Académique Documents

Professionnel Documents

Culture Documents

Glossary - Pharma Packaging Solutions

Transféré par

Ashish MittalTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Glossary - Pharma Packaging Solutions

Transféré par

Ashish MittalDroits d'auteur :

Formats disponibles

2/14/2016

Glossary|PharmaPackagingSolutions

Home

Products & Services Expert Insights

About Us

Quality

Markets

Case Studies

Community

Home Expert Insights Glossary

GLOSSARY

Medical Packaging Glossary

Pharmaceutical Terminology

Medical Packaging Glossary

As published in Packaging Digest, 9/25/2008

Adhesive:

a substance capable of the surface bonding together of materials.

AIM:

Automatic Identification Manufacturers.

AIM International

is a global affiliation of trade associations.

Algorithm:

a set of steps taken to make a desired calculation.

Alphanumeric:

character set made up of digits and letters of the

alphabet.

Ampoule:

single dosage container made from glass sealed after filling by fusing the glass neck.

ANA (UK):

Article Numbering Association.

Application weight:

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

1/17

2/14/2016

Glossary|PharmaPackagingSolutions

the amount of adhesive or other coating per unit area.

Artwork:

copy supplied for origination purposes, indicating colour separation and half-tones.

ASCII:

American Standard Code for Information Interchange (a computer code consisting of 128 alphanumeric

and control characters used for the exchange of information between computerised systems).

Aseptic packaging:

a system in which the product is sterilised before filling into pre-sterilised packs under aseptic conditions.

Auger feed:

screw feeder used to discharge known volumes of powder or paste products.

Auto discrimination:

the ability of a bar code reader system to distinguish automatically between two or more symbologies.

Bar code:

an array of parallel rectangular bars, arranged according to specific rules, to represent data in machinereadable form.

Bar code character:

a group of bars and spaces within a bar code that represent a single letter, number or character.

Bar code density:

the number of characters that are represented in a bar code per unit of length (characters per inch, cpi.).

Bar code reader:

a device used to capture the data encoded within a bar code and convert it into computer compatible

data or a human readable characters display.

Bar code symbol:

the combination of characters required by a particular symbology that makes up a scan able entity.

Batch code:

combination of characters that facilitates tracing of the product to the batch in which it was processed

(see LOT).

Bioburden:

population of viable microorganisms on an item (ref. ISO 11607:2003(E)).

Biodegradable:

degradable under natural conditions, e.g. in landfill.

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

2/17

2/14/2016

Glossary|PharmaPackagingSolutions

Blister pack:

a piece of thermoformed material bonded to flat

material to form a closure (lid).

Blister packer:

a system to fill, lid and seal blister packs.

Board:

papers equal to or greater than 220gsm.

Bond:

the union of two substrates.

Bowl feeder:

vibratory bowl used to feed components up a spiral

ramp.

Calliper:

the thickness of a sheet of board.

Carton:

a container made from folding boxboard and supplied flat for erection when filling.

Carton blank:

an unglued carton, which is glued during the filling process.

Cartonboard:

material of defined substance and thickness made from one or more layers of paper to form a rigid or

semi-rigid sheet.

Cats whisker:

the sharp pointed protrusion from a blister that can arise when using a cross cutting blade and slitter to

cut out individual packs on a form fill seal machine.

Cavity wall:

a carton or fitment where the sidewalls are constructed so as to form a hollow frame effect.

Chase:

a frame used for locking cutting forms in place.

Check character (check digit):

a character calculated from the numerical value of the other characters in the code that is used to ensure

that the code is correctly processed.

Chevron pouch:

a pouch where one end seal is in the shape of a chevron (like sergeants stripe).

Closure:

means used to close a package where no seal is formed

EXAMPLE: Repeated folding to construct a tortuous path (ref. ISO 11607:2003(E)).

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

3/17

2/14/2016

Glossary|PharmaPackagingSolutions

Closure integrity:

Condition of the closure that ensures that the closure presents a microbial barrier to at least the same

extent as the rest of the packaging (ref. ISO 11607: 2003(E)).

Compliance qualification:

Documented evidence that packaging meets the requirements for packaging for terminally sterilized

medical devices based on testing for conformity to an agreed material specification (ref. ISO 11607:

2003(E)).

Code 39 (3 of 9):

a bar code symbology that encodes 43 data elements (0-9, A-Z and 7 special characters). Each character

has 9 elements, bars have two widths.

