Académique Documents

Professionnel Documents

Culture Documents

1.2 KM Long Pipe Lines and Concrete Pump Schwing Stetter

Transféré par

Hiren DesaiDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1.2 KM Long Pipe Lines and Concrete Pump Schwing Stetter

Transféré par

Hiren DesaiDroits d'auteur :

Formats disponibles

1.

2 KM's of Pipeline &

A Concrete Pump - Creating Benchmarks.

ON THE SPOT

Pratibha Modak Sagar Tunnel Project

R E P O R T N o . 3

Concrete was pumped to a whopping distance of 1180 meters inside a tunnel by employing a single Schwing

Stetter's stationary concrete pump SP 3500HD. Its performance was not just limited to the distance pumped

(1180 meters), but also in the pumping volume achieved. Customer was able to complete 450 meters of

tunneling in a month, against 250 meter/month earlier and also did a matchless 82 m3 in four hours of time.

Project description

Brihanmumbai Municipal Corporation (BMC) is supplying

drinking water to Mumbai City and suburbs to the tune of

3,350 mld (million liters per day), making its water supply

system eighth largest in the world. With the growing

demand, it was necessary for them to raise their capacity

to 4,200 million liters per day from the existing 3350

million liters.

To meet this increasing demand, a new reservoir 'Middle

Vaitarana' along the Vaitarna River as a third source was

constructed recently between the already existing two

reservoirs Lower and Upper Vaitarna under the MumbaiIV Water Supply project. The water from middle Vaitarna

dam will be released into the lower lake also called Modak

Sagar in a controlled manner from where it will be drawn

for treatment and supplied to the city.

The tunnel which is being constructed by Pratibha

Industries in joint venture with Austria-based Ostu-Stettin

Hoch u Tiefbau GmbH has done long distance pumping at

1180 meter at Modaksagar site using Schwing Stetter SP

3500HD Pump. Schwing Stetter India has supplied its

equipment for the concreting of Modaksagar Tunnel

linings, which is situated at the very west end of the MVP

project area, approximately 100 kms outside the city of

Mumbai.

Modak Sagar Tunnel Project Site

Modak Sagar dam

Modak Sagar Tunnel Project Plan

Source : Pratibha Industries Limited

This project involves the construction of a 7.5 km long tunnel of 4,100 mm diameter with allied works such as intake and pipeline for

transportation of water. The tunnel is laid around 90 meters below the ground level, which will have their intake close to Modaksagar dam, and

their outlets within the same existing service- and bifurcation chamber at Bell Nallah.

SCHWING STETTER MOVES CONCRETE. WORLDWIDE

Consistent: SP 3500HDR Pump

Schwing portable concrete pumps are successfully deployed

worldwide, whenever vast quantity of concrete have to be pumped

over extremely long horizontal and vertical distance. They are also

fast, reliable and economically efficient in handling concrete under

challenging conditions with regard to concrete design, jobsite and

climate.

Schwing SP 3500HD

Schwing & Prathiba Team with Schwing SP 3500HD

A Schwing SP 3500 HD pump with Rock Valve technology was

being used for this project. Its long stroke length of 2000 mm

helped to reduce the number of Rock Valve shifting, thus

increasing the pumping capacity and reducing wear and tear of

significant parts. The pump has a 125 mm diameter differential

cylinder and 180 mm delivery cylinder. It gave an area ratio of 2.07

i.e. a maximum hydraulic pressure of 350 bar leading to a concrete

pressure of 169 bar approximately.

Efficient: Tunnel setup for pumping

The concrete pump was placed inside shaft bottom below 100

meters from the ground level and the pipeline was laid using

concrete thrust blocks supports and anchoring the pipes on the

tunnel walls. The concrete from batching plant was transported

using a Transit Mixer, which unloaded the concrete into another

Transit Mixer placed at the shaft bottom around 100 meter below.

Subsequently, the concrete which was collected by Transit Mixer is

then fed into the concrete pump for lining the tunnel. For the

efficient work progress the cleaning system components were kept

organized near the concrete pump and a compressor was also

placed for emergency cleaning at the outlet end.

To maintain the pipeline clean in case of blockage, water line was

reserved for every 300 meters.

