Académique Documents

Professionnel Documents

Culture Documents

PDF 181

Transféré par

Komali Narasimha ReddyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PDF 181

Transféré par

Komali Narasimha ReddyDroits d'auteur :

Formats disponibles

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl.

, 122- 133

Research article

Available online www.ijsrr.org

ISSN: 22790543

International Journal of Scientific Research and Reviews

Assessment of Efficiency of The Sewage Treatment Plant at Sri

Balaji Technical Campus

Bhagat Suraj Kumar *, Tiyasha

M.Tech* (Environmental Engg.), Deptt, of Civil Engg., SBCET, Jaipur,

M.Tech* (Environmental Engg.), Deptt, of Civil Engg., Poornima Group of Institution, Jaipur

ABSTRACT

The area irrigated with waste water varies around 10 % of the total world irrigated area so

waste water can be used efficiently. Adequate treatment is necessary to prevent the bad effect on

the receiving water bodies, whether it is for water supply, recreation, or any other purposes. Sri

Balji Technical Campus has 100 KLD Sewage Treatment Plant with two Aeration Tank of 35

KLD each and one Settling Tank lead to Filter Tank which treated the waste water of same place

and purified water is used by gardening as well as agriculture in neighbor area (25-30 ha).

Vegetable as well crop grown in nearby locality is used by local people so Sewage Treatment

Plant must work efficiently to produce good quality of water which will improve health as well

as social life of residents. Raw water and purified water were analyzed in terms of Temperature,

BOD5, Taste, Odour, Total Solid, pH, Fluoride, Conductivity, and NO3.

KEYWORD: KLD, Aeration Tank, Settling Tank, Filter Tank, Sewage Treatment Plant,

BOD5, NO3, Total Solid, and Conductivity.

Suraj Kumar Bhagat

M.Tech* (Environmental Engineering),

Department of Civil Engineering,

Sri Balaji College of Engineering and Technology, Jaipur,

E-mail: suraj_futuretech@yahoo.com, Mob: 08233404815

IJSRR 2013, 2(1) Special Issue April May 2013

Page122

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl., 122- 133

INTRODUCTION

The waters from sky, the waters of rivers, and water in the well, whose source is the

ocean, may all these sacred waters protect me (Rig Veda). It is estimated that about 20 million

hectare in 50 countries are irrigated with raw or partially treated wastewater. Wastewater (WW)

is a combination of the liquid, or water carrying wastes, removed from domestic, institutions,

commercial and industrial establishments together with surface/ground/storm water. Wastewater

treatment consists of applying known technology to improve or upgrade the quality of a

wastewater.

History

You may be surprised to learn that the treatment of wastewater is not a modern practice.

Removal of foul-smelling from sewer water was common in ancient Rome; it was not until the

19th century that large cities began to understand the necessity of reducing the amount of

pollutants in the used water they were discharging to the environment. Despite large supplies of

fresh water and the natural ability of surface waters to clean them over time, populations had

become so concentrated by 1850 that outbreaks of life-threatening diseases became common.

These outbreaks were due to pathogenic bacteria found in the polluted water. What happens in a

wastewater treatment plant is essentially the same as what occurs naturally in an ocean, lake,

river or stream1. The function of a wastewater treatment plant is to speed up self-cleansing

process. The practice of wastewater collection and treatment has been developed and upgraded,

using advanced biological, physical, chemical and mechanical techniques available presently.

As a result, public health and water quality has been secured better today than ever before2.

Wastewater treatment, however, can also be classified by the nature of the treatment

process operation being used; for example, physical, chemical or biological. Examples of these

treatment steps are shown below. A common wastewater treatment system may consist of the

application of a number of physical, chemical and biological processes3.

Our study focused more on the wastewater treatment in Sri Balaji Technical Campus

(SBT) and research on the processes that contribute in enhancing the Wastewater treatment;

toward making SBT Campus a green campus.

Need of Study

This type of studies is beneficial for the waste water management of the campus So that if

in future there is any requirement for taking any action to managing or changing the strategy of

Wastewater management than this study will be very informative. This type of studies are never

carried out in campus thats why this topic is quite a new study for the SBT campus, since it is

rare in other campuses. The need of study is also due to the problem associated by the

Wastewater, that is treated or disposed off in unsatisfactory way which may cause severe

IJSRR 2013, 2(1) Special Issue April May 2013

Page123

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl., 122- 133

aesthetic nuisance in terms of smell and appearance, flies breeding in some sites of wastewater,

and as we know flies are very effective vectors that spreading diseases.

