Académique Documents

Professionnel Documents

Culture Documents

NDE Associates, Inc. - Ultrasonic Testing - Phased Array

Transféré par

aldeanucu32030 évaluation0% ont trouvé ce document utile (0 vote)

93 vues2 pagesphased array

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentphased array

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

93 vues2 pagesNDE Associates, Inc. - Ultrasonic Testing - Phased Array

Transféré par

aldeanucu3203phased array

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

NDE Associates, Inc.

- Ultrasonic Testing - Phased Array

Phased Array Ultrasonic Testing (PAUT)

Terms of Use

PAUT for Weld Inspections

Home

NDT TRAINING

UT- Ultrasonics

ET - Eddy Current

PT - Liquid Penetrant

MT - Magnetic Particle

VT - Visual

Research

Publications

Clients

Personnel

Employment

About Us

Contact Us

Terms of Use

SERVICES OFFERED

NDE Associates offers the following services for Phased Array inspections

Phased Array for Weld Inspections

Phased Array of Complex Components

Phased Array for Defect Sizing

"Ultrasonic Phased Arrays for Weld Testing",

Paper Copyright by Materials Evaluation,

ASNT, Columbus, Ohio.

Phased Array in Lieu of Radiography

Phased array technology offers an attractive option to perform UT in lieu of

radiography. This main advantage being that phased array inspection does not

interfere with surrounding work. Radiography requires barricading a perimeter during

the exposures.

Why use Ultrasonic Phased Arrays ?

Unlike conventional and automated ultrasonic testing, which is performed for fixed

angles of 45, 60 and 70 degrees, phased array testing can cover all angles in this

range. This is significant as a single phased array inspection can cover all angles from

40 to 75 degrees and displays the image in real time. The real time image is direct

superimposition of the ultrasonic illumination on the test piece and is easy to

interpret. Using swept angle S-scans, PAUT requires smaller surface distance for

inspection compared to AUT or manual UT. PAUT can cover a large cross-section of the

test piece from a single probe location. On the contrary, AUT either requires raster

scanning or multiple probes placed over a range of surface distance to cover the entire

cross-section of the test piece. When properly used, phased arrays can be used on all

ultrasonic applications and result in a highly reliable NDT inspection.

Phased Array Tests on Weld flaws

We have tested the capability of phased arrays for detection of defects in weld test

samples. These samples include plate and pipe sections. Weld flaws in these samples

include toe cracks, center line crack, LOF, LOP, slag and porosity. Tests were

conducted using two different systems. Test results showed that both systems

successfully detected all the defect types. Defects were definitely easy to detect and

interpret with the phased arrays compared to the conventional A-Scan machine proving

the reliability of phased arrays for weld inspection. For further reading see "Ultrasonic

Phased Arrays for Weld Testing", Paper Copyright by Materials Evaluation, ASNT,

Columbus, Ohio.

ID Crack detected on 0.5 inch thick plate

vee weld.

Phased Array Testing of Butter Welds

Butter welds are commonly used for subsea applications. These can include both carbon

steel and A625 butter welds. The most common flaw in butter welds is lack of fusion

(LOF) between the beads. These welds can be easily inspected using phased arrays. The

inspection is done by scanning a PAUT probe from the ID surface of the pipe. Refracted

shear waves are used for carbon steel butter welds and A625 welds are inspected using

refracted L-waves. L-waves are also used when the ID has a A625 clad. The technique

reliably detects flaws in butter welds.

LOF detected on 0.5 inch thick 8 inch dia

pipe.

PAUT Inspection Technique. The probe

mounted on a radiused wedge is scanned

from the pipe ID surface.

Indications detected by PAUT in butter

welds verified by Liquid Penetrant Testing

Crack sizing with Phased Arrays.

