Académique Documents

Professionnel Documents

Culture Documents

Process Engineer Job Des.

Transféré par

Donesh Varshney0 évaluation0% ont trouvé ce document utile (0 vote)

41 vues2 pagesprocess engineer

Titre original

Process Engineer Job Des. (2)

Copyright

© © All Rights Reserved

Formats disponibles

DOCX, PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentprocess engineer

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

41 vues2 pagesProcess Engineer Job Des.

Transféré par

Donesh Varshneyprocess engineer

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme DOCX, PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Process Engineer: Job Description

Process Engineer develops and optimizes economical industrial processes

to make the huge range of products on which modern society depends. A

Process Engineer may work in small, medium and large businesses. The

work is concerned with chemical and biochemical processes in which raw

materials undergo change, and involves scaling up processes from the

laboratory into the processing plant. Responsibilities involve designing

equipment, understanding the reactions taking place, installing control

systems, and starting, running and upgrading the processes.

Environmental protection and health and safety aspects are also

significant concerns.

Work is project-orientated and you may be working on a number of

projects, all at various different stages, at any given time. Several process

engineering companies act as consultancies.

Typical work activities include:

Assessing processes for their relevance, and assessing the adequacy

of engineering equipment;

Reviewing existing data (also lab analysis) to see if more research

and information need to be collated;

Designing,

installing and commissioning new production units,

monitoring modifications and upgrades, and troubleshooting

existing processes;

Applying the principles of mass, momentum and heat transfer to

process and equipment design, including conceptual, scheme and

detail design;

Conducting

process

development

experiments

to

scale

in

laboratory;

Preparing reports, flow diagrams and charts;

Assessing the availability of raw materials and the safety and

environmental impact of the plant;

Managing the cost and time constraints of projects;

Selecting, managing and working with sub-contractors;

Supporting

the

conversion

of

small-scale

commercially viable large-scale operations;

processes

into

Assuming responsibility for risk assessment, including hazard and

operability (hazop) studies, for the health and safety of both

company staff and the wider community;

Working closely with chemical engineers to monitor and improve the

efficiency, output and safety of a plant;

Ensuring the process works at the optimum level, to the right rate

and quality of output, in order to meet supply needs;

Making observations and taking measurements directly, as well as

collecting and interpreting data from the other technical and

operating staff involved;

Assuming responsibility for environmental monitoring and ongoing

performance of processes and process plant;

Ensuring that all aspects of an operation or process meet specified

regulations;

Working

closely with other specialists, including: scientists

responsible for the quality control of raw materials, intermediates

and finished products; engineers responsible for plant maintenance;

commercial colleagues on product specifications and production

schedules; and the operating crew.

Vous aimerez peut-être aussi

- Process Engineer: Job DescriptionDocument2 pagesProcess Engineer: Job DescriptionaustinPas encore d'évaluation

- Professional Opportunities in Eni For Chemical EngineersDocument4 pagesProfessional Opportunities in Eni For Chemical Engineersanon_552162647Pas encore d'évaluation

- Process EngineeringDocument1 pageProcess EngineeringNitish SharmaPas encore d'évaluation

- Roles and Responsibilities of Unit HeadDocument1 pageRoles and Responsibilities of Unit HeadSahil PatilPas encore d'évaluation

- Chemical EngineersDocument3 pagesChemical Engineersazeem1236Pas encore d'évaluation

- Mem Construction 3Document5 pagesMem Construction 3Georgina SulePas encore d'évaluation

- Cadet Engineer Checklist ClearanceDocument3 pagesCadet Engineer Checklist Clearancejosuedelios88Pas encore d'évaluation

- Dy. Manager (Process Engg.)Document3 pagesDy. Manager (Process Engg.)vishal9patel-63Pas encore d'évaluation

- What Is Process EngineeringDocument3 pagesWhat Is Process EngineeringmulerPas encore d'évaluation

- Chemical Engineer Skill SetDocument2 pagesChemical Engineer Skill SetJunaid AhmadPas encore d'évaluation