Benefits of Sewage treatment:

1. Safeguard the health of people who eat and produce food grown in recycled water i.e.

residents of neighborhoods near irrigated areas

2. Safeguard the health of operators who irrigate the land with untreated or partially treated

waste water and come to the direct contact of wastewater.

3. The prevention of contamination and degradation of land, ground water as well as

escaping of contaminants to surface water sources.

4. Regulating the level of nutritional material liquefied in water and suitable corrections to

meet the requirements of the vegetation

5. Quality crops for wastewater attribute.

6. Expulsion of growth inhibiting liquefied materials and poisons into food chain.

OBJECTIVE OF STUDY

Evaluation of present status of the waste water management of SBT campus.

To identify the problems related to STP of SBT campus.

To characterize physical and chemical properties of the Wastewater being generated in

SBT campus.

Evaluation of the fate of the wastewater being generated in SBT campus.

The overall water management objectives of wastewater treatment are associated with the

removal of pollutants and the protection and preservation of our natural water resources. Specific

concern is protection of human health by the destruction of pathogenic organisms present in

wastewater prior to treated effluent being discharged to receiving bodies.

MATERIALS AND METHOD4,5,6

Evaluation of Current Status of SBT Campus

In the subsequent section a brief methodology of evaluating the present status has been discuss.

Study Area (SBT Campus)

The college is spread over 30 acres of land. It is nearest to the main Railway Station and Central

Bus Stand among all the engineering colleges in Jaipur City. College has all the facilities in the

campus itself. SBTC has well furnished separate hostel for boys and girls. In the campus to

accommodate 400 boys and 150 girls and have pleasant surrounding

IJSRR 2013, 2(1) Special Issue April May 2013

Page124

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl., 122- 133

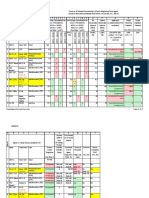

Demographic Study

Population data of academic building, workshop, girls hostel, boys hostel, staff quarters, guest

house and canteen is given in table 3.1.

Sl. No.

Table 3.1 Population with the name of places

Name of Building

Population

Girls hostel

105

Boys hostel

350

Department

1754

Guest House

21

Staff quarters

11

Canteen

Workshop

Hostel mesh

17

TOTAL

2270 persons

An overview on Sewage Treatment Plant of SBT Campus:

Fig: A photo of Sewage Treatment Plant at Sri Balaji Technical Campus

IJSRR 2013, 2(1) Special Issue April May 2013

Page125

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl., 122- 133

Sewage Treatment Plant has following technical steps:

First Storage Tank:

This has 1.25 Lacks liter capacity with two air blower inlet

It supports both aerobic respirations of microbes as well as removal of smell.

This collects waste water of Sri Balaji Technical campus.

Inlet of waste water varies with season and semester working-holiday calendar schedule.

Aeration Tank:

There are two aeration tanks with 35 KLD capacities.

Both are connected to each-other with PVC pipe half meter below from top of the tank

It contains air blower (Everest company) inlet for aeration

It supports both aerobic respirations of microbes as well as removal of smell.

Second aeration tank leads their aerated wastewater to the settling tank

Settling Tank:

It takes aerated water from second aeration tank by inlet opening 1 m from bottom.

It make possible to settle to settelable partical and this is enhanced with tube settler tank

It takes 1-1.5 hr to reach their outlet opening through tube settler

Second Storage Tank:

It stores water for extra feeding and leads to fine filter tank

Give another chance to settle the practical which are remains after settling tank.

Fine Filter with Pump:

It clears the water from fine particle size varies from 1 to 0.5 mm.

It creates pressure to send the purified water to the agricultural & gardening land.

Sludge Disposal:

20-25 kg sludge have to dispose every day which has been stored, dried and used as

manure as good practice in agriculture.

PHYSICAL ANALYSIS 2, 5

I.

II.

Temperature: this is measured by thermometer just after collecting sample.

Color: The method is useful in the field by comparing the color of sample with a

comparator. When viewed by transmitted light through a depth of several feet, pure water

exhibits a light blue color which may be altered by the presence of organic matter to

greenish blue, green, greenish yellow, yellow or brown. Colour is removed to make water

IJSRR 2013, 2(1) Special Issue April May 2013

Page126

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl., 122- 133

suitable for general and industrial applications. In such a case, an instrumental method is

useful. Colour expressed in terms of Pt/Co standard unit.

III.

