvula Relief Pruebas y Ajustes 325blDocument9 pagesValvula Relief Pruebas y Ajustes 325blcristian chuquicondor torresPas encore d'évaluation

- Transmission Forward Low and RDocument2 pagesTransmission Forward Low and Rvalterrip100% (1)

- Control Valve D8R..Document2 pagesControl Valve D8R..SyahdiPas encore d'évaluation

- 324D Hyd PDFDocument11 pages324D Hyd PDFdemetrio castillo obleaPas encore d'évaluation

- 785D Off-Highway Truck Hydraulic System Systems OperationDocument24 pages785D Off-Highway Truck Hydraulic System Systems Operation1Pas encore d'évaluation

- 966 CatDocument12 pages966 CatnajafaliPas encore d'évaluation

- Senr6587 03 01 AllDocument92 pagesSenr6587 03 01 AllJohn SuarezPas encore d'évaluation

- 777D PDFDocument2 pages777D PDFJoshua FloresPas encore d'évaluation

- 950G Wheel Loader Electro-Hydraulic SystemDocument45 pages950G Wheel Loader Electro-Hydraulic SystemAlha DPas encore d'évaluation

- Group 3 Electrical Component SpecificationDocument9 pagesGroup 3 Electrical Component SpecificationPhan DungPas encore d'évaluation

- Pressure Limiter Valve - Test: Essai Et RéglageDocument6 pagesPressure Limiter Valve - Test: Essai Et RéglagechakrounePas encore d'évaluation

- Boom Drift Reduction ValveDocument4 pagesBoom Drift Reduction ValveJuan Daniel Martinez MontoyaPas encore d'évaluation

- 740 Artiiculated Truck Power TrainDocument37 pages740 Artiiculated Truck Power TrainFabrizio Jesús100% (1)

- WDM D9R PTDocument2 pagesWDM D9R PTRendy PratamaPas encore d'évaluation

- Power Train Hydraulic System (SENR9159-10)Document3 pagesPower Train Hydraulic System (SENR9159-10)Anderson Oliveira SilvaPas encore d'évaluation

- Power Train Troubleshooting: Essai Et RéglageDocument15 pagesPower Train Troubleshooting: Essai Et RéglageAly AbdelhamedPas encore d'évaluation

- Pilot Valve (Command Control Steering) 966Document16 pagesPilot Valve (Command Control Steering) 966Ahmed RezkPas encore d'évaluation

- Componentes de Maquina de Oruga D10RDocument152 pagesComponentes de Maquina de Oruga D10RJesús Abreu100% (1)

- Transmission Hydraulic System 966Document5 pagesTransmission Hydraulic System 966Walid HouranPas encore d'évaluation

- Hydraulic Fan SystemDocument4 pagesHydraulic Fan SystemEVER DAVID SAAVEDRA HUAYHUA100% (1)

- Caterpillar 325 SENR6239Document2 pagesCaterpillar 325 SENR6239Jaime Villalba FlorPas encore d'évaluation

- Tea Sensor de Velocidade 3Document7 pagesTea Sensor de Velocidade 3Valmaq Prestação Serviço LdaPas encore d'évaluation

- 330D L Excavator Pilot Hydraulic System DocumentationDocument8 pages330D L Excavator Pilot Hydraulic System DocumentationMiguel Angel Garrido CardenasPas encore d'évaluation

- C374342 Moto 160MDocument28 pagesC374342 Moto 160MJairo Acosta100% (1)

- Electronic Control Module (ECM) - Replace... 312C and 315C Excavators Tool Control System Caterpillar - Spare PartsDocument2 pagesElectronic Control Module (ECM) - Replace... 312C and 315C Excavators Tool Control System Caterpillar - Spare PartsEdwar JulianPas encore d'évaluation

- ControlsDocument26 pagesControlsLucky Okote0% (1)

- Hydraulic Fan Speed - Test and Adjust: Shutdown SIS Previous ScreenDocument9 pagesHydraulic Fan Speed - Test and Adjust: Shutdown SIS Previous ScreenAbi JithPas encore d'évaluation

- Cat 730Document26 pagesCat 730Miguel Quispe Flores100% (1)

- Brake System (KENR8395-13)Document29 pagesBrake System (KENR8395-13)Anderson Oliveira SilvaPas encore d'évaluation

- Plano de Transmision D6TDocument2 pagesPlano de Transmision D6TronaldPas encore d'évaluation

- RENR8305RENR8305-04 - SIS 777f 1Document4 pagesRENR8305RENR8305-04 - SIS 777f 1gadolineo100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document12 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document12 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Claudio CuevasPas encore d'évaluation

- Esquema Hidráulico Motoniveladora 140KDocument22 pagesEsquema Hidráulico Motoniveladora 140KAnonymous Dq7m7Hq7ar100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document33 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document7 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaPas encore d'évaluation

- Senr1678senr1678 Sis PDFDocument2 pagesSenr1678senr1678 Sis PDFDennis OlayaPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document12 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaPas encore d'évaluation

- Esquema Hidráulico CS56Document2 pagesEsquema Hidráulico CS56Anonymous Dq7m7Hq7ar100% (1)

- Diagrama Electrico PDFDocument9 pagesDiagrama Electrico PDFhenotharenas100% (1)

- Senr1677senr1677-01 Sis PDFDocument2 pagesSenr1677senr1677-01 Sis PDFDennis OlayaPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document14 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Vladimir Illich Pinzon100% (2)

- Plano Hydo InteractivoDocument11 pagesPlano Hydo InteractivoalexPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document7 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaPas encore d'évaluation

- Uenr1382uenr1382-01 Sis PDFDocument2 pagesUenr1382uenr1382-01 Sis PDFDennis OlayaPas encore d'évaluation