Code 128:

a bar code symbology that encodes the complete 128 ASCII characters set. Characters are made up of

bars and spaces in three widths.

Co extrusion:

a multi-layer structure prepared by extruding a number of polymers through a single die (with tie layers

as necessary).

Cohesive failure:

failure of a bond within the adhesive itself.

Contaminants:

any unacceptable or unintended trace materials.

Corrugated board:

board consisting of one or more fluted sheets between

flat facing plies.

Crash-bottom carton:

a carton where the base panel locks in place when the

body is squared up.

Crashlock base:

a carton where the base locks in place automatically

when pressed from opposite corners.

Development:

process of refining a prototype design or process to meet established product criteria (ref. ISO 11607:

2003(E)).

Die: (i)

solid sheet or cylinder into which knives and rules are fixed to create carton shapes.

Die: (ii)

solid sheet or cylinder into which knives are fixed to create label shapes.

Die-cut labels:

labels that are cut to shape by a cutting die.

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

4/17

2/14/2016

Glossary|PharmaPackagingSolutions

Double tuck carton:

carton in the form of a sleeve, with extended side flaps that tuck in to form the end closures.

DSD:

Duales System Deutschland.

Duplex board:

a multi-ply board mainly made from mechanical pulp with a bleached chemical pulp facing layer.

EAN:

Originally European Article Number and now used to denote International Article Number and the

International Article Numbering Association.

EAN-8:

Short form, 8-digit version of the International Article Number.

EAN-13:

Full 13-digit version of the International Article Number.

Expiry date.

Expiry

(Exp) Date Nov 2001 means do not use this product after November 2001.

Failure:

event in which a component of the package does not perform one or more of its required functions

within the specified limits under specified conditions (ref. ISO 11607: 2003(E)).

Failure analysis:

logical, systematic examination of an item to identify and analyze the probability, causes and

consequences of potential and real failures (ref. ISO 11607: 2003(E)).

Field:

an area in a computer file designated for one item of data.

Film:

a non-fibrous, non-metallic flexible material available in a range of thickness.

Final package:

primary containment system in which the product is sterilized (excluding shelf cartons and shipping

containers) that protects the contents to the intended level over a specific period of time.

Note The intended level may be e.g. a barrier to physical, microbial or chemical challenges (ref. ISO 11607:

2003(E)).

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

5/17

2/14/2016

Glossary|PharmaPackagingSolutions

Flexography:

a rotary printing process that prints by the use of

flexible relief plates that directly apply the image to the

substrate.

Foil:

rolled metal in flexible sheet form. Typically this is

aluminium sheet, available in a range of thickness.

Form/fill/seal:

a system where packs are formed (typically from film or

foil), filled and closed in one continuous operation.

Gang:

the term used to describe a grouping of labels supplied

in sheet form

Gravure:

a printing process where the image is engraved

(electronically or chemically) in the form of cells in the

surface of a metal cylinder. Ink is transferred to the substrate by passage between the inked cylinder and

an impression cylinder under pressure.

Guard bars:

auxiliary characters at both ends and centre of EAN/UPC bar codes which provide reference points for

scanning and act as start/stop characters.

Gusset:

the folded inward portion of a flexible bag.

Heat-seal able film:

film that may be joined to itself or another substrate through the use of heat and pressure (without the

use of adhesives).

Heat-sealing:

joining together by using heat and pressure.

Heat-sealing adhesive:

an adhesive coating previously applied that forms a bond between two surfaces when heat and pressure

is applied.

Heat shrinking:

application of heat to shrink a band of plastics material around product.

Impulse sealing:

short rapid electrical resistance heating of metal strip or wire to seal plastics film.

Ink Jet Printing:

non-contact printing process that uses a modulated jet of ink to spray the image onto the substrate.

Label [1]:

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

6/17

2/14/2016

Glossary|PharmaPackagingSolutions

the USA Federal Food, Drug and Cosmetic Act in Section 201(k) defines "label" as a:

"display of written, printed, or graphic matter upon the immediate container of any article..."

Label [2]:

ASTM, D 996 defines label as a piece of paper or other material to be affixed to a container or article,

on which is printed a legend, information concerning the product, or addresses. It may also be printed

directly on the container.

Labeling:

the USA Federal Food, Drug and Cosmetic Act in Section 201(m) defines "labeling" as:

"all labels and other written, printed, or graphic matter (1) upon any article or any of its containers or

wrappers, or (2) accompanying such article" at any time while a device is held for sale after shipment or

delivery for shipment in interstate commerce.

