Académique Documents

Professionnel Documents

Culture Documents

Almix

Transféré par

Francisco MendozaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Almix

Transféré par

Francisco MendozaDroits d'auteur :

Formats disponibles

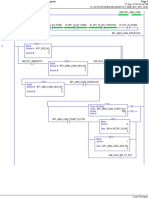

Dispatch - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 4

Page 1

22/12/2015 08,36,49

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

JSR

Jump To Subroutine

Routine Name Arranque

JSR

Jump To Subroutine

Routine Name Condiciones_Auto_PID

JSR

Jump To Subroutine

Routine Name Niveles_de_Tanques

JSR

Jump To Subroutine

Routine Name Densidades

(End)

RSLogix 5000

Arranque - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 27

Page 1

22/12/2015 08,40,30

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Control de HWD Automtico

BTN_HMI_HWD

CTRL_Temp_HWD

0

PIDE_TT310_V360.ProgOper

PIDE_TT310_V360.Auto

Flags_GNRL.0

ONS

Single Speed Motor

Program Command to

Start Motor

P_Motor_M700.PCmd_Start

L

Solenoid Operated

Valve Program

Command to Open

Valve

P_ValveSO_V370.PCmd_Open

L

BTN_HMI_HWD

0(XIC) 1(XIO)

CTRL_Temp_HWD

*0(OTE)

Flags_GNRL.0

*0(ONS)

P_Motor_M700.PCmd_St *0(OTL)

art

P_ValveSO_V370.PCmd *0(OTL)

_Open

PIDE_TT310_V360.Auto 0(XIC)

PIDE_TT310_V360.Prog 0(XIC)

Oper

BTN_HMI_HWD

/

Flags_GNRL.1

ONS

Paro_Emergencia

/

Single Speed Motor

Program Command to

Stop Motor

P_Motor_M700.PCmd_Stop

L

Solenoid Operated

Valve Program

Command to Close

Valve

P_ValveSO_V370.PCmd_Close

L

Flags_GNRL.12

U

BTN_HMI_HWD

0(XIC) 1(XIO)

Flags_GNRL.1

*1(ONS)

Flags_GNRL.12

*1(OTU)

P_Motor_M700.PCmd_St *1(OTL)

op

P_ValveSO_V370.PCmd *1(OTL)

_Close

Paro_Emergencia

1(XIO) 5(XIO) 11(XIO) 17(XIO) 19(XIO) 21(XIO) 23(XIO) 25(XIO) 26(XIO)

RSLogix 5000

Arranque - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 27

Bomba_Torre_Running

2

Bomba_Torre_Running

2(XIC) 3(XIO)

Flags_GNRL.22

*2(ONS)

Page 2

22/12/2015 08,40,30

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Flags_GNRL.22

ONS

Solenoid Operated

Valve Program

Command to Open

Valve

P_ValveSO_300.PCmd_Open

L

Flags_GNRL.23

ONS

Solenoid Operated

Valve Program

Command to Close

Valve

P_ValveSO_300.PCmd_Close

L

P_ValveSO_300.PCmd_ *2(OTL)

Open

Bomba_Torre_Running

/

Bomba_Torre_Running

2(XIC) 3(XIO)

Flags_GNRL.23

*3(ONS)

P_ValveSO_300.PCmd_ *3(OTL)

Close

Control Automatico PID Temperatura de Enfriador

BTN_HMI_Enfriador

CTRL_Temp_Enfriador

Flags_GNRL.7

ONS

Single Speed Motor

Program Command to

Start Motor

P_Motor_Agua_Hielo.PCmd_Start

L

Solenoid Operated

Valve Program

Command to Open

Valve

P_ValveSO_310.PCmd_Open

L

BTN_HMI_Enfriador

4(XIC) 5(XIO)

CTRL_Temp_Enfriador

*4(OTE)

Flags_GNRL.7

*4(ONS)

P_Motor_Agua_Hielo.PC *4(OTL)

md_Start

P_ValveSO_310.PCmd_ *4(OTL)

Open

RSLogix 5000

Arranque - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 27

BTN_HMI_Enfriador

/

Page 3

22/12/2015 08,40,30

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Flags_GNRL.8

ONS

Single Speed Motor

Program Command to

Stop Motor

P_Motor_Agua_Hielo.PCmd_Stop

L

Solenoid Operated

Valve Program

Command to Close

Valve

P_ValveSO_310.PCmd_Close

L

Paro_Emergencia

/

Flags_GNRL.11

U

BTN_HMI_Enfriador

4(XIC) 5(XIO)

Flags_GNRL.8

*5(ONS)

Flags_GNRL.11

*5(OTU)

P_Motor_Agua_Hielo.PC *5(OTL)

md_Stop

P_ValveSO_310.PCmd_ *5(OTL)

Close

Paro_Emergencia

1(XIO) 5(XIO) 11(XIO) 17(XIO) 19(XIO) 21(XIO) 23(XIO) 25(XIO) 26(XIO)

BTN CIP no permite que se abrn las Vlvulas V300 y V310

BTN_HMI_CIP

CIP_ON

BTN_HMI_CIP

6(XIC)

CIP_ON

*6(OTE)

BTN_HMI_Dosificar

7

BTN_HMI_Dosificar

7(XIC) 8(XIC) 10(XIC)

Stop_Dosificador_2

*7(OTU) 8(XIO) *11(OTL) 12(XIC) *13(OTU)

Stop_Dosificador_2

U

RSLogix 5000

Arranque - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 27

BTN_HMI_Dosificar

BTN_HMI_Dosificar_Tk1

BTN_HMI_Dosificar_Tk2

Page 4

22/12/2015 08,40,30

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Discrete Input

Discrete Input

Status (incl.

Debounce, Manual

Override, if used)

P_DIn_LS100.Sts

/

Stop_Dosificador_2

/

Discrete Input

Discrete Input

Status (incl.

Debounce, Manual

Override, if used)

P_DIn_LS200.Sts

/

CTRL_Dosificador

L

Flags_GNRL.2

ONS

BTN_HMI_Dosificar

TOT_FT100.ProgResetReq

L

7(XIC) 8(XIC) 10(XIC)

BTN_HMI_Dosificar_Tk1 8(XIC) 11(XIC) 11(XIO)

BTN_HMI_Dosificar_Tk2 8(XIC) 11(XIC) 11(XIO)

CTRL_Dosificador

*8(OTL) 11(XIC) *11(OTU) 12(XIC) *13(OTU)

Flags_GNRL.2

*8(ONS)

P_DIn_LS100.Sts

8(XIO) 11(XIC)

P_DIn_LS200.Sts

8(XIO) 11(XIC)

Stop_Dosificador_2

*7(OTU) 8(XIO) *11(OTL) 12(XIC) *13(OTU)

TOT_FT100.ProgResetR *8(OTL) *9(OTU)

eq

TOT_FT100.ProgResetDone

9

TOT_FT100.ProgResetReq

U

TOT_FT100.ProgResetD 9(XIC) 10(XIC)

one

TOT_FT100.ProgResetR *8(OTL) *9(OTU)

eq

RSLogix 5000

Arranque - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 27

Page 5

22/12/2015 08,40,30

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Se inicia la dosificacion de leche o agua

BTN_HMI_Dosificar

TOT_FT100.ProgResetDone

10

Flags_GNRL.9

ONS

TOT_Start

L

Solenoid Operated

Valve Program

Command to Open

Valve

P_ValveSO_V350.PCmd_Open

L

BTN_HMI_Dosificar

7(XIC) 8(XIC) 10(XIC)

Flags_GNRL.9

*10(ONS)

P_ValveSO_V350.PCmd *10(OTL)

_Open

TOT_FT100.ProgResetD 9(XIC) 10(XIC)

one

TOT_Start

*10(OTL) *12(OTU)

Stop_Dosificador

Stop_Dosificador_2

L

11

CTRL_Dosificador

CTRL_Dosificador

BTN_HMI_Dosificar_Tk1

Discrete Input

Discrete Input

Status (incl.