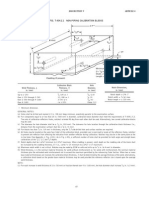

Accurate sizing of flaws requires a small focal spot size at the defect location. The

three figures above show improvement in sizing with increased probe aperture: 12 mm,

18 mm and 24 mm. Probe frequency is 5MHz. Accurate flaw sizing requires probes

with high frequencies and large apertures. As a rule of thumb for flaw sizing, the

phased array active aperture should at least be 0.4 times the part thickness and a

preferred frequency of 5 MHz. Therefore, to inspect a 2 inch (50 mm) plate, the

active aperture of the probe should be at least 20 mm. Smaller probes will result is

large beam spread and over sizing sizing of flaws. (Note: Active aperture is the element

size x no. of elements that are active, eg: a probe with sixteen 0.75 mm elements has a

active aperture of 12 mm. In case, only 12 consecutive elements are used, the active

aperture drops to 9 mm )

http://www.nde.com/phased_array_applications.htm[22/07/2013 8:46:56]

Inspection of Turbine Steam Chest for

thermal fatigue cracking. Instrument: Phasor

NDE Associates, Inc. - Ultrasonic Testing - Phased Array

Improvement in Flaw Sizing with increased PA Aperture (Top Left) Root Crack - 3 mm

(0.120") (Top right) 5 MHz, 12 mm aperture. Flaw shown by dark black lines is oversized

to almost double its size. (Bottom left) 5 MHz, 12 mm aperture. (Bottom right) 5 MHz,

24 mm aperture. Flaw correctly sized.

See also PA Technology

NDE Associates, Inc.

515 Tristar Drive

Webster, TX 77598

Phone: 281 -488 -8944

Fax: 281 -488 -8485

http://www.nde.com/phased_array_applications.htm[22/07/2013 8:46:56]

Vous aimerez peut-être aussi

- Muscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeDocument4 pagesMuscle and Fitness Hers Features Elite Lifestyle Chef Carlo FilipponeCarlo FilipponePas encore d'évaluation

- Profile Radiography Article Estimationof CorrosionDocument10 pagesProfile Radiography Article Estimationof Corrosioncoolguy12345Pas encore d'évaluation

- Corrosion Mapping With Phased Array UltrasonicsDocument27 pagesCorrosion Mapping With Phased Array UltrasonicsIvan MauricioPas encore d'évaluation

- Time of Flight Diffraction (Tofd) Technique - Asme VDocument5 pagesTime of Flight Diffraction (Tofd) Technique - Asme VAngelTinocoPas encore d'évaluation

- Ultrasonic Matrix ArrayDocument10 pagesUltrasonic Matrix ArrayMohsin IamPas encore d'évaluation

- QUSE PA Crack Sizing Test Procedure API UT 11 May 2017Document12 pagesQUSE PA Crack Sizing Test Procedure API UT 11 May 2017solrac4371100% (2)

- Ost Specifications State A Requirement For Conducting This Check, But Do Not Provide A ProcedureDocument6 pagesOst Specifications State A Requirement For Conducting This Check, But Do Not Provide A ProcedureshifaPas encore d'évaluation

- Lesson 3 - IsO 9712Document13 pagesLesson 3 - IsO 9712Abdelaziz AbdoPas encore d'évaluation

- Introduction To Eddy Current TestingDocument26 pagesIntroduction To Eddy Current TestingvibinkumarsPas encore d'évaluation

- Product TechnologyDocument138 pagesProduct TechnologyRaja SekarPas encore d'évaluation

- ACFM Applications1Document12 pagesACFM Applications1naoufel1706Pas encore d'évaluation

- Qualification Process For Phased Array UT Using DNV RP-F118Document12 pagesQualification Process For Phased Array UT Using DNV RP-F118aztec20100% (1)

- High Temperature Ultrasonic ScanningDocument7 pagesHigh Temperature Ultrasonic ScanningscribdmustaphaPas encore d'évaluation

- Small Diameter Tube and Pipe Inspection With Phased Array PDFDocument7 pagesSmall Diameter Tube and Pipe Inspection With Phased Array PDFAlanka PrasadPas encore d'évaluation

- Toft Method For Sizing and Detection BSEN583-6 PDFDocument19 pagesToft Method For Sizing and Detection BSEN583-6 PDFThe Normal HeartPas encore d'évaluation

- Phased Array CiorauDocument9 pagesPhased Array Ciorausolrac4371Pas encore d'évaluation

- Lrut Teletest Focus - TwiDocument6 pagesLrut Teletest Focus - TwiJaya DiPas encore d'évaluation

- Advanced NDTEquipmentsDocument4 pagesAdvanced NDTEquipmentsshamsPas encore d'évaluation

- API UT21 ThicknessProcedure 20190304Document7 pagesAPI UT21 ThicknessProcedure 20190304michaelPas encore d'évaluation