Labelling:

Council Directive 92/27/EEC of March 1992 on the labeling of medicinal products for human use and on

package leaflets defines Labelling as information on the immediate or outer packaging.

Labelling System [1]:

assembly of the package and label and any supplied information on usage that is included within or in

contact with the final package (ref. ISO 11607: 2003(E)).

Labelling System [2]:

the means by which information is controlled and applied to a packaging component.

Laminate:

a material made by joining together complete surfaces of any combination of films, foils and papers.

Letterpress:

a printing process where ink is transferred from raised

areas to the substrate under pressure.

Lidding Stock:

material used to seal a blister pack.

Lithography:

a printing process in which oil based ink is transferred

from ink retaining areas on a treated plate to a

substrate. Water is used to contain the ink in the

required areas. In offset lithography the image is

transferred first to a rubber blanket and then the

substrate.

Life Cycle Analysis:

the measurement and aggregation of all factors relating

to the production, use and disposal of materials.

Manufacturer:

natural or legal person, individual or organization with the responsibility for packaging and/or sterilizing

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

7/17

2/14/2016

Glossary|PharmaPackagingSolutions

the medical device (ref. ISO 11607: 2003(E)).

Manufacturer Number:

the digits allocated by an EAN numbering authority to a labeller which, together with the prefix, item

reference and check digits, make up the standard article number.

Manufacturers joint:

the part of a case that is joined together by the manufacturer.

Metallised films:

flexible films coated with an ultra-thin layer of metal, usually aluminium.

Microbial barrier:

attribute of the packaging system that prevents the ingress of microorganisms under specified conditions

(ref. ISO 11607: 2003(E)).

Modified Atmosphere Packaging:

a process by which air in a pack is replaced with another gas.

MVTR:

Moisture Vapour Transmission Rate is the quantity of moisture transmitted (through a barrier) during a

specified period of time.

One-trip:

pack or container designed for single use only.

Over wrap:

a wrapping enclosing one or more packs.

Package integrity:

unimpaired physical condition of a final package.

Packaging compatibility:

attribute of the packaging material and/or system to allow it to achieve the required performance

without detrimental effect on the medical device (ref. ISO 11607: 2003(E)).

Packaging material:

any material used in the fabrication or sealing of a packaging system or primary package (ref. ISO 11607:

2003(E)).

Packaging system (1):

one or more packaging materials assembled into a single unit intended as part or all of a primary package

(ref. ISO 11607: 2003(E)).

Packaging system (2):

process by which one or more packaging materials are formed into a product container.

Parallel tuck carton:

a carton with both tuck ends attached to the same panel.

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

8/17

2/14/2016

Glossary|PharmaPackagingSolutions

Partial over wrap:

a wrapping partially enclosing one or more packs.

Peel strength:

the measured stress through peeling of a bonded

surface resulting in an adhesive failure.

Performance qualification:

documented evidence that packaging meets the

appropriate requirements for sterile packaging based

on testing of the particular packaging material for

compliance with the applicable requirements of this

international standard (ref. ISO 11607: 2003(E)).

Eastar

PETG

copolyester 6763, a glycol-modified polyethylene terephthalate, is a clear amorphous polymer. The

modification is made by adding a second glycol, cyclohexanedimethanol, during the polymerization

stages.

PET:

polyethylene terephthalate.

Plug:

a push fitting closure.

Plug lid:

a removable lid that is a push fit into the opening of a container.

Pouch:

a rectangular bag with three sides sealed prior to filling and closing.

Primary Pack:

the definition of this term in EN 868-1 is synonymous with the above definition of

Final Package

(ref. ISO 11607: 2003(E)).

Primary package:

sealed or closed packaging system that forms a microbial barrier, enclosing a medical device (ref. ISO

11607: 2003(E)).

Printer-slotter:

a printing machine which also converts corrugated board into cases using simple wheel or cross creasing

and punch-slotting devices.

Producer:

natural or legal person, individual or organisation with the responsibility for manufacturing the packaging

material and/or system (ref. ISO 11607: 2003(E)).

Product:

combination of both the medical device and/or additional components with the final package (ref. ISO

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

9/17

2/14/2016

Glossary|PharmaPackagingSolutions

11607: 2003(E)).