Debounce, Manual

Override, if used)

P_DIn_LS100.Sts

BTN_HMI_Dosificar_Tk2

Discrete Input

Discrete Input

Status (incl.

Debounce, Manual

Override, if used)

P_DIn_LS200.Sts

BTN_HMI_Dosificar_Tk1

/

BTN_HMI_Dosificar_Tk2

/

CTRL_Dosificador

U

Paro_Emergencia

/

CTRL_Dosificador

BTN_HMI_Dosificar_Tk1 8(XIC) 11(XIO) 11(XIC)

BTN_HMI_Dosificar_Tk2 8(XIC) 11(XIO) 11(XIC)

CTRL_Dosificador

*8(OTL) *11(OTU) 11(XIC) 12(XIC) *13(OTU)

P_DIn_LS100.Sts

8(XIO) 11(XIC)

P_DIn_LS200.Sts

8(XIO) 11(XIC)

Paro_Emergencia

1(XIO) 5(XIO) 11(XIO) 17(XIO) 19(XIO) 21(XIO) 23(XIO) 25(XIO) 26(XIO)

Stop_Dosificador

11(XIC) *13(OTU)

Stop_Dosificador_2

*7(OTU) 8(XIO) *11(OTL) 12(XIC) *13(OTU)

RSLogix 5000

Arranque - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 27

CTRL_Dosificador

Page 6

22/12/2015 08,40,30

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

TOT_FT100.TargetFlag

12

Stop_Dosificador_2

Flags_GNRL.3

ONS

Analog Input Analog

Value (after

Substitute PV, if

used)

LES

Less Than (A<B)

Source A P_AIn_FT100.Val

0.0

Source B

30

CTRL_Dosificador

*8(OTL) *11(OTU) 11(XIC) 12(XIC) *13(OTU)

Flags_GNRL.3

*12(ONS)

Flags_GNRL.4

*12(ONS)

P_AIn_FT100.Val

12(LES)

Solenoid Operated

Valve Program

Command to Close

Valve

P_ValveSO_V350.PCmd_Close

L

Flags_GNRL.4

ONS

TOT_Start

U

TON

Timer On Delay

Timer TON_Reset_TOT

Preset

300

Accum

0

EN

DN

P_ValveSO_V350.PCmd *12(OTL)

_Close

Stop_Dosificador_2

*7(OTU) 8(XIO) *11(OTL) 12(XIC) *13(OTU)

TON_Reset_TOT

*12(TON)

TOT_FT100.TargetFlag

12(XIC)

TOT_Start

*10(OTL) *12(OTU)

TON_Reset_TOT.DN

13

Flags_GNRL.10

ONS

CTRL_Dosificador

U

Stop_Dosificador_2

U

Stop_Dosificador

U

CTRL_Dosificador

*8(OTL) *11(OTU) 11(XIC) 12(XIC) *13(OTU)

Flags_GNRL.10

*13(ONS)

Stop_Dosificador

11(XIC) *13(OTU)

Stop_Dosificador_2

*7(OTU) 8(XIO) *11(OTL) 12(XIC) *13(OTU)

TON_Reset_TOT.DN

13(XIC)

RSLogix 5000

Arranque - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 27

Page 7

22/12/2015 08,40,30

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Se Arranca el Almix y La Bomba M1

BTN_HMI_Almix

CTRL_Almix

14

Flags_GNRL.5

ONS

BTN_HMI_Almix

14(XIC) 17(XIO)

CTRL_Almix

*14(OTE) 15(XIC) 16(XIC)

Flags_GNRL.5

*14(ONS)

Single Speed Motor

Program Command to

Start Motor

P_Motor_M100.PCmd_Start

L

P_Motor_M100.PCmd_St *14(OTL)

art

CTRL_Almix

TON

Timer On Delay

Timer TON_CTRL_Almix

Preset

5000

Accum

0

15

CTRL_Almix

*14(OTE) 15(XIC) 16(XIC)

TON_CTRL_Almix

*15(TON)

CTRL_Almix

TON_CTRL_Almix.DN

16

CTRL_Almix

*14(OTE) 15(XIC) 16(XIC)

Flags_GNRL.13

*16(ONS)

Flags_GNRL.13

ONS

EN

DN

Single Speed Motor

Program Command to

Start Motor

P_Motor_Almix.PCmd_Start

L

P_Motor_Almix.PCmd_St *16(OTL)

art

TON_CTRL_Almix.DN

16(XIC)

RSLogix 5000

Arranque - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 27

BTN_HMI_Almix

/

17

Page 8

22/12/2015 08,40,30

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Single Speed Motor

Program Command to

Stop Motor

P_Motor_Almix.PCmd_Stop

L

Flags_GNRL.6

ONS

Single Speed Motor

Program Command to

Stop Motor

P_Motor_M100.PCmd_Stop

L

Paro_Emergencia

/

BTN_HMI_Almix

14(XIC) 17(XIO)

Flags_GNRL.6

*17(ONS)

P_Motor_Almix.PCmd_St *17(OTL)

op

P_Motor_M100.PCmd_St *17(OTL)

op

Paro_Emergencia

1(XIO) 5(XIO) 11(XIO) 17(XIO) 19(XIO) 21(XIO) 23(XIO) 25(XIO) 26(XIO)

Control de Bomba de Transferencia

BTN_HMI_Transferencia

CTRL_Transferencia

18

Flags_GNRL.14

ONS

Single Speed Motor

Program Command to

Start Motor

P_Motor_M300.PCmd_Start

L

BTN_HMI_Transferencia 18(XIC) 19(XIO)

CTRL_Transferencia

*18(OTE)

Flags_GNRL.14

*18(ONS)

P_Motor_M300.PCmd_St *18(OTL)

art

19

BTN_HMI_Transferencia

/

Flags_GNRL.15

ONS

Single Speed Motor

Program Command to

Stop Motor

P_Motor_M300.PCmd_Stop

L

Paro_Emergencia

/

BTN_HMI_Transferencia 18(XIC) 19(XIO)

Flags_GNRL.15

*19(ONS)

P_Motor_M300.PCmd_St *19(OTL)

op

Paro_Emergencia

1(XIO) 5(XIO) 11(XIO) 17(XIO) 19(XIO) 21(XIO) 23(XIO) 25(XIO) 26(XIO)

RSLogix 5000

Arranque - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 27

Page 9

22/12/2015 08,40,30

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Control de Agitador Tk 1

BTN_HMI_Agit_Tk1

20

BTN_HMI_Agit_Tk1

20(XIC) 21(XIO)

Flags_GNRL.16

*20(ONS)

Single Speed Motor

Program Command to

Start Motor

P_Motor_M500.PCmd_Start

L

Flags_GNRL.16

ONS

P_Motor_M500.PCmd_St *20(OTL)

art

BTN_HMI_Agit_Tk1

/

21

Single Speed Motor

Program Command to

Stop Motor

P_Motor_M500.PCmd_Stop

L

Flags_GNRL.17

ONS

Paro_Emergencia

/

BTN_HMI_Agit_Tk1

20(XIC) 21(XIO)

Flags_GNRL.17

*21(ONS)

P_Motor_M500.PCmd_St *21(OTL)

op

Paro_Emergencia

1(XIO) 5(XIO) 11(XIO) 17(XIO) 19(XIO) 21(XIO) 23(XIO) 25(XIO) 26(XIO)

Control de Agitador Tk 2

BTN_HMI_Agit_Tk2

22

BTN_HMI_Agit_Tk2

22(XIC) 23(XIO)

Flags_GNRL.18

*22(ONS)