- Long IFTPS 2015Document38 pagesLong IFTPS 2015Mohamed Ali BoumarafPas encore d'évaluation

- QC Specialist Holly Springs, NC 12 Months: Minimum RequirementsDocument7 pagesQC Specialist Holly Springs, NC 12 Months: Minimum Requirementschintan patelPas encore d'évaluation

- Technical Integrity Engineering Is A Term Applied To The Engineering Disciplines Associated With TheDocument5 pagesTechnical Integrity Engineering Is A Term Applied To The Engineering Disciplines Associated With TheVenkatesh PethurajPas encore d'évaluation

- 1styear Lecture 1 PDFDocument11 pages1styear Lecture 1 PDFwissem metidjiPas encore d'évaluation

- PSE-1 Introduction b06 - 317Document4 pagesPSE-1 Introduction b06 - 317Anonymous N3LpAXPas encore d'évaluation

- Senior Process Engineer: Main Duties & Responsibilities: 1. General DutyDocument4 pagesSenior Process Engineer: Main Duties & Responsibilities: 1. General DutyClarence ChPas encore d'évaluation

- Health & Safety Professioanl CVDocument5 pagesHealth & Safety Professioanl CVnaveedPas encore d'évaluation

- Process DevelopmentDocument8 pagesProcess DevelopmentJesus DanielPas encore d'évaluation

- Process Design EngineeringDocument196 pagesProcess Design EngineeringAriyanto Purnomo IlBewokll100% (2)

- Process Design Engineering Manual Part 1-1Document67 pagesProcess Design Engineering Manual Part 1-1Shrikant Yadav100% (1)

- Plant Design & Economics (2020-CH-243)Document28 pagesPlant Design & Economics (2020-CH-243)Hassan Bashir100% (1)

- Hse Manager Job DescriptionDocument14 pagesHse Manager Job DescriptionAnsarMahmoodPas encore d'évaluation

- Industrial and ProductionDocument4 pagesIndustrial and ProductionnetsimastudioPas encore d'évaluation

- 323 Chapter 1 Methods, Standards, and Work DesignDocument18 pages323 Chapter 1 Methods, Standards, and Work DesignCristi EteganPas encore d'évaluation

- Haji List Hajj 2017Document2 pagesHaji List Hajj 2017aftabseven2Pas encore d'évaluation

- Plant HeadDocument25 pagesPlant Headpankajmpawar1986Pas encore d'évaluation

- HSE Management ProfessionalDocument10 pagesHSE Management ProfessionalRicardoPas encore d'évaluation

- Process Design and Development: Introduction To Chemical Engineering Plant DesignDocument10 pagesProcess Design and Development: Introduction To Chemical Engineering Plant DesignCenter of KnowledgePas encore d'évaluation

- Director Manufacturing in Greater Denver CO Resume Erik Van HornDocument2 pagesDirector Manufacturing in Greater Denver CO Resume Erik Van HornErik Van HornPas encore d'évaluation

- Senior Project Manager (Mar 2023)Document3 pagesSenior Project Manager (Mar 2023)vikas595Pas encore d'évaluation

- Job Assessment Report: Mahmudul HasnerDocument9 pagesJob Assessment Report: Mahmudul HasnerMahmudul HasnerPas encore d'évaluation

- Process Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDocument2 pagesProcess Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDouglasWilkinsPas encore d'évaluation

- Chemical Lab Manager Project Manager in Houston TX Resume Oludayo KehindeDocument2 pagesChemical Lab Manager Project Manager in Houston TX Resume Oludayo KehindeOludayo KehindePas encore d'évaluation

- Senior Chemical Process Engineer in Boston MA Resume Albert PorrasDocument3 pagesSenior Chemical Process Engineer in Boston MA Resume Albert PorrasAlbertPorrasPas encore d'évaluation

- Ped, PD, Pi, Mto, Mo, Et, HT UsesDocument8 pagesPed, PD, Pi, Mto, Mo, Et, HT UsesShrey PatelPas encore d'évaluation