Total Solid: This is done by the evaporation method, i.e. Residue left after the

evaporation and subsequent drying in oven at specific temperature 103-105C of a known

volume of sample are total solids. Total solids include Total suspended solids (TSS)

and Total dissolved solids (TDS) .

CHEMICAL ANALYSIS2, 3, 5

I.

pH: In this is study the pH of all sample are measured by electrometric method which is

the electromotive force (emf) of a cell comprising of an indicator electrode (an electrode

responsive to hydrogen ions such as glass electrode) immersed in the test solution and a

reference electrode (usually a calomel electrode).

II.

BOD: The test is mainly a bio-assay procedure, it is necessary to provide standard

conditions of temperature, nutrient supply, pH (6.5-7.5), adequate population of

microorganisms and absence of microbial-growth-inhibiting substances. Generally,

temperature is controlled at 20C and the test is conducted for 5 days, as 70 to 80% of the

carbonaceous wastes are oxidized during this period. The test can be performed at any

other temperature provided the correlation between BOD5 20 C is established.

III.

Total Hardness: This is accomplished by titration method which is EDTA method.

Where phenolphthalein is used as indicator.

IV.

NO3: This is measured by Spectrophotometer, for use at 220nm and 275nm with

matched silica cells of 1cm or longer light path. Nitrate is determined by measuring the

absorbance at 220nm in sample containing 1mL of hydrochloric acid (1N) in 100mL

sample. The concentration is calculated from graph from standard nitrate solution in

range 1-11mg/L.

V.

Fluoride (F-): This is measured by Ion selective electrode method, when the fluoride

electrode is dipped in sample whose concentration is to be measured, a potential is

established by the presence of fluoride ions by any modern pH meter having an expanded

millivolt scale.

VI.

Conductivity: This method is used to measure the conductance generated by various

ions in the solution/water. Rough estimation of dissolved ionic contents of water sample

can be made by multiplying specific conductance (in mS/cm) by an empirical factor

IJSRR 2013, 2(1) Special Issue April May 2013

Page127

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl., 122- 133

which may vary from 0.55 to 0.90 depending on the soluble components of water and on

the temperature of measurement.

RESULT AND DISCUSSION

Physical Characterizations:

I.

Temperature: All 15 days sample reveals the following graphical fluctuation in which

mean value have been shown which is the minor change in respect of the Indian standard.

Temperature

30

25

20

15

10

5

0

Temperat

ure

Graph 1: Comparative graphs for Temperature

*IW is for Irrigated Water

*DW is for Drinking Water

*Experimental Data is a value calculated in lab

The above result of Temperature shows the slightly higher temperature of the treated

water by the Sewage Treatment Plant which indicates the lack of optimum detention time

for aerobic respiration.

II.

Color: Comparator shows the color of treated water is resemble with brownish color

which indicates that the incomplete the work of either settling or aerobic digestion by the

aerobic microbes.

III.

Total Solid: The experimental data shows the near 50% reduction in the Total Solid of

Treated Wastewater. It can be improved by the increasing the settling time.

IJSRR 2013, 2(1) Special Issue April May 2013

Page128

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl., 122- 133

Total Solid

2500

2000

1500

1000

500

0

Total Solid

Graph 2: Comparative graphs for Total Solid

Chemical Characterizations:

I.

pH: Experimental value reveals the higher value of pH than standards. Which indicates

the treated water is slightly saline. It is due to the presence of basic component which

may not be degraded by the microbes due to lack of time in aerobic tank. Chemicals can

be added to decrease salt load or neutralizing by remixing the sludge with more acidic

waste can be a solution.

pH

7

6

5

4

3

2

1

0

pH

Graph 3: Comparative graphs for pH

IJSRR 2013, 2(1) Special Issue April May 2013

Page129

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl., 122- 133

II.

BOD: Experimental data shows the low degradation in BOD value comparison with

drinking water data. Retention time of aerobic tank should be more to reduce the value of

BOD. But in case it is used for irrigation purpose it is in permissible limit.

B.O.D

120

100

80

60

40

20

0

B.O.D

Graph 4: Comparative graphs for BOD

I.

Total Hardness: Experimental data shows that it can be used for irrigation purpose since

it is in permissible limit but for drinking water it should be more lower.

Total Hardness

360

350

340

330

320

310

300

290

280

270

Total

Hardness

Graph 5: Comparative graphs for Total Hardness

II.

Nitrate (NO3-): The experimental data shows the nearly complete degradation of NO3. It

has shown good result during microbial process in such a given retention time.