Flags_GNRL.18

ONS

Single Speed Motor

Program Command to

Start Motor

P_Motor_M600.PCmd_Start

L

P_Motor_M600.PCmd_St *22(OTL)

art

RSLogix 5000

Arranque - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 27

BTN_HMI_Agit_Tk2

/

23

Page 10

22/12/2015 08,40,30

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Single Speed Motor

Program Command to

Stop Motor

P_Motor_M600.PCmd_Stop

L

Flags_GNRL.19

ONS

Paro_Emergencia

/

BTN_HMI_Agit_Tk2

22(XIC) 23(XIO)

Flags_GNRL.19

*23(ONS)

P_Motor_M600.PCmd_St *23(OTL)

op

Paro_Emergencia

1(XIO) 5(XIO) 11(XIO) 17(XIO) 19(XIO) 21(XIO) 23(XIO) 25(XIO) 26(XIO)

Control de Bomba de CIP

BTN_HMI_Bomba_CIP

24

BTN_HMI_Bomba_CIP

24(XIC) 25(XIO)

Flags_GNRL.20

*24(ONS)

Flags_GNRL.20

ONS

Single Speed Motor

Program Command to

Start Motor

P_Motor_M400.PCmd_Start

L

P_Motor_M400.PCmd_St *24(OTL)

art

BTN_HMI_Bomba_CIP

/

25

Flags_GNRL.21

ONS

Single Speed Motor

Program Command to

Stop Motor

P_Motor_M400.PCmd_Stop

L

Paro_Emergencia

/

BTN_HMI_Bomba_CIP

24(XIC) 25(XIO)

Flags_GNRL.21

*25(ONS)

P_Motor_M400.PCmd_St *25(OTL)

op

Paro_Emergencia

26

1(XIO) 5(XIO) 11(XIO) 17(XIO) 19(XIO) 21(XIO) 23(XIO) 25(XIO) 26(XIO)

Paro_Emergencia

/

Alm_Paro_Emergencia

RSLogix 5000

Arranque - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 27

Alm_Paro_Emergencia

*26(OTE)

Paro_Emergencia

1(XIO) 5(XIO) 11(XIO) 17(XIO) 19(XIO) 21(XIO) 23(XIO) 25(XIO) 26(XIO)

Page 11

22/12/2015 08,40,30

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

(End)

RSLogix 5000

Condiciones_Auto_PID - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 4

CTRL_Temp_Enfriador

Page 1

22/12/2015 08,44,36

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Flags_GNRL.11

/

PIDE_TT300_V320.OperAutoReq

L

TON

Timer On Delay

Timer TON_CTRL_TempEnfriador

Preset

3000

Accum

0

CTRL_Temp_Enfriador

0(XIC)

Flags_GNRL.11

0(XIO) *1(OTL)

EN

DN

PIDE_TT300_V320.Oper *0(OTL)

AutoReq

TON_CTRL_TempEnfriad*0(TON)

or

PIDE_TT300_V320.OperProgReq

L

LIM

Limit Test (CIRC)

Low Limit

1500

Test TON_CTRL_TempEnfriador.ACC

0

High Limit

1800

Flags_GNRL.11

Flags_GNRL.11

L

0(XIO) *1(OTL)

PIDE_TT300_V320.Oper *1(OTL)

ProgReq

TON_CTRL_TempEnfriad1(LIM)

or.ACC

CTRL_Temp_HWD

2

Flags_GNRL.12

/

PIDE_TT310_V360.OperAutoReq

L

TON

Timer On Delay

Timer TON_CTRL_TempHWD

Preset

3000

Accum

0

CTRL_Temp_HWD

2(XIC)

Flags_GNRL.12

2(XIO) *3(OTL)

EN

DN

PIDE_TT310_V360.Oper *2(OTL)

AutoReq

TON_CTRL_TempHWD *2(TON)

RSLogix 5000

Condiciones_Auto_PID - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 4

LIM

Limit Test (CIRC)

Low Limit

Page 2

22/12/2015 08,44,36

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

PIDE_TT310_V360.OperProgReq

L

1500

Test TON_CTRL_TempHWD.ACC

0

High Limit

1800

Flags_GNRL.12

Flags_GNRL.12

L

2(XIO) *3(OTL)

PIDE_TT310_V360.Oper *3(OTL)

ProgReq

TON_CTRL_TempHWD. 3(LIM)

ACC

(End)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

Page 1

22/12/2015 08,45,24

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Mueve los valores de Nombre y Densidad segun este seleccionado TK1

COP

Equal

Copy File

Source A Producto_Tk1

Source Producto1.Producto

Dest Nombre_Producto_Tk1

14

Length

30

Source B

1

EQU

MOV

Move

Source Producto1.Densidad

1.0

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto1

0(COP) 15(COP)

Producto1.Densidad

0(MOV) 15(MOV)

EQU

Equal

Source A Producto_Tk1

14

Source B

2

COP

Copy File

Source Producto2.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto2.Densidad

1.001

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto2

1(COP) 16(COP)

Producto2.Densidad

1(MOV) 16(MOV)

Densidad_Tk100

EQU

Equal

Source A Producto_Tk1

14

Source B

3

COP

Copy File

Dest Nombre_Producto_Tk1

Source Producto3.Producto

Length

30

MOV

Move

Source Producto3.Densidad

1.1

Dest Densidad_Tk100

1.14

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

Page 2

22/12/2015 08,45,24

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto3

2(COP) 17(COP)

Producto3.Densidad

2(MOV) 17(MOV)

EQU

Equal

Source A Producto_Tk1

14

Source B

4

COP

Copy File

Source Producto4.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto4.Densidad

1.2

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto4

3(COP) 18(COP)

Producto4.Densidad

3(MOV) 18(MOV)

EQU

Equal

Source A Producto_Tk1

14

Source B

5

COP

Copy File

Source Producto5.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto5.Densidad

1.5

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto5

4(COP) 19(COP)

Producto5.Densidad

4(MOV) 19(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

5

EQU

Equal

Source A Producto_Tk1

14

Source B

6

Page 3

22/12/2015 08,45,24

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

COP

Copy File

Source Producto6.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto6.Densidad

1.999

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto6

5(COP) 20(COP)

Producto6.Densidad

5(MOV) 20(MOV)

EQU

Equal

Source A Producto_Tk1

14

Source B

7

COP

Copy File

Source Producto7.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto7.Densidad

1.7

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto7

6(COP) 21(COP)

Producto7.Densidad

6(MOV) 21(MOV)

Densidad_Tk100

EQU

Equal

Source A Producto_Tk1

14

Source B

8

COP

Copy File

Source Producto8.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto8.Densidad

1.8

Dest Densidad_Tk100

1.14

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

Page 4

22/12/2015 08,45,24

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto8

7(COP) 22(COP)

Producto8.Densidad

7(MOV) 22(MOV)

EQU

Equal

Source A Producto_Tk1

14

Source B

9

COP

Copy File

Source Producto9.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto9.Densidad

1.9

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto9

8(COP) 23(COP)

Producto9.Densidad

8(MOV) 23(MOV)

EQU

Equal

Source A Producto_Tk1

14

Source B

10

COP

Copy File

Source Producto10.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto10.Densidad

1.101

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto10

9(COP) 24(COP)

Producto10.Densidad

9(MOV) 24(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

10

EQU

Equal

Source A Producto_Tk1

14

Source B

11

Page 5

22/12/2015 08,45,24

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

COP

Copy File

Source Producto11.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto11.Densidad

1.11

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto11

10(COP) 25(COP)

Producto11.Densidad

10(MOV) 25(MOV)

11

EQU

Equal

Source A Producto_Tk1

14

Source B

12

COP

Copy File

Source Producto12.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto12.Densidad

1.12

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto12

11(COP) 26(COP)

Producto12.Densidad

11(MOV) 26(MOV)

12

Densidad_Tk100

EQU

Equal

Source A Producto_Tk1

14

Source B

13

COP

Copy File

Source Producto13.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto13.Densidad

1.13

Dest Densidad_Tk100

1.14

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

Page 6

22/12/2015 08,45,24

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto13

12(COP) 27(COP)

Producto13.Densidad

12(MOV) 27(MOV)

13

EQU

Equal

Source A Producto_Tk1

14

Source B

14

COP

Copy File

Source Producto14.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto14.Densidad

1.14

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto14

13(COP) 28(COP)

Producto14.Densidad

13(MOV) 28(MOV)

14

EQU

Equal

Source A Producto_Tk1

14

Source B

15

COP

Copy File

Source Producto15.Producto

Dest Nombre_Producto_Tk1

Length

30

MOV

Move

Source Producto15.Densidad

1.15

Dest Densidad_Tk100

1.14

Densidad_Tk100

*0(MOV) *1(MOV) *2(MOV) *3(MOV) *4(MOV) *5(MOV) *6(MOV) *7(MOV) *8(MOV) *9(MOV) *10(MOV) *11(MOV) *12(MOV)

*13(MOV) *14(MOV)

Nombre_Producto_Tk1

*0(COP) *1(COP) *2(COP) *3(COP) *4(COP) *5(COP) *6(COP) *7(COP) *8(COP) *9(COP) *10(COP) *11(COP) *12(COP) *13(COP)

*14(COP)

Producto_Tk1

0(EQU) 1(EQU) 2(EQU) 3(EQU) 4(EQU) 5(EQU) 6(EQU) 7(EQU) 8(EQU) 9(EQU) 10(EQU) 11(EQU) 12(EQU) 13(EQU) 14(EQU)

Producto15

14(COP) 29(COP)

Producto15.Densidad

14(MOV) 29(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

Page 7

22/12/2015 08,45,24

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Mueve los valores de Nombre y Densidad segun este seleccionado TK1

COP

Equal

Copy File

Source A Producto_Tk2

Source Producto1.Producto

Dest Nombre_Producto_Tk2

2

Length

30

Source B

1

EQU

15

MOV

Move

Source Producto1.Densidad

1.0

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto1

0(COP) 15(COP)

Producto1.Densidad

0(MOV) 15(MOV)

16

EQU

Equal

Source A Producto_Tk2

2

Source B

2

COP

Copy File

Source Producto2.Producto

Dest Nombre_Producto_Tk2

Length

30

MOV

Move

Source Producto2.Densidad

1.001

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto2

1(COP) 16(COP)

Producto2.Densidad

1(MOV) 16(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

17

EQU

Equal

Source A Producto_Tk2

2

Source B

3

Page 8

22/12/2015 08,45,24

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

COP

Copy File

Source Producto3.Producto

Dest Nombre_Producto_Tk2

Length

30

MOV

Move

Source Producto3.Densidad

1.1

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto3

2(COP) 17(COP)

Producto3.Densidad

2(MOV) 17(MOV)

18

EQU

Equal

Source A Producto_Tk2

2

Source B

4

COP

Copy File

Dest Nombre_Producto_Tk2

Source Producto4.Producto

Length

30

MOV

Move

Source Producto4.Densidad

1.2

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto4

3(COP) 18(COP)

Producto4.Densidad

3(MOV) 18(MOV)

19

Densidad_Tk200

EQU

Equal

Source A Producto_Tk2

2

Source B

5

COP

Copy File

Source Producto5.Producto

Dest Nombre_Producto_Tk2

Length

30

MOV

Move

Source Producto5.Densidad

1.5

Dest Densidad_Tk200

1.001

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

Page 9

22/12/2015 08,45,24

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto5

4(COP) 19(COP)

Producto5.Densidad

4(MOV) 19(MOV)

20

EQU

Equal

Source A Producto_Tk2

2

Source B

6

COP

Copy File

Dest Nombre_Producto_Tk2

Source Producto6.Producto

Length

30

MOV

Move

Source Producto6.Densidad

1.999

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto6

5(COP) 20(COP)

Producto6.Densidad

5(MOV) 20(MOV)

21

EQU

Equal

Source A Producto_Tk2

2

Source B

7

COP

Copy File

Source Producto7.Producto

Dest Nombre_Producto_Tk2

Length

30

MOV

Move

Source Producto7.Densidad

1.7

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto7

6(COP) 21(COP)

Producto7.Densidad

6(MOV) 21(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

22

EQU

Equal

Source A Producto_Tk2

2

Source B

8

Page 10

22/12/2015 08,45,25

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

COP

Copy File

Source Producto8.Producto

Dest Nombre_Producto_Tk2

Length

30

MOV

Move

Source Producto8.Densidad

1.8

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto8

7(COP) 22(COP)

Producto8.Densidad

7(MOV) 22(MOV)

23

EQU

Equal

Source A Producto_Tk2

2

Source B

9

COP

Copy File

Dest Nombre_Producto_Tk2

Source Producto9.Producto

Length

30

MOV

Move

Source Producto9.Densidad

1.9

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto9

8(COP) 23(COP)

Producto9.Densidad

8(MOV) 23(MOV)

24

Densidad_Tk200

EQU

Equal

Source A Producto_Tk2

2

Source B

10

COP

Copy File

Source Producto10.Producto

Dest Nombre_Producto_Tk2

Length

30

MOV

Move

Source Producto10.Densidad

1.101

Dest Densidad_Tk200

1.001

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

Page 11

22/12/2015 08,45,25

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto10

9(COP) 24(COP)

Producto10.Densidad

9(MOV) 24(MOV)

25

EQU

Equal

Source A Producto_Tk2

2

Source B

11

COP

Copy File

Dest Nombre_Producto_Tk2

Source Producto11.Producto

Length

30

MOV

Move

Source Producto11.Densidad

1.11

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto11

10(COP) 25(COP)

Producto11.Densidad

10(MOV) 25(MOV)

26

EQU

Equal

Source A Producto_Tk2

2

Source B

12

COP

Copy File

Source Producto12.Producto

Dest Nombre_Producto_Tk2

Length

30

MOV

Move

Source Producto12.Densidad

1.12

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto12

11(COP) 26(COP)

Producto12.Densidad

11(MOV) 26(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

27

EQU

Equal

Source A Producto_Tk2

2

Source B

13

Page 12

22/12/2015 08,45,25

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

COP

Copy File

Source Producto13.Producto

Dest Nombre_Producto_Tk2

Length

30

MOV

Move

Source Producto13.Densidad

1.13

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto13

12(COP) 27(COP)

Producto13.Densidad

12(MOV) 27(MOV)

28

EQU

Equal

Source A Producto_Tk2

2

Source B

14

COP

Copy File

Dest Nombre_Producto_Tk2

Source Producto14.Producto

Length

30

MOV

Move

Source Producto14.Densidad

1.14

Dest Densidad_Tk200

1.001

Densidad_Tk200

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto14

13(COP) 28(COP)

Producto14.Densidad

13(MOV) 28(MOV)

29

Densidad_Tk200

EQU

Equal

Source A Producto_Tk2

2

Source B

15

COP

Copy File

Source Producto15.Producto

Dest Nombre_Producto_Tk2

Length

30

MOV

Move

Source Producto15.Densidad

1.15

Dest Densidad_Tk200

1.001

*15(MOV) *16(MOV) *17(MOV) *18(MOV) *19(MOV) *20(MOV) *21(MOV) *22(MOV) *23(MOV) *24(MOV) *25(MOV) *26(MOV)

RSLogix 5000

Densidades - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 30

Page 13

22/12/2015 08,45,25

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

*27(MOV) *28(MOV) *29(MOV)

Nombre_Producto_Tk2

*15(COP) *16(COP) *17(COP) *18(COP) *19(COP) *20(COP) *21(COP) *22(COP) *23(COP) *24(COP) *25(COP) *26(COP)

*27(COP) *28(COP) *29(COP)

Producto_Tk2

15(EQU) 16(EQU) 17(EQU) 18(EQU) 19(EQU) 20(EQU) 21(EQU) 22(EQU) 23(EQU) 24(EQU) 25(EQU) 26(EQU) 27(EQU) 28(EQU)