- MFL Compendium 002Document59 pagesMFL Compendium 002kingston67% (3)

- Proc. For Radiographic Profile Thk. MeasurementDocument7 pagesProc. For Radiographic Profile Thk. MeasurementSergey KichenkoPas encore d'évaluation

- Ultrasonic Phased Array Technique For Austenitic Weld Inspection PDFDocument4 pagesUltrasonic Phased Array Technique For Austenitic Weld Inspection PDFRAFAEL ANDRADEPas encore d'évaluation

- Earth Loop ImpedanceDocument5 pagesEarth Loop ImpedanceKaranjaPas encore d'évaluation

- NDT Basics PresentationsDocument154 pagesNDT Basics Presentationskirans60100% (1)

- TOFDDocument14 pagesTOFDaliextoma100% (1)

- Industrial radiography A Complete Guide - 2019 EditionD'EverandIndustrial radiography A Complete Guide - 2019 EditionPas encore d'évaluation

- Rms Auto Ut Corrosion Mapping PDFDocument6 pagesRms Auto Ut Corrosion Mapping PDFSangeeth Kavil PPas encore d'évaluation

- Transient Electromagnetic-Thermal Nondestructive Testing: Pulsed Eddy Current and Transient Eddy Current ThermographyD'EverandTransient Electromagnetic-Thermal Nondestructive Testing: Pulsed Eddy Current and Transient Eddy Current ThermographyÉvaluation : 5 sur 5 étoiles5/5 (1)

- Application of Phased Array For Corrosion Resistant Alloy (CRA) WeldsDocument6 pagesApplication of Phased Array For Corrosion Resistant Alloy (CRA) WeldsKevin HuangPas encore d'évaluation

- PAUT of ''CRA WELDSDocument7 pagesPAUT of ''CRA WELDSDurgamadhaba Mishra100% (1)

- Postoperative Care in Thoracic Surgery A Comprehensive GuideDocument397 pagesPostoperative Care in Thoracic Surgery A Comprehensive GuideΑΘΑΝΑΣΙΟΣ ΚΟΥΤΟΥΚΤΣΗΣ100% (1)

- Liquid Penetrant Testing Module 3Document5 pagesLiquid Penetrant Testing Module 3mujjamilPas encore d'évaluation

- 220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsDocument34 pages220hp Caterpillar 3306 Gardner Denver SSP Screw Compressor DrawingsJVMPas encore d'évaluation

- PA in Lieu of RT - CurtisDocument21 pagesPA in Lieu of RT - CurtisDennis ChaiPas encore d'évaluation

- 9 Data Processing of Tofd FilesDocument6 pages9 Data Processing of Tofd FilesPuneet Vikram SinghPas encore d'évaluation

- How To Calculate AWS D1.1 Indication Rating - LinkedInDocument6 pagesHow To Calculate AWS D1.1 Indication Rating - LinkedInAhmed LepdaPas encore d'évaluation

- 7 GinzelDocument12 pages7 GinzelMahade Hasan Dipu100% (1)

- Brief On RFET Based Systems & ServicesDocument3 pagesBrief On RFET Based Systems & ServicesKollabo SysPas encore d'évaluation

- Phased ArrayDocument8 pagesPhased Arraysankaran_muthukumarPas encore d'évaluation

- Eddy Current Array Technology For The Inspection of Aircraft and EngineDocument37 pagesEddy Current Array Technology For The Inspection of Aircraft and EnginealadinsanePas encore d'évaluation

- Small Diameter Tube and Pipe Inspection With Phased Array PDFDocument7 pagesSmall Diameter Tube and Pipe Inspection With Phased Array PDFAlanka PrasadPas encore d'évaluation

- 2008 Development of A Procedure For The Ultrasonic Examination of Nickel LNG Storage Tank Welds Using Phased Array TechnologyDocument5 pages2008 Development of A Procedure For The Ultrasonic Examination of Nickel LNG Storage Tank Welds Using Phased Array Technologyநந்த குமார் சம்பத் நாகராஜன்Pas encore d'évaluation

- Thickness Gauging Level 2 (Questions & Answers)Document3 pagesThickness Gauging Level 2 (Questions & Answers)kingston100% (2)