- What Is Manufacturing Engineering?Document50 pagesWhat Is Manufacturing Engineering?mariappanPas encore d'évaluation

- Nabeel Ahmed Malik: ExperienceDocument3 pagesNabeel Ahmed Malik: ExperiencenabeelPas encore d'évaluation

- Good Engineering Practice Based On The ISPE Guide LinesDocument94 pagesGood Engineering Practice Based On The ISPE Guide LinesJitesh Pushpangadan100% (2)

- HSE Supervisor: QualificationsDocument5 pagesHSE Supervisor: QualificationsAshraf BeramPas encore d'évaluation

- RCM (Instrument) Engineer IMS One World - Jubail: Required SkillsDocument4 pagesRCM (Instrument) Engineer IMS One World - Jubail: Required SkillsadibPas encore d'évaluation

- Head, Process Safety - Job Description PDFDocument2 pagesHead, Process Safety - Job Description PDFMalik RiazPas encore d'évaluation

- Mechanical Design Engineer2Document8 pagesMechanical Design Engineer2Arnold LicayanPas encore d'évaluation

- IntroductionDocument38 pagesIntroductionGoa Trip100% (1)

- Carrer Inenvironmental EngineeringDocument6 pagesCarrer Inenvironmental EngineeringdinaPas encore d'évaluation

- Mohsin Siraj: Nestle Pakistan Limited 04, April 2011 To OnwardDocument4 pagesMohsin Siraj: Nestle Pakistan Limited 04, April 2011 To OnwardMOHSIN SIRAJPas encore d'évaluation

- Process Engineer: Learn, Develop and Thrive in Our High-Performance CultureDocument2 pagesProcess Engineer: Learn, Develop and Thrive in Our High-Performance CultureSameh MohamedPas encore d'évaluation

- Nace InvoiceDocument11 pagesNace InvoiceOwais Manzoor MalikPas encore d'évaluation

- Unit#2 SummaryDocument3 pagesUnit#2 SummaryHdhd HdhhdPas encore d'évaluation

- Arun Mohanty: ObjectiveDocument4 pagesArun Mohanty: ObjectiveSAMSON GLOBALPas encore d'évaluation

- NTCC PPDocument13 pagesNTCC PPSubodh SinghPas encore d'évaluation

- Associate Process Development EngineerDocument3 pagesAssociate Process Development EngineerSindhuraj MukherjeePas encore d'évaluation

- Learning Outcomes For EngineerDocument5 pagesLearning Outcomes For EngineerAmmar YasirPas encore d'évaluation

- Environmental Health Safety in Princeton NJ Resume Cliff LandriganDocument2 pagesEnvironmental Health Safety in Princeton NJ Resume Cliff LandriganCliffLandriganPas encore d'évaluation

- Pom U12Document43 pagesPom U12techworkpressPas encore d'évaluation

- What Is A Process Safety EngineerDocument3 pagesWhat Is A Process Safety Engineerdaimon_pPas encore d'évaluation

- Sample Resume Process Engineer Economic RecoveryDocument10 pagesSample Resume Process Engineer Economic RecoveryVijay RajaindranPas encore d'évaluation

- Lecture 1Document26 pagesLecture 1Yadeta RegasaPas encore d'évaluation

- Experience As A Process EngineerDocument1 pageExperience As A Process EngineerKaren RomeroPas encore d'évaluation

- HSE MANAGEMENT PLANDocument16 pagesHSE MANAGEMENT PLANsam rahbiPas encore d'évaluation

- Jocta 1Document5 pagesJocta 1Donesh VarshneyPas encore d'évaluation

- JKXKJXHDocument1 pageJKXKJXHDonesh VarshneyPas encore d'évaluation

- GJKJHKJ KHKJGHKDHG DDKFJDDocument1 pageGJKJHKJ KHKJGHKDHG DDKFJDDonesh VarshneyPas encore d'évaluation