- D7R Diag Hyd PDFDocument4 pagesD7R Diag Hyd PDFluis eduardo corzo enriquezPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document12 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaPas encore d'évaluation

- 324D Hyd PDFDocument11 pages324D Hyd PDFdemetrio castillo obleaPas encore d'évaluation

- Retroexacavadora 430 F Planos HidraulicosDocument2 pagesRetroexacavadora 430 F Planos Hidraulicosedison barrionuevoPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document8 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document13 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document11 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Yancarlos Quispe AmayaPas encore d'évaluation

- Senr1668senr1668-01 Sis PDFDocument2 pagesSenr1668senr1668-01 Sis PDFDennis Olaya100% (1)

- D5G Hidraulico Serie RKG PDFDocument7 pagesD5G Hidraulico Serie RKG PDFAnonymous KOtSfT6qPas encore d'évaluation

- 160k Electrical Accugrade SZMDocument2 pages160k Electrical Accugrade SZMqwureyquwery100% (1)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document7 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Dennis OlayaPas encore d'évaluation

- Kenr5128kenr5128-02 SisDocument14 pagesKenr5128kenr5128-02 Sisygor valdezPas encore d'évaluation

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document7 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768CARHUAMACA PASCUAL mh100% (1)

- SGM LEKTRA Pmag - T - ENDocument48 pagesSGM LEKTRA Pmag - T - ENEynar FrancoPas encore d'évaluation

- Diagnostico Backup Switch 320D GKLDocument11 pagesDiagnostico Backup Switch 320D GKLDavid Ceron60% (5)

- WT 258 Revolvedoor eDocument12 pagesWT 258 Revolvedoor eHenry MPas encore d'évaluation

- Hawker-Siddeley HS.748 V1 ManualDocument18 pagesHawker-Siddeley HS.748 V1 Manualdani20100% (1)

- PCB Relay G5LA Cube Single-Pole 10A Power RelayDocument6 pagesPCB Relay G5LA Cube Single-Pole 10A Power Relaygary omanaPas encore d'évaluation

- Wiring Devices, Junction Boxes & Electrical ComponentsDocument33 pagesWiring Devices, Junction Boxes & Electrical ComponentsJoyce LapuzPas encore d'évaluation

- Manual - InterSystems HD-PRT-HYD SamplerDocument40 pagesManual - InterSystems HD-PRT-HYD Sampler张群利Pas encore d'évaluation

- E 7403-9002g Motor List CustomerDocument5 pagesE 7403-9002g Motor List Customerraobabar21Pas encore d'évaluation

- Distributed Safety: Sensor-Actuator Interfacing: SITRAIN Training ForDocument23 pagesDistributed Safety: Sensor-Actuator Interfacing: SITRAIN Training Forcarsan87Pas encore d'évaluation

- AP60,70,80 Level 300Document170 pagesAP60,70,80 Level 300Gary Gouveia100% (1)

- SUL 181 H 12V: DescriptionDocument2 pagesSUL 181 H 12V: DescriptionpuspitaPas encore d'évaluation

- Troubleshooting H.I.B Chiller at Error and Warning MessagesDocument7 pagesTroubleshooting H.I.B Chiller at Error and Warning MessagesDenPas encore d'évaluation

- GW - Glasses, Window System & MirrorsDocument20 pagesGW - Glasses, Window System & MirrorsBRILLIANCE AUTO LIFEPas encore d'évaluation

- 4 JB 1Document60 pages4 JB 1Rex Palmitos100% (1)

- 1MRK505005-BEN A en Breaker-Failure Protection RAICADocument8 pages1MRK505005-BEN A en Breaker-Failure Protection RAICAs_banerjeePas encore d'évaluation

- Revised Standard Data For ElectrificationDocument120 pagesRevised Standard Data For ElectrificationKishore Ainavilli100% (1)

- Qs1 Info ManualDocument8 pagesQs1 Info Manualspaul297Pas encore d'évaluation

- Mitfuso Owners Manual 2014 FefgDocument468 pagesMitfuso Owners Manual 2014 FefgSam ArevaloPas encore d'évaluation

- Kyoritsu Digital Insulation/Continuity Tester ManualDocument24 pagesKyoritsu Digital Insulation/Continuity Tester ManualRozaimi GhazaliPas encore d'évaluation

- AutoMate 552 Install ManualDocument42 pagesAutoMate 552 Install ManualNathan MossorPas encore d'évaluation

- 3.6 Technical Specifications For Procurement of Generating Equipment PDFDocument156 pages3.6 Technical Specifications For Procurement of Generating Equipment PDFaudiihussainPas encore d'évaluation

- F (C) D Mini Float Level Switch - B0Document28 pagesF (C) D Mini Float Level Switch - B0Tu WentingPas encore d'évaluation

- CAC - EU Universal - OUT IM - DB68-06488A-01 - EN - 20170615 PDFDocument54 pagesCAC - EU Universal - OUT IM - DB68-06488A-01 - EN - 20170615 PDFMaxiaires RefrigeracionPas encore d'évaluation

- RT115Q en 4 1Document193 pagesRT115Q en 4 1Fernando Omar Arena100% (1)

- Vehicle InterfaceDocument20 pagesVehicle InterfaceNgoc NguyenPas encore d'évaluation

- 1989 GM Light Truck Wiring Diagram PDFDocument143 pages1989 GM Light Truck Wiring Diagram PDFralleman1100% (2)

- RS-485 MEMOBUS/Modbus Interface: Technical ManualDocument30 pagesRS-485 MEMOBUS/Modbus Interface: Technical ManualRobert AguilarPas encore d'évaluation

- KS3 Electricity and Magnetism Revision EssentialsDocument4 pagesKS3 Electricity and Magnetism Revision EssentialsMargarida SeromenhoPas encore d'évaluation