Académique Documents

Professionnel Documents

Culture Documents

Pump SPI PDF

Transféré par

RaghDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Pump SPI PDF

Transféré par

RaghDroits d'auteur :

Formats disponibles

SPI

Heavy Duty Vertical

Inline API 610

Process Pump

Ruhrpumpen is an innovative and efficient centrifugal pump technology

company and offers operators of Pump Systems, a wide range of quality

products.

Ruhrpumpen is committed to global excellence with a complete range of Pumps, Fire Pump packages and related products,

such as Decoking Systems and Tools to support the core markets, namely Oil & Gas, Petrochemical, Power, Heavy Industry

applications, Mining and Water services.

The broad product line complies with the most demanding quality specifications and go beyond stringent industry standards

such as API, ANSI, Hydraulic Institute, Underwriters Laboraties, Factory Mutual and ISO 9001.

Ruhrpumpens quality program and in-house foundry, along with the latest testing equipment, ensures that the pumps we

manufacture will provide long operating life, even under the most severe conditions.

SPI Pumps

Intensive research and development ensures that the

products of Ruhrpumpen are continuously improved to

meet the latest technical requirements.

The SPI is a vertical inline, single stage, single suction

centrifugal pump accordance to API 610, 8th Edition

with mechanical seal chamber in accordance with API

682.

It is only possible to achieve these aims by means of highly

sophisticated CNC controlled machines in our modern

machine shop, supplemented by our test and development

departments as well as the latest industry standard

inspection and control procedures. All in our ISO 9001

certified facilities. The application of modern, reliable

methods, data processing and sophisticated software with

high performance, state of the art IT offers our customers

high reliability and speed in all working processes, from

planning and production to the providing of spare parts.

The pump is suitable for being directly mounted into the

piping without the need of a foundation.

The SPI pumps are designed to handle a wide range of

process fluids and has one of the broadest hydraulic

coverages in the industry.

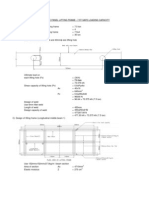

Selection Chart SPI

Qualified specialists in all departments ensure that the

pumps and equipment from our facilities are able to

operate under the most severe conditions.

Selection Chart

SPI Various Poles

50 Hz

TOTAL HEAD

ft

ft

9 11

15 19

28

38

57

76

114

189

284 m/h

9 11 14

18 23

34 45

68

91

136

227

341 m/h

m

694

1000

305

212

556

417

800

600

244

183

169

127

347

278

500

400

152

122

106

85

64

208

300

91

139

200

61

42

104

150

46

32

69

56

100

80

30

24

21

17

42

35

28

14

0

60

50

40

20

0

18

15

12

6

0

13

11

8

4

0

10

20

30

40 50 60

80 100

150 200

300 400

600

1000

1500 gpm

17

25

33 42 50

67 83

125 167

250 333

500

833

1250 gpm

FLOW

60 Hz

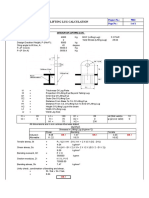

Heavy Duty Vertical In-Line

API 610 Process Pump

Characteristics

1

2

BEARINGS

Antifriction bearings are

designed with a

minimum B10 life of

25,000hr. Double

angular contact bearings

are available for high

suction pressure

applications

SEAL

Mechanical

seal chamber

dimensions in full

compliance with

API 610 and API 682

Description

SHAFT

Large shaft design results in

deflections at the mechanical

seal less than 0.002 in. This

results in maximized seal life

and minimized vibrations

ensuring a long lasting,

smooth running pump

Heavy Duty Vertical In-Line

Heavy duty process design according to API 610

latest edition (OH3 type)

Vertical arrangement

Process design

Radially split, vertical inline centrifugal pump

Single stage

Separate bearing frame

Single suction, dynamically balanced, closed

impeller.

Foot mounted

Single & Double volute casings, depending on size

Thrust compensation by balance holes.

Side-Side inline nozzle arrangement.

Other materials on request.

Design Features

Heavy duty process design according to API 610 latest

edition (OH3 type).

Separate bearing bracket to absorb all pump thrusts.

Replaceable wear rings for casing and impeller.

SIZE

19 pump sizes

from 1 1/2 to

8 discharge

nozzles. Built

in accordance

with API 610,

8th Edition.

CASING

Double volute casings

are standard for sizes

greater than 3

nozzles.(except

4x4x12 & 4x4x15

are single volute)

SPI

Applications

Petroleum Refining

Production and Distribution

Petrochemical

Chemical

Process Industry

SUPPORT

Foundation support

is possible with the

integral foot-plate

*Images for general arrangement use only, not certified for construction.

SPI Performance Data

Capacity

Head

Speed

Temperature

MAWP

2.5 to 615 m3/h

15 to 290 m

up to 3600 RPM

up to 260 C

up to 40 bar

11 to 2,700 U.S. gpm

52 to 950 ft

500 F

600 psi

Note: For Pump operation outside this range, please

contact a Ruhrpumpen representative.

Ruhrpumpen Plants

International service and support

USA, TULSA & ORLAND

MEXICO, MONTERREY

BRAZIL, RIO DE JANEIRO

ARGENTINA, BUENOS AIRES

RP-BR-SPI-EN-V1-130819

GERMANY, WITTEN

EGYPT, SUEZ

INDIA, CHENNAI

CHINA, CHANGZHOU

More Information:

August.13

www.ruhrpumpen.com

Vous aimerez peut-être aussi

- Application Edge-MV VFDs Acceptance TestingDocument3 pagesApplication Edge-MV VFDs Acceptance TestingThọ NguyễnPas encore d'évaluation

- Ro-Flo Iom Manual EngDocument52 pagesRo-Flo Iom Manual EngSlamet Purwadi S.T100% (1)

- AISC Design Guide 33 Curved Member Design 2018Document166 pagesAISC Design Guide 33 Curved Member Design 2018saital92% (12)

- CP HorizontalDoubleCasing E00609Document5 pagesCP HorizontalDoubleCasing E00609douglas marcanoPas encore d'évaluation

- Electrical Equipment ListDocument12 pagesElectrical Equipment ListShadab WaseemPas encore d'évaluation

- Pipe Stress Analysis Tutorial: Basic ConceptsDocument32 pagesPipe Stress Analysis Tutorial: Basic ConceptsRene RenanPas encore d'évaluation

- Catalogo PNRDocument115 pagesCatalogo PNRKaren Isabel Ambiado RivasPas encore d'évaluation

- Goulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610Document40 pagesGoulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610sebasPas encore d'évaluation

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)

- Engineers Guide To Shaft AllignmentDocument0 pageEngineers Guide To Shaft AllignmentnasirfahimPas encore d'évaluation

- IEE On-Site GuideDocument179 pagesIEE On-Site GuideMahmud Sied100% (5)

- 3DG-P45-00001 (Pipe Stress Analysis 190)Document33 pages3DG-P45-00001 (Pipe Stress Analysis 190)Ali Metin100% (1)

- Grundfos PumpsDocument120 pagesGrundfos PumpsNaser TahaPas encore d'évaluation

- Astm B725 - 1993Document5 pagesAstm B725 - 1993Teymur RegenmaisterPas encore d'évaluation

- BS-2654 1989 Design Standard For Vert Steel Welded Storage TanksDocument103 pagesBS-2654 1989 Design Standard For Vert Steel Welded Storage TanksAndrew Ko100% (2)

- SEALDocument6 pagesSEALkishorsinghPas encore d'évaluation

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalPas encore d'évaluation

- Strength Calculation For PlatformDocument2 pagesStrength Calculation For PlatformRaghPas encore d'évaluation

- STEAM TRACING Engineering - Guide PDFDocument0 pageSTEAM TRACING Engineering - Guide PDFkresimir.mikoc9765Pas encore d'évaluation

- Weld WeightDocument10 pagesWeld WeightDivyesh PatelPas encore d'évaluation

- Rectangular TankDocument6 pagesRectangular TankEsapermana RiyanPas encore d'évaluation

- A User's Guide To Spray NozzlesDocument29 pagesA User's Guide To Spray NozzlesBilly Hagantha SembiringPas encore d'évaluation

- Lifting FrameDocument8 pagesLifting FrameSaravanan SKPas encore d'évaluation

- 21TXVLVC Valve Top Valve Control SolutionDocument43 pages21TXVLVC Valve Top Valve Control Solutionmgkvpr100% (1)

- Engineering Standard Specification For Steam TracingDocument53 pagesEngineering Standard Specification For Steam Tracingkaruna346100% (1)

- Flowserve Erpn PDFDocument8 pagesFlowserve Erpn PDFJaluk 1zinPas encore d'évaluation

- Smaw and Tig WeldingDocument46 pagesSmaw and Tig WeldingRajesh Kumar Ravi100% (1)

- Inspection and Test Plan: Contract NoDocument2 pagesInspection and Test Plan: Contract NoAhmed Samir SalimPas encore d'évaluation

- The Study of A Centrifugal Pump Impeller by Varying The Outlet Blade AngleDocument29 pagesThe Study of A Centrifugal Pump Impeller by Varying The Outlet Blade Anglevamshimurali.07310017Pas encore d'évaluation

- 7977 8cd2Document2 pages7977 8cd2Pete Pompes0% (1)

- Tank ErectionDocument13 pagesTank Erectionsajay2010Pas encore d'évaluation

- Lifting Lug - Skid - 2018.07.16Document4 pagesLifting Lug - Skid - 2018.07.16RaghPas encore d'évaluation

- API 685 BrochureDocument8 pagesAPI 685 BrochureDenar PurnamaPas encore d'évaluation

- CFDforCentrifugalPumpsA Review PDFDocument6 pagesCFDforCentrifugalPumpsA Review PDFAnonymous K48TgviPas encore d'évaluation

- A Look at Centrifugal Pump Suction Hydraulic - Part 1Document4 pagesA Look at Centrifugal Pump Suction Hydraulic - Part 1Said Ahmed SalemPas encore d'évaluation

- Pump SCE B 2Document8 pagesPump SCE B 2Zankar R ParikhPas encore d'évaluation

- MSRODocument1 pageMSROAjay ChodankarPas encore d'évaluation

- Design Considerations Orifice Plate 1590507843 PDFDocument5 pagesDesign Considerations Orifice Plate 1590507843 PDFmanansudiPas encore d'évaluation

- 1 Introduction To Bridge EngineeringDocument46 pages1 Introduction To Bridge EngineeringRYAN JOSEPH QUIMOPas encore d'évaluation

- Technical SpecificationDocument6 pagesTechnical Specificationjimboy_123Pas encore d'évaluation

- 799 AaDocument106 pages799 AabondsivamaniPas encore d'évaluation

- Wind Turbine Fire ProtectionDocument26 pagesWind Turbine Fire ProtectionAsif MohammedPas encore d'évaluation

- Profile of the International Pump Industry: Market Prospects to 2010D'EverandProfile of the International Pump Industry: Market Prospects to 2010Évaluation : 1 sur 5 étoiles1/5 (1)

- SFS Products BrochureDocument14 pagesSFS Products BrochureJoshuaPas encore d'évaluation

- Herematic Pumps - CNP - CNPF - CNPKDocument16 pagesHerematic Pumps - CNP - CNPF - CNPKdineshanbalaganPas encore d'évaluation

- BRE Specifying Structural TimberDocument9 pagesBRE Specifying Structural Timberalberto5791Pas encore d'évaluation

- Spirajet Spray NozzleDocument2 pagesSpirajet Spray NozzleykozePas encore d'évaluation

- OutoKumpu SS Pipe-2010Document124 pagesOutoKumpu SS Pipe-2010ahmedalishPas encore d'évaluation

- PST - F5 - AM - F-500 Fire Suppression MechanicsDocument39 pagesPST - F5 - AM - F-500 Fire Suppression MechanicsDSGPas encore d'évaluation

- API 610 PumpsDocument8 pagesAPI 610 PumpsSaurabh Singh67% (3)

- Angus MonitorsDocument16 pagesAngus Monitorsmuhammadtayyab_87Pas encore d'évaluation

- Bomba CPKDocument20 pagesBomba CPKPatricio Andres Silva SanzanaPas encore d'évaluation

- 600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)Document8 pages600 Hand Tube Bender Instruction Sheet: (Figure 3) (Figure 4) (Figure 5)LeonardPas encore d'évaluation

- bb1 CatDocument7 pagesbb1 CatrohituchaniPas encore d'évaluation

- DNV Offshore Wind Seminar Poland - IC - tcm144-460298Document9 pagesDNV Offshore Wind Seminar Poland - IC - tcm144-460298Juan CarlosPas encore d'évaluation

- Goulds 3910 BulletinDocument12 pagesGoulds 3910 BulletinlubangjarumPas encore d'évaluation

- ASABE Spray Droplet Sizing BasicsDocument35 pagesASABE Spray Droplet Sizing BasicssaeedkheiratiPas encore d'évaluation

- Check List For FiCheck List For Fire Protection Planre Protection PlanDocument4 pagesCheck List For FiCheck List For Fire Protection Planre Protection Planismail_gdiPas encore d'évaluation

- PB09FGe WS 10n-CAFS 07.2014 PDFDocument2 pagesPB09FGe WS 10n-CAFS 07.2014 PDFNarendra Reddy BhumaPas encore d'évaluation

- Skum Silv-Ex G F201132 - FDS14121 0214 LR PDFDocument2 pagesSkum Silv-Ex G F201132 - FDS14121 0214 LR PDFAhmed El Sayed SalamaPas encore d'évaluation

- Direct Contact Desuperheaters TI-P475-01Document9 pagesDirect Contact Desuperheaters TI-P475-01LucasZanaPas encore d'évaluation

- Portable Foam Applicator Set Technical Data and InstructionsDocument4 pagesPortable Foam Applicator Set Technical Data and InstructionsMaksym KovalPas encore d'évaluation

- General Features of Cfturbo: Useful For Impeller, Stator & Volute DesignDocument11 pagesGeneral Features of Cfturbo: Useful For Impeller, Stator & Volute DesignPrakash KhavasadPas encore d'évaluation

- ACAF Fire Suppression BrochureDocument4 pagesACAF Fire Suppression Brochure1029384765qazwsxPas encore d'évaluation

- Arup Renewable Energy BrochureDocument6 pagesArup Renewable Energy BrochuretangoquebecPas encore d'évaluation

- Cfturbo-Pumps en PDFDocument2 pagesCfturbo-Pumps en PDFsugiantobarusPas encore d'évaluation

- Machines by Webster)Document4 pagesMachines by Webster)dadajee420100% (2)

- PD763 Centrifugal Pumps: Testing, Design and Analysis Day OneDocument2 pagesPD763 Centrifugal Pumps: Testing, Design and Analysis Day OneshanatokiPas encore d'évaluation

- Jhonson PumpsDocument8 pagesJhonson PumpsortegaroberPas encore d'évaluