Académique Documents

Professionnel Documents

Culture Documents

DFMEA

Transféré par

Sumeet SainiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DFMEA

Transféré par

Sumeet SainiDroits d'auteur :

Formats disponibles

Project

Year

Team Members

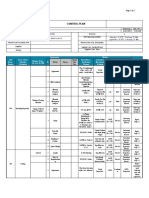

DESIGN FAILURE MODE AND EFFECT ANALYSIS

(DFMEA)

Mainstream

Revsion Date

2007-2008

Revision Number

Nathan Barrett, Michael Elger, Aaron Gauthier, Linsey Abo, and Cody Newbill

ITEM AND FUNCTION

POTENTIAL FAILURE MODE(S)

POTENTIAL

EFFECT(S) OF

FAILURE

S

E

V

A Frame

Weld Failure

Frame falls

Failure in cross brace

System falls

Cable failure

U-bolt failure

Mounting plate failure

Load Cell

Inaccurate readings

Mechanical failure

Pipes/Transport

O

C

C

U

R

CURRENT DESIGN CONTROLS

D

E

T

E

C

T

R

P

N

Overloading, bad

welding, excessive

dynamic loads

Welding and Bolts

40

Calculate Stresses

at fillet welds at

worst case

Overloading, excessive

dynamics, fatigue

Saftey facros

Make sure the

system isn't

overloaded

No control of

linear slide

Overload, wear on cable

strong cable, good winch

Prototype

Load cell falls in

water

Overload, too much

torque on bolt

Design for worst case

Test

4 bolts, supports

Bolt failure analysis

1000 lb load cell with

much less actual load

45

Load cell falls in

water

Mis-readings,

inaccurate data

LC breaks, misreadings

8

5

POTENTIAL CAUSE(S) OF

FAILURE

March 4, 2008

1

3/16" bolts fail, too much

torsion

Dirty environment,

overload

RECOMMENDED

ACTIONS

Torsion, mis-handling

All load is axial

64

Talk to installation

and users

Poor pipe connections

Proven materials and

parts.

30

Solid Connections

and pressure

calculations

18

Consulted with pipe

specialist.

Pipe Leak

Minor Flooding

Pipe Break

Major Flooding

Funnel

Doesn't

deliver sediment to drum

Weight data

inaccurate

Flume

Section

Falls off

Proper training for

person that

installs/removes

funnel

Inspect flume

periodically

Drum not installed

properly

Tank window

Gate, tank and

flume section fall

into sump

10

Bolts shear,

inadequate attatchment

Accurate bolt/weld

calculations

Severe Leaks

Flow profile

altered

Improperly

sealed

Accurate bolt/weld

calculations

4 112

Inspect flume

periodically

Falls off

Tank, auger,

piping

break/fall into

sump

10

Bad welding/

manufacturing

Accurate bolt/weld

calculations

30

Inspect flume

periodically

Severe Leaks

Sediment leaks

into sump,

flow profile altered

Poorly designed/

manufactured

Accurate bolt/weld

calculations

28

Inspect flume

periodically

Drum

Drum stops

turning

Sediment piles

back into flume

and sump

Agitator fails

Drum Jams

Visual through

tank window

Auger

Clogs

Large sediment

particles

Motor fails

Tank

Stops

Slurry

Pump

Tank fills with

sediment

Tank fills with

sediment

Large diameter piping

6 144

80

3 120

70

Tank window

63

Clogs

Sediment backfills

into tank/flume

Sediment chokes

pipe

Seperator no

longer filling

8 128

Stops

Sediment backfills

into

tank/flume

Motor fails

Seperator no longer filling

8 168

Check drum

periodically

Vous aimerez peut-être aussi

- Design Fmea ExampleDocument2 pagesDesign Fmea ExampleSenthil_KPas encore d'évaluation

- Dfmea TemplateDocument5 pagesDfmea TemplateHerbert WeigeltPas encore d'évaluation

- Design FMEA ExampleDocument3 pagesDesign FMEA ExampleJosé Ignacio SánchezPas encore d'évaluation

- DFMEA Chryslerexample PDFDocument2 pagesDFMEA Chryslerexample PDFSASIKUMARPas encore d'évaluation

- Feleffektsanalys/Failure Mode and Effect Analysis Konstruktion/DesignDocument12 pagesFeleffektsanalys/Failure Mode and Effect Analysis Konstruktion/DesignKristof MCPas encore d'évaluation

- GS-0002D, Design FMEADocument26 pagesGS-0002D, Design FMEAmesa142100% (1)

- Customer Name: Schneider Electric: SPL ClassDocument2 pagesCustomer Name: Schneider Electric: SPL ClassSachin Sam100% (1)

