Académique Documents

Professionnel Documents

Culture Documents

Bottom Bracket Calculation

Transféré par

Amro Ahmad AliCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Bottom Bracket Calculation

Transféré par

Amro Ahmad AliDroits d'auteur :

Formats disponibles

PROFIS Anchor 2.3.

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Gutmann ME

A.A

-|-

Page:

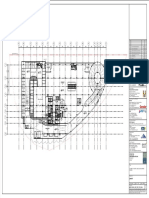

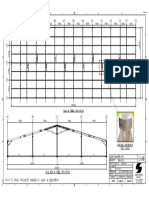

Project:

Sub-Project I Pos. No.:

Date:

1

Al-GHUWAIRIYA CLINIC

Prototype - A

12/29/2013

Specifier's comments:

1. Input data

Anchor type and diameter:

Effective embedment depth:

Material:

Evaluation Service Report::

Issued I Valid:

Proof:

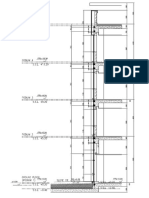

Stand-off installation:

Anchor plate:

Profile

Base material:

Reinforcement:

HST, M12

h ef = 70 mm, h nom = 80 mm

ETA 98/0001

2/20/2013 | 2/20/2018

SOFA design method + fib (07/2011) - after ETAG testing

e b = 0 mm (no stand-off); t = 8 mm

lx x l y x t = 150 x 160 x 8 mm (Recommended plate thickness: not calculated)

Double flat bar; (L x W x T) = 136 mm x 34 mm x 6 mm

cracked concrete , C40/50, f c = 40.00 N/mm; h = 400 mm

no reinforcement or reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

with longitudinal edge reinforcement d >= 12 [mm]

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

PROFIS Anchor 2.3.5

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

Gutmann ME

A.A

-|-

2

Al-GHUWAIRIYA CLINIC

Prototype - A

12/29/2013

2. Load case/Resulting anchor forces

Load case (Design loads):

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Anchor

Tension force

Shear force

Shear force x

Shear force y

1.298

3.500

3.500

0.000

1.298

3.500

3.500

0.000

max. concrete compressive strain []: 0.09

max. concrete compressive stress [N/mm]: 2.57

resulting tension force in (x/y)=(-5/0) [kN]: 2.597

resulting compression force in (x/y)=(59/0) [kN]: 6.518

Compression

Tension

3. Tension load SOFA (fib (07/2011), section 10.1)

Load [kN]

Capacity [kN]

Utilization bN [%]

Status

Steel Strength*

1.298

30.000

OK

Pullout Strength*

1.298

11.314

11

OK

Concrete Breakout Strength**

2.597

18.903

14

OK

Splitting failure**

2.597

21.304

12

OK

Proof

* anchor having the highest loading

**anchor group (anchors in tension)

Steel Strength

NRk,s [kN]

g M,s

NRd,s [kN]

NSd [kN]

45.000

1.500

30.000

1.298

NRk,p [kN]

yc

g M,p

NRd,p [kN]

NSd [kN]

12.000

1.414

1.500

11.314

1.298

Pullout Strength

Concrete Breakout Strength

2

Ac,N [mm ]

Ac,N [mm ]

y A,N

c cr,N [mm]

s cr,N [mm]

49500

44100

1.122

105

210

e c1,N [mm]

y ec1,N

e c2,N [mm]

y ec2,N

y s,N

y re,N

k1

1.000

1.000

0.886

1.000

7.700

NRk,c [kN]

g M,c

NRd,c [kN]

NSd [kN]

28.521

1.500

18.903

2.597

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

PROFIS Anchor 2.3.5

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

Gutmann ME

A.A

-|-

3

Al-GHUWAIRIYA CLINIC

Prototype - A

12/29/2013

Splitting failure

2

Ac,N [mm ]

Ac,N [mm ]

y A,N

c cr,sp [mm]

s cr,sp [mm]

y h,sp

49500

44100

1.122

105

210

1.127

e c1,N [mm]

y ec1,N

e c2,N [mm]

y ec2,N

y s,N

y re,N

k1

1.000

1.000

0.886

1.000

7.700

NRk,c [kN]

g M,sp

N Rd,sp [kN]

NSd [kN]

28.521

1.500

21.304

2.597

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

PROFIS Anchor 2.3.5

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

Gutmann ME

A.A

-|-

4

Al-GHUWAIRIYA CLINIC

Prototype - A

12/29/2013

4. Shear load SOFA (fib (07/2011), section 10.2)

Proof

Utilization bV [%]

Load [kN]

Capacity [kN]

3.500

28.000

12

OK

N/A

N/A

N/A

N/A

Pryout Strength**

6.999

41.587

17

OK

Concrete edge failure in direction

3.500

4.691

75

OK

Steel Strength (without lever arm)*

Steel failure (with lever arm)*

Status

y+**

* anchor having the highest loading

**anchor group (relevant anchors)

Steel Strength (without lever arm)

VRk,s [kN]

g M,s

V Rd,s [kN]

VSd [kN]

35.000

1.250

28.000

3.500

Pryout Strength

0

Ac,N [mm ]

Ac,N [mm ]

y A,N

c cr,N [mm]

s cr,N [mm]

k4

49500

44100

1.122

105

210

2.200

e c1,V [mm]

y ec1,N

e c2,V [mm]

y ec2,N

y s,N

y re,N

1.000

1.000

0.886

1.000

NRk,c [kN]

g M,c,p

VRd,c1 [kN]

VSd [kN]

28.521

1.500

41.587

6.999

Concrete edge failure in direction y+

lf [mm]

d nom [mm]

kv

70

12

1.700

0.051

0.054

c 1 [mm]

Ac,V [mm ]

A c,V [mm ]

y A,V

267

60000

320000

0.188

y s,V

y h,V

y a,V

e c,V [mm]

y ec,V

y re,V

y 90,V

0.749

1.000

1.500

1.000

1.000

1.500

VRk,c [kN]

g M,c

VRd,c [kN]

VSd [kN]

66.828

1.500

4.691

3.500

Note: Resistance limit acc. to fib (07/2011) Eq. (10.2-7) is governing

5. Combined tension and shear loads SOFA (fib (07/2011), section 10.3)

steel

concrete

a

bN

bV

Utilization bN,V [%]

Status

0.043

0.125

2.0

OK

0.137

0.746

1.5

70

OK

bN + bV <= 1

6. Displacements

The displacement of the highest loaded anchor should be calculated according to the relevant approval. The displacement due to hole

tolerances can be neglected, because this method assumes that no hole clearance between anchors and fixture is present. The characteristic

loads of the highest loaded anchor are

NSk

0.960 [kN]

VSk

2.590 [kN]

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

PROFIS Anchor 2.3.5

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Gutmann ME

A.A

-|-

Page:

Project:

Sub-Project I Pos. No.:

Date:

5

Al-GHUWAIRIYA CLINIC

Prototype - A

12/29/2013

7. Warnings

The design method fib (07/2011) assumes that no hole clearance between the anchors and the fixture is present. This can be achieved by

filling the gap with mortar of sufficient sompressive strength (e.g. by using the Hilti Dynamic Set) or by other suitable means.

The compliance with current standards (e.g. EC3) is the responsibility of the user

The anchor plate overlaps the concrete plate edges. A local concrete spalling due to compression has to be checked separately!

Checking the transfer of loads into the base material is required in accordance with fib (07/2011)!

To avoid failure of the anchor plate the required thickness can be calculated in PROFIS Anchor. Load re-distributions on the anchors due to

elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be sufficiently stiff, in order not to be deformed

when subjected to the loading!

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to be

followed to ensure a proper installation.

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

PROFIS Anchor 2.3.5

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

Gutmann ME

A.A

-|-

6

Al-GHUWAIRIYA CLINIC

Prototype - A

12/29/2013

8. Installation data

Anchor plate, steel: Anchor type and diameter: HST, M12

Profile: Double flat bar, 136 mm x 34 mm x 6 mm

Installation torque: 0.060 kNm

Hole diameter in the fixture: df = 14 mm

Hole diameter in the base material: 12 mm

Plate thickness (input): 8 mm

Hole depth in the base material: 95 mm

Recommended plate thickness: not calculated

Minimum thickness of the base material: 140 mm

Cleaning: Manual cleaning of the drilled hole according to instructions for use is required.

Annular gap must be removed by e.g. filling the holes with mortar of sufficient compressive strength.