IJSRR 2013, 2(1) Special Issue April May 2013

Page130

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl., 122- 133

NO3

25

20

15

10

5

0

NO3

Graph 6: Comparative graphs for NO3

III.

Fluoride (F-): Experimental value reveals the presence of Fluoride which indicates the

no specific treatment has been done for the fluoride removal.

Fluoride

4

3.5

3

2.5

2

1.5

1

0.5

0

Fluoride

Graph 7: Comparative graphs for Fluoride

IV.

Conductivity: The experimental data reveals that the high value of the conductance of

the sample which mean to be presence of organic or inorganic ion which needs more time

to degrade by the microbes.

IJSRR 2013, 2(1) Special Issue April May 2013

Page131

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl., 122- 133

Conductivity

240

230

220

210

200

190

180

Conductivit

y

Graph 8: Comparative graphs for Conductivity

CONCLUSION

Sewage Treatment Plant of Sri Balaji Technical Campus can improve their efficiency by taking

the followings steps:

1.

2.

3.

4.

5.

By installing the Primary and Secondary Clarifier

By increasing the settling time

By using Disinfection method

The Disposal of sludge of the STP as Fertilizer in irrigation

Neutralization should be done by remixing the sludge with more acidic waste.

This project can improve the water scarcity challenge near by the college area especially during

summer season. It might full fill the requirement of Drinking water after reverse osmosis which

will be considered under the Indian standards

Approximately 4000 people get benefited now which will increase with time So it is required to

pay attention on the quality of treated water of Sewage Treatment Plant water of Sri Balaji

Technical Campus.

REFFERENCES

1. Campos, J.R., E. Foresti and R.D.P. Camacho, Anaerobic treatment in the food

processing industry: Two case studies, Water Science Technology. 1986; 18:87-97.

2. G.D. 188/2002 - Annexe 3. Normative concerning pollutant loading limits for industrial

and municipal wastewater at discharging in natural receivers, NTPA-001/2002;

3. Sayed, S.K.I., J. van der Zanden, R. Wijffels and G. Lettinga, Anaerobic degradation of

the various fractions of slaughterhouse wastewater. Biological Wastes. 1988; 23:117-142.

4. Tritt, W.P. and F. Schuchardt, Materials flow and possibilities of treating liquid and solid

wastes from slaughterhouses in Germany. Bioresource Technology. 1992; 41:235-245.

IJSRR 2013, 2(1) Special Issue April May 2013

Page132

Bhagat Suraj Kumar et al., IJSRR 2013, 2(1) Suppl., 122- 133

5. Dague, R.R., R.F. Urell and E.R. Krieger, Treatment of pork processing wastewater in a

covered anaerobic lagoon with gas recovery. In Proceedings of the 44th Industrial Waste

Conference, Ann Arbor, MI: Ann Arbor Science; 1990; 815-823.

6. Guide Manual of water and wastewater analysis by Central Pollution Control Board, New

Delhi.

7. APHA. Standard Methods for the Examination of Water and Wastewater. Washington.

DC: American Public Health Association. 1992;

8. M. Gopalakrishnan, Secretary General, ICID, President IWRS & NDC-WWC

9. AOAC., Official Methods of Analysis of the Association of Official Analytical

Chemists., Arlington VA: Association of Official Analytical Chemists1984;

10. Banu C., Food Industry Engineer Book, Tehnical Publishing House, Bucharest. 2002,

11. Bara V. One C., Hygiene Guide in Food Units, University of Oradea Publishing House

2008;

12. G.D. 188/2002 Annexe 2. Normative regarding conditions of wastewater discharging in

municipal sewer and in plant units, NTPA-002/2002;

13. Municipal Wastewater Treatment Plant Energy Baseline Study by M/J Industrial

Solutions San Francisco, CA 94122 in 2012

IJSRR 2013, 2(1) Special Issue April May 2013

Page133

Vous aimerez peut-être aussi

- Water 02 00101Document19 pagesWater 02 00101vk100Pas encore d'évaluation

- Benefits of Cool PavementsDocument10 pagesBenefits of Cool PavementsKomali Narasimha ReddyPas encore d'évaluation

- Determine The inDocument3 pagesDetermine The inKomali Narasimha ReddyPas encore d'évaluation

- Field Density Tests: Volume of Hole (Sand Method)Document1 pageField Density Tests: Volume of Hole (Sand Method)Komali Narasimha ReddyPas encore d'évaluation