- CP20200804-A Model Control Plan - FoundationsDocument6 pagesCP20200804-A Model Control Plan - Foundationsmanno200Pas encore d'évaluation

- Dfmea ExampleDocument3 pagesDfmea ExampleParag Kulkarni100% (1)

- Pes Modern College of Engineering Shivaji Nagar Pune-5 Team Pegasus Design Failure Modes & Effects AnalysisDocument9 pagesPes Modern College of Engineering Shivaji Nagar Pune-5 Team Pegasus Design Failure Modes & Effects AnalysisPranav EkhandePas encore d'évaluation

- 36 PfmeaDocument9 pages36 Pfmeamscsmn100% (1)

- Apqp Advanced Product Quality PlanningDocument27 pagesApqp Advanced Product Quality PlanningRajesh KumarPas encore d'évaluation

- DFMEADocument11 pagesDFMEARajashekar Kamatan100% (1)

- 48 Point Ppap Check SheetDocument39 pages48 Point Ppap Check SheetSanjay KumarPas encore d'évaluation

- PS - APQP Check ListDocument15 pagesPS - APQP Check ListKristof MCPas encore d'évaluation

- Design Report DFMEA & Validation PresentationDocument65 pagesDesign Report DFMEA & Validation Presentationakshayupadhyay75% (4)

- Layout Inspection Report XH5DR June 20 2012Document17 pagesLayout Inspection Report XH5DR June 20 2012nathiven100% (1)

- The 5 Core ToolDocument17 pagesThe 5 Core ToolRajesh GhoshPas encore d'évaluation

- Vda FmeaDocument30 pagesVda Fmealalit GuptaPas encore d'évaluation

- Dfmea TeamDocument2 pagesDfmea TeamjnmanivannanPas encore d'évaluation

- Risk Assessment Tools For IVD AssaysDocument52 pagesRisk Assessment Tools For IVD AssaysOiinkiePas encore d'évaluation

- APQP Manual VolvoDocument30 pagesAPQP Manual VolvoVictor Hugo50% (2)

- QP 73001 Rev 07 Product Design and Development ProcedureDocument8 pagesQP 73001 Rev 07 Product Design and Development ProcedurevinayPas encore d'évaluation

- Supplier Deviation Request Form N°:: Part Description Part No: Revision PO NumberDocument1 pageSupplier Deviation Request Form N°:: Part Description Part No: Revision PO NumberBESPas encore d'évaluation

- Design Fmea 1 ST Pipe Teflon HoseDocument11 pagesDesign Fmea 1 ST Pipe Teflon HoseSandeep PandeyPas encore d'évaluation

- PS - APQP Check ListDocument17 pagesPS - APQP Check ListalexrferreiraPas encore d'évaluation

- Un-qd-ff-860 Fai ביצוע - engDocument6 pagesUn-qd-ff-860 Fai ביצוע - engmsy021yahoo.comPas encore d'évaluation

- DVP R Test PlanDocument2 pagesDVP R Test PlandavidPas encore d'évaluation

- Design Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportDocument6 pagesDesign Verification Process Project III Samudra Indonesia 20/11/2019 Samudra Indonesia 21/12/2019 See Project III R1 ReportAufa Jaya Perkasa LegalityPas encore d'évaluation

- D10414410a Fmea CastingDocument7 pagesD10414410a Fmea CastingSuraj RawatPas encore d'évaluation

- Mizenboushi Method (未然防止法) : Good Design, Good Discussion, Good DissectionDocument45 pagesMizenboushi Method (未然防止法) : Good Design, Good Discussion, Good DissectionXin Li100% (1)

- APQP MatrixDocument3 pagesAPQP Matrixsabareeson100% (1)

- Spec Characteristics GdlnesDocument2 pagesSpec Characteristics Gdlnessathyabalaraman0% (1)

- SC FORM 132 Supplier Deviation FormDocument2 pagesSC FORM 132 Supplier Deviation Formcandra trisilawatiPas encore d'évaluation

- FMEA TemplateDocument6 pagesFMEA TemplateHiếu Trần100% (1)

- APQP Timing PlanDocument2 pagesAPQP Timing PlandanielsasikumarPas encore d'évaluation

- Setco Automotive LTD.: NP ChartDocument4 pagesSetco Automotive LTD.: NP ChartDisha ShahPas encore d'évaluation

- 18 Point Ppap Plan Approval-WaiverDocument4 pages18 Point Ppap Plan Approval-WaiverBrenda GillPas encore d'évaluation

- FMEA Proses&DesignDocument34 pagesFMEA Proses&DesignRizky Sihab100% (2)