Push fit closure:

a closure, usually plastic, that is pushed into the neck or opening of a container to form a seal and is held

in place by friction.

Qualification:

documented evidence that all specified design and

performance requirements are met (ref. ISO 11607:

2003(E)).

Release coating:

coating applied to label backing paper to aid removal of

self-adhesive labels.

Release paper:

easily removed backing paper for self-adhesive labels.

Relieved area:

an area, outside the product containment zone, that is designated to remain not sealed; this is to

facilitate ease of opening.

Revalidation:

documented procedure to reconfirm an established validation (ref. ISO 11607: 2003(E)).

Reverse tuck in end carton:

carton where the end tuck flaps are extensions of opposite carton faces.

Sachet:

a small flexible package made by bonding two layers together on all four sides.

Seal:

result of joining of packaging layers.

NOTE: A seal may be created, e.g., by use of adhesives or thermal fusion (ref. ISO 11607: 2003(E)).

Seal integrity:

condition of the seal that ensures that it presents a microbial barrier to at least the same extent as the

rest of the packaging

Note: In EN 868-1 the definition of this term differs slightly (ref. ISO 11607: 2003(E)).

Seal strength:

mechanical strength of the seal (ref. ISO 11607: 2003(E)).

Self-adhesive:

an adhesive that bonds by pressure only. Used for pressure-sensitive labels.

Self-checking:

denoting a bar code system using a checking algorithm.

Shaft encoder:

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

10/17

2/14/2016

Glossary|PharmaPackagingSolutions

a device, for measuring the speed of an object, that converts this information into a series of signals,

which may be interpreted by an ink jet printer.

Shelf life:

the period of time during which a packaged product retains its minimum acceptable quality or safety.

Shrink-banding:

heat tightening of a band of plastic material, to collate goods or seal a closure (may alternatively be

achieved by moisture loss from a cellulose band).

Shrink wrapping:

over-wrapping in plastic film, which retracts when

heated to produce a tight wrap.

Skin packaging:

using vacuum to pull heat-softened plastic film tightly

over a product whilst sealing the film to an underlying

porous surface.

Start/stop character:

a bar code character included in a symbol to indicate to

the scanner the beginning and end of the code.

Sterile:

free from viable microorganisms.

NOTE: For the purposes of EN 868-1, the term sterile is defined in EN 556 (ref. ISO 11607: 2003(E)).

Sterile fluid-path packaging:

system of protective port covers and/or packaging designed to ensure sterility of the portion of the

medical device intended for contact with fluids (ref. ISO 11607: 2003(E)).

Sterile barrier system:

the means by which a manufacturer ensures that a sterilized device remains in a sterile state until used in

the manner intended. Typically such a system comprises a sealed unit surrounding the device that is an

integral part of the product. When a healthcare professional purchases a sterile medical device, sterility is

part of the product (ref. EUCOMED-ESPA Position Paper: Sterile barrier systems and Directive 94/62/EC).

Sterilization compatibility:

attributes of the packaging material and/or system that allow it to both withstand the sterilization process

and attain the required conditions for sterilization within the final package (ref. ISO 11607: 2003(E)).

Stretch wrapping;

a method of wrapping/collating product with an elastic film under tension.

Symbol length:

total length of a bar code including the quiet zones preceding the start code and following the stop code.

Symbology:

the system of representing data in a bar code.

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

11/17

2/14/2016

Glossary|PharmaPackagingSolutions

Tamper-evident closure:

a closure that incorporates a feature that indicates any unauthorised tampering or interference.

Terminally sterilized:

term for medical devices that are sterilized after being completely sealed or enclosed in at least the

primary package.

Thermal printing:

the system whereby direct heating of the paper by the print head produces an image.

Thermal transfer printing:

the system where the heating, by a print head, of an ink layer on a thin film, causes ink to be released and

transferred to a substrate.

Thermoforming:

a process where film softened by heat is forced into or

over a mould.

Thermoform/fill/seal:

a system where packs are thermoformed from a plastic

sheet; then filled and lidded in one continuous

operation.

Thermoplastic:

a plastic that softens when heated and re-hardens when

cooled.

Tyvek:

a Dupont product. Non-woven spun bonded, polyethylene sheeting with good bacteria penetration

resistance; made from very fine, high-density polyethylene fibres.

UCC:

Uniform Code Council, the American organisation that administers the UPC system in North America.

UPC:

Uniform Product Code, the American standard article number.