SSI and BASF engineers worked jointly to formulate a successful

concrete placing cycle. The entire concrete in the pipeline was

utilized into the pour by the Schwing Rock Valve with the water

cleaning system after every pour. This unique feature

demonstrates the sealing efficiency of Rock Valve technology.

Schwing Stetter Transit Mixer unloading the concrete

Top view inside the shaft

Transit Mixer & Pump placed below 100 mtrs from the ground level

Hydraulically operated shutters

Pipeline laid inside the tunnel

Triumph - Record during the pour

Initially the project was started with conventional concreting with

short distance concrete pump with agitator cars for concrete

tunnel lining. The lining was done using hydraulically operated

shutters with M25 grade concrete at 300 mm thickness. The

agitator car which was pulled using diesel locomotive had a

maximum capacity of 9 m3 and achieved maximum average speed

of 250 meters of tunnel construction in a month.

To amplify the speed of concrete lining, customer adopted the new

technology of long distance concrete pumping and installed for

pumping at a distance of 1180 meters. The customer has achieved

highest progress of 450 meter tunnel construction in a month and

82 m3 in a four hours of time by using Schwing Stetter concrete

pump.

Customer Talk

Schwing & Prathiba Team at Project site

Mr. Vivek P.V, Manager Projects,

Pratibha Industries Limited

Pratibha Industries felt that working with the

innovative idea of long distance pumping was

one of the challenging jobs it has faced during

this project. But with the dedicated expert

team's support from Schwing Stetter India,

this job was accomplished with great success,

setting a new benchmark.

Schwing Stetter has helped in training their team (Pratiba

Industries Limited) to achieve maximum results He also added that

employing Schwing Stetter's equipment, has saved them in their

capital cost, time and workforce thus adding up to their

profitability.

With a touch of contentment from doing business with SSI, he

added We are very delighted with the technical support extended

by SSI for this unique and challenging assignment and amazed at

their expertise in concrete pumping. This concrete pump SP

3500HD is truly a winner in proving its capabilities

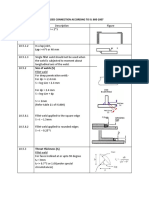

Details:

Owner: Municipal Corp of Greater Mumbai

General Contractor: Pratibha Ostu-Stettin Joint Venture

SSI Equipment: SP3500 HD/1820 and 3 nos of TMs.

F 71 - 72, SIPCOT Industrial Park, Irungattukottai, Sriperumpudur Taluk, Kancheepuram District,Tamil Nadu - 602105.

Phone : 044 2715 6780 / 781, 47108100 / 33555588 Fax : 044 27156539 Visit us at www.schwingstetterindia.com

MUMBAI 022 25624863 / 64, 30718300 / 33555588 I NEW DELHI 011 3092 8500 / 33555588

HYDERABAD 040 6615 1783 / 33555588 I BANGALORE 080 4243 8400 / 33555588

KOLKATA 033 3322 3300 / 33555588 I COCHIN 0484 4055984 / 3355558

AHMEDABAD 079 40244200 / 33555588 I PUNE 020 26055651 / 2 / 33555588

CHANDIGARH 0172 3957500 / 3957503 I BHUBANESWAR 0674 2463999 / 3355558 I GUWAHATI 0361 2234738 I RAIPUR 0771 2562325

Vous aimerez peut-être aussi

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!D'EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Évaluation : 5 sur 5 étoiles5/5 (2)

- Placing Concrete by Pumping: Department of Civil Engineering Pimpri Chinchwad Polytechnic, Nigdi, Pune-44Document5 pagesPlacing Concrete by Pumping: Department of Civil Engineering Pimpri Chinchwad Polytechnic, Nigdi, Pune-44Catnis TomPas encore d'évaluation

- 119.PDF Pump ConcreteDocument7 pages119.PDF Pump Concreterahul khanPas encore d'évaluation

- Concrete Pumping Service Study USDocument6 pagesConcrete Pumping Service Study USShekhar SoniPas encore d'évaluation

- Effect of Coarse Aggregate Size On PumpingDocument8 pagesEffect of Coarse Aggregate Size On PumpingsaiPas encore d'évaluation