29(EQU)

Producto15

14(COP) 29(COP)

Producto15.Densidad

14(MOV) 29(MOV)

(End)

RSLogix 5000

Niveles_de_Tanques - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 4

Page 1

22/12/2015 08,46,09

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Niveles Tanque Tk110

AFI

LES

Less Than (A<B)

Source A LT100_Escalado

0.0

Source B H_Cono_Tk100

0

CPT

Compute

Expression (3.1416*(( Diametro_Tk100/2)**2)* LT100_Escalado/3*1000)*(1/ Den

Mov

Sour

Densidad_Tk100

0(CPT) 1(CPT) 2(CPT)

Diametro_Tk100

0(CPT) 1(CPT) 2(CPT)

H_Cono_Tk100

0(LES) 1(CPT) 1(GEQ)

LT100

*0(MOV) *1(ADD)

LT100_Escalado

0(CPT) 0(LES) 1(CPT) 1(GEQ) 2(CPT)

Nivel_Cono_LT100

*0(CPT) 0(MOV) 1(ADD)

RSLogix 5000

Niveles_de_Tanques - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 4

alado/3*1000)*(1/ Densidad_Tk100)

Dest Nivel_Cono_LT100

0

MOV

Move

Source Nivel_Cono_LT100

0

Page 2

22/12/2015 08,46,09

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Dest

LT100

0

GEQ

Grtr Than or Eql (A>=B)

Source A LT100_Escalado

0.0

Source B H_Cono_Tk100

0

Densidad_Tk100

0(CPT) 1(CPT) 2(CPT)

Diametro_Tk100

0(CPT) 1(CPT) 2(CPT)

H_Cono_Tk100

0(LES) 1(CPT) 1(GEQ)

LT100

*0(MOV) *1(ADD)

LT100_Escalado

0(CPT) 0(LES) 1(CPT) 1(GEQ) 2(CPT)

Nivel_Cilindro_LT100

*1(CPT) 1(ADD)

Nivel_Cono_LT100

*0(CPT) 0(MOV) 1(ADD)

CPT

Compute

Expression (3.1416*(( Diametro_Tk100/2)**2)*( LT100_Escalado- H_Cono_Tk100)*1000)*(1

RSLogix 5000

Niveles_de_Tanques - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 4

ono_Tk100)*1000)*(1/Densidad_Tk100)

Page 3

22/12/2015 08,46,09

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Dest Nivel_Cilindro_LT100

0

ADD

Add

Source A Nivel_Cilindro_LT100

0

Source B

Nivel_Cono_LT100

0

Dest

LT100

0

Niveles Tanque Tk110

2

AFI

LES

Less Than (A<B)

Source A LT200_Escalado

0.72

Source B H_Cono_Tk200

0

CPT

Compute

Expression (3.1416*(( Diametro_Tk100/2)**2)* LT100_Escalado/3*1000)*(1/ Den

Mov

Sour

Densidad_Tk100

0(CPT) 1(CPT) 2(CPT)

Diametro_Tk100

0(CPT) 1(CPT) 2(CPT)

H_Cono_Tk200

2(LES) 3(CPT) 3(GEQ)

LT100_Escalado

0(LES) 0(CPT) 1(GEQ) 1(CPT) 2(CPT)

LT200

*2(MOV) *3(ADD)

LT200_Escalado

2(LES) 3(CPT) 3(GEQ)

Nivel_Cono_LT200

2(MOV) *2(CPT) 3(ADD)

RSLogix 5000

Niveles_de_Tanques - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 4

alado/3*1000)*(1/ Densidad_Tk100)

Dest Nivel_Cono_LT200

0

MOV

Move

Source Nivel_Cono_LT200

0

Page 4

22/12/2015 08,46,10

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Dest

GEQ

Grtr Than or Eql (A>=B)

Source A LT200_Escalado

0.72

Source B H_Cono_Tk200

0

Densidad_Tk200

3(CPT)

Diametro_Tk200

3(CPT)

H_Cono_Tk200

2(LES) 3(CPT) 3(GEQ)

LT200

*2(MOV) *3(ADD)

LT200_Escalado

2(LES) 3(CPT) 3(GEQ)

Nivel_Cilindro_LT200

*3(CPT) 3(ADD)

Nivel_Cono_LT200

*2(CPT) 2(MOV) 3(ADD)

LT200

2734

CPT

Compute

Expression (3.1416*(( Diametro_Tk200/2)**2)*( LT200_Escalado- H_Cono_Tk200)*1000)*(1

RSLogix 5000

Niveles_de_Tanques - Ladder Diagram

TetraPak_Mezclado_de_Leche:Logica:Logica

Total number of rungs in routine: 4

ono_Tk200)*1000)*(1/Densidad_Tk200)

Page 5

22/12/2015 08,46,10

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Dest Nivel_Cilindro_LT200

2734

ADD

Add

Source A Nivel_Cilindro_LT200

2734

Source B

Nivel_Cono_LT200

0

Dest

LT200

2734

(End)

RSLogix 5000

Dispatch - Ladder Diagram

TetraPak_Mezclado_de_Leche:Lazos:Lazos

Total number of rungs in routine: 1

0

Page 1

22/12/2015 08,47,39

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

JSR

Jump To Subroutine

Routine Name Blk_PIDE

(End)

RSLogix 5000

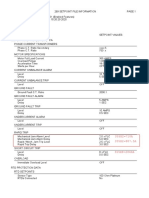

Dispatch - Ladder Diagram

TetraPak_Mezclado_de_Leche:Equipos:Equipos

Total number of rungs in routine: 7

Page 1

22/12/2015 08,48,02

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

JSR

Jump To Subroutine

Routine Name Blk_Agitadores

JSR

Jump To Subroutine

Routine Name Blk_Bombas

JSR

Jump To Subroutine

Routine Name Blk_Dosificadores

JSR

Jump To Subroutine

Routine Name Blk_Nivel_Analog

JSR

Jump To Subroutine

Routine Name Blk_Nivel_Dig

JSR

Jump To Subroutine

Routine Name Blk_Temperatura

JSR

Jump To Subroutine

Routine Name Blk_Valvulas

(End)

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Data Context: P_AIn <definition>

Page 1

22/12/2015 08,49,31

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Normal Scan - PV is scaled and alarms are generated

============================================================

P_AIn: PROCESS -- ANALOG INPUT

============================================================

Revision 2.0-02 Release: 2013-03-15

V2.0-00 2011-09-30: Added Inf_Tab, Inf_Type; added logic for Sts_MaintByp,

Sts_AlmInh for breadcrumbs; using P_Alarm, P_Mode 2.0; changed Alarm timers

to On-Delay and Off-Delay; added Val_Fdbk, Val_Sts, Val_Fault, Val_Mode;

added Val_PVMinCapt, Val_PVMaxCapt, clear capture commands.

Added OCmd_ResetAckAll, Rdy_ResetAckAll.

Fixed handling of Input Infinite or Not a Number.

Added display of Local STRING Tags on header (this) rung.

V2.0-01 2012-07-17: Edge/Level behavior for P_Alarm 2.0-01.

Improved handling of timers with presets = 0.

V2.0-02 2013-03-15: Buffering of Val_Sts, Val_Fault, etc.

============================================================

This Instruction monitors an Analog Input from a flow, level, pressure,

temperature, or any other analog sensor, and provides:

* Scaling, from Input (Raw) to PV (Engineering) Units

* High-High, High, Low and Low-Low Alarms with configurable delay times and deadbands

* Monitoring of input bad/uncertain variable/communication status and out-of-range conditions with alarm

* Setting of a simulated input signal for process simulation

* Capturing of the lowest and highest PV excursion values

* Program and Operator Settings for Alarm Thresholds

* Maintenance Commands to allow manual override of the input signal (Substitute PV)

Modes are provided by a P_Mode Add-On Instruction instance.