Use by date:

Use by Nov. 2009, means do not use this product after 31st October 2009.

User:

natural or legal person, individual or organization with the responsibility for making use of the product

(ref. ISO 11607: 2003(E)).

Vacuum pack:

a package from which the air has been withdrawn before sealing.

Vacuum packaging:

the withdrawal of air from a pack immediately prior to sealing its closure.

Validation:

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

12/17

2/14/2016

Glossary|PharmaPackagingSolutions

documented procedure for obtaining, recording and interpreting the results required to establish that a

process will consistently yield product complying with predetermined specifications (ref. ISO 11607:

2003(E)).

Pharmaceutical Terminology

As posted by Healthcare Packaging, August 15, 2007

Accelerated aging

- artificially seeing how a medical product will age without

waiting for it to age in real-time. Using heat and pressure,

the product is quicker to the shelf. The process is based on

conditions that stimulate the effects of aging on materials.

Anti-counterfeiting

- methods of ensuring the validity of products to prevent

occasions of counterfeit. Drugs can be stolen, inaccurately

reproduced, resold, or merely replaced with a placebo. This

can cause problems in brand protection, and in the health

and safety of consumers. Tamper-evident seals, unique

carton numbers, bar code printing, and RFID are methods

of product tracking that prevent counterfeiting.

CFR 21 part 11

- an FDA (US Food and Drug Administration) code of

federal regulations (CFR) issued March of 2000 requiring

electronic records and signatures for products. Importance

of keeping up-to-date with technology was stressed.

Systems validation, audit trails, time stamps, general security and archiving became requirements. The

current requirements are under constant revision as technology changes.

Child-resistant

- a way of sealing a product to prevent a child from opening it, usually in the line of pharmaceuticals or

products that would cause children harm. Packages often require a dexterity that comes with age, or a

series of opening steps that have to be read on the package.

Clinical trials

- trials done on set groups of consenting patients to determine the effects of a product. Medical research

on real humans provides the best clue into consumer reactions and they have the best results when staff

and patients follow the protocol and keep in frequent contact. Ethical and legal medical practice codes

still apply and though there are risks, there are great medical benefits as well.

Cold chain

- a temperature-controlled supply chain. Hopefully uninterrupted, its a series of storage and distribution

activities which maintain a given temperature range. Temperatures depend on the product, but many

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

13/17

2/14/2016

Glossary|PharmaPackagingSolutions

products like vaccines are ineffective if cold is not maintained. Often the range is 2-8 degrees celsius.

Combination product

- a product comprised of two or more components, drug/device, drug/biologic, or drug/device/biologic

either mixed into one entity, packaged separately but bought together as a unit, or bought separately

with the intention of using them together. An inhaler is an example, where a drug is intended to be taken

with a device, and though they are bought separately, they combine in intention.

Current good manufacturing practices (cGMP)

- regulations issued by the FDA as minimum requirements. Most countries have their own, and they

require quality systems of design, manufacture, packaging, labeling, storage, installation, and servicing of

medical devices. Going beyond samples, the entire system is expected to be up to par, and

documentation facilitates this.

Dietary supplement

- vitamins, minerals, herbs, or amino acids. Dietary substances intended to supplement the diet and

intended for ingestion in pill, capsule, tablet, powder, or liquid form. Labeled as a dietary supplement, and

not represented as real food or as a sole ingredient to a diet.

FDA recalls

- the action needed when the FDA doesn't approve of a food or drug item. If it doesn't fit into the

guidelines for safety and efficacy of pharmaceuticals, the company often will recall the item themselves,

but in serious situations the FDA will have to inform the public. Class I recalls - reasonable probability that

it'll cause injury or death. Class II - exposure may cause temporary injury. Class III - unlikely to cause

adverse health reactions, but just wrong labeling or manufacturing regulations.

Inhalers

- a medical device used to deliver medication into the body via the lungs. It's a combination product

combining a drug and a device that need to be delivered together.

Lyophilized drugs

- freeze-dried drugs. Vaccines are transformed from liquid to solid powder. This process enhances shelflife and stability of vaccines. Vapor products can be transformed directly to solid without the liquid

phase, easing production.

Medical device packaging

- wrapping, packaging, preparing a medical device for

shipping, display, and purchase. Devices, like the drugs

themselves often need certain requirements for safe

packaging, requiring sterility, shape and delicate

protection, certain temperatures, or other such

necessities. A difficult business to be in, because of the

requirements for entry and procedure.