- Sizing Piping Calibration Blocks For ASME V: Holloway NDT & Engineering IncDocument5 pagesSizing Piping Calibration Blocks For ASME V: Holloway NDT & Engineering IncJulio SaintDLCPas encore d'évaluation

- Rotoscan General and Technical DataDocument15 pagesRotoscan General and Technical DataElsayed AbdeenPas encore d'évaluation

- Ultrasonic Testing - Wikipedia PDFDocument26 pagesUltrasonic Testing - Wikipedia PDFKarthicWaitingPas encore d'évaluation

- Prxnrnant Testtng: Buane & Ii T P O'NeillDocument6 pagesPrxnrnant Testtng: Buane & Ii T P O'NeillAzeem ShaikhPas encore d'évaluation

- Paut Calibration Summary Both-Single Side (CS & SS)Document20 pagesPaut Calibration Summary Both-Single Side (CS & SS)prabhu_trichyPas encore d'évaluation

- A Study On HOMC Guided Waves in Industrial PipesDocument40 pagesA Study On HOMC Guided Waves in Industrial PipesParas ThakurPas encore d'évaluation

- 1100 Gorman RT-UT Presentation For CTMS Oct 07Document29 pages1100 Gorman RT-UT Presentation For CTMS Oct 07Sagar NaduvinamaniPas encore d'évaluation

- Karl Kraft's 2014 Level III BrochureDocument2 pagesKarl Kraft's 2014 Level III Brochureviller_lpPas encore d'évaluation

- Floormap3d MFL Tank Inspection PDFDocument4 pagesFloormap3d MFL Tank Inspection PDFassurendran0% (1)

- Ultrasonic Inspection 2Document21 pagesUltrasonic Inspection 2pktienPas encore d'évaluation

- Bevel Information Bevel Data Table BevelDocument3 pagesBevel Information Bevel Data Table BevelJ.CarrascoPas encore d'évaluation

- Guia Calibracion TofdDocument47 pagesGuia Calibracion Tofdinspeccion_179116669100% (2)

- BLOQUEDocument1 pageBLOQUEAlvaro Alexis Mendoza PradaPas encore d'évaluation

- Dye Penetration TestDocument66 pagesDye Penetration Testezarul fitri100% (1)

- CIVA NDT SoftwareDocument8 pagesCIVA NDT SoftwareBala KrishnanPas encore d'évaluation

- Time of Flight Diffraction - An Alternative To Radiography For Examination of Thick Walled Stainless Steel WeldmentsDocument6 pagesTime of Flight Diffraction - An Alternative To Radiography For Examination of Thick Walled Stainless Steel WeldmentsKhafdi99Pas encore d'évaluation

- Formulas For Nondestructive TestingDocument6 pagesFormulas For Nondestructive Testinggokulnath81Pas encore d'évaluation

- MX2 Training Program 10G VerifyExitAngleDelay On IIWDocument21 pagesMX2 Training Program 10G VerifyExitAngleDelay On IIWANH TAI MAIPas encore d'évaluation

- NDT of CompositeDocument24 pagesNDT of CompositePavana KumaraPas encore d'évaluation

- Pre-Almond Supplemental Forage Improves Colony SurDocument11 pagesPre-Almond Supplemental Forage Improves Colony Suraldeanucu3203Pas encore d'évaluation

- Nutritional Status of Honey Bee (Apis Mellifera L.) Workers Across An Agricultural Land-Use GradientDocument11 pagesNutritional Status of Honey Bee (Apis Mellifera L.) Workers Across An Agricultural Land-Use Gradientaldeanucu3203Pas encore d'évaluation

- Landscape Factors Influencing Honey Bee Colony BehDocument16 pagesLandscape Factors Influencing Honey Bee Colony Behaldeanucu3203Pas encore d'évaluation

- The Origin of Honey Bees, Life: A Viewpoint: Journal of Entomology and Zoology Studies January 2015Document4 pagesThe Origin of Honey Bees, Life: A Viewpoint: Journal of Entomology and Zoology Studies January 2015aldeanucu3203Pas encore d'évaluation

- Of The Nuclear Safety Standards Commission (KTA)Document34 pagesOf The Nuclear Safety Standards Commission (KTA)aldeanucu3203Pas encore d'évaluation

- Evaluation of ASME Section XI Reference Level Sensitivity For Initiation of Ultrasonic Inspection Examination PDFDocument78 pagesEvaluation of ASME Section XI Reference Level Sensitivity For Initiation of Ultrasonic Inspection Examination PDFaldeanucu3203100% (2)

- Hydrolysis and Fermentation of Sweetpotatoes For Production of Fermentable Sugars and EthanolDocument11 pagesHydrolysis and Fermentation of Sweetpotatoes For Production of Fermentable Sugars and Ethanolkelly betancurPas encore d'évaluation

- Notice of Privacy Practices (Generic)Document3 pagesNotice of Privacy Practices (Generic)cecilled_08Pas encore d'évaluation

- Biology Q PDFDocument9 pagesBiology Q PDFsumon chowdhuryPas encore d'évaluation

- Group 5 - Ethical PrinciplesDocument11 pagesGroup 5 - Ethical Principlesvirgo paigePas encore d'évaluation

- Chapter One - FiveDocument118 pagesChapter One - FivePrecious AnthonyPas encore d'évaluation

- An Energy Saving Guide For Plastic Injection Molding MachinesDocument16 pagesAn Energy Saving Guide For Plastic Injection Molding MachinesStefania LadinoPas encore d'évaluation

- Maya Mendez ResumeDocument2 pagesMaya Mendez Resumeapi-520985654Pas encore d'évaluation

- ომარ ხაიამი - რობაიები (პარალელური ტექსტები)Document31 pagesომარ ხაიამი - რობაიები (პარალელური ტექსტები)გენო მუმლაძეPas encore d'évaluation

- f2607-#### f2607 20191203 111644Document2 pagesf2607-#### f2607 20191203 111644คุณชายธวัชชัย เจริญสุขPas encore d'évaluation

- Doingwell Coaching ServicesDocument4 pagesDoingwell Coaching ServicesPaweł PawełPas encore d'évaluation

- Constantino V MendezDocument3 pagesConstantino V MendezNīc CādīgālPas encore d'évaluation

- Faraz Chem ProjectDocument13 pagesFaraz Chem ProjectFaraz AhmedPas encore d'évaluation

- Index Medicus PDFDocument284 pagesIndex Medicus PDFVania Sitorus100% (1)

- 2015 12 17 - Parenting in America - FINALDocument105 pages2015 12 17 - Parenting in America - FINALKeanePas encore d'évaluation

- Electric Field Summary NotesDocument11 pagesElectric Field Summary NotesVoyce Xavier PehPas encore d'évaluation

- Radproduction Chapter 2-9Document276 pagesRadproduction Chapter 2-9Christian DioPas encore d'évaluation

- Varioklav Steam Sterilizer 75 S - 135 S Technical SpecificationsDocument10 pagesVarioklav Steam Sterilizer 75 S - 135 S Technical Specificationssagor sagorPas encore d'évaluation

- Tiếng AnhDocument250 pagesTiếng AnhĐinh TrangPas encore d'évaluation

- 4EVC800802-LFEN DCwallbox 5 19Document2 pages4EVC800802-LFEN DCwallbox 5 19michael esoPas encore d'évaluation

- 2020 Q2 CushWake Jakarta IndustrialDocument2 pages2020 Q2 CushWake Jakarta IndustrialCookiesPas encore d'évaluation

- 2021 Life Skills ATP Grade 5Document10 pages2021 Life Skills ATP Grade 5Koketso SekwenyanePas encore d'évaluation

- OM Hospital NEFTDocument1 pageOM Hospital NEFTMahendra DahiyaPas encore d'évaluation

- Careerride Com Electrical Engineering Interview Questions AsDocument21 pagesCareerride Com Electrical Engineering Interview Questions AsAbhayRajSinghPas encore d'évaluation

- CASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICADocument3 pagesCASE DIGEST GAISANO CAGAYAN vs. INSURANCE COMPANY OF NORTH AMERICAclairePas encore d'évaluation

- Dando Watertec 12.8 (Dando Drilling Indonesia)Document2 pagesDando Watertec 12.8 (Dando Drilling Indonesia)Dando Drilling IndonesiaPas encore d'évaluation

- Cannabis Effects On Driving SkillsDocument15 pagesCannabis Effects On Driving SkillsCharles PetersPas encore d'évaluation