Alarms are provided by P_Alarm Add-On Instruction instances.

Modes of operation: Operator, Program, Maintenance

============================================================

SHOW LOCAL STRINGS

============================================================

The STRINGs containing the text associated with each instance of this

instruction cannot be Input or Output Parameters, because STRINGs are not

'atomic' types. (Inputs and Outputs must be SINT, INT, DINT, REAL, or BOOL.)

In order to make it easier to find and configure these STRINGs, this rung

was added. THE JMP (and the LBL on the following rung)

MUST NOT BE REMOVED!!!

SkipText

JMP

Cfg_Desc

0(CONCAT)

Cfg_EU

*0(CONCAT)

Cfg_Label

0(CONCAT)

Cfg_Tag

0(LOWER)

Inf_Type

*0(LOWER)

To view the STRINGs, go to the instruction instance (in LD or FBD), RIGHT-click

to bring up the context menu and select "Open Instruction Logic".

This rung will appear with the STRING values for the selected instance.

You may double-click the STRING values here to modify them as well.

Label for graphic

Tagname for display

symbol displayed on

on HMI

HMI

LOWER

CONCAT

Lower Case

String Concatenate

Dest Inf_Type

Dest

Source Cfg_Tag

Source A Cfg_Label

'P_AIn'

'P_AIn'

'Analog Input'

Source B Cfg_Desc

'Analog Input'

Cfg_EU

'%'

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Data Context: P_AIn <definition>

Page 2

22/12/2015 08,49,32

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Normal Scan - PV is scaled and alarms are generated

============================================================

MODE PROCESSING

============================================================

This rung handles received Mode Inputs and Commands:

NOTE: All Commands for Mode, Alarm are aliased directly to the

corresponding Commands in the contained P_Mode and P_Alarm AOIs.

This object does NOT have the following Modes:

Hand

Override

Analog Input Mode

Analog Input Mode

Selection 1=Select

Selection 1=Select

Override (typ.

Hand (typ.

Process/Safety

Analog Input Mode

hardwired) Mode

Interlock) Mode

Selection

Mode.Inp_Hand

Mode.Inp_Ovrd

P_Mode

U

U

Mode

P_Mode

Mode ...

Sts_Hand

Inp_Hand

0

Sts_Maint

Inp_Ovrd

0

Sts_Ovrd

Sts_Prog

Sts_Oper

Sts_ProgOperLock

SkipText

LBL

Signature ID: C1F72CF2

Mode

*1(P_Mode)

Mode.Inp_Hand

*1(OTU)

Mode.Inp_Ovrd

*1(OTU)

============================================================

OWNERSHIP ARBITRATION

============================================================

This rung handles simple First-Come First-Served Ownership Arbitration.

If a requestor supplies a non-zero Owner ID and the current owner is NONE (zero),

Ownership is assigned to the requesting ID. When that requestor sets the Owner ID back

to zero, Ownership is relinquished back to NONE.

Program Owner

Request ID

(non-zero) or

Current Object Owner

Release (zero)

ID (0=not owned)

EQU

MOV

Equal

Move

Source A PSet_Owner

Source PSet_Owner

Dest Val_Owner

0

0

0

Source B

0

Program Owner

Request ID

(non-zero) or

Release (zero)

NEQ

Not Equal

Source A PSet_Owner

0

Source B

0

PSet_Owner

Current Object Owner

ID (0=not owned)

EQU

Equal

Source A Val_Owner

0

Source B

0

2(MOV) 2(EQU) 2(NEQ)

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Val_Owner

Page 3

22/12/2015 08,49,32

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

*2(MOV) 2(EQU)

============================================================

CONFIGURATION PROCESSING

============================================================

This rung publishes the Values for the scaled range.

If this instruction is reverse scaled by reversing the scaled (EU) min and max configurations,

the values are swapped so the the EUMax Value is always greater than the EUMin Value.

This makes the HMI bargraph and trend coding easier, and provides values

that can be pinned to the configuration of a PID, so the AIn and PID ranges are in lockstep.

PV (Output) Maximum

for Scaling to EU

GEQ

Grtr Than or Eql (A>=B)

Source A Cfg_PVEUMax

100.0

Source B Cfg_PVEUMin

0.0

Minimum of scaled

range = MIN

(Cfg_PVEUMin,

Cfg_PVEUMax)

MOV

Move

Source Cfg_PVEUMin

0.0

Dest Val_PVEUMin

0.0

Maximum of scaled

range = MAX

(Cfg_PVEUMin,

Cfg_PVEUMax)

MOV

Move

Source Cfg_PVEUMax

100.0

PV (Output) Maximum

for Scaling to EU

LES

Less Than (A<B)

Source A Cfg_PVEUMax

100.0

Source B Cfg_PVEUMin

0.0

Dest Val_PVEUMax

100.0

Maximum of scaled

range = MAX

(Cfg_PVEUMin,

Cfg_PVEUMax)

MOV

Move

Source Cfg_PVEUMin

0.0

Dest Val_PVEUMax

100.0

Minimum of scaled

range = MIN

(Cfg_PVEUMin,

Cfg_PVEUMax)

MOV

Move

Source Cfg_PVEUMax

100.0

Cfg_PVEUMax

3(LES) 3(GEQ) 3(MOV) 4(EQU) 16(CPT)

Cfg_PVEUMin

3(MOV) 3(GEQ) 3(LES) 4(EQU) 16(CPT) 16(MOV)

Val_PVEUMax

*3(MOV)

Val_PVEUMin

*3(MOV)

Dest Val_PVEUMin

0.0

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Data Context: P_AIn <definition>

Page 4

22/12/2015 08,49,32

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Normal Scan - PV is scaled and alarms are generated

Flag a Configuration Error if the raw input range or scaled PV range

max and min are set the same (invalid range), or if the

Analog Input Filter Time Constant is set to a negative value.

Input (unscaled)

Maximum for Scaling

EQU

Equal

Source A Cfg_InpRawMax

100.0

Source B Cfg_InpRawMin

0.0

PV (Output) Maximum

for Scaling to EU

EQU

Equal

Source A Cfg_PVEUMax

100.0

Source B Cfg_PVEUMin

0.0

PV Filter Time

Constant (sec),

0.0 = unfiltered

LES

Less Than (A<B)

Source A Cfg_FiltTC

0.0

Source B

0.0

Cfg_FiltTC

4(LES) 23(LEQ) 23(GRT) 23(CPT)

Cfg_InpRawMax

4(EQU) 16(CPT)

Cfg_InpRawMin

4(EQU) 16(CPT)

Cfg_PVEUMax

3(MOV) 3(GEQ) 3(LES) 4(EQU) 16(CPT)

Cfg_PVEUMin

3(MOV) 3(LES) 3(GEQ) 4(EQU) 16(CPT) 16(MOV)

Err_EU

*4(OTE) 6(XIC) 16(XIC) 16(XIO)

Err_Filt

*4(OTE) 6(XIC)

Err_Raw

*4(OTE) 6(XIC) 16(XIC) 16(XIO)

1=Error in Config:

Raw Input Scaling

Min = Max

Err_Raw

1=Error in Config:

Scaled EU Min = Max

Err_EU

1=Error in Config:

PV filter params

(RateTime, TC)

Err_Filt

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Data Context: P_AIn <definition>

Page 5

22/12/2015 08,49,32

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Normal Scan - PV is scaled and alarms are generated

Flag a Configuration Error if any Status On-Delay or Off-Delay timer preset is invalid

(and set timer to a default, non-faulting value).

High-High Status

On-Dealy Timer

MUL

5

Multiply

Source A Cfg_HiHiOnDly

0

Source B

1000

High-High Status

On-Dealy Timer

Wrk_HiHiOnDlyT.PRE.31

1=Error in Config:

On Delay, Off Delay

Time Invalid (use 0

to 2147483 sec)

Err_Timer

Dest Wrk_HiHiOnDlyT.PRE

0

High-High Status

On-Dealy Timer

CLR

Clear

Dest Wrk_HiHiOnDlyT.PRE

0

High-High Status

Off-Delay Timer

MUL

Multiply

Source A Cfg_HiHiOffDly

0

Source B

1000

High-High Status

Off-Delay Timer

Wrk_HiHiOffDlyT.PRE.31

Dest Wrk_HiHiOffDlyT.PRE

0

High-High Status

Off-Delay Timer

CLR

Clear

Dest Wrk_HiHiOffDlyT.PRE

0

High Status On-Delay

Timer

MUL

Multiply

Source A Cfg_HiOnDly

0

Source B

1000

High Status On-Delay

Timer

Wrk_HiOnDlyT.PRE.31

Dest Wrk_HiOnDlyT.PRE

0

High Status On-Delay

Timer

CLR

Clear

Dest Wrk_HiOnDlyT.PRE

0

High Status

Off-Delay Timer

MUL

Multiply

Source A Cfg_HiOffDly

0

Source B

1000

High Status

Off-Delay Timer

Wrk_HiOffDlyT.PRE.31

Dest Wrk_HiOffDlyT.PRE

0

High Status

Off-Delay Timer

CLR

Clear

Dest Wrk_HiOffDlyT.PRE

0

Low Status On-Delay

Timer

Low Status On-Delay

Timer

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Data Context: P_AIn <definition>

Page 6

22/12/2015 08,49,32

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Normal Scan - PV is scaled and alarms are generated

Timer

Timer

Wrk_LoOnDlyT.PRE.31

MUL

Multiply

Source A Cfg_LoOnDly

0

Source B

1000

Dest Wrk_LoOnDlyT.PRE

0

Low Status On-Delay

Timer

CLR

Clear

Dest Wrk_LoOnDlyT.PRE

0

Low Status Off-Delay

Timer

MUL

Multiply

Source A Cfg_LoOffDly

0

Source B

1000

Low Status Off-Delay

Timer

Wrk_LoOffDlyT.PRE.31

Dest Wrk_LoOffDlyT.PRE

0

Low Status Off-Delay

Timer

CLR

Clear

Dest Wrk_LoOffDlyT.PRE

0

Low-Low Status

On-Delay Timer

MUL

Multiply

Source A Cfg_LoLoOnDly

0

Source B

1000

Low-Low Status

On-Delay Timer

Wrk_LoLoOnDlyT.PRE.31

Dest Wrk_LoLoOnDlyT.PRE

0

Low-Low Status

On-Delay Timer

CLR

Clear

Dest Wrk_LoLoOnDlyT.PRE

0

Low-Low Status

Off-Delay Timer

MUL

Multiply

Source A Cfg_LoLoOffDly

0

Source B

1000

Low-Low Status

Off-Delay Timer

Wrk_LoLoOffDlyT.PRE.31

Dest Wrk_LoLoOffDlyT.PRE

0

Low-Low Status

Off-Delay Timer

CLR

Clear

Dest Wrk_LoLoOffDlyT.PRE

0

Fail Status On-Delay

Timer

MUL

Multiply

Source A Cfg_FailOnDly

0

Source B

1000

Fail Status On-Delay

Timer

Wrk_FailOnDlyT.PRE.31

Dest Wrk_FailOnDlyT.PRE

0

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Data Context: P_AIn <definition>

Source B

Page 7

22/12/2015 08,49,32

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Normal Scan - PV is scaled and alarms are generated

1000

Fail Status On-Delay

Timer

CLR

Clear

Dest Wrk_FailOnDlyT.PRE

0

Fail Status

Off-Delay Timer

MUL

Multiply

Source A Cfg_FailOffDly

0

Source B

1000

Fail Status

Off-Delay Timer

Wrk_FailOffDlyT.PRE.31

Dest Wrk_FailOffDlyT.PRE

0

Fail Status

Off-Delay Timer

CLR

Clear

Dest Wrk_FailOffDlyT.PRE

0

Cfg_FailOffDly

5(MUL)

Cfg_FailOnDly

5(MUL)

Cfg_HiHiOffDly

5(MUL)

Cfg_HiHiOnDly

5(MUL)

Cfg_HiOffDly

5(MUL)

Cfg_HiOnDly

5(MUL)

Cfg_LoLoOffDly

5(MUL)

Cfg_LoLoOnDly

5(MUL)

Cfg_LoOffDly

5(MUL)

Cfg_LoOnDly

5(MUL)

Err_Timer

*5(OTE)

Wrk_FailOffDlyT.PRE

*5(CLR) *5(MUL)

Wrk_FailOffDlyT.PRE.31 5(XIC)

Wrk_FailOnDlyT.PRE

*5(MUL) *5(CLR)

Wrk_FailOnDlyT.PRE.31 5(XIC)

Wrk_HiHiOffDlyT.PRE

*5(MUL) *5(CLR)

Wrk_HiHiOffDlyT.PRE.31 5(XIC)

Wrk_HiHiOnDlyT.PRE

*5(MUL) *5(CLR)

Wrk_HiHiOnDlyT.PRE.31 5(XIC)

Wrk_HiOffDlyT.PRE

*5(MUL) *5(CLR)

Wrk_HiOffDlyT.PRE.31

5(XIC)

Wrk_HiOnDlyT.PRE

*5(CLR) *5(MUL)

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Wrk_HiOnDlyT.PRE.31

5(XIC)

Wrk_LoLoOffDlyT.PRE

*5(MUL) *5(CLR)

Page 8

22/12/2015 08,49,32

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Wrk_LoLoOffDlyT.PRE.3 5(XIC)

1

Wrk_LoLoOnDlyT.PRE

*5(MUL) *5(CLR)

Wrk_LoLoOnDlyT.PRE.3 5(XIC)

1

Wrk_LoOffDlyT.PRE

*5(MUL) *5(CLR)

Wrk_LoOffDlyT.PRE.31 5(XIC)

Wrk_LoOnDlyT.PRE

*5(MUL) *5(CLR)

Wrk_LoOnDlyT.PRE.31

5(XIC)

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Data Context: P_AIn <definition>

Page 9

22/12/2015 08,49,32

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Normal Scan - PV is scaled and alarms are generated

This rung handles the reports of all Bad Configuration Status.

Individual bits are provided for various status:

Bad Raw Scaling configs

Bad Engineering Units Scaling configs

Bad 1st-Order Filter configs

Bad Alarm Deadband configs

Bad Alarm Minimum Duration configs

Then a summary Bad Config status is provided, simply an OR of the individual bits.

1=Error in Config

(see detail Err_

bits for reason),

display icon

Sts_Err

1=Error in Config:

Raw Input Scaling

Min = Max

Err_Raw

6

1=Error in Config:

Scaled EU Min = Max

Err_EU

1=Error in Config:

PV filter params

(RateTime, TC)

Err_Filt

High-High Status

Deadband (EU)

LES

Less Than (A<B)

Source A Cfg_HiHiDB

1.0

Source B

0.0

1=Error in Config: a

Status Deadband is <

0.0

Err_DB

High Status Deadband

(EU)

LES

Less Than (A<B)

Source A Cfg_HiDB

1.0

Source B

0.0

Low Status Deadband

(EU)

LES

Less Than (A<B)

Source A Cfg_LoDB

1.0

Source B

0.0

Low-Low Status

Deadband (EU)

LES

Less Than (A<B)

Source A Cfg_LoLoDB

1.0

Source B

0.0

Out-of-Range (fail)

High/Low Deadband

(EU)

LES

Less Than (A<B)

Source A Cfg_FailDB

0.41666666

Source B

0.0

High-High Alarm

1=Error in Config:

see detail Err_ bits

for reason

HiHi.Sts_Err

1=Error in Config:

Alarm Min On Time or

Severity

Err_Alarm

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Data Context: P_AIn <definition>

Page 10

22/12/2015 08,49,32

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Normal Scan - PV is scaled and alarms are generated

High Alarm 1=Error

in Config: see

detail Err_ bits for

reason

Hi.Sts_Err

Low Alarm 1=Error in

Config: see detail

Err_ bits for reason

Lo.Sts_Err

Low-Low Alarm

1=Error in Config:

see detail Err_ bits

for reason

LoLo.Sts_Err

Analog Input Failure

Alarm (bad quality

or out of range)

1=Error in Config:

see detail Err_ bits

for reason

Fail.Sts_Err

Cfg_FailDB

6(LES) 31(CMP)

Cfg_HiDB

6(LES) 28(CMP)

Cfg_HiHiDB

6(LES) 27(CMP)

Cfg_LoDB

6(LES) 29(CMP)

Cfg_LoLoDB

6(LES) 30(CMP)

Err_Alarm

*6(OTE)

Err_DB

*6(OTE)

Err_EU

*4(OTE) 6(XIC) 16(XIO) 16(XIC)

Err_Filt

*4(OTE) 6(XIC)

Err_Raw

*4(OTE) 6(XIC) 16(XIC) 16(XIO)

Fail.Sts_Err

6(XIC)

Hi.Sts_Err

6(XIC)

HiHi.Sts_Err

6(XIC)

Lo.Sts_Err

6(XIC)

LoLo.Sts_Err

6(XIC)

Sts_Err

*6(OTE) 33(XIC)

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Data Context: P_AIn <definition>

Page 11

22/12/2015 08,49,32

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Normal Scan - PV is scaled and alarms are generated

==================

==================

Th

When the Mod

Alarm Thresholds, an

for bump

When the Mod

Alarm Thresholds, an

for bump

Analog Input Mode

Selection 1=Mode is

Program

Mode.Sts_Prog

<Sts_Prog>

7

Move

Source

1.50000

1=PSets track OSe

in Oper, OSets trac

PSets in Prog, 0=n

tracking

Cfg_SetTrack

Move

Source

1.5000

Analog Input Mode

Selection 1=Mode is

Operator

Mode.Sts_Oper

<Sts_Oper>

Analog Input Mode

Selection 1=Mode is

Maintenance

(supersedes Ovrd,

Prog, Oper)

Mode.Sts_Maint

<Sts_Maint>

Current High-High

Status Threshold

MOV

Move

Source OSet_HiHiLim

1.50000000e+038

1=PSets track OSets

in Oper, OSets track

PSets in Prog, 0=no

tracking

Cfg_SetTrack

7(XIC) 8(XIO) 17(XIC) 20(XIC)

Mode.Sts_Maint

7(XIC) 8(XIC) 9(XIC) 10(XIC)

Move

Source OS

1.50000

Program-Entered

High-High Status

Threshold (EU)

MOV

Move

Source Val_HiHiLim

1.50000000e+038

Cfg_SetTrack

Dest

Val_HiHiLim

1.50000000e+038

Dest PSet_HiHiLim

1.50000000e+038

Move

Source

1.5000

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Mode.Sts_Oper

7(XIC) 8(XIC)

Mode.Sts_Prog

7(XIC)

OSet_HiHiLim

7(MOV) *7(MOV)

OSet_HiLim

7(MOV) *7(MOV)

OSet_LoLim

*7(MOV) 7(MOV)

OSet_LoLoLim

*7(MOV) 7(MOV)

PSet_HiHiLim

7(MOV) *7(MOV)

PSet_HiLim

*7(MOV) 7(MOV)

PSet_LoLim

7(MOV) *7(MOV)

PSet_LoLoLim

7(MOV) *7(MOV)

Sts_Maint

13(XIC)

Val_HiHiLim

7(MOV) *7(MOV) 27(GEQ) 27(CMP)

Val_HiLim

7(MOV) *7(MOV) 28(GEQ) 28(CMP)

Val_LoLim

7(MOV) *7(MOV) 29(LEQ) 29(CMP)

Val_LoLoLim

7(MOV) *7(MOV) 30(LEQ) 30(CMP)

Page 12

22/12/2015 08,49,32

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

===========================================================

SETTINGS PROCESSING

===========================================================

These rungs handle received Settings:

When the Mode is Program, use the Program Settings for the

Alarm Thresholds, and copy the Program Settings to the Operator Settings

for bumpless transition from Program to Operator.

When the Mode is Operator, use the Operator Settings for the

Alarm Thresholds, and copy the Operator Settings to the Program Settings

for bumpless transition from Operator to Program.

Current High-H

Status Thresh

MOV

Move

Source PSet_HiHiLim

1.50000000e+038

Current High Status

Threshold

MOV

PSet_HiLim

1.50000000e+038

Dest

Val_HiLim

1.50000000e+038

Current Low Status

Threshold

MOV

Move

Source PSet_LoLim

-1.50000000e+038

Dest

Val_LoLim

-1.50000000e+038

1=PSets track OSets

in Oper, OSets track

PSets in Prog, 0=no

Current Low-Low

Status Threshol

MOV

Move

Source PSet_LoLoLim

-1.50000000e+038

Operator-Ent

High-High St

Threshold (

MOV

Move

Source Val_HiHiLim

1.50000000e+038

Operator-Entered

High Status

Threshold (EU)

MOV

Val_HiLim

1.50000000e+038

Dest

OSet_HiLim

1.50000000e+038

Operator-Entered Low

Status Threshold

(EU)

MOV

Move

Source

Val_LoLim

-1.50000000e+038

Dest

OSet_LoLim

-1.50000000e+038

Operator-Entere

Low-Low Statu

Threshold (EU

MOV

Move

Source Val_LoLoLim

-1.50000000e+038

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Data Context: P_AIn <definition>

Page 13

22/12/2015 08,49,33

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Normal Scan - PV is scaled and alarms are generated

Current High-High

Status Threshold

Dest

Val_HiHiLim

1.50000000e+038

Current Low-Low

Status Threshold

Dest

Val_LoLoLim

-1.50000000e+038

Operator-Entered

High-High Status

Threshold (EU)

Dest OSet_HiHiLim

1.50000000e+038

Operator-Entered

Low-Low Status

Threshold (EU)

Dest OSet_LoLoLim

-1.50000000e+038

Current Low-Low

Status Threshold

Dest

Val_LoLoLim

-1.50000000e+038

Program-Entered

Low-Low Status

Threshold (EU)

Dest PSet_LoLoLim

-1.50000000e+038

RSLogix 5000

Logic - Ladder Diagram

TetraPak_Mezclado_de_Leche:Add-On Instructions:P_AIn

Total number of rungs in routine: 42

Data Context: P_AIn <definition>

Page 14

22/12/2015 08,49,33

F:\TetraPak_Mezclado_de_Leche_13052014.ACD

Normal Scan - PV is scaled and alarms are generated

Ready to receive other Operator Settings (OSet_xxx) if tracking is NOT enabled,

or we're in Operator or Maintenance Mode.

1=PSets track OSets

in Oper, OSets track

PSets in Prog, 0=no

tracking

Cfg_SetTrack

/

1=Ready to receive

OSets (enables data

entry fields)

Rdy_OSet

Analog Input Mode

Selection 1=Mode is

Operator

Mode.Sts_Oper

<Sts_Oper>

Analog Input Mode

Selection 1=Mode is

Maintenance

(supersedes Ovrd,

Prog, Oper)

Mode.Sts_Maint

<Sts_Maint>

Cfg_SetTrack

7(XIC) 8(XIO) 17(XIC) 20(XIC)

Mode.Sts_Maint

7(XIC) 8(XIC) 9(XIC) 10(XIC)

Mode.Sts_Oper

7(XIC) 8(XIC)

Rdy_OSet

*8(OTE)

Sts_Maint

13(XIC)

============================================================