Académique Documents

Professionnel Documents

Culture Documents

Pressure-Temp Ratings of Flanges-Graph

Transféré par

Baha Eddine GharbiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pressure-Temp Ratings of Flanges-Graph

Transféré par

Baha Eddine GharbiDroits d'auteur :

Formats disponibles

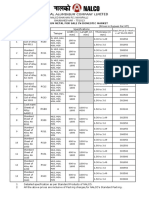

PRESSURE AND

TEMPERATRUE

RATINGS OF

STEEL FLANGES

List of Material Specifications

Material

Group

Applicable ASTM Specifications (a)

Nominal Designation

Forgings

1.1

CSi

A 105 (1)

CMnSi

A 350 Gr. LF2 (1)

Castings

A 216 Gr. WCB (1)

Plates (b)

A 515 Gr. 70 (1)

A 516 Gr. 70 (1) (2)

A 537 Cl. 1 (3)

1.2

CMnSiV

A 350 Gr. LF6 CI. 1 (4)

312 Ni

A 350 Gr. LF3

CMnSi

A 216 Gr. WCC (1)

A 352 Gr. LCC (5)

CMnSiV

1.3

A 350 Gr. LF6 Cl. 2 (4)

212Ni

A 352 Gr. LC2

A 203 Gr. B (1)

312Ni

A 352 Gr. LC3

A 203 Gr. E (1)

CSi

A 352 Gr. LCB (5)

A 515 Gr. 65 (1)

CMnSi

A 516 Gr. 65 (1) (2)

2 12Ni

A 203 Gr. A (1)

3 12Ni

A 203 Gr. D (1)

C12Mo

A 217 Gr. WC1 (6) (7)

A 352 Gr. LC1 (5)

1.4

1.5

CSi

A 515 Gr. 60 (1)

CMnSi

A 350 Gr. LF1 Cl. 1 (1)

A 516 Gr. 60 (1) (2)

C12Mo

A 182 Gr. F1 (6)

A 204 Gr. A (6)

A 204 Gr. B (6)

1.7

1.9

12Cr12Mo

A 182 Gr. F2 (8)

Ni12Cr12Mo

A 217 Gr. WC4 (7) (8)

34Ni34Cr1Mo

A 217 Gr. WC5 (7)

114Cr12Mo

A 217 Gr. WC6 (7) (10)

A 387 Gr. 11 Cl. 2 (9)

114Cr12MoSi

A 182 Gr. F11 CL.2 (7) (9)

1.10

2 14Cr1Mo

A 182 Gr. F22 Cl. 3 (9)

1.11

C12Mo

1.13

5Cr12Mo

A 182 Gr. F5a

A 217 Gr. C5 (7)

1.14

9Cr1M0

A 182 Gr. F9

A 217 Gr. C12 (7)

1.15

9Cr1M0V

A 182 Gr. F91

A 217 Gr. C12A

A 387 Gr. 91 Cl. 2

1.17

1Cr12Mo

A 182 Gr. F12 Cl. 2 (7) (9)

5Cr12Mo

A 182 Gr. F5

18Cr8Ni

A 182 Gr. F304 (11)

A 351 Gr. CF3 (12)

A 240 Gr. 304 (11)

A 182 Gr. F304H

A 351 Gr. CF8 (11)

A 240 Gr. 304H

A 182 Gr. F316 (11)

A 351 Gr. CF3M (2)

A 240 Gr. 316 (11)

A 182 Gr. F316H

A 351 Gr. CF8M (11)

A 240 Gr. 316H

2.1

2.2

16Cr12Ni2Mo

18Cr13Ni3Mo

2.4

A 387 Gr. 22 Cl. 2 (9)

A 204 Gr. C (6)

A 182 Gr. F317 (11)

19Cr10Ni3Mo

2.3

A 217 Gr. WC9 (7) (10)

A 240 Gr. 317 (11)

A 351 Gr. CG8M (8)

18Cr8Ni

A 182 Gr. F304L (12)

A 240 Gr. 304L (12)

16Cr12Ni2Mo

A 182 Gr. F316L

A 240 Gr. 316L

18Cr10NiTi

A 182 Gr. F321 (8)

A 240 Gr. 321 (8)

A 182 Gr. F321H (13)

A 240 Gr. 321H (13)

List of Material Specifications (cont'd)

Material

Group

Applicable ASTM Specifications (a)

Nominal Designation

Forgings

2.5

18Cr10NiCb

2.6

23Cr12Ni

2.7

25Cr20Ni

A 182 Gr. F310 (11) (14)

2.8

20Cr18Ni6Mo

22Cr5Ni3MoN

25Cr7Ni4MoN

24Cr10Ni4MoV

25Cr5Ni2Mo3Cu

A 182 Gr. F44

A 182 Gr. F51 (15)

A 182 Gr. F53 (15)

A 182 Gr. F347 (8)

A 182 Gr. F347H (13)

A 182 Gr. F348 (8)