8.1. Required accessories

Cleaning

Manual blow-out pump

Drilling

Suitable Rotary Hammer

Properly sized drill bit

Setting

Dynamic set

Torque wrench

Hammer

20.0

80.0

20.0

80.0

Coordinates Anchor [mm]

Anchor

x

y

1

0

-60

2

0

60

c -x

65

65

c +x

85

85

c -y

940

1060

75.0

75.0

75.0

75.0

c +y

10060

9940

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

PROFIS Anchor 2.3.5

www.hilti-me.com

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Gutmann ME

A.A

-|-

Page:

Project:

Sub-Project I Pos. No.:

Date:

7

Al-GHUWAIRIYA CLINIC

Prototype - A

12/29/2013

9. Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted prior

to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the data you

put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be put in by

you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly with regard

to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an aid to interpret

norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or suitability for a

specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for the

regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do not

use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software in

each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- A 503 Window Schedule1699537950122Document1 pageA 503 Window Schedule1699537950122Amro Ahmad AliPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A 308 Service Block Sections Details1578487928531Document1 pageA 308 Service Block Sections Details1578487928531techPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- I-501.11 (c00) XD Penthouse - Lower Floor - Power-Data - Part BDocument1 pageI-501.11 (c00) XD Penthouse - Lower Floor - Power-Data - Part BAmro Ahmad AliPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Podium Section ModelDocument1 pagePodium Section ModelAmro Ahmad AliPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Anchor Analysis - HorizontalDocument7 pagesAnchor Analysis - HorizontalAmro Ahmad AliPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Updated Schematic Design Rev10Document1 pageUpdated Schematic Design Rev10Amro Ahmad AliPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Mathcad - Inputs Design As Per DEWADocument3 pagesMathcad - Inputs Design As Per DEWAAmro Ahmad AliPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A 204 Elevation d1578487924094Document1 pageA 204 Elevation d1578487924094Amro Ahmad AliPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- A 204 Elevation d1578487924094Document1 pageA 204 Elevation d1578487924094Amro Ahmad AliPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- I-501.17 (c00) XD Penthouse - Upper Floor RCP - Part ADocument1 pageI-501.17 (c00) XD Penthouse - Upper Floor RCP - Part AAmro Ahmad AliPas encore d'évaluation

- Work in Progress: Dubai Creek ResidencesDocument1 pageWork in Progress: Dubai Creek ResidencesAmro Ahmad AliPas encore d'évaluation

- 5120544-Spo-A-5906-0 (T)Document1 page5120544-Spo-A-5906-0 (T)Amro Ahmad AliPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Aed130164 00 DD SD 0427 CDocument1 pageAed130164 00 DD SD 0427 CAmro Ahmad AliPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- M-GW-03-51dB DOOR-proposal Model PDFDocument1 pageM-GW-03-51dB DOOR-proposal Model PDFAmro Ahmad AliPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Aed130164 00 DD SD 0403 CDocument1 pageAed130164 00 DD SD 0403 CAmro Ahmad AliPas encore d'évaluation

- Ar 13 SectionDocument1 pageAr 13 SectionAmro Ahmad AliPas encore d'évaluation

- Aed130164 00 DD SD 0404 CDocument1 pageAed130164 00 DD SD 0404 CAmro Ahmad AliPas encore d'évaluation

- Plan & ElevationDocument1 pagePlan & ElevationAmro Ahmad AliPas encore d'évaluation

- 600 Glass Balustrade ARCH DET 3-2-2016Document1 page600 Glass Balustrade ARCH DET 3-2-2016Amro Ahmad AliPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Bill No.3Document14 pagesBill No.3Amro Ahmad AliPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Work in Progress: Dubai Creek ResidencesDocument1 pageWork in Progress: Dubai Creek ResidencesAmro Ahmad AliPas encore d'évaluation

- Eff AreaDocument1 pageEff AreaAmro Ahmad AliPas encore d'évaluation

- Plate MatDocument12 pagesPlate MatPrantik Adhar SamantaPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- KWT NG 01 03 00Document1 pageKWT NG 01 03 00Amro Ahmad AliPas encore d'évaluation

- M GW 03 51dB DOOR Proposal ModelDocument1 pageM GW 03 51dB DOOR Proposal ModelAmro Ahmad AliPas encore d'évaluation

- UuhtgDocument1 pageUuhtgAmro Ahmad AliPas encore d'évaluation

- Grid & Detail ModelDocument1 pageGrid & Detail ModelAmro Ahmad AliPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Ar-39 Wall SecDocument1 pageAr-39 Wall SecAmro Ahmad AliPas encore d'évaluation

- Ipl SGN Salao 2Document9 pagesIpl SGN Salao 2Prie DitucalanPas encore d'évaluation

- Sales OutlineDocument43 pagesSales OutlineJam Charmaine M. BelenPas encore d'évaluation