- GJKJHKJDocument1 pageGJKJHKJDonesh VarshneyPas encore d'évaluation

- JKXKJXHDocument1 pageJKXKJXHDonesh VarshneyPas encore d'évaluation

- KGKGKJGKJDocument1 pageKGKGKJGKJDonesh VarshneyPas encore d'évaluation

- JKXKJXHDocument1 pageJKXKJXHDonesh VarshneyPas encore d'évaluation

- JKXKJXHDocument1 pageJKXKJXHDonesh VarshneyPas encore d'évaluation

- GJKJHKJDocument1 pageGJKJHKJDonesh VarshneyPas encore d'évaluation

- JKXKJXHDocument1 pageJKXKJXHDonesh VarshneyPas encore d'évaluation

- GJKJHKJ KHKJGHKDHG DDKFJDDocument1 pageGJKJHKJ KHKJGHKDHG DDKFJDDonesh VarshneyPas encore d'évaluation

- JKXKJXHDocument1 pageJKXKJXHDonesh VarshneyPas encore d'évaluation

- Mechanics - Applied Mechanics (CE) - Equilibrium of Systems of ForcesDocument17 pagesMechanics - Applied Mechanics (CE) - Equilibrium of Systems of ForcesDonesh VarshneyPas encore d'évaluation

- Test Certificate: Date CustomerDocument1 pageTest Certificate: Date CustomerDonesh VarshneyPas encore d'évaluation

- Asxjdgkjsds DDDFJKLDJFDocument1 pageAsxjdgkjsds DDDFJKLDJFDonesh VarshneyPas encore d'évaluation

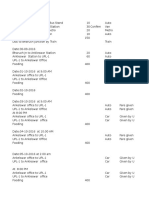

- Expense EvesrestDocument4 pagesExpense EvesrestDonesh VarshneyPas encore d'évaluation

- Asxjdgkjsds DDDFJKLDJFDocument1 pageAsxjdgkjsds DDDFJKLDJFDonesh VarshneyPas encore d'évaluation

- Expense EvesrestDocument4 pagesExpense EvesrestDonesh VarshneyPas encore d'évaluation

- Asxjdgkjsds DDDFJKLDJFDocument1 pageAsxjdgkjsds DDDFJKLDJFDonesh VarshneyPas encore d'évaluation

- As DDDFJKLDJFDocument1 pageAs DDDFJKLDJFDonesh VarshneyPas encore d'évaluation

- Dear Sir3Document2 pagesDear Sir3Donesh VarshneyPas encore d'évaluation

- As DDDFDocument1 pageAs DDDFDonesh VarshneyPas encore d'évaluation

- Dear Sir2Document1 pageDear Sir2Donesh VarshneyPas encore d'évaluation

- ORP Transmitter To Check RO-I and RO-II Feed Quality Interlocking With AutoDocument1 pageORP Transmitter To Check RO-I and RO-II Feed Quality Interlocking With AutoDonesh VarshneyPas encore d'évaluation

- ORP Transmitter To Check RO-I and RO-II Feed Quality Interlocking With AutoDocument1 pageORP Transmitter To Check RO-I and RO-II Feed Quality Interlocking With AutoDonesh VarshneyPas encore d'évaluation

- Organization Chart: Mr.S.Shar MaDocument2 pagesOrganization Chart: Mr.S.Shar MaDonesh VarshneyPas encore d'évaluation

- Dear Sir3Document2 pagesDear Sir3Donesh VarshneyPas encore d'évaluation

- Dear Sir3Document2 pagesDear Sir3Donesh VarshneyPas encore d'évaluation

- Dear SirDocument1 pageDear SirDonesh VarshneyPas encore d'évaluation

- Vacuum System-Donesh CalDocument26 pagesVacuum System-Donesh CalDonesh VarshneyPas encore d'évaluation

- Psan en Tcd210185ab 20220523 Inst WDocument2 pagesPsan en Tcd210185ab 20220523 Inst Wsinar automationPas encore d'évaluation

- Conventional Smoke DetectorDocument1 pageConventional Smoke DetectorThan Htike AungPas encore d'évaluation

