Académique Documents

Professionnel Documents

Culture Documents

Test Program Famida

Transféré par

alsitorCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Test Program Famida

Transféré par

alsitorDroits d'auteur :

Formats disponibles

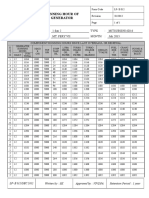

Form

LF- E 035

Revision

TEST PROGRAM

Page

Vessel

Name :

OB FAMIDA

Period :

April 2015

Date Last

Overhoul

January-14

PERIOD OF PMS REPORT

PMS No.

Unit / System

5.1

TEMPERATURE INDICATOR

Remove temperature indicator from the place, cleaning sensor

from sludge and be sure temperature indicator normaly

function

Visual check condition of sensor and temperature casing not

broken

Visual check condition, when temperature indicator working

no oil leaking, repair if necessary

Compared with other thermometers when thermometer

working.

INDIKATOR TEMPERATUR

Lepas indikator temperatur dari tempatnya dan bersihkan

sensor dari jelaga pastikan indikator temperatur berfungsi

dengan baik

check kondisi visual sensor dan casing temperatur tidak ada

yg pecah atau rusak

check kondisi visual ketika temperatur dipasang tidak ada

kebocoran atau rembesan oli, perbaiki jika diperlukan

Bandingkan dengan thermometer lain ketika thermometer

bekerja

PRESSURE SWITCHES

Connect the test equipment to the test cock. Raise the test

pressure to the value above the switch setting and then slowly

reduce the pressure until the pressure switch contacts work.

PRESSURE SWITCHES

Hubungkan peralatan pengujian untuk cock uji . Tingkatkan

tekanan tes dengan nilai di atas pengaturan switch dan

kemudian perlahan-lahan kurangi tekanan sampai kontak

saklar tekanan bekerja.

5.1.1

5.1.2

5.1.3

5.1.4

5.2

5.2.1

Unit / System

PERIOD OF PMS REPORT

: Overdue Maintenance for This Month

2015

PIC

Last Maint. Date

Running

Hours

30/Mar/15

30-Jun-15

30/Mar/15

30-Apr-15

30/Mar/15

30-Apr-15

30/Mar/15

30-Apr-15

30/Mar/15

30-Jun-15

30-Jun-15

Interval

Months Hours

Est. Next Due

Jan-15

Feb-15

Mar-15

Apr-15

30/Mar/15

5.2.3

30/Mar/15

30-Jun-15

Check cable connections and cable entries to the sensor.

Check that there is no leakage of oil or water inside the

sensor. If any, clean the sensor and make repairs to eliminate

further leakage.

Periksa kabel koneksi dan kabel yang masuk ke sensor

Periksa bahwa tidak ada kebocoran oli atau air dari sensor

atau koneksi sensor. Jika ada , bersihkan sensor dan perbaiki

untuk menghindari kebocoran lebih lanjut.

30/Mar/15

30-Apr-15

30/Mar/15

30-Apr-15

5.3

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.7

GENERAL

Check general condition of Insulation of exhaust pipes

Test Emergency stop of Cargo engine from main deck

Test Fire pump

Test quick closing valve

Test emergency stop blower PR

Test emergency lighting

Check general condition of Control consoles

GENERAL

Check general condition of Isolasi pipa gas buang

Test Emergency stop untuk mesin cargo di main deck

Test fire pump

Test quick closing valve

Test emergency stop blower PR

Test emergency lighting

Check general condition of konsol control

30/Mar/15

30/Mar/15

30/Mar/15

30/Mar/15

30/Mar/15

30/Mar/15

30/Mar/15

1

1

1

1

1

1

1

1

1

1

1

1

1

1

30-Apr-15

30-Apr-15

30-Apr-15

30-Apr-15

30-Apr-15

30-Apr-15

30-Apr-15

C

C

C

C

C

C

C

S

S

S

S

S

S

S

5.4

5.4.1

5.4.2

5.4.3

5.4.4

BILGE & BALLAST SYSTEM

Test E.R. bilge FWD high level alarm

Test E.R. bilge aft high level alarm

Test Steering bilge high level alarm

Test Sludge tank high level alarm

BILGE & BALLAST SYSTEM

Test E.R. bilge FWD high level alarm

Test E.R. bilge aft high level alarm

Test Steering bilge high level alarm

Test Sludge tank high level alarm

30/Mar/15

30/Mar/15

30/Mar/15

30/Mar/15

1

1

1

1

1

1

1

1

30-Apr-15

30-Apr-15

30-Apr-15

30-Apr-15

C

C

C

C

S

S

S

S

5.5

5.5.1

5.5.2

5.5.3

ADDITIONAL ALARMS

Test Fire alarm

Test Gas detector P.R

Test Fire detector alarm

ADDITIONAL ALARMS

Test Fire alarm

Test Gas detector P.R

Test Fire detector alarm

30/Mar/15

30/Mar/15

30/Mar/15

1

1

1

1

1

1

30-Apr-15

30-Apr-15

30-Apr-15

C

C

C

S

S

S

COMPLETE MAINTENANCE ITEM FOR

April-15

23

MAINTENANCE OVERDUE ITEM FOR

April-15

PERFORMANCE 100%

PMS TEST PROGRAM FOR

THIS MONTH

EXCELLENT

Summary of Overdue Maintenance

Reason

Remarks

May-15

2015

Jun-15

Jul-15

Jika set -point tidak sesuai dengan pengaturan sebelumnya sesuaikan kembali jika perlu.

Item Maintenance

: Completed Maintenance for This Month

If the set-point is not in accordance with the previous setting

readjust if necessary.

PMS

No.

THN

Observe the alarm lamp on the engine alarm panel. Check the Amati lampu alarm pada panel alarm mesin . Periksa

pressure gauge on the test equipment (pressure test pump)

pengukur tekanan pada alat uji ( tes tekanan pompa ) selama

during the test.

pengujian

5.2.5

: Scheduled Maintenance for Next Month

BLN

Symbol

April 2015

TGL

5.2.2

5.2.4

1 Of 2

Aug-15

Sep-15

Oct-15

Nov-15

Dec-15

PMS No.

Unit / System

Unit / System

PIC

Last Maint. Date

Chief Engineer

Running

Hours

Interval

Months Hours

Est. Next Due

Jan-15

Feb-15

Mar-15

Apr-15

May-15

Master

Date :

Written by :HST

Aug-15

Sep-15

Oct-15

Nov-15

Dec-15

Technical Superintendent

Date :

LF- E 035/DES 2012

2015

Jun-15

Jul-15

Date :

Approved by : VP / DPA

Retention Period : 1 Year

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Blaster's Handbook PDFDocument180 pagesBlaster's Handbook PDFsaiful100% (1)

- Diamond DA 42 Systems - V12 - 5clases 19 de JunioDocument402 pagesDiamond DA 42 Systems - V12 - 5clases 19 de JunioLiu Antonio Tang100% (1)

- RC2 Series Screw Compressor Maintenance ManualDocument161 pagesRC2 Series Screw Compressor Maintenance ManualMichele CassiniPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- FV 623 CatalogDocument50 pagesFV 623 CatalogOmar Coronado50% (2)

- Apelco Fishfinder 365Document83 pagesApelco Fishfinder 365Ivan Campione100% (1)

- PMS Checklist for OB LSBL XVIIIDocument5 pagesPMS Checklist for OB LSBL XVIIIalsitorPas encore d'évaluation

- Tec-B 028 Engine Room Critical Test B.indoDocument13 pagesTec-B 028 Engine Room Critical Test B.indoalsitorPas encore d'évaluation

- Damage report formDocument1 pageDamage report formalsitor0% (1)

- Corrosion Types and Prevention Methods in 40 CharactersDocument75 pagesCorrosion Types and Prevention Methods in 40 CharactersCipri Croitor0% (1)

- Vessel Name: TB SADP XXX Date Position Description Tested by Sensor AlarmDocument4 pagesVessel Name: TB SADP XXX Date Position Description Tested by Sensor AlarmalsitorPas encore d'évaluation

- Giignl Custody Transfer Handbook 6.0 - May 21 0Document195 pagesGiignl Custody Transfer Handbook 6.0 - May 21 0Александр КарташовPas encore d'évaluation

- Tata Cara PengisiDocument327 pagesTata Cara PengisialsitorPas encore d'évaluation

- Technical Superintendent Visit: Superintendent'S Detailed ReportDocument8 pagesTechnical Superintendent Visit: Superintendent'S Detailed ReportalsitorPas encore d'évaluation

- Fire Load CalculationDocument6 pagesFire Load CalculationGunvant Patel91% (11)

- MT FERY VII MAINTENANCE REPAIR REPORTDocument1 pageMT FERY VII MAINTENANCE REPAIR REPORTalsitorPas encore d'évaluation

- DECK MAINTENANCE SCHEDULE"MaxIntervalJanFebMarAprMayJunJulAugSepOctNovDec1mth1mth1mth3mths1mth6mthsas reqd1mth1mth1mth3mths1mth6mthsas reqd1mth3mths1yrDocument12 pagesDECK MAINTENANCE SCHEDULE"MaxIntervalJanFebMarAprMayJunJulAugSepOctNovDec1mth1mth1mth3mths1mth6mthsas reqd1mth1mth1mth3mths1mth6mthsas reqd1mth3mths1yralsitorPas encore d'évaluation

- Synchronization of GeneratorsDocument3 pagesSynchronization of Generatorsneo_nitinPas encore d'évaluation

- (782982478) Monthly Fuel, Lo Consumption Report - February 2016Document1 page(782982478) Monthly Fuel, Lo Consumption Report - February 2016alsitorPas encore d'évaluation

- Maintenance Plan Bg. TaisirDocument12 pagesMaintenance Plan Bg. TaisiralsitorPas encore d'évaluation

- Pms Deck Nasyda LinsoDocument21 pagesPms Deck Nasyda Linsoalsitor100% (1)

- Pms Deck Nasyda LinsoDocument21 pagesPms Deck Nasyda Linsoalsitor100% (1)

- Pms Engine Nasyda LinsoDocument12 pagesPms Engine Nasyda LinsoalsitorPas encore d'évaluation

- 2016.04.13 S30 - Monitoring ROB (Dumai-Merak)Document2 pages2016.04.13 S30 - Monitoring ROB (Dumai-Merak)alsitorPas encore d'évaluation

- Pms Engine Lintas Ix LinsoDocument27 pagesPms Engine Lintas Ix LinsoalsitorPas encore d'évaluation

- Pms Engine TB Fery 03 LinsoDocument15 pagesPms Engine TB Fery 03 LinsoalsitorPas encore d'évaluation

- Pms June @LSBL XviiiDocument32 pagesPms June @LSBL XviiialsitorPas encore d'évaluation

- Pms Deck TB Fery 03 LinsoDocument15 pagesPms Deck TB Fery 03 LinsoalsitorPas encore d'évaluation

- Croscheck PMS LSBL XIX Agustus 2015Document7 pagesCroscheck PMS LSBL XIX Agustus 2015alsitorPas encore d'évaluation

- Monthly work reportDocument11 pagesMonthly work reportalsitor100% (2)

- Tec-B 014 Running Hour Ae 1Document2 pagesTec-B 014 Running Hour Ae 1alsitorPas encore d'évaluation

- TB SADP XXX Exhaust Vent Emergency Stop Test RecordsDocument4 pagesTB SADP XXX Exhaust Vent Emergency Stop Test RecordsalsitorPas encore d'évaluation

- Technical Superintendent Visit: Superintendent'S Detailed ReportDocument8 pagesTechnical Superintendent Visit: Superintendent'S Detailed ReportalsitorPas encore d'évaluation

- Technical Superintendent Visit: Superintendent'S Detailed ReportDocument8 pagesTechnical Superintendent Visit: Superintendent'S Detailed ReportalsitorPas encore d'évaluation

- LF - e 012 Running Hour of GeneratorDocument2 pagesLF - e 012 Running Hour of GeneratoralsitorPas encore d'évaluation

- LF - e 011 Inventory Spare Parts JuliDocument1 pageLF - e 011 Inventory Spare Parts JulialsitorPas encore d'évaluation

- Standarisasi: Perawatan Generator AE (Cleaning) MT - Fery XVIDocument2 pagesStandarisasi: Perawatan Generator AE (Cleaning) MT - Fery XVIalsitorPas encore d'évaluation

- LF - e 011 Inventory Spare Parts JuliDocument1 pageLF - e 011 Inventory Spare Parts JulialsitorPas encore d'évaluation

- Monthly fuel and lube reportDocument1 pageMonthly fuel and lube reportalsitorPas encore d'évaluation

- Checklist Pms TB Tytyan Karimata 02Document3 pagesChecklist Pms TB Tytyan Karimata 02alsitorPas encore d'évaluation

- Ulei Honda Jazz 1.4i CVTDocument1 pageUlei Honda Jazz 1.4i CVTcmlad1Pas encore d'évaluation

- Westinghouse Manuals PDFDocument38 pagesWestinghouse Manuals PDFCarl HensonPas encore d'évaluation

- Caterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)Document28 pagesCaterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)kfsmmePas encore d'évaluation

- Durehete 1055Document5 pagesDurehete 1055alextentwenty100% (1)

- Unit One: Wind LoadsDocument67 pagesUnit One: Wind Loadsabdu yimerPas encore d'évaluation

- (Reprint From Handbuch Der Physik - Encyclopedia of Physics) R. N. Bracewell (Auth.) - Radio Astronomy Techniques-Springer-Verlag Berlin Heidelberg (1962)Document91 pages(Reprint From Handbuch Der Physik - Encyclopedia of Physics) R. N. Bracewell (Auth.) - Radio Astronomy Techniques-Springer-Verlag Berlin Heidelberg (1962)garfacio30Pas encore d'évaluation

- CHEMISTRY MID-TERM ASSESSMENTDocument12 pagesCHEMISTRY MID-TERM ASSESSMENTRamana PadalaPas encore d'évaluation

- Squashing Commits with RebaseDocument4 pagesSquashing Commits with RebaseDavid BeaulieuPas encore d'évaluation

- Materials System SpecificationDocument8 pagesMaterials System Specificationnadeem shaikhPas encore d'évaluation

- Sewing 04-Needle Class 118 of Groz-Beckert For Union Special FlatseamersDocument6 pagesSewing 04-Needle Class 118 of Groz-Beckert For Union Special Flatseamersfriendztoall4351Pas encore d'évaluation

- SyllabusDocument2 pagesSyllabusjackychen101Pas encore d'évaluation

- Last Name, First CHE426:: F C V C V C F + F F CDocument6 pagesLast Name, First CHE426:: F C V C V C F + F F Clợi trầnPas encore d'évaluation

- UNIT 1 PPT Satellite CommunicationDocument34 pagesUNIT 1 PPT Satellite Communicationselvi100% (1)

- Classification of Breast Cancer Histopathological ImagesDocument20 pagesClassification of Breast Cancer Histopathological Imagesdolar singhPas encore d'évaluation

- Slope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060Document20 pagesSlope Stability Then and Now: Professor Emeritus, Virginia Tech, 1600 Carlson DR., Blacksburg, VA, 24060anarPas encore d'évaluation

- Banyule Standard DrawingsDocument103 pagesBanyule Standard DrawingsTarek AbulailPas encore d'évaluation

- Ansi/Ashrae/Ies Standard 90.1-2013 HVAC: Building Energy CodesDocument146 pagesAnsi/Ashrae/Ies Standard 90.1-2013 HVAC: Building Energy CodesLeong Ion ChunPas encore d'évaluation

- Vend RegDocument49 pagesVend RegProcaeHexdofPas encore d'évaluation

- 567 MSDSDocument3 pages567 MSDSPete DechaPas encore d'évaluation

- Unit 2 - EDDocument42 pagesUnit 2 - EDMohit L.E. 008Pas encore d'évaluation

- Traffic Engineering Bachelor of Science in Civil EngineeringDocument22 pagesTraffic Engineering Bachelor of Science in Civil EngineeringDaisy AstijadaPas encore d'évaluation