Nutraceuticals

- refers to foods claiming to have a medicinal effect on human health. Also called functional foods. Some

examples are Flavanoids, Anti-Oxidants such as gamma linolenic acid, beta carateins, anthocyanins, etc.

OTC Products

- Over The Counter products. Medical or healthful products that can be purchased over the counter

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

14/17

2/14/2016

Glossary|PharmaPackagingSolutions

without a prescription.

Package design

- the art and technology of enclosing or protecting products for distribution, storage, sale, and use. More

specifically it is the design and layout of the package structure and labeling integrated with the products

use and necessities.

Package testing

- tests to ensure that packaged products will survive the environmental hazards of temperature, humidity,

shock, vibration, compression, altitude or impacts when shipped to customers.

Packaging automation

- the world of machinery and production behind packaging controls and information technologies.

Relating physical machinery and design imagery.

Parenterals

- medicine taken into the body or administered in a manner other than through the digestive (alimentary)

tract, as by intravenous or intramuscular injection. Total parenteral nutrition (TPN) is meant to drip

through a needle or catheter placed in a vein. TPN is used for patients who cannot or should not get their

nutrition through eating.

Patient compliance

- refers to a patient both agreeing to and then

undergoing some part of their treatment program as

advised by a medicine package, their doctor, or another

healthcare worker.

Personalized medicine

- personalized medicine would allow a doctor to

prescribe precisely the right drug at the right dose to

an individual based on that persons unique DNA. A

possibility stemming from the human genome project

that would revolutionize the healthcare packaging industry.

Process analytical technology (PAT)

- a way to approach validation for pharmaceuticals since the FDA regulations associated with CFR 21 part

11.

RFID

- Radio-frequency identification (RFID) is an automatic identification method, relying on storing and

remotely retrieving data using devices called RFID tags or transponders. The current thrust in RFID use is

in supply chain management for large enterprises. RFID increases the speed and accuracy with which

inventory can be tracked and managed thereby saving money for the business.

Risk management

- Risk management is the human activity which integrates recognition of risk, risk assessment, developing

strategies to manage it, and mitigation of risk using managerial resources. Evaluate and work to prevent

risks in the packaging field. Identify every possible risk scenario for all identified functions. Match those

scenarios with their likely effect(s). For instance, if a stopper is not placed properly in a vial (a possible

risk), the possible effects could include spilled product, product thats underweight/under dose, or

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

15/17

2/14/2016

Glossary|PharmaPackagingSolutions

product that appears to have been tampered with.

Senior friendly

- a package that is designed with the elderly in mind, perhaps easy-open for those with less agile hands,

perhaps with large-print type for those with failing vision, etc.

Sterilization

- any process that effectively kills or eliminates transmissible agents (such as fungi, bacteria, viruses and

prions) from a surface, equipment, foods, medications, or biological culture medium. Sterilization can be

achieved through application of heat, chemicals, irradiation, or filtration. Packaging medical devices and

medicines to remain sterilized is then necessary.

Tamper evident

- a device or process that makes unauthorised access to the

protected object easily detected. This may take the form of seals,

markings or other techniques. Tamper-evident design is perhaps

most visible in the area of product packaging and labelling, where it

can be vital to know that the product has not been altered since it

left the manufacturer.

Track and trace

- the process of recording the past and present whereabouts of a

shipment, as it passes through different handlers on its way to its

destination. Typical applications for Track & Trace are to identify

where a product was "diverted" from its intended course (parallel

importing), or where a fake product was introduced.

Unit - of - use packaging

- packaging designed to be taken one dose at a time, often in a blister pack, to prevent the rest of the

medication from being contaminated, or to easily keep track of how many have been taken and how

many remain. This makes patient compliance easier.

Validation

- a total process involving the identification and control of materials and processing variables that affect

the ability of a packaged device to meet its acceptance requirements. Involves knowing that the medicine

you're taking is the medicine you're supposed to be taking, and that it hasn't been tampered with.

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

16/17

2/14/2016

Glossary|PharmaPackagingSolutions

PHARMA PACKAGING SOLUTIONS

South

8654946000

South

341 JD Yarnell Industrial

Newsletter Sign Up

Sign up to stay up to date with everything at

8887009002

Parkway

Pharma.

Clinton, TN 37716

Midwest

Midwest

101 First Quality Drive

4193425010

8005337744

Shelby, OH 44875

Email

ask@pharmapacksol.com

ABOUT US

MARKETS

Email Address...