- Easa Basic RegulationDocument35 pagesEasa Basic RegulationAhmed ShahPas encore d'évaluation

- Kiamco V CA DigestDocument2 pagesKiamco V CA DigestAlegria IrisPas encore d'évaluation

- Comparative Police System - BookDocument70 pagesComparative Police System - BookJovie Masongsong100% (2)

- Child Marriage and The LawDocument11 pagesChild Marriage and The LawA y u s hPas encore d'évaluation

- (CPR) Collantes v. MabutiDocument5 pages(CPR) Collantes v. MabutiChristian Edward Coronado50% (2)

- Petition For A Decree of Nullity: Absence of Canonical FormDocument1 pagePetition For A Decree of Nullity: Absence of Canonical FormMelissa Benesisto CamposanoPas encore d'évaluation

- Holy See Wins Sovereign Immunity CaseDocument3 pagesHoly See Wins Sovereign Immunity CaseSai Pastrana100% (2)

- 08 Benatiro vs. Heirs of Evaristo Cuyos, 560 SCRA 478, G.R. No. 161220 July 30, 2008Document25 pages08 Benatiro vs. Heirs of Evaristo Cuyos, 560 SCRA 478, G.R. No. 161220 July 30, 2008Galilee RomasantaPas encore d'évaluation

- Undue Influence in EquityDocument12 pagesUndue Influence in EquitymuhumuzaPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Essay FinalDocument5 pagesEssay FinalJaya Malathy0% (2)

- Haron v. Gonzales Et Al - Document No. 2Document3 pagesHaron v. Gonzales Et Al - Document No. 2Justia.comPas encore d'évaluation

- Atex DirectiveDocument4 pagesAtex DirectiveMichaelPas encore d'évaluation

- Material Safety Data Sheet (MSDS) : 1. IdentificationDocument8 pagesMaterial Safety Data Sheet (MSDS) : 1. IdentificationPlant Head PrasadPas encore d'évaluation

- In The High Court of South Africa (Gauteng Division, Pretoria)Document7 pagesIn The High Court of South Africa (Gauteng Division, Pretoria)NthabiPas encore d'évaluation

- Lawsuit Against Charles PolevichDocument15 pagesLawsuit Against Charles PolevichLaw&CrimePas encore d'évaluation

- According To The Parties BoundDocument4 pagesAccording To The Parties BoundTin RobisoPas encore d'évaluation

- Report and Recommendation I. RecommendationDocument15 pagesReport and Recommendation I. RecommendationGeneration GenerationPas encore d'évaluation

- University of Professional Studies, Accra (Upsa) : 1. Activity 1.1 2. Activity 1.2 3. Brief The Following CasesDocument8 pagesUniversity of Professional Studies, Accra (Upsa) : 1. Activity 1.1 2. Activity 1.2 3. Brief The Following CasesADJEI MENSAH TOM DOCKERY100% (1)

- Is Community Service Really A PunishmentDocument3 pagesIs Community Service Really A PunishmentcigaraintcoolyallPas encore d'évaluation

- Cases PersonsDocument115 pagesCases PersonsChano MontyPas encore d'évaluation

- (A.C. No. 10911. June 6, 2017.) Virgilio J. Mapalad, Sr. vs. Atty. Anselmo S. Echanez PrincipleDocument2 pages(A.C. No. 10911. June 6, 2017.) Virgilio J. Mapalad, Sr. vs. Atty. Anselmo S. Echanez Principlechrystel0% (1)

- A.M. No. 08-11-7-SCDocument18 pagesA.M. No. 08-11-7-SCStenaArapocPas encore d'évaluation

- PTC Vs Sps RoxasDocument3 pagesPTC Vs Sps RoxasToni Rose Abrera100% (1)

- Pre-Enrolment Health AssessmentDocument2 pagesPre-Enrolment Health AssessmentVictor VigoPas encore d'évaluation

- Montemayor v. Bundalian Case DigestDocument1 pageMontemayor v. Bundalian Case Digestpa0l0sPas encore d'évaluation

- An Overview of Land Titles and DeedsDocument5 pagesAn Overview of Land Titles and DeedsowenPas encore d'évaluation

- Outcome of Board Meeting (Board Meeting)Document2 pagesOutcome of Board Meeting (Board Meeting)Shyam Sunder100% (1)

- Oath of Office for SK TreasurerDocument2 pagesOath of Office for SK TreasurerJustin Tagumasi AgustinPas encore d'évaluation