Académique Documents

Professionnel Documents

Culture Documents

Catalogo CLARKSON - KGD Wafer Style Slurry Knife Gate Valve

Transféré par

muahdibCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Catalogo CLARKSON - KGD Wafer Style Slurry Knife Gate Valve

Transféré par

muahdibDroits d'auteur :

Formats disponibles

Clarkson KGD Wafer Style Slurry Knife Gate Valve

2 thru 24

The Clarkson KGD wafer style slurry knife gate

valve offers value and high performance in a

compact package.

Features

Patented, field replaceable elastomer

sleeves available in a wide range

of elastomers to meet varied

applications.

Dynamic self-adjusting secondary

seal.

Long lasting lubrication.

No metal parts in contact with the

flowing slurry.

Unobstructed flow eliminates

turbulence, minimizes pressure drop

across valve.

100% Isolation; bubble-tight shut-off

results in absolutely zero downstream

leakage.

Double-seated design provides

bi-directional flow and shut-off.

No seat cavity where solids can

collect and prevent full gate closure.

No gate or stem packing is required,

eliminating packing leakage and

maintenance.

Adaptable frame (yoke) design

featuring a top-removal stem nut, can

be field modified to an air cylinder or

bevel gear in the field without welding.

Open-Closed lockout brackets

standard, ready for optional factory

supplied or customer supplied lockout

pins.

General applications

Technical data

Mining

Size range

:2 thru 16 rated to 150 psi

:18 thru 24 rated to 90 psi

Sleeve

:Gum rubber standard

Power

Pulp and paper

Alumina

Chemical

Cement

Temperatures :Standard sleeve rated

to 160F, up to 300F

with proper elastomer

selection

Flow Control

Total Flow Control Solutions

Tyco reserves the right to change product design and specifications

without notice. Copyright 2003 by Tyco International Ltd.

CLKMC-0112-US-0306

Clarkson KGD Wafer Style Slurry Knife Gate Valve

2 thru 24

How the KGD sleeves work

Matching sleeves are placed in the

KGD valve housing to seal against the

gate when the valve is closed and seal

against each other when the valve is

open. This tight seal contains the

internal line pressure, precluding direct

pressure against the secondary seal.

As the gate moves from open to closed

position, it separates the facing

sleeves. The unique KGD sleeve

assembly provides positive sealing

action when the valve gate is closed

and when the gate is open; the sleeves

provide an unobstructed port and

protect metal parts from the flowing

slurry.

Open position:

Closed position:

Gate positioned above

seals

Gate travels completely

through sleeves to

provide blind flange shut

off and expel solids.

Tight fit between sleeves

contains internal pressure

Metal parts not in contact

with slurry

Unobstructed port area

eliminates turbulence,

minimizes pressure drop

across valve

No seat cavity where

solids can collect and

prevent full gate closure

Lubricant

Contact

Ribs

Standard configuration

Optional

Various gate materials

316 stainless steel gate

Universal body housing drilled and

tapped to match ANSI B16.5 Class 150

companion flanges

High tear strength gum rubber sleeves

with integral support rings

Gum rubber secondary seal

Double-seated design

provides bi-directional

flow and shut-off

Tight fit between sleeves

and gate contains internal

pressure

Splash containment

Secondary seal

The one-piece, self-adjusting, molded elastomer secondary seal eliminates any leakage

between the knife gate and top of the valve body in any orientation. The seal also prevents

any outside contaminants from getting inside the valve. It is dynamically self-adjusting,

eliminating the need for continual adjustment required with conventional style packing. The

secondary seal is also used to lubricate the gate as it cycles through the seal, providing

smoother gate movement and longer seal life, as well as reducing the force required to

actuate the gate. Silicon-based lubricant is held inside a series of rib cavities built into the

seal, each time the gate passes through the seal, a small amount of the long-lasting

lubricant is released. The seal is replaceable and can be changed while the valve is in the

line.

Ductile iron body housings

100% Isolation-bubble

tight shut-off results in

absolutely zero

downstream leakage

316L SS

317L SS

317L MN

Alloy 20

17-4 PH

Jessop 700

Others

Hastelloy C-276

Feralium 255

316 SS body housing (4 thru 12)

Sleeves (see page 3)

Drain plate

Actuators (see page 4)

Stem covers

Control accessories

Metric flange drilling

Tyco reserves the right to change product design and specifications

without notice. Copyright 2003 by Tyco International Ltd.

CLKMC-0112

2

The KGD valve incorporates a built-in

clean-out area at the base of the valve

body. The clean-out area may be enclosed

by an optional, removable drain plate that

is provided with ports to drain away any

accumulated solids that may prevent full

gate closure. Flush water can both enter

and exit the clean-out area through the

ports or enter through a flush port at the

top of the valve body. With the drain plate

in place, any solids, slurry, or flush water

ejected from the valve can be handled in a

controlled manner.

Clarkson KGD Wafer Style Slurry Knife Gate Valve

2 thru 24

Available sleeve materials

Features

Gum Rubber: This category includes all

natural gum elastomers, both filled and

unfilled and synthetic Polyisoprene. Has

high tensile strength, superior resistance to

tear and abrasion and good flexibility at

low temperatures. Maximum continuous

operating temperature 160F.

Heavy-duty frame (yoke) designed to

accept top removal stem nut, bevel

gear or cylinder actuator without

welding

EPDM-HTP: Advantages, excellent

Standard open and closed

lockout/tagout positions

resistance to heat, ozone and sunlight,

very good flexibility at low temperature,

good resistance to alkalis, acids, and

oxygenated solvents and superior

resistance to water and steam. Limitations,

poor resistance to oil, gasoline, and

hydrocarbon based solvents. Maximum

continuous operating temperature 250F.

The stainless steel gate is completely

withdrawn from the process flow in

the open position and can be

inspected or replaced without taking

the valve out of service

316 stainless steel gate is standard

Nitrile and Nitrile-HTP: Advantages, very

good resistance to oil, gasoline, alkalis and

acids. Good resistance to hydrocarbon

based solvents. Limitations, Inferior

resistance to ozone and oxygenated

solvents. Maximum continuous operating

temperature 225F for HTP and 200F for

standard Nitrile.

Dynamic self-adjusting secondary

seal retains long lasting internal

lubrication

Patented, field replaceable elastomer

sleeves

Unobstructed flow area, fully lined

with elastomer sleeves, no metal to

metal contact, no guides or wedges

Hypalon: Advantages, good abrasion

resistance, excellent resistance to alkalies

and acids, moderate resistance to oil and

gasoline. Limitations, poor resistance to

aromatic solvents, limited flexibility at low

temperature. Maximum continuous

operating temperature 200F.

Double sleeved design provides a

blind flange shut-off when the gate is

closed. Tight fit between sleeves

contains internal pressure

No need for flange gaskets

Fluoroelastomer: Advantages, outstanding

Universal cast ductile full-flanged

body housing to suit ANSI B16.5/150,

PN10 or PN16 as required

resistance to high heat, excellent

resistance to oil, gasoline and hydrocarbon

solvents. Very good impermeability to

gases, vapor and oxygen. Limitations, poor

resistance to tear and cut growth, very little

resistance to oxygenated solvents.

Maximum continuous operating

temperature 400F (Consult factory for

temperatures higher than 400F).

Lockwashers used on all bolting

Clean-out area

Specification

Clarkson KGD Wafer Style Slurry Knife Gate Valve

Wafer style, slurry knife gate valve shall be, packing less,

rubber-lined, bi-directional valve suitable for a wide range of

industrial applications. The full port design shall have no internal

obstructions and will provide a blind flange shut-off when the gate

is closed. The valves sealing surface is to be between two rubber

sleeves that are compressed into the ductile iron valve housings. The

sleeve will be molded with an integral stiffener ring that locates the

sleeve in the valve housing and helps the sleeves resist the high

shearing forces present when the gate is driven between them. Valve

shall have a one-piece, molded, replaceable elastomer secondary

seal to eliminate any leakage between the knife gate and top of the

valve body in any orientation and prevent any outside contaminants

from getting inside the valve. It shall be dynamically self-adjusting,

eliminating the need for continual adjustment. The secondary seal

shall retain a Silicon-based lubricant to lubricate the gate as it cycles

through the seal, providing smoother gate movement and longer seal

life, as well as reducing the force required to actuate the gate. The

stainless steel gate shall be completely withdrawn from the process

flow when in the open position, and can be inspected and replaced,

if necessary, without taking the valve out of service. When the valve

is in the closed position, the downstream sleeve can be replaced

while the upstream portion of the valve is still holding pressure. The

valve body housing to be full flanged, universal type, standard drilled

and tapped to suit ANSI B16.5/150 with optional PN10 or PN16 or

others, as required. Valve is equipped with a heavy steel fabricated

handwheel frame (yoke) which can be converted to bevel gear or

cylinder operator in the field without welding, complete with a 304

stainless steel rising stem. All nonferrous exterior surfaces shall be

painted to factory standard. Specify Clarkson KGD slurry knife

gate valve from Tyco Valves & Controls.

Tyco reserves the right to change product design and specifications

without notice. Copyright 2003 by Tyco International Ltd.

CLKMC-0112

3

Clarkson KGD Wafer Style Slurry Knife Gate Valve

2 thru 24

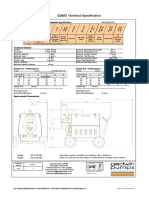

Dimensions and Weight

MH

BG

AC

HC

C

A

H. Port diameter

J. Inlet diameter

B*

Valve

Size

B1*

B2*

2

3

4

6

8

10

12

14

16

18

20

24

6.90

8.00

9.60

11.00

13.50

16.40

19.00

21.00

23.75

25.50

28.00

33.00

2.25

2.44

2.44

2.68

3.19

3.25

3.50

3.50

4.00

4.06

5.13

5.19

2.13

2.25

2.25

2.50

3.00

3.00

3.25

3.25

3.75

3.76

4.76

4.76

4.00

4.88

4.69

5.75

7.03

8.23

9.75

10.77

11.88

12.13

14.50

16.50

19.17

22.35

24.45

29.45

34.94

41.07

22.18

24.09

25.16

33.02

36.39

44.30

47.52

52.79

56.53

66.17

71.79

85.13

21.29

24.70

26.27

31.63

37.00

43.91

50.13

53.90

59.07

68.05

73.97

87.25

22.04

25.20

27.27

32.51

37.88

44.79

50.76

54.03

59.20

68.42

74.10

88.00

1.85

2.81

3.81

5.80

7.73

9.74

11.73

12.96

15.00

17.00

19.03

23.21

J

2.00

3.00

4.00

6.00

8.00

10.00

12.00

13.25

15.25

17.25

19.25

23.45

7.50

8.75

10.50

12.63

14.75

17.50

20.38

22.55

24.47

26.32

28.06

35.00

5.25

6.39

6.91

9.13

10.31

13.38

13.45

14.75

14.75

17.00

18.88

18.88

15.13

15.75

16.63

17.68

18.75

23.87

29.06

30.15

31.11

30.26

31.13

34.60

12.00

12.00

12.00

16.00

20.00

20.00

12.00

12.00

12.00

12.00

12.00

24.00

24.00

24.00

24.00

24.00

24.00

24.00

Universal flanges drilled and tapped to ANSI B 16.5/150 or PN10 and PN16 or others, as required.

B1 = minimum dimension required for installation.

B2 = installed face-to-face.

Actuation

Note: Not all actuators shown are available on all valve sizes.

MH Manual Handwheel

BG Manual Bevel Gear

AC Air Cylinder

HC Hydraulic Cylinder

EM Electro-mechanical

RA-Ratchet

Reno Facility Phone: 775-359-4100

Tyco Valves & Controls

www.tycovalves.com

The data presented in this bulletin is for general information only. Manufacturer is not responsible for acceptability of these products in relation to system requirements. Patents and Patents

Pending in U.S. and foreign countries. All rights reserved. Printed in U.S.A. Tyco reserves the right to change product design and specifications without notice. Copyright 2003.

Tyco reserves the right to change product design and specifications

without notice. Copyright 2003 by Tyco International Ltd.

CLKMC-0112

4

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Godwin HL 100 MDocument14 pagesGodwin HL 100 MmuahdibPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Flygt BS2250 MTDocument16 pagesFlygt BS2250 MTmuahdibPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- 3M Heavy Wall Heat Shrink Tubing ITCSNDocument4 pages3M Heavy Wall Heat Shrink Tubing ITCSNmuahdibPas encore d'évaluation

- CD100MDocument2 pagesCD100MmuahdibPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- CD103M Technical Specification: Standard Pump Material SpecificationDocument2 pagesCD103M Technical Specification: Standard Pump Material SpecificationmuahdibPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- 06B52-B ManualDocument38 pages06B52-B ManualmuahdibPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Engineering Catalog: HL160M Dri-Prime Pump Engineering DataDocument6 pagesEngineering Catalog: HL160M Dri-Prime Pump Engineering DatamuahdibPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- HH160i MANUAL USA BUILD 1 - 23-03-09 PDFDocument107 pagesHH160i MANUAL USA BUILD 1 - 23-03-09 PDFmuahdib100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- CD80D Technical Specification: Standard Pump Material SpecificationDocument2 pagesCD80D Technical Specification: Standard Pump Material SpecificationmuahdibPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Motobombas GodwinDocument12 pagesMotobombas GodwinmuahdibPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Motobomba SykesDocument144 pagesMotobomba Sykesmuahdib100% (1)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- CD75 Technical Specification: Standard Pump Material SpecificationDocument2 pagesCD75 Technical Specification: Standard Pump Material SpecificationmuahdibPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Manual - Wat - Sykes Parts - HH160i - Rev00 Sept12 PDFDocument27 pagesManual - Wat - Sykes Parts - HH160i - Rev00 Sept12 PDFmuahdibPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Manual de Instalacion, Operacion y Mantenimiento de Bomba Gorman Rupp Serie vg3c3Document30 pagesManual de Instalacion, Operacion y Mantenimiento de Bomba Gorman Rupp Serie vg3c3muahdib100% (1)

- PC9727 JD6090HF475 Parts Manual PDFDocument15 pagesPC9727 JD6090HF475 Parts Manual PDFmuahdibPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Curva de Bomba Bs 2400Document1 pageCurva de Bomba Bs 2400muahdibPas encore d'évaluation

- HardwreDocument66 pagesHardwrecaldaseletronica280Pas encore d'évaluation

- Curva de Bomba Bs 2400Document1 pageCurva de Bomba Bs 2400muahdibPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Microsoft Word - F12254-CDB-W03-QUA-ITP-60053 - 06-001 PDFDocument7 pagesMicrosoft Word - F12254-CDB-W03-QUA-ITP-60053 - 06-001 PDFmuahdib100% (1)

- Curb InletDocument1 pageCurb InletJoseph MathewPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Board To Board ConnectorsDocument38 pagesBoard To Board Connectorsjagadees21Pas encore d'évaluation

- A638A638M-10 Standard Specification For Precipitation Hardening Iron Base Superalloy Bars, Forgings, and Forging Stock For High-Temperature ServiceDocument3 pagesA638A638M-10 Standard Specification For Precipitation Hardening Iron Base Superalloy Bars, Forgings, and Forging Stock For High-Temperature Servicetjt4779Pas encore d'évaluation

- Wr2 ChecklistDocument14 pagesWr2 Checklistvaithy2011Pas encore d'évaluation

- Nippon Steel Catalog PDFDocument18 pagesNippon Steel Catalog PDFHAPPYPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Internship ReportDocument52 pagesInternship ReportLokesh N KumbarPas encore d'évaluation

- JWS 185 Pal 001Document10 pagesJWS 185 Pal 001JuprayPas encore d'évaluation

- 092 (2006)Document2 pages092 (2006)hrk100Pas encore d'évaluation

- Crushing and Grinding Calculations NewDocument20 pagesCrushing and Grinding Calculations NewTsakalakis G. Konstantinos100% (25)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- 1108 Metric Data SheetDocument1 page1108 Metric Data SheetVoele paterPas encore d'évaluation

- High Quality Products For Welding and CladdingDocument25 pagesHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- Miller SAW HandbookDocument76 pagesMiller SAW HandbookDeena McgeePas encore d'évaluation

- Chemical RestorationDocument40 pagesChemical RestorationEdisson MoraPas encore d'évaluation

- API CI-4 Plus Performance Category: Test Type Purpose Parameter RequirementDocument2 pagesAPI CI-4 Plus Performance Category: Test Type Purpose Parameter RequirementPorfirio Duarte ZaratePas encore d'évaluation

- A1003A1003M-15 Standard Specification For Steel Sheet, Carbon, Metallic - and Nonmetallic - Coated For Cold-Formed Framing MembersDocument9 pagesA1003A1003M-15 Standard Specification For Steel Sheet, Carbon, Metallic - and Nonmetallic - Coated For Cold-Formed Framing MembersDiego Egoávil MéndezPas encore d'évaluation

- English Teekay BrochureDocument48 pagesEnglish Teekay BrochuresalicurriPas encore d'évaluation

- BS en 10113 2 PDFDocument15 pagesBS en 10113 2 PDF9245126694Pas encore d'évaluation

- Review On Thermomechanical Processing of Advanced High Strength SteelsDocument130 pagesReview On Thermomechanical Processing of Advanced High Strength SteelsharishPas encore d'évaluation

- Comparison of Asme Specifications - 4Document1 pageComparison of Asme Specifications - 4MechanicalPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Pumpable Shotcrete in LadleDocument9 pagesPumpable Shotcrete in LadlePartha Pratim Singha RoyPas encore d'évaluation

- Procast - ESI - Casting SimulationsDocument14 pagesProcast - ESI - Casting Simulationsvmgobinath100% (2)

- Lecture Chapter 4 Phase Transformation and Metal AlloysDocument79 pagesLecture Chapter 4 Phase Transformation and Metal AlloysWinni TanPas encore d'évaluation

- High-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickDocument2 pagesHigh-Strength Low-Alloy Structural Steel With 50 Ksi (345 Mpa) Minimum Yield Point To 4 In. (100 MM) ThickSadashiva sahooPas encore d'évaluation

- Heat Treatment of Tool Steels PDFDocument20 pagesHeat Treatment of Tool Steels PDFwilldoahPas encore d'évaluation

- Allowable StressDocument3 pagesAllowable StressYuliana SyPas encore d'évaluation

- Pressure Safety ValveDocument11 pagesPressure Safety ValveamitpallathPas encore d'évaluation

- Aluminium Brazing 7 - StepsDocument6 pagesAluminium Brazing 7 - StepsPrashant NankarPas encore d'évaluation

- Nominal Size 20mm (/ In) : Flange TablesDocument1 pageNominal Size 20mm (/ In) : Flange TablesReşat DEMİRPas encore d'évaluation

- Zam-Introduction (Steel)Document14 pagesZam-Introduction (Steel)lymacsausarangPas encore d'évaluation

- Chapter 14Document4 pagesChapter 14Hania UmarPas encore d'évaluation

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tD'EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tÉvaluation : 4.5 sur 5 étoiles4.5/5 (27)

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneD'EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)