Académique Documents

Professionnel Documents

Culture Documents

10 0000@www Doiserbia NB rs@generic-9B9F376580BE PDF

Transféré par

eidelsayedDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

10 0000@www Doiserbia NB rs@generic-9B9F376580BE PDF

Transféré par

eidelsayedDroits d'auteur :

Formats disponibles

Electrochemical and wetting behavior of as-cast SnZnSb lead free

solder alloys

Srba A. Mladenovi, Ljubica S. Ivani, Mirjana M. Raji-Vujasinovi, Svetlana Lj. Ivanov,

Dragoslav M. Guskovi

University of Belgrade, Technical Faculty in Bor, Bor, Serbia

Abstract

Ternary alloys SnZn12Sb8, SnZn10Sb10, SnZn8Sb12, SnZn6Sb14 and SnZn2Sb18 were prepared by induction melting. The electrochemical and wetting (contact angle) behavior of

prepared as-cast samples were investigated using open circuit potential measurements

and the sessile drop technique. The results of the electrochemical investigation show that

the open-circuit potential, a few seconds after the immersion of electrodes, shifts toward

more negative values, indicating a relatively smaller rate of dissolution during the spontaneous dissolution process under curentless conditions. After that period, the values of

the potential tend to remain constant with time. It was found that all investigated alloys

have poor wettability on copper substrates and that the contact angle values decrease

with increasing superheat temperature.

SCIENTIFIC PAPER

UDC 544.6:544.632.4:669.4

Hem. Ind. 67 (3) 477484 (2013)

doi: 10.2298/HEMIND120608084M

Keywords: open-circuit potential, contact angle, step soldering alloys, sessile drop technique.

Available online at the Journal website: http://www.ache.org.rs/HI/

Lead is a heavy poisonous metal harmful to human

health, but, in spite of that, leadtin alloys have been

widely used as soldering materials. Multicomponent

alloys based on the SnZn eutectic belong to a group of

materials with perspectives to apply in the industry of

electronic systems apart from near-eutectic AgSnCu

alloys. Bismuth, indium and antimony are the most

popular metals among the modifiers of soldering properties of the SnZn eutectic [1].

SnSb alloys are important high-temperature solders. The melting points of SnSb alloys are higher than

that of conventional eutectic SnPb solder and they

have been used as high-temperature solders in step

soldering processes. Step soldering refers to the circumstance in which soldering processes occur at various steps because more than one soldering process is

needed for some electronic products. To avoid remelting of the earlier solder joints in the later soldering processes, solders with different melting points are used

[2].

Various SnSb based alloys have been developed as

high-temperature solders in compliance with recent

Pb-free requirements for electronic products. Among

various lead-free solders, SnSb based alloy is one of

the promising candidates for the replacement of the

high-melting-point Sn95wt%Pb alloy. Hence, ternary

SnZnSb alloys may also be considered as promising

lead-free solders. Investigations of SnZnSb alloys

Correspondence: S. Mladenovi, Technical Faculty in Bor, Vojske Jugoslavije 12, 19210 Bor, Serbia.

E-mail: smladenovic@tf.bor.ac.rs

Paper received: 8 June, 2012

Paper accepted: 11 July, 2012

with constant atomic percent of tin and high, variable

contents of Zn and Sb (calculated phase diagram presented in Figure 1 [3,4]) are conducted in very small scale.

Figure 1. The calculated isothermal section of the SnZnSb

system at room temperature.

The electrochemical behavior of pure tin in different media has been studied previously [5,6] but the

electrochemical behavior studies of complex SnZnSb

alloys have not yet been done.

Solder spreading on a substrate is fundamental for

the development of new solders. It is a complex pheno-

477

S.A. MLADENOVI et al.: As-CAST SnZn-Sb LEAD FREE SOLDER ALLOYS

menon involving joint configuration, flux selection,

substrate finishing and many other factors [7]. When

the solder melts, the increase in contact area indicates

the wetting behavior of solder [8]. The extent of wetting is measured by the contact angle that is formed at

the juncture of solid and liquid (molten solder), as

shown in Figure 2.