Follow on Twitter

Friend on Facebook

PRODUCTS & SERVICES

Our Story

Products

Timeline

Services

QUALITY

CASE STUDIES

Certifications

Memberships

Our Locations

EXPERT INSIGHTS

COMMUNITY

Compliance Packaging White Paper 2014

News

Innovation and Expert Tips

Media

White Papers

Events

Glossary

Sustainability

Memberships

Community Support

Awards

Copyright 2016 Pharma Packaging Soluions. All Rights Reserved. Site by designsensory.

http://www.pharmapackagingsolutions.com/expertinsights/glossary/

17/17

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Vendour Evaluation Report - JSL PDFDocument3 pagesVendour Evaluation Report - JSL PDFMitesh SinghPas encore d'évaluation

- Cosmetics Labeling Guide - FDADocument50 pagesCosmetics Labeling Guide - FDADiego Astorga Diaz LealPas encore d'évaluation

- Bayonne PackagingDocument13 pagesBayonne PackagingHariharan Alavandan100% (2)

- Steel Wire, Carbon, For General UseDocument3 pagesSteel Wire, Carbon, For General Userobert gridleyPas encore d'évaluation

- Food ProcessingDocument73 pagesFood ProcessingAnkit SawantPas encore d'évaluation

- Packaging General Requirements PDFDocument86 pagesPackaging General Requirements PDFtranngocvuongPas encore d'évaluation

- Pharmaceutical Companies in Himachal PradeshDocument25 pagesPharmaceutical Companies in Himachal PradeshAshish MittalPas encore d'évaluation

- Costco Food Safety Expectations PDFDocument27 pagesCostco Food Safety Expectations PDFJatniel GuamánPas encore d'évaluation

- General Standard For The Labelling of Prepackaged FoodDocument9 pagesGeneral Standard For The Labelling of Prepackaged FoodAubreyPas encore d'évaluation

- PackagingDocument36 pagesPackagingChandarana Zalak0% (1)

- CBLMDocument20 pagesCBLMAngee PotPas encore d'évaluation

- FMEA Training TextDocument54 pagesFMEA Training TextCHULYUN JUNGPas encore d'évaluation

- Finding The Square of The Given Number - Gr8AmbitionZDocument13 pagesFinding The Square of The Given Number - Gr8AmbitionZAshish MittalPas encore d'évaluation

- Difference Between Humidity and Relative HumidityDocument1 pageDifference Between Humidity and Relative HumidityAshish MittalPas encore d'évaluation

- How Should I Prepare For SSC CGL (Tier 1 and Tier 2) 2016 - QuoraDocument12 pagesHow Should I Prepare For SSC CGL (Tier 1 and Tier 2) 2016 - QuoraAshish MittalPas encore d'évaluation

- FAQ of Blister Packaging Machine-Jornen Machinery - Blister Machine, Blister Packaging Machine, Blister Packing Machine, Cartoner, Cartoning Machine For Pharmaceutical PackagingDocument3 pagesFAQ of Blister Packaging Machine-Jornen Machinery - Blister Machine, Blister Packaging Machine, Blister Packing Machine, Cartoner, Cartoning Machine For Pharmaceutical PackagingAshish MittalPas encore d'évaluation

- Adele 25 (Target Exclusive Deluxe Edition) (2015) Flac 2LT Torrent - FLAC Torrents - Music Torrents - ExtraTorrentDocument3 pagesAdele 25 (Target Exclusive Deluxe Edition) (2015) Flac 2LT Torrent - FLAC Torrents - Music Torrents - ExtraTorrentAshish Mittal50% (4)

- PARWANOODocument8 pagesPARWANOOAshish Mittal100% (1)

- Respiratory Stimulants, Expectorants and Anti-TussivesDocument16 pagesRespiratory Stimulants, Expectorants and Anti-TussivesAshish Mittal0% (3)

- Mechi MechiDocument15 pagesMechi MechiAshish MittalPas encore d'évaluation

- How Aluminium ROPP (Roll-On Pilfer Proof) Closures Are MadeDocument4 pagesHow Aluminium ROPP (Roll-On Pilfer Proof) Closures Are MadeAshish MittalPas encore d'évaluation

- Biopharmaceutical Classification System and Formulation DevelopmentDocument18 pagesBiopharmaceutical Classification System and Formulation DevelopmentAshish Mittal100% (1)

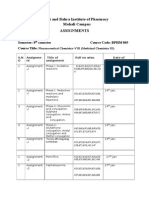

- Rayat and Bahra Institute of Pharmacy Mohali Campus AssignmentsDocument3 pagesRayat and Bahra Institute of Pharmacy Mohali Campus AssignmentsAshish MittalPas encore d'évaluation

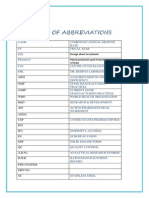

- List of Abbreviations: Aids GMP CGMP WHO R&D API Anda USP ISO IPA EU SDF QC A.R.No. B.M.R Fifo System GRN No. SSDocument2 pagesList of Abbreviations: Aids GMP CGMP WHO R&D API Anda USP ISO IPA EU SDF QC A.R.No. B.M.R Fifo System GRN No. SSAshish MittalPas encore d'évaluation

- Excerpts From My Training Experience at Alembic Pharmaceuticals, BaddiDocument1 pageExcerpts From My Training Experience at Alembic Pharmaceuticals, BaddiAshish MittalPas encore d'évaluation

- Scheme & Syllabus of Bachelor in Pharmacy: Batch 2011 2012Document102 pagesScheme & Syllabus of Bachelor in Pharmacy: Batch 2011 2012Ashish MittalPas encore d'évaluation

- Corporate Profile About Us: Alembic at A GlanceDocument1 pageCorporate Profile About Us: Alembic at A GlanceAshish MittalPas encore d'évaluation

- NNVF Discussion Document - Guidance For The Visual Inspection of HEPA FiltersDocument23 pagesNNVF Discussion Document - Guidance For The Visual Inspection of HEPA FiltersEm GerPas encore d'évaluation

- The Prevention of Food Adulteration Act, 1954 Full PaperDocument23 pagesThe Prevention of Food Adulteration Act, 1954 Full PaperAshraf Ali100% (1)

- Afghanistan Saffron Company IntroductionDocument4 pagesAfghanistan Saffron Company IntroductionMasihullah EbadiPas encore d'évaluation

- TD EGGER Eurodekor Packaging enDocument2 pagesTD EGGER Eurodekor Packaging enabuyeheaPas encore d'évaluation

- Solutions: Sachet and Stick PackDocument20 pagesSolutions: Sachet and Stick PackSatish HiremathPas encore d'évaluation

- Career ObjectiveDocument3 pagesCareer ObjectiveSiva Teja Dinakar TalluriPas encore d'évaluation

- STEICO Hardboard HB en I USADocument2 pagesSTEICO Hardboard HB en I USAClaudiu BaditaPas encore d'évaluation

- 20137Document8 pages20137willygansPas encore d'évaluation

- Vitek 2 Smart Carrier Station Service ManualDocument66 pagesVitek 2 Smart Carrier Station Service ManualMohamad ziadPas encore d'évaluation

- Assignment 3 PACK 750 Fall 2019Document4 pagesAssignment 3 PACK 750 Fall 2019Gwyneth SerraoPas encore d'évaluation

- SRO Amendmnets in Labeling Packing RulesDocument8 pagesSRO Amendmnets in Labeling Packing RulesAli SaeedPas encore d'évaluation

- What TitleDocument17 pagesWhat TitleBernathTurnipPas encore d'évaluation

- 0 PRNT 123 - Fund of Food TechnologyDocument10 pages0 PRNT 123 - Fund of Food TechnologyPrincess Fatima De JuanPas encore d'évaluation

- Q-Pack and Global BrandsDocument37 pagesQ-Pack and Global BrandsCălin Rareș-MihaiPas encore d'évaluation

- Plastic Woven SacksDocument25 pagesPlastic Woven Sacksaldiabl100% (2)

- Nandos Australia Apc Action PlanDocument18 pagesNandos Australia Apc Action PlanSarah Tasnia100% (1)

- Biodegradable Packaging - Valentina TrinettaDocument2 pagesBiodegradable Packaging - Valentina Trinettajohnb2bPas encore d'évaluation

- Jatin KumarDocument4 pagesJatin KumarJatinPas encore d'évaluation

- TxDoT 6240 Geogrid For Base Embnakment Reinforcement PDFDocument3 pagesTxDoT 6240 Geogrid For Base Embnakment Reinforcement PDFthadikkaranPas encore d'évaluation