- DFMEA Worshop FinalDocument18 pagesDFMEA Worshop FinalRishi KumarPas encore d'évaluation

- NCR Supplier PPAP Training PresentationDocument166 pagesNCR Supplier PPAP Training PresentationAmitava Datta67% (3)

- FMEA - Quick Reference Guide: Actions Are Required: (By Priority)Document2 pagesFMEA - Quick Reference Guide: Actions Are Required: (By Priority)Igor PPas encore d'évaluation

- Format No-Blank/Dir: Detail Inspection ReportDocument18 pagesFormat No-Blank/Dir: Detail Inspection ReportRock RockyPas encore d'évaluation

- ATTRIBUTE MSADocument2 pagesATTRIBUTE MSADINESHCHOUDHARY880% (1)

- Ppap Level III RequirementsDocument1 pagePpap Level III Requirementsapi-383246575% (4)

- EDP 3 Product DevelopmentDocument15 pagesEDP 3 Product DevelopmentatulkirarPas encore d'évaluation

- Process Audit Preparation "Turtle Diagram": Design & DevelopmentDocument7 pagesProcess Audit Preparation "Turtle Diagram": Design & Developmentkhwanta-bta100% (2)

- Master Form VDADocument4 pagesMaster Form VDAapi-3856433Pas encore d'évaluation

- 8d's y 5 Por Que de NissanDocument8 pages8d's y 5 Por Que de NissanSergio RuizPas encore d'évaluation

- PSW BoschDocument1 pagePSW BoschMemo Gonzalez Aleman100% (1)

- FMEADocument6 pagesFMEANavnath TamhanePas encore d'évaluation

- Engineering Change NoteDocument2 pagesEngineering Change NoteasderbvaPas encore d'évaluation

- Design FMEA (DFMEA) TutorialDocument18 pagesDesign FMEA (DFMEA) Tutorialpiero_rsPas encore d'évaluation

- Guidelines For Making PFMEA - A PDFDocument10 pagesGuidelines For Making PFMEA - A PDFKalimuthu PsPas encore d'évaluation

- 167 Pipe Support FailureDocument0 page167 Pipe Support FailureKhaled AbdelbakiPas encore d'évaluation

- Pipe Support FailureDocument39 pagesPipe Support Failuresdfsfg100% (1)

- Catalog - Conductor Bar Insul-8 BarSide ContactDocument52 pagesCatalog - Conductor Bar Insul-8 BarSide ContactarmandoPas encore d'évaluation

- Call Letter For InterviewDocument1 pageCall Letter For InterviewSumeet SainiPas encore d'évaluation

- (Ebook) Catia Tutorial PDFDocument38 pages(Ebook) Catia Tutorial PDFmahesh89% (57)

- Covid 19 RajkotDocument4 pagesCovid 19 RajkotSumeet SainiPas encore d'évaluation

- Defects Count Cumulative Amount Cummulative % Dent 1000 1000 39% Rust 900 1900 75% Plating 500 2400 94% Od 100 2500 98% Crack 50 2550 100% Total 2550Document3 pagesDefects Count Cumulative Amount Cummulative % Dent 1000 1000 39% Rust 900 1900 75% Plating 500 2400 94% Od 100 2500 98% Crack 50 2550 100% Total 2550Sumeet SainiPas encore d'évaluation

- Indian Novel Writers and Their Contribution Salman RushdieDocument6 pagesIndian Novel Writers and Their Contribution Salman RushdieSumeet SainiPas encore d'évaluation

- 2.5third Angle ProjectionDocument6 pages2.5third Angle ProjectionSumeet Saini0% (1)

- Slides Sep2014 AbhiDocument19 pagesSlides Sep2014 AbhiSumeet SainiPas encore d'évaluation

- ch12Document10 pagesch12Sumeet SainiPas encore d'évaluation

- Rules and Concepts of GD&TDocument31 pagesRules and Concepts of GD&TSumeet Saini75% (4)

- Tolerance Stackup AnalysisDocument1 pageTolerance Stackup AnalysisSumeet Saini100% (1)

- CH 5 Casting FundamentalsDocument14 pagesCH 5 Casting FundamentalsSumeet SainiPas encore d'évaluation

- Online Student RegistrationDocument1 pageOnline Student RegistrationSumeet SainiPas encore d'évaluation

- Eng Castingdesign RibsDocument3 pagesEng Castingdesign RibsSumeet SainiPas encore d'évaluation

- ch12Document10 pagesch12Sumeet SainiPas encore d'évaluation

- List of NADCA Standards, Guidelines & Chec Klists: ToolingDocument1 pageList of NADCA Standards, Guidelines & Chec Klists: ToolingSumeet SainiPas encore d'évaluation

- Tutorial Mass TransferDocument5 pagesTutorial Mass TransferAimy YasminPas encore d'évaluation

- Distillation - Written ReportDocument17 pagesDistillation - Written ReportmichsantosPas encore d'évaluation

- Khosla S Theory and Concept of Flow NetsDocument3 pagesKhosla S Theory and Concept of Flow NetstilayeyidegPas encore d'évaluation

- CD250M 1750RPM (US) - CurvaDocument1 pageCD250M 1750RPM (US) - CurvaNils Enrique Hansen GamarraPas encore d'évaluation

- Ce6303 - Mechanics of Fluids: Unit - IDocument19 pagesCe6303 - Mechanics of Fluids: Unit - ImanojPas encore d'évaluation

- Kinetics of Wet Oxidation of Formic Acid and Acetic AcidDocument6 pagesKinetics of Wet Oxidation of Formic Acid and Acetic AcidVerónica ArévaloPas encore d'évaluation

- Applied Thermal Engineering: Ralf Starkloff, Falah Alobaid, Karl Karner, Bernd Epple, Martin Schmitz, Felix BoehmDocument11 pagesApplied Thermal Engineering: Ralf Starkloff, Falah Alobaid, Karl Karner, Bernd Epple, Martin Schmitz, Felix Boehmjhugo_mirandaPas encore d'évaluation

- L16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiDocument25 pagesL16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyPas encore d'évaluation

- Marathon-Fluid Mechanics by Sandeep Jyani Sir WIFISTUDY PDF Version 2Document443 pagesMarathon-Fluid Mechanics by Sandeep Jyani Sir WIFISTUDY PDF Version 2Nandkishore MeenaPas encore d'évaluation

- 1.4 Centrifugal Compressor Structure1Document42 pages1.4 Centrifugal Compressor Structure1ramakrishnanPas encore d'évaluation

- Standard Procedure For Hydrotest As Per Asme?Document4 pagesStandard Procedure For Hydrotest As Per Asme?Faraz ArshadPas encore d'évaluation

- Practice Problem Turbine Fans and Blower and CompressorDocument3 pagesPractice Problem Turbine Fans and Blower and CompressorRey Regaspi Tuyay50% (2)

- Convertidos de PDFDocument136 pagesConvertidos de PDFJohn Nilton Ccama LipaPas encore d'évaluation

- Seminar ReportDocument13 pagesSeminar Reportgunjan pratapPas encore d'évaluation

- Inconel 625 TubingDocument2 pagesInconel 625 TubingSTEEL TUBES INDIAPas encore d'évaluation

- PMS Air Compressor PackageDocument1 pagePMS Air Compressor Packagetommy prastomoPas encore d'évaluation

- Final Project (Team)Document5 pagesFinal Project (Team)bintangPas encore d'évaluation

- Reciprocating Pump PratishthaDocument13 pagesReciprocating Pump Pratishthamike rosaPas encore d'évaluation

- Atmospheric Foam TankDocument5 pagesAtmospheric Foam TankAndro SidhomPas encore d'évaluation

- The Nature of EnergyDocument35 pagesThe Nature of EnergyJustine Valad-onPas encore d'évaluation

- Chilled Water Pump Head CalculationDocument6 pagesChilled Water Pump Head CalculationMohammed Hassan Mohiuddin Khan67% (3)

- Rotameter CalibrationDocument14 pagesRotameter CalibrationJatin Acharya100% (1)

- Pump piCLASSIC Xi40 3Document5 pagesPump piCLASSIC Xi40 3Pablo CGPas encore d'évaluation

- Gas Turbine TribologyDocument19 pagesGas Turbine TribologyChukkur HaliPas encore d'évaluation

- Compressed Air System in Thermal Power PlantDocument12 pagesCompressed Air System in Thermal Power PlantAshwani Dogra100% (4)

- Boge DryersDocument20 pagesBoge Dryersigor_sandulenkoPas encore d'évaluation

- Chapter 4 Molecular Diffusion in SolidsDocument16 pagesChapter 4 Molecular Diffusion in SolidsrushdiPas encore d'évaluation

- ASME VIII Unfired Vessel Relief ValvesDocument53 pagesASME VIII Unfired Vessel Relief Valvessaid530Pas encore d'évaluation

- CFX Fsi 14.5 l4 - Two - Way - Setup 46Document46 pagesCFX Fsi 14.5 l4 - Two - Way - Setup 46Moh SenPas encore d'évaluation

- Jun 09 Cooling Water Chemical Dosing SystemDocument6 pagesJun 09 Cooling Water Chemical Dosing SystemRKVSK1Pas encore d'évaluation