A 182 Gr. F348H (13)

2.9

A 240 Gr. 347 (8)

A 240 Gr. 347H (13)

A 240 Gr. 348 (8)

A 240 Gr. 348H (13)

A 240 Gr. 310H

A 351 Gr. CK3MCuN

A 351 Gr. CD3MWCuN (15)

A 182 Gr. F55 (15)

A 240 Gr. S32760 (15)

A 240 Gr. 309S (11) (14)

(16)

A 240 Gr. 310S (11) (14)

(16)

23Cr12Ni

25Cr12Ni

A 240 Gr. S31254

A 240 Gr. S31803 (15)

A 240 Gr. S32750 (15)

A 351 Gr. CE8MN (15)

A 351 Gr. CD4MCu (15)

25Cr20Ni

2.10

Plates (b)

A 240 Gr. 309H

25Cr7Ni3.5MoW Cb

5Cr7Ni3.5MoN

CuW

Castings

A 351 Gr. CH8 (11)

A 351 Gr. CH20 (11)

2.11

18Cr10NiCb

A 351 Gr. CF8C (11)

2.12

25Cr20Ni

A 351 Gr. CK20 (11)

NOTES:

(a) ASME Boiler and Pressure Vessel Code, Section II materials may also be used provided the requirements of the ASME

specification are identical to or more stringent than the corresponding ASTM specification for the Grade, Class, or Type listed.

(b) Plate materials are listed only for use as blind flanges and reducing flanges without hubs (see para. 5.1 of B16.5).

Additional plate materials listed in ASME B16.34 may also be used with corresponding B16.34 Standard Class

ratings.

(1) Upon prolonged exposure to temperatures above 425C, the carbide phase of steel may be converted to graphite.

Permissible but not recommended for prolonged use above 425C.

(2) Not to be used over 455C.

(3) Not to be used over 370C.

(4) Not to be used over 260C.

(5) Not to be used over 340C.

(6) Upon prolonged exposure to temperatures above 465C, the carbide phase of steel may be converted to graphite.

Permissible, but not recommended for prolonged use above 465C.

(7) Use normalized and tempered material only.

(8) Not to be used over 538C.

(9) Permissible, but not recommended for prolonged use above 590C.

(10) Not to be used over 590C.

(11) At temperatures over 538C, use only when the carbon content is 0.04% or higher.

(12) Not to be used over 425C.

(13) At temperatures over 538C, use only if the material is heat treated by heating to a minimum temperature of

1095C.

(14) Service temperatures of 565C and above should be used only when assurance is provided that grain size is not

finer than ASTM 6.

(15) This steel may become brittle after service at moderately elevated temperatures. Not to be used over 315C.

(16) At temperatures above 538C, use only if the material is solution heat treated to the minimum temperature specified

in the specification but not lower than 1035C, and quenching in water or rapidly cooling by other means.

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- ASTM B85-B85M-18e1Document9 pagesASTM B85-B85M-18e1Djaffar Salahoui100% (3)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Saej 356 V 002Document7 pagesSaej 356 V 002Evandro Luis GomesPas encore d'évaluation

- 180-Smaw-Zug-Asme (Andhika Rolando-3g) - WPQDocument4 pages180-Smaw-Zug-Asme (Andhika Rolando-3g) - WPQMuhammad Fitransyah Syamsuar PutraPas encore d'évaluation

- Failures - Lamellar Tearing Overview and Failures CasesDocument4 pagesFailures - Lamellar Tearing Overview and Failures Cases^passwordPas encore d'évaluation

- Guide To Types of Welding PDFDocument24 pagesGuide To Types of Welding PDFbhaskarjalanPas encore d'évaluation

- CSA W47.1 and CSA W59 Exam QuestionsDocument5 pagesCSA W47.1 and CSA W59 Exam QuestionsAlex Alex100% (2)

- As 4458-1997 Pressure Equipment - ManufactureDocument11 pagesAs 4458-1997 Pressure Equipment - ManufactureSAI Global - APAC100% (1)

- General Requirements For Chemical Check Analysis Limits For Nickel, Nickel Alloys and Cobalt AlloysDocument4 pagesGeneral Requirements For Chemical Check Analysis Limits For Nickel, Nickel Alloys and Cobalt AlloysTanmoy Dutta100% (1)

- Magnesium AlloysDocument14 pagesMagnesium AlloysTamerPas encore d'évaluation

- QRA Presentation 5Document1 pageQRA Presentation 5Baha Eddine GharbiPas encore d'évaluation

- QRA Presentation 1Document1 pageQRA Presentation 1Baha Eddine GharbiPas encore d'évaluation

- QRA Presentation 3Document1 pageQRA Presentation 3Baha Eddine GharbiPas encore d'évaluation

- Relationship Between Frequency and The Number of People Suffering From A Specified Level of Harm From The Realisation of Specific HazardsDocument1 pageRelationship Between Frequency and The Number of People Suffering From A Specified Level of Harm From The Realisation of Specific HazardsBaha Eddine GharbiPas encore d'évaluation

- QRA Presentation 1Document1 pageQRA Presentation 1Baha Eddine GharbiPas encore d'évaluation

- QRA Presentation 3Document1 pageQRA Presentation 3Baha Eddine GharbiPas encore d'évaluation

- MR For Check Valves MR For Globe Valves MR For Ball Valves MR For Ball Valves MR For Globe Valves MR For Check Valves MR For Ball ValvesDocument1 pageMR For Check Valves MR For Globe Valves MR For Ball Valves MR For Ball Valves MR For Globe Valves MR For Check Valves MR For Ball ValvesBaha Eddine GharbiPas encore d'évaluation

- Centifugal Compressor TDS API 617Document1 pageCentifugal Compressor TDS API 617Baha Eddine GharbiPas encore d'évaluation

- Gas Composition - Centrifugal Compressor TDS API 617Document2 pagesGas Composition - Centrifugal Compressor TDS API 617Baha Eddine GharbiPas encore d'évaluation

- Astm STDDocument2 pagesAstm STDBaha Eddine GharbiPas encore d'évaluation

- Carbon Steel Piping SizesDocument10 pagesCarbon Steel Piping SizesBaha Eddine GharbiPas encore d'évaluation

- 8 FormulinoxUSDémoDocument6 pages8 FormulinoxUSDémoThe TechnicalsPas encore d'évaluation

- Casting Def MetDocument8 pagesCasting Def MetBalakrishnan RagothamanPas encore d'évaluation

- Tem Grids & Tem Support Films: Ted Pella, IncDocument35 pagesTem Grids & Tem Support Films: Ted Pella, IncVictor BermejoPas encore d'évaluation

- Smaw NC Ii Pre TestDocument22 pagesSmaw NC Ii Pre TestOFFSHORE-ONSHORE INSTITUTE OF TECHNOLOGY INCPas encore d'évaluation

- App10 Fundamentals of ConnectionsDocument23 pagesApp10 Fundamentals of ConnectionsjdmacbookPas encore d'évaluation

- Avesta 309 Strip Cladding DilutionDocument4 pagesAvesta 309 Strip Cladding Dilutionchris amonPas encore d'évaluation

- Roller Conveyor ChainsDocument36 pagesRoller Conveyor Chainsaiyubi2Pas encore d'évaluation

- Design of Butterfly Valve Components IJERTV5IS020242Document7 pagesDesign of Butterfly Valve Components IJERTV5IS020242shashibagewadiPas encore d'évaluation

- Green / White Patina Solution For Copper, Brass or Bronze 15, 30 or 45ml (Approx)Document3 pagesGreen / White Patina Solution For Copper, Brass or Bronze 15, 30 or 45ml (Approx)Marco BriskyPas encore d'évaluation

- 2-Conduction in SolidDocument46 pages2-Conduction in SolidRichard Adventus HutasoitPas encore d'évaluation

- SynopsisDocument3 pagesSynopsismoderate machines pvt. ltd.Pas encore d'évaluation

- Rolled Coil Sheet 16 03 2022Document1 pageRolled Coil Sheet 16 03 2022muraliPas encore d'évaluation

- Haynes - A Guide To The Metallurgical Corrosion and Wear CharacteristicsDocument65 pagesHaynes - A Guide To The Metallurgical Corrosion and Wear CharacteristicsLiu YangtzePas encore d'évaluation

- ASTM B348-06aStandardSpecificationforTitaniumandTitaniumAlloyBarsandBillets PDFDocument8 pagesASTM B348-06aStandardSpecificationforTitaniumandTitaniumAlloyBarsandBillets PDFtahirabbasPas encore d'évaluation

- L73 Aluminum AlloyDocument42 pagesL73 Aluminum AlloyBrian ForsmanPas encore d'évaluation

- FQ 069Document1 pageFQ 069Chava TejaPas encore d'évaluation

- Sae Ams 5556H-2008Document8 pagesSae Ams 5556H-2008Mehdi MokhtariPas encore d'évaluation

- Orthodontic Biomaterials: From The Past To The Present: Review ArticleDocument12 pagesOrthodontic Biomaterials: From The Past To The Present: Review ArticleYeraldin EspañaPas encore d'évaluation

- Niir Steel Rolling Technology Handbook Niir ContentDocument10 pagesNiir Steel Rolling Technology Handbook Niir ContentSailen GopePas encore d'évaluation

- FORA 500: A 500 HB Wear Resistant SteelDocument4 pagesFORA 500: A 500 HB Wear Resistant SteelLaura BejaranoPas encore d'évaluation

- Cerium Mischmetal, Cerium Alloys, and Cerium Compounds: Rare Earth Elements)Document16 pagesCerium Mischmetal, Cerium Alloys, and Cerium Compounds: Rare Earth Elements)jaimePas encore d'évaluation