- Field Density Test by Sand Replacement MethodDocument5 pagesField Density Test by Sand Replacement Methodngo_truong7820041757100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Conceptual FrameworkDocument24 pagesConceptual Frameworkmarons inigoPas encore d'évaluation

- MMW FinalsDocument4 pagesMMW FinalsAsh LiwanagPas encore d'évaluation

- Feasibility StudyDocument47 pagesFeasibility StudyCyril Fragata100% (1)

- Computer Portfolio (Aashi Singh)Document18 pagesComputer Portfolio (Aashi Singh)aashisingh9315Pas encore d'évaluation

- Cisco CMTS Feature GuideDocument756 pagesCisco CMTS Feature GuideEzequiel Mariano DaoudPas encore d'évaluation

- SD-SCD-QF75 - Factory Audit Checklist - Rev.1 - 16 Sept.2019Document6 pagesSD-SCD-QF75 - Factory Audit Checklist - Rev.1 - 16 Sept.2019Lawrence PePas encore d'évaluation

- Inventarisasi Data Kondisi Jalan Ke Dalam Aplikasi Sistem Informasi Geografis (Sig)Document10 pagesInventarisasi Data Kondisi Jalan Ke Dalam Aplikasi Sistem Informasi Geografis (Sig)Wiro SablengPas encore d'évaluation

- S2 Retake Practice Exam PDFDocument3 pagesS2 Retake Practice Exam PDFWinnie MeiPas encore d'évaluation

- 00 CCSA TestDocument276 pages00 CCSA TestPedro CubillaPas encore d'évaluation

- Restructuring Egypt's Railways - Augst 05 PDFDocument28 pagesRestructuring Egypt's Railways - Augst 05 PDFMahmoud Abo-hashemPas encore d'évaluation

- Clean Agent ComparisonDocument9 pagesClean Agent ComparisonJohn APas encore d'évaluation

- ROM Flashing Tutorial For MTK Chipset PhonesDocument5 pagesROM Flashing Tutorial For MTK Chipset PhonesAriel RodriguezPas encore d'évaluation

- What is zone refining processDocument1 pageWhat is zone refining processKeshav MadanPas encore d'évaluation

- Childrens Ideas Science0Document7 pagesChildrens Ideas Science0Kurtis HarperPas encore d'évaluation

- MORTGAGE Short NotesDocument11 pagesMORTGAGE Short Noteshamzatariq015Pas encore d'évaluation

- Injection Timing (5L) : InspectionDocument2 pagesInjection Timing (5L) : InspectionaliPas encore d'évaluation

- Benjie Reyes SbarDocument6 pagesBenjie Reyes Sbarnoronisa talusobPas encore d'évaluation

- Fiera Foods - Production SupervisorDocument1 pageFiera Foods - Production SupervisorRutul PatelPas encore d'évaluation

- Ali ExpressDocument3 pagesAli ExpressAnsa AhmedPas encore d'évaluation

- Modified Release Drug ProductsDocument58 pagesModified Release Drug Productsmailtorubal2573100% (2)

- IP68 Rating ExplainedDocument12 pagesIP68 Rating ExplainedAdhi ErlanggaPas encore d'évaluation

- 2002, Vol.86, Issues 4, Hospital MedicineDocument221 pages2002, Vol.86, Issues 4, Hospital MedicineFaisal H RanaPas encore d'évaluation

- Expressive Matter Vendor FaqDocument14 pagesExpressive Matter Vendor FaqRobert LedermanPas encore d'évaluation

- FBCA Biomarkers and ConditionsDocument8 pagesFBCA Biomarkers and Conditionsmet50% (2)

- Key ssl101 Academic Skills For University Success ssl101cDocument196 pagesKey ssl101 Academic Skills For University Success ssl101cHùng NguyễnPas encore d'évaluation

- DSE61xx Configuration Suite Software Manual PDFDocument60 pagesDSE61xx Configuration Suite Software Manual PDFluisPas encore d'évaluation

- Socially Responsible CompaniesDocument2 pagesSocially Responsible CompaniesItzman SánchezPas encore d'évaluation

- Modern Indian HistoryDocument146 pagesModern Indian HistoryJohn BoscoPas encore d'évaluation

- A General Guide To Camera Trapping Large Mammals in Tropical Rainforests With Particula PDFDocument37 pagesA General Guide To Camera Trapping Large Mammals in Tropical Rainforests With Particula PDFDiego JesusPas encore d'évaluation

- Ryerson EthicsDocument20 pagesRyerson EthicssinghbabaPas encore d'évaluation