Figure 2. Schematic presentation of the contact angle, ,

between an alloy drop and a substrate, where SL, SF, and

LF refer to the surface tension of liquid/substrate, substrate/environment, and liquid/environment, respectively.

In this work, electrochemical and wetting (contact

angle) behavior of SnZnSb alloys with high amount of

antimony were studied, and several results were

obtained.

Hem. ind. 67 (3) 477484 (2013)

polished, washed out, dried, and finally, immersed into

lectrolyte. Grinding was performed by the finest grinding paper, polishing by alumina (0.05 m), and washing

by distilled water and alcohol.

Figure 3. Working electrode construction: 1 copper wire,

2 mold, 3 SIMGAL mass, 4 alloys samples, 5 conducting

silver glue.

The electrochemical investigations were conducted

using the setup shown in Figure 4.

EXPERIMENTAL

Electrochemical investigations

The investigations were performed in 0.1 mol/dm3

H2SO4 (pH 1) and 0.01 mol/dm3 NaOH (pH 11) by open

circuit potential measurements at 25 C, using a saturated calomel electrode as a reference. For the opencircuit measurements, a counter electrode was not used.

The body of the electrochemical cell was a double-wall

vessel made of Pyrex glass. The body was covered with

a lid with five holes, where electrodes, thermometer,

and gas inlet (if used) are put through. The solution was

prepared from p.a. NaOH and H2SO4 (Zorka, Serbia) and

distilled water. The system for electrochemical measurements consisted of hardware (PC, AD-DA converter

NI6251 produced by National Instruments (Austin, TX)

and analog interface) and software for excitation and

measurement (Lab-View 8.2 platform and application

software; National Instruments) both fully developed

by the Technical Faculty in Bor [9]. Good reproducibility

was proven by repeating the experiments under the

same conditions.

All investigated samples were prepared in the form

of electrodes (Figure 3). Electrical contact between the

copper wire and the electrode material was achieved

by using conducting silver glue IM-P3014 (Iritel, Belgrade, Serbia) and then mounted in cold polymerized

SIMGAL mass (Galenika, Belgrade, Serbia). For each set

of experiments, the working electrodes were ground,

478

Figure 4. Experimental set-up for electrochemical

investigations.

Wetting investigation

The five investigated alloys from SnZnSb system

were prepared from high purity (99.9 wt.%) tin, zinc

and antimony. They were melted in a graphite crucible

at 450 C in an electrical furnace under an inert argon

atmosphere. The chemical compositions of the investigated alloys are presented in Table 1.

Table 1. Composition (wt.%) of investigated alloys

Alloy

A1/ (Sn-12Zn-8Sb)

A2/ (Sn-10Zn-10Sb)

A3/ (Sn-8Zn-12Sb)

A4/ (Sn-6Zn-14Sb)

A5/ (Sn-2Zn-18Sb)

Sn

80.31

80.39

80.37

80.38

80.52

Zn

11.72

9.57

7.93

5.49

1.91

Sb

7.97

10.04

11.70

14.13

17.57

S.A. MLADENOVI et al.: As-CAST SnZn-Sb LEAD FREE SOLDER ALLOYS

The investigated alloys were remelted at 400 C and

poured into a mold to make a disc of 20 mm in diameter and 5 mm in thickness. Then, the disc was cut into

cylinders 10 mm in diameter, with mass around 4 g.

The aforementioned samples of alloys were remelted

and sessile drops of about 4 g for each studied alloy

were deposited on copper substrate (with thickness of

about 0.8 mm for substrate) under two different melt

superheats (50 and 100 C above liquidus temperature

of the alloy). Both superheat and substrate materials

were chosen in order to simulate various industrial

applications. The substrates were sequentially degreased

in a 5% NaOH solution at room temperature for 15 s,

and finally washed in ethanol for quick drying. Each

solidified alloy drop was examined using an image processing system (stereomicroscope and Adobe Photoshop 7.0). Contact angles were measured using Image

J. The images of the melted alloy drop and the analytical analyzing process are presented in Figures 5 and 6.

Hem. ind. 67 (3) 477484 (2013)

phase, representing primary crystals of Zn, Sn-matrix,

and intermetallic SbSn-phase, occuring at higher antimony contents. The primary Sb crystals are also present at higher antimony contents [10]. The characteristic microstructure for A2 alloy is presented in Figure 7.