- Elsa CableDocument2 pagesElsa CableJay WangPas encore d'évaluation

- History of JS: From Netscape to Modern WebDocument2 pagesHistory of JS: From Netscape to Modern WebJerraldPas encore d'évaluation

- ATHENAEUMDocument4 pagesATHENAEUMShubhra PatraPas encore d'évaluation

- My Oracle Support - Knowledge Browser - 1441364Document9 pagesMy Oracle Support - Knowledge Browser - 1441364Aman Khan Badal KhanPas encore d'évaluation

- 1 GPM V1 vacuum dehydrator removes water down to 20 PPMDocument3 pages1 GPM V1 vacuum dehydrator removes water down to 20 PPMLuis100% (1)

- Ijso 2012Document5 pagesIjso 2012bhaskarPas encore d'évaluation

- Free Space Optical Communication PDFDocument233 pagesFree Space Optical Communication PDFIgor Novid100% (1)

- ZI-Manual en PDFDocument56 pagesZI-Manual en PDFhaphapPas encore d'évaluation

- Kali Linux For BeginnersDocument13 pagesKali Linux For Beginnersnihal0% (1)

- Categoria ApiDocument61 pagesCategoria ApiHector MARTINEZ DEL ANGELPas encore d'évaluation

- Load Case CombinationsDocument5 pagesLoad Case CombinationsFrancisco UgartePas encore d'évaluation

- Pfaff 360 Sewing Machine Instruction ManualDocument55 pagesPfaff 360 Sewing Machine Instruction ManualiliiexpugnansPas encore d'évaluation

- Ibm Lenovo Whistler Rev s1.3 SCHDocument52 pagesIbm Lenovo Whistler Rev s1.3 SCH1cvbnmPas encore d'évaluation

- Real Time Automatic Helmet Detection of Bike Riders PDFDocument3 pagesReal Time Automatic Helmet Detection of Bike Riders PDFShubhPas encore d'évaluation

- 747ERDocument8 pages747ERelmobareck elghadhiPas encore d'évaluation

- SCT3030AL: 650V V R (Typ.) 30mDocument14 pagesSCT3030AL: 650V V R (Typ.) 30mSas Pro EletronicaPas encore d'évaluation

- Operating Procedure ERLDCDocument154 pagesOperating Procedure ERLDCbramhanand vermaPas encore d'évaluation

- Reduce Drum Pitch, Yarn Tension and Cradle LoadDocument16 pagesReduce Drum Pitch, Yarn Tension and Cradle LoadJigneshSaradavaPas encore d'évaluation

- Methode of Statement Lightning Protection & Earthing System Review 4Document27 pagesMethode of Statement Lightning Protection & Earthing System Review 4firman zakirPas encore d'évaluation

- Rocket Icluster V8.1Document16 pagesRocket Icluster V8.1Felipe Cervantes EspinosaPas encore d'évaluation

- Fobasv 6Document3 pagesFobasv 6Satyabrat Gaan100% (3)

- PBM and PBZ Crown Techniques ComparedDocument6 pagesPBM and PBZ Crown Techniques ComparedDonanguyenPas encore d'évaluation

- Phaser3300MFP Firmware Upgrade Instructions CWISDocument2 pagesPhaser3300MFP Firmware Upgrade Instructions CWISAlgenis De Leon RamirezPas encore d'évaluation

- Xiv 11.5.1 XcliDocument704 pagesXiv 11.5.1 XcliMuthu LPas encore d'évaluation

- Physics Exit 3q1718 .Document16 pagesPhysics Exit 3q1718 .Mikaella Tambis0% (1)

- BPM Third Wave Smith Fingar Apr2003 PDFDocument10 pagesBPM Third Wave Smith Fingar Apr2003 PDFNadeem AzadPas encore d'évaluation

- pd1185 Fire CodeDocument3 pagespd1185 Fire CodeCamille MangaranPas encore d'évaluation

- EMB 20100301 Mar 2010Document156 pagesEMB 20100301 Mar 2010agnithiumPas encore d'évaluation