- Lubrication Layer Properties During Concrete PumpingDocument10 pagesLubrication Layer Properties During Concrete PumpingsaiPas encore d'évaluation

- Scorpion User ManualDocument29 pagesScorpion User ManualElmer RafaelPas encore d'évaluation

- Concrete Pumping Cop 2019 PDFDocument59 pagesConcrete Pumping Cop 2019 PDFaung moe tunPas encore d'évaluation

- Hydraulic CylinderDocument40 pagesHydraulic CylinderYandapalli Sai ramPas encore d'évaluation

- Pumped ConcreteDocument7 pagesPumped ConcreteSa ReddiPas encore d'évaluation

- SP 1800Document1 pageSP 1800Anass ChtaybiPas encore d'évaluation

- Microsurfacing of BT RoadsDocument5 pagesMicrosurfacing of BT RoadssombansPas encore d'évaluation

- Pumping ConcreteDocument4 pagesPumping ConcreteAmit VashisthPas encore d'évaluation

- Stationary Pump BP350XTDocument4 pagesStationary Pump BP350XTRithan BPas encore d'évaluation

- Proceedings HM 2014Document751 pagesProceedings HM 2014goranb87Pas encore d'évaluation

- Concrete Recycling Systems: The Choice of ProfessionalsDocument6 pagesConcrete Recycling Systems: The Choice of ProfessionalsSanjay BaidPas encore d'évaluation

- Check List For Concrete Pump Installation: S.No Description of Items L&T/ L&T P&M SS Tce/ SgiplDocument1 pageCheck List For Concrete Pump Installation: S.No Description of Items L&T/ L&T P&M SS Tce/ SgiplGuna SekaranPas encore d'évaluation

- Pumping of Concrete and MortarDocument46 pagesPumping of Concrete and Mortarسامح الجاسمPas encore d'évaluation

- KHRI-Webinar (04-05-2020) - Pumping of Concrete - Challenges & Way Forward - DR Prakash Nandagopalan (IITB)Document50 pagesKHRI-Webinar (04-05-2020) - Pumping of Concrete - Challenges & Way Forward - DR Prakash Nandagopalan (IITB)brahmabul100% (1)

- Stationary Pumps RangeDocument17 pagesStationary Pumps RangeBulli Reddy KarriPas encore d'évaluation

- CONCRETEDocument29 pagesCONCRETEOmar Daniel VelandiaPas encore d'évaluation

- 3.concrete - ProductionDocument24 pages3.concrete - ProductionSUMANT KUMARPas encore d'évaluation

- Stationary Concrete Pumps en G 16345-0 PDFDocument20 pagesStationary Concrete Pumps en G 16345-0 PDFLUIS ISAAC LEON PAROPas encore d'évaluation

- Concrette Pump STD Main PumpDocument3 pagesConcrette Pump STD Main PumpHidayatPas encore d'évaluation

- Mechtcherine (2013) - Testing Pumpability of Concrete Using Sliding Pipe Rheometer PDFDocument12 pagesMechtcherine (2013) - Testing Pumpability of Concrete Using Sliding Pipe Rheometer PDFManu K Mohan100% (1)

- Reich 0001 PDFDocument87 pagesReich 0001 PDFYordys Domínguez RodríguezPas encore d'évaluation

- PuztmeisterDocument3 pagesPuztmeisterEdgar Quispe LaricoPas encore d'évaluation

- Concrete Boom Pump Pipelines Checking Procedure 23 Jan 2020Document19 pagesConcrete Boom Pump Pipelines Checking Procedure 23 Jan 2020sengottaiyan100% (1)

- DC Water Works Job CenterDocument7 pagesDC Water Works Job CenterCM Kenyan McDuffiePas encore d'évaluation

- Concrete: Concrete Is A Composite Material Composed of Fine and Coarse Aggregate BondedDocument24 pagesConcrete: Concrete Is A Composite Material Composed of Fine and Coarse Aggregate BondedMohamed SemlaliPas encore d'évaluation

- Book - Advanced Steel Structures, Fire and Fatigue Design - by W LuDocument118 pagesBook - Advanced Steel Structures, Fire and Fatigue Design - by W LuAbbes ChakchoukPas encore d'évaluation

- KCET BrochureDocument43 pagesKCET BrochureAlan GirishPas encore d'évaluation

- Seminer On Material Handeling Systyem in Cement IndustryDocument12 pagesSeminer On Material Handeling Systyem in Cement IndustryBivekAdhikari100% (1)

- s32x s36x BrochureDocument6 pagess32x s36x Brochurebeto pagoadaPas encore d'évaluation

- Mini Excavator Design and AnalysisDocument9 pagesMini Excavator Design and AnalysisInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- World Record in Long Distance Pumping - Case Study V1Document28 pagesWorld Record in Long Distance Pumping - Case Study V1Kaleeswari GPas encore d'évaluation

- 4634 PDFDocument7 pages4634 PDFMuthu KumarPas encore d'évaluation

- Resume: Er. Amjad Hussain KhanDocument3 pagesResume: Er. Amjad Hussain KhanPrabhakar JawadePas encore d'évaluation

- Hydraulic Cartridge Logic Valves - Hydraulic ValveDocument2 pagesHydraulic Cartridge Logic Valves - Hydraulic Valveasif bashaPas encore d'évaluation

- Chapter 1Document56 pagesChapter 1Surbhi JainPas encore d'évaluation

- Concrete Pump Pipe CatalogDocument7 pagesConcrete Pump Pipe CatalogSiddhi SparesPas encore d'évaluation

- 1 PDFDocument41 pages1 PDFChan Peng SwanPas encore d'évaluation

- Australian Manufactured Sand GuidelineDocument2 pagesAustralian Manufactured Sand GuidelineahmadiahreadymixlabPas encore d'évaluation

- Magnum 140 Ing BXDocument12 pagesMagnum 140 Ing BXJavier Marcelo BPas encore d'évaluation

- Kadapa Offer Concrete Batching Plant 18 Cu M Per HrsDocument7 pagesKadapa Offer Concrete Batching Plant 18 Cu M Per HrsAnil Kumar Reddy ChinthaPas encore d'évaluation

- Bal Gangadhar Tilak BiographyDocument2 pagesBal Gangadhar Tilak Biographydipendra2004100% (1)

- Stationary Mixing Batching PlantsDocument16 pagesStationary Mixing Batching PlantsErtan YücePas encore d'évaluation

- Chapter 2.1-History of Concrete Machinery IndustryDocument12 pagesChapter 2.1-History of Concrete Machinery IndustrykckhoaPas encore d'évaluation

- Mixer TheoryDocument8 pagesMixer TheorySheikh Nouman Mohsin RamziPas encore d'évaluation

- Batching PlantDocument12 pagesBatching PlantPratik LikharPas encore d'évaluation

- Project Report: Summer Training at JMC Projects India Ltd. NoidaDocument57 pagesProject Report: Summer Training at JMC Projects India Ltd. NoidahjPas encore d'évaluation

- Volumetric Concrete Mixer Proposal For Ready Mix CompaniesDocument6 pagesVolumetric Concrete Mixer Proposal For Ready Mix CompaniesHabtamu Sedie0% (1)

- Concrete Design PDFDocument121 pagesConcrete Design PDFDusanJankovicPas encore d'évaluation

- IRC 15-2002 Standard Specifications and Code of Practice ForDocument66 pagesIRC 15-2002 Standard Specifications and Code of Practice ForAnkit Gupta80% (5)

- KCET - 2023 Infomration Bulletin NewDocument55 pagesKCET - 2023 Infomration Bulletin NewWalker GamingPas encore d'évaluation

- Concreting Times by Schwing Stetter Vol 2 Issue 6Document12 pagesConcreting Times by Schwing Stetter Vol 2 Issue 6Hiren Desai0% (1)

- JR YamunaExpressway enDocument8 pagesJR YamunaExpressway enShikhin GargPas encore d'évaluation

- Report 7Document29 pagesReport 7MannanLE -A0105Pas encore d'évaluation

- DCLDocument100 pagesDCLkrmcharigdc100% (1)

- Curve Jacking - Paper Bangkok T-1ThorenDocument10 pagesCurve Jacking - Paper Bangkok T-1ThorenCheng KimHuaPas encore d'évaluation

- 19 Steps To A VictimDocument1 page19 Steps To A VictimHiren DesaiPas encore d'évaluation

- Excon 2017 Space RentalsDocument2 pagesExcon 2017 Space RentalsHiren DesaiPas encore d'évaluation

- A Framework For Development of Quality Control Model For Indian Ready Mixed Concrete IndustryDocument15 pagesA Framework For Development of Quality Control Model For Indian Ready Mixed Concrete IndustryHiren DesaiPas encore d'évaluation

- An Advanced Software For The Geotechnical Design of FoundationsDocument6 pagesAn Advanced Software For The Geotechnical Design of FoundationsHiren DesaiPas encore d'évaluation

- Non-Linear Static Push Over AnalysisDocument12 pagesNon-Linear Static Push Over Analysismrnicus100% (1)

- Purpose of Provision of Concrete CoverDocument17 pagesPurpose of Provision of Concrete CoverHiren DesaiPas encore d'évaluation

- Insert Plate DetailDocument1 pageInsert Plate DetailRafaArdiSyahrezaPas encore d'évaluation

- Assignment 2Document3 pagesAssignment 2Hiren DesaiPas encore d'évaluation

- Foundation Layout With GridsDocument1 pageFoundation Layout With GridsHiren DesaiPas encore d'évaluation

- Structural Systems: Er. Hiren G. DesaiDocument13 pagesStructural Systems: Er. Hiren G. DesaiHiren DesaiPas encore d'évaluation

- Insert Plate DetailDocument1 pageInsert Plate DetailRafaArdiSyahrezaPas encore d'évaluation

- Acceptance of Criteria of Concrete 100Document5 pagesAcceptance of Criteria of Concrete 100Lucky ChopraPas encore d'évaluation

- Surat Municipal CorporationDocument6 pagesSurat Municipal CorporationHiren DesaiPas encore d'évaluation

- Seismic Analysis: Earthquake EngineeringDocument4 pagesSeismic Analysis: Earthquake EngineeringHiren DesaiPas encore d'évaluation

- Welded Connection SummaryDocument4 pagesWelded Connection SummaryHiren DesaiPas encore d'évaluation

- Student Ebook Introduction PagesDocument13 pagesStudent Ebook Introduction PagesHiren DesaiPas encore d'évaluation

- Insert Plate DetailDocument1 pageInsert Plate DetailRafaArdiSyahrezaPas encore d'évaluation

- Facad TechDocument140 pagesFacad TechAnonymous IwqK1NlPas encore d'évaluation

- ErectionDocument55 pagesErectionAjay Sastry100% (7)

- He Next HaitiDocument7 pagesHe Next HaitiHiren DesaiPas encore d'évaluation

- Table1 PDFDocument1 pageTable1 PDFHiren DesaiPas encore d'évaluation

- Green Building SefiDocument3 pagesGreen Building SefiHiren DesaiPas encore d'évaluation

- Geophysical Methods & ApplicationsDocument10 pagesGeophysical Methods & ApplicationsmlakkissPas encore d'évaluation

- Foundation Layout With GridsDocument1 pageFoundation Layout With GridsHiren DesaiPas encore d'évaluation

- TATA Structura BrochureDocument20 pagesTATA Structura Brochurecjm100% (2)

- Frei OttoDocument11 pagesFrei Ottoparatinadana100% (2)

- 4.soil Investigation SummaryDocument7 pages4.soil Investigation SummaryHiren DesaiPas encore d'évaluation

- Arup in India Leaflet 2011vera PDFDocument2 pagesArup in India Leaflet 2011vera PDFHiren DesaiPas encore d'évaluation

- Classification Scheme For Services Under GSTDocument37 pagesClassification Scheme For Services Under GSTArul PrakashPas encore d'évaluation

- Certificate: Vision ArchitectsDocument1 pageCertificate: Vision ArchitectsHiren DesaiPas encore d'évaluation

- Drag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Document2 pagesDrag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Arthur Saw Sher-QenPas encore d'évaluation

- Engine Test CellDocument44 pagesEngine Test Cellgrhvg_mct8224Pas encore d'évaluation

- FP CLOCK - csproj.FileListAbsoluteDocument14 pagesFP CLOCK - csproj.FileListAbsolutePhi Huỳnh NgôPas encore d'évaluation

- Visilume Standard Sightglass: (Also Available Complete With Wiper Assembly)Document2 pagesVisilume Standard Sightglass: (Also Available Complete With Wiper Assembly)Dương HoàngPas encore d'évaluation

- 1233 Pid 03Document11 pages1233 Pid 03Reza AranPas encore d'évaluation

- Financial Auditor Job DescriptionDocument8 pagesFinancial Auditor Job Descriptionfinancemanagement702Pas encore d'évaluation

- CI 1580A ENG User ManualDocument50 pagesCI 1580A ENG User ManualArdy KristianPas encore d'évaluation

- Kubota Dual Fuel Series SpecificationDocument10 pagesKubota Dual Fuel Series Specificationפטריה מוזרPas encore d'évaluation

- Item 103 Structure ExcavationDocument3 pagesItem 103 Structure ExcavationGerry Velicaria100% (1)

- 1 Introduction To Thermal System DesignDocument43 pages1 Introduction To Thermal System DesignAbhishek KullurPas encore d'évaluation

- Steel Erection Code of PracticeDocument94 pagesSteel Erection Code of Practicedadz mingiPas encore d'évaluation

- Kočnice Shimano BR-M422Document1 pageKočnice Shimano BR-M422salecello2113Pas encore d'évaluation

- Ormin ElementaryDocument19 pagesOrmin ElementaryPRC Board100% (1)

- New V70 XC70 Owners Manual MY05 en Tp7551Document226 pagesNew V70 XC70 Owners Manual MY05 en Tp7551dynax4Pas encore d'évaluation

- Review B4C Jace4865 Boron Carbide Structure Properties and Stability Under StressDocument24 pagesReview B4C Jace4865 Boron Carbide Structure Properties and Stability Under StressAlexandru PrisecaruPas encore d'évaluation

- Trouble Shooting Dewatering PumpDocument136 pagesTrouble Shooting Dewatering PumpMuhammad NoorPas encore d'évaluation

- IM KR180A E 4thDocument80 pagesIM KR180A E 4thbatizap batizapPas encore d'évaluation

- Fiber Optic CablesDocument24 pagesFiber Optic CablesARCC2030Pas encore d'évaluation

- West Virginia Transporter 2017Document16 pagesWest Virginia Transporter 2017Kyle LangsleyPas encore d'évaluation

- 320d WiringDocument2 pages320d WiringMohamed Harb100% (5)

- Microstrip Patch Antenna DesignDocument19 pagesMicrostrip Patch Antenna DesignNgoc Lan Nguyen50% (2)

- Top 10 Masturbation Tips From WomenDocument3 pagesTop 10 Masturbation Tips From WomengmeadesPas encore d'évaluation

- Altapail Ii: 20-Liter or 5-Gallon Pail MeltersDocument2 pagesAltapail Ii: 20-Liter or 5-Gallon Pail MeltersjorgeramosvasPas encore d'évaluation

- Administration-Guide Open Bee OCSDocument7 pagesAdministration-Guide Open Bee OCSpeka76Pas encore d'évaluation

- Bucher LRV Hydraulic ValveDocument90 pagesBucher LRV Hydraulic Valvedean_lockey0% (1)

- SQAP For Pumps 2017Document79 pagesSQAP For Pumps 2017MukeshPas encore d'évaluation

- DSTV Channel PublicDocument3 pagesDSTV Channel PublicCalvin MulaudziPas encore d'évaluation

- TR33 0298Document4 pagesTR33 0298N APas encore d'évaluation

- CS 450 Assignment 5 SolutionsDocument3 pagesCS 450 Assignment 5 Solutionshidrovo3589Pas encore d'évaluation

- Hanro Tools Incorporation Delhi IndiaDocument10 pagesHanro Tools Incorporation Delhi IndiaHanro Tools IncorporationPas encore d'évaluation