Figure 7. SEM micrograph of A2 alloy.

Figure 5. Formed alloy Sn12Zn8Sb drop on Cu substrate

inside electrical resistance furnace (temperature superheat

100 C above liquidus temperature).

Figure 6. Analytical determination of contact angle for alloy

Sn12Zn8Sb and Cu substrate (superheat temperature, 100

C above liquidus temperature).

RESULTS AND DISCUSSION

Electrochemical investigation

The microstructural investigations of the alloys

showed that in system SnZnSb, at room temperature, the following phases were present: -phase,

which is actually the ZnSb-phase and represents an

intermetallic compound of antimony and zinc, the Zn-

These results are in good agreement with the results obtained from analytically determined SnZnSb

system for the investigated concentration area presented in Figure 1. Considering the chemical composition of investigated alloys presented in Table 1, for

electrochemical investigations, the Pourbaix diagrams

for Sn, Zn and Sb were calculated using the CALPHAD

method and shown in Figure 8.

The Pourbaix diagrams give insight into the thermodynamic possibilities of some reactions taking place at

certain pH and potential values [11].

The examination of the potential vs. pH equilibrium

diagrams indicated that a tin electrode could be active

or passive, depending on the applied potential. In most

neutral solutions, the resistance of tin to corrosive

attack is good because of the presence of oxide films.

The Pourbaix diagrams for zinc show that under acidic conditions no surface oxides of zinc are stable,

whereas under neutral or slightly alkaline conditions

zinc corrosion products are formed, which are more

stable [12].

The Pourbaix diagrams for antimony show that

under acidic and alkaline conditions and positive values

of applied potential, antimony oxide films are formed,

whereas under negative values of applied potential the

antimony is stable and doesnt dissolute. Considering

all E vs. pH diagrams, it can be observed that zinc, as

the active element, has a central role in the electrochemical behavior of the investigated alloys.

Open-circuit potential measurements (OCP) for five

investigated alloys in acidic and alkaline solutions are

479

S.A. MLADENOVI et al.: As-CAST SnZn-Sb LEAD FREE SOLDER ALLOYS

Figure 8. Calculated EpH diagrams for the systems: a) SnH2O, b) ZnH2O and c) SbH2O at 25 C.

480

Hem. ind. 67 (3) 477484 (2013)

S.A. MLADENOVI et al.: As-CAST SnZn-Sb LEAD FREE SOLDER ALLOYS

presented in Figures 9 and 10, respectively. These measurements were conducted as a function of exposure

time over a period of 20 s in naturally aerated, unstirred solutions. All electrodes had negative potentials

and immediatly after imersing the electrodes in 0.1 M

H2SO4 or 0.01 M NaOH, the potential values shifted to

more negative values. This phenomenon is a result of

dissolution of zinc in acidic and alkaline solutions. After

that period, the potential values tend to remain constant with time, which is a result of the formation of

stable oxides layers. Alloys with high Zn contents have

more negative potential values and alloys in acidic

solution have nobler potential than in alkaline solution.

Hem. ind. 67 (3) 477484 (2013)

Wetting investigation

The liquidus temperatures for the investigated alloys

were determined by the CALPHAD method and calculated with Pandat Software, version 8.0. An example

of the calculated solidification path for alloy A5 is

showed in Figure 11.

These calculations were used for the determination

of superheat temperature for the investigations of contact angle between the alloys and copper substrates.

The superheat temperatures are given in Table 2.

Experimental results of contact angles on the copper substrate as a function of melt superheat (50 and

100 C above the liquidus temperatures) for the five

Figure 9. Open circuit potential of the SnZnSb alloys in 0.1 M H2SO4 solution at 298 K.

Figure 10. Open circuit potential of the SnZnSb alloys in 0.01 M NaOH solution at 298 K.

481

S.A. MLADENOVI et al.: As-CAST SnZn-Sb LEAD FREE SOLDER ALLOYS

Hem. ind. 67 (3) 477484 (2013)

Figure 11. Calculated solidification path for alloy A5.

Table 2. Calculated superheat temperatures (C) of investigated alloys

Alloy

A1

A2

A3

A4

A5

50 oC above liquidus temperature

362

367

368

364

352

ternary alloys are shown in Figure 12. It is important to

remark that the shape of the sessile drops of the

investigated alloys was not perfectly ellipsoidal but

irregular in about 5% of the experimental drops. These

irregular drops were not considered for determination

of average values of wetting angles. Leonardo et al.

also reported this phenomenon and explained these

irregular shapes as they were associated with oxidation

[13]. The presence of surface-active elements such as

oxygen will have a significant influence on measurements of contact angle. The formation of a zinc oxide

film can provoke drop surface distortions. Atmospheric

oxygen molecules pass through this oxide and promote

a diffusion reaction within the solder to form a thick

oxide layer. Suganuma et al. [14] have also reported

that sessile drops can be distorted due to oxidation

preventing the solders from uniform wetting and

spreading.

The contact angles on the Cu substrate for all alloys

examined generally tended to attain their lowest values

for a melt superheat of 100 C, as can be seen in Figure

482

100 oC above liquidus temperature

412

417

418

414

402

12. However, based on the range of values of contact

angles given by the error bars (maximum and minimum

values), average values of about 138 and 130 C can be

considered for all investigated alloys. Many researchers

have reported that the contact angle decreases with

increasing melting temperature, which is associated

with lower viscosity and consequent better metal/substrate wetting. Lower contact angles are associated

with higher fluidity. It has been demonstrated that the

best fluidity is generally attained for pure components,

eutectics or phases that solidifies congruently, whereas

fluidity decreases with increasing solidification range

[15,16]. Comparing the experimental results of contact

angle for all the studied alloys, it can be observed that

alloy A1 had minimum values of contact angle 50 and

100 above the liquidus temperature. Alloy A2 had the

highest values of contact angle with an average contact

angle of about 140 for the first superheat temperature

and 135 for the second.

S.A. MLADENOVI et al.: As-CAST SnZn-Sb LEAD FREE SOLDER ALLOYS

Hem. ind. 67 (3) 477484 (2013)

Figure 12. Contact angle values as a function of melt superheat for the investigated alloys.

CONCLUSION

These experimental investigations confirmed poor

corrosion and wetting properties of the investigated

alloys, which is in good agreement with some earlier

investigations of alloys with similar chemical composition. Additional alloying of investigated SnZnSb

alloys can probably contribute to better electrochemical and wetting behavior, and further investigations are

needed.

[7]

[8]

[9]

[10]

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

T. Gancarz, W. Gasior, EMF study of the liquid Sb-Sn-Zn

Alloys, J. Phase Equilib. Diff. 32 (2011) 398406.

S.W. Chen, P.Y. Chen, C.H. Wang, Lowering of SnSb

alloy melting points caused by substrate dissolution, J.

Electron. Mater. 35 (2006) 19821985.

H.L. Lukas, S.G. Fries, B. Sundman, Computational Thermodynamics: CALPHAD Method, Cambridge University

Press, Cambridge, 2007.

A.T. Dinsdale, A. Kroupa, J. Vzdal, J. Vrestal, A. Watson,

A. Zemanova: COST 531 Database for Lead-free Solders,

ver. 3.0, 2008.

M Drogowska, H. Menard, Electrochemical behavior of

tin in bicarbonate solution at pH 8, J. Appl. Electrochem.

21 (1991) 8490.

P. Alvarez, S. Ribbota, M. Folquer, C. Gervasi, J. Vilche,

Potentiodynamic behavior of tin in different buffer solutions, Coros. Sci. 44 (2002) 4965.

[11]

[12]

[13]

[14]

[15]

[16]

E. Saiz, C.W. Hwang, K. Sugunama, A.P. Tomsia, Spreading of SnAg solders on Fe-Ni alloys, Acta Mater. 51

(2003) 31853197.

M. Ramani, A.B. Ismail, Z.A. Ahmad, T. Ariga, L.B. Hussain, Wetting properties of Sn-Pb, Sn-Zn and Sn-Zn-Bi

lead free alloys, J. Teknol. 46C (2007) 114.

Z. Stevi, M. Raji-Vujasinovi, System for electrochemical investigations based on a PC and the Lab VIEW

package, Hem. Ind. 61 (2007) 16 (in Serbian).

S. Mladenovi, D. Markovi, Lj. Ivani, S. Ivanov, D.

Guskovi, The microstructure and mechanical properties

of as-cast Sn-Sb-Zn lead free solder alloys, Metal. Int.

17(4) (2012) 3438.

M. Raji-Vujasinovi, S. Nestorovi, V. Grekulovi, I.

Markovi, Z. Stevi, Electrochemical behavior of sintered

CuAg4 at. pct alloy, Metall. Mater. Trans., B 41B (2010)

955961.

M. Pourbaix, Atlas of Electrochemical Equilibria in Aqueous Solutions, 2nd ed., NACE International, Houston, TX,

1974.

L. Garsia, W. Osorio, L. Peixoto, A. Garcia, Wetting behavior and mechanical properties of Sn-Zn and Sn-Pb

solder alloys, J. Electron. Mater. 38 (2009) 24052414.

K. Suganuma, K. Niihara, T. Shoutoku, Y. Nakamura,

Wetting and interface microstructure between Sn-Zn

binary alloys and Cu, J. Mater. Res. 13 (1998) 2859

2865.

C. Wu, C. Law, D. Yu, L. Wang, The wettability and microstructure of SnZnRe alloys, J. Electron. Mater. 32

(2003) 7080.

C. Wu, D. Yu, C. Law, L. Wang, Properties of lead-free

solder alloys with rare earth element additions, Mater.

Sci. Eng. 44 (2004) 144.

483

S.A. MLADENOVI et al.: As-CAST SnZn-Sb LEAD FREE SOLDER ALLOYS

Hem. ind. 67 (3) 477484 (2013)

IZVOD

ELEKTROHEMIJSKO PONAANJE I KVALJIVOST LIVENIH BEZOLOVNIH LEMNIH LEGURA U SISTEMU Sn-Zn-Sb

Srba A. Mladenovi, Ljubica S. Ivani, Mirjana M. Raji-Vujasinovi, Svetlana Lj. Ivanov, Dragoslav M. Guskovi

Univerzitet u Beogradu, Tehniki fakultet u Boru, Bor, Srbija

(Nauni rad)

Sprovedena istraivanja imala su za cilj pronalaenje adekvatnih zamena olovnim legurama u razliitim aspektima njihove primene. Jedan od segmenata primene olovnih lemnih legura je kod tehnike stepenastog lemljenja, koja pretpostavlja spajanje elektronskih komponenti i substrata u nekoliko faza. Kako se ne bi

prethodno zalemljene komponente odlemile koriste se lemni materijali sa razliitim temperaturama topljenja. U ranijoj praksi jedna od korienih legura bila je

SnPb95. Mogua zamena za ovu leguru pretpostavlja se da moe biti i neka legura

iz trojnog sistema SnZnSb. U ovom radu ispitivano je elektrohemijsko ponaanje

i kvaljivost legura sa konstantnim procentom kalaja (80 at.%) i promenljivim

odnosom Zn i Sb. Elektrohemijska ispitivanja sprovedena su merenjem potencijala

otvorenog kola legura iz ispitivanog sistema, dok je kvaljivost odnosno vrednost

kontaktnog ugla izmeu pomenutih legura i bakarnog substrata ispitivana pomou metode leee kapi. Elektrohemijska ispitivanja su pokazala da se vrednosti

potencijala otvorenog kola nekoliko sekundi nakon uranjanja elektroda kreu ka

negativnim vrednostima ukazujui na relativno malo rastvaranje cinka prisutnog u

leguri u kiselim i baznim reagensima. Nakon toga, vrednosti su skoro konstantne

sa vremenom. Ispitivanjima sprovedenim u ovome radu ustanovljeno je da legure

iz ispitivanog koncentracionog podruja sistema SnZnSb imaju veoma slabu

kvaljivost bakarnog substrata i da se vrednosti kontaktnog ugla smanjuju sa

poveanjem temperature pregrevanja rastopa legure. Potvreno je i zapaanje

mnogih istraivaa da najnie vrednosti kontaktnog ugla imaju legure koje se tope

na konstantnoj temperaturi i da se sa poveanjem opsega izmeu temperature

solidusa i temperature likvidusa kvaljivost legura pogorava.

484

Kljune rei: Potencijal otvorenog kola

Kontaktni ugao Legure za stepenasto

lemljenje Metod leee kapi

Vous aimerez peut-être aussi

- 28 3267am0612 239 252 PDFDocument14 pages28 3267am0612 239 252 PDFeidelsayedPas encore d'évaluation

- 7 - Characterization and Transport Properties PDFDocument10 pages7 - Characterization and Transport Properties PDFeidelsayedPas encore d'évaluation

- 19 Al-Si - Dendritik PDFDocument10 pages19 Al-Si - Dendritik PDFeidelsayedPas encore d'évaluation

- Film Boiling Heat Transfer of Droplet Streams and SpraysDocument15 pagesFilm Boiling Heat Transfer of Droplet Streams and SprayseidelsayedPas encore d'évaluation

- 04lgomidzelovic PDFDocument8 pages04lgomidzelovic PDFeidelsayedPas encore d'évaluation

- Surface Effects of Ordering in Binary Alloys: Topical ReviewDocument34 pagesSurface Effects of Ordering in Binary Alloys: Topical RevieweidelsayedPas encore d'évaluation

- Evaluation of The Heat Transfer Coefficient at The Metal-Mould Interface During FlowDocument4 pagesEvaluation of The Heat Transfer Coefficient at The Metal-Mould Interface During FloweidelsayedPas encore d'évaluation

- Recovered PDF 17210 PDFDocument5 pagesRecovered PDF 17210 PDFeidelsayedPas encore d'évaluation

- LIU Wsu 0251E 10640 PDFDocument119 pagesLIU Wsu 0251E 10640 PDFeidelsayedPas encore d'évaluation

- Prediction of Ferroelectricity in Batio / Srtio Superlattices With DomainsDocument3 pagesPrediction of Ferroelectricity in Batio / Srtio Superlattices With DomainseidelsayedPas encore d'évaluation

- Phase-Field Simulation of 2-D Ostwald Ripening in The High Volume Fraction RegimeDocument13 pagesPhase-Field Simulation of 2-D Ostwald Ripening in The High Volume Fraction RegimeeidelsayedPas encore d'évaluation

- Quantitative Interface Models For Simulating Microstructure EvolutionDocument8 pagesQuantitative Interface Models For Simulating Microstructure EvolutioneidelsayedPas encore d'évaluation

- Philosophical Magazine Letters: Phase-Field Model For Ferromagnetic Shape-Memory AlloysDocument10 pagesPhilosophical Magazine Letters: Phase-Field Model For Ferromagnetic Shape-Memory AlloyseidelsayedPas encore d'évaluation

- Recovered PDF 17204 PDFDocument11 pagesRecovered PDF 17204 PDFeidelsayedPas encore d'évaluation

- Recovered PDF 17199 PDFDocument7 pagesRecovered PDF 17199 PDFeidelsayedPas encore d'évaluation

- Recovered PDF 17202 PDFDocument8 pagesRecovered PDF 17202 PDFeidelsayedPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Mathematics4 q4 Week4 v4Document11 pagesMathematics4 q4 Week4 v4Morales JinxPas encore d'évaluation

- Tekla SoakwayDocument2 pagesTekla SoakwayBalaji Naik100% (1)

- Philips HD 9 User ManualDocument3 pagesPhilips HD 9 User ManualNdangoh DerekPas encore d'évaluation

- (Word 365-2019) Mos Word MocktestDocument4 pages(Word 365-2019) Mos Word MocktestQuỳnh Anh Nguyễn TháiPas encore d'évaluation

- The Technology Procurement HandbookDocument329 pagesThe Technology Procurement HandbookAlexander Jose Chacin NavarroPas encore d'évaluation

- IU IIDC Time Management and Organizational SkillsDocument40 pagesIU IIDC Time Management and Organizational SkillsAsger HamzaPas encore d'évaluation

- InterviewDocument8 pagesInterviewswapnadip kumbharPas encore d'évaluation

- Aicte Internship Approval Pending 1Document7 pagesAicte Internship Approval Pending 1Anisha KumariPas encore d'évaluation

- Learning Plans in The Context of The 21 ST CenturyDocument29 pagesLearning Plans in The Context of The 21 ST CenturyHaidee F. PatalinghugPas encore d'évaluation

- Powerplant QuestionsDocument19 pagesPowerplant QuestionsAshok KumarPas encore d'évaluation

- Application Letter For Promotion T2 T3Document24 pagesApplication Letter For Promotion T2 T3FGacadSabadoPas encore d'évaluation

- Brp-Rotax Chassis Approval FormDocument3 pagesBrp-Rotax Chassis Approval Formdelta compPas encore d'évaluation

- Control System PPT DO1Document11 pagesControl System PPT DO1Luis AndersonPas encore d'évaluation

- Emerson Mentor MP ManualDocument182 pagesEmerson Mentor MP ManualiampedrooPas encore d'évaluation

- CUIT 201 Assignment3 March2023Document2 pagesCUIT 201 Assignment3 March2023crybert zinyamaPas encore d'évaluation

- College of Engineering Cagayan State UniversityDocument16 pagesCollege of Engineering Cagayan State UniversityErika Antonio GutierrezPas encore d'évaluation

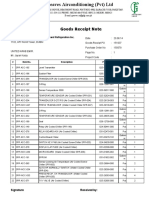

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocument4 pagesGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanPas encore d'évaluation

- 5 Grade: Daily MathDocument130 pages5 Grade: Daily MathOLIVEEN WILKS-SCOTT100% (3)

- Swenson 1 Dan Swenson Printing Press: Part One (Timeline)Document6 pagesSwenson 1 Dan Swenson Printing Press: Part One (Timeline)Dan SwensonPas encore d'évaluation

- Handbook On National Spectrum Management 2015Document333 pagesHandbook On National Spectrum Management 2015Marisela AlvarezPas encore d'évaluation

- 8051 Programs Using Kit: Exp No: Date: Arithmetic Operations Using 8051Document16 pages8051 Programs Using Kit: Exp No: Date: Arithmetic Operations Using 8051Gajalakshmi AshokPas encore d'évaluation

- SAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitDocument61 pagesSAP Solution Manager - CHARM - Retrofit - Change Request Management Enhanced RetrofitARPITA BISWASPas encore d'évaluation

- (Ug, PG & PHD) Fellowship: Tih-Iot Chanakya GroupDocument3 pages(Ug, PG & PHD) Fellowship: Tih-Iot Chanakya GroupVijay M.MPas encore d'évaluation

- OPENING & CLOSING PROGRAM NARRATIVE REPORT (Grade 7)Document4 pagesOPENING & CLOSING PROGRAM NARRATIVE REPORT (Grade 7)Leo Jun G. Alcala100% (1)

- Admission: North South University (NSU) Question Bank Summer 2019Document10 pagesAdmission: North South University (NSU) Question Bank Summer 2019Mahmoud Hasan100% (7)

- SIMPLE PlaybookDocument12 pagesSIMPLE PlaybookMatt LylesPas encore d'évaluation

- Problems: C D y XDocument7 pagesProblems: C D y XBanana QPas encore d'évaluation

- Modular Heavy Duty Truck TransmissionDocument6 pagesModular Heavy Duty Truck Transmissionphucdc095041Pas encore d'évaluation

- Corrosion Protection PT Tosanda Dwi SapurwaDocument18 pagesCorrosion Protection PT Tosanda Dwi SapurwaYoga FirmansyahPas encore d'évaluation

- n4 HandoutDocument2 pagesn4 HandoutFizzerPas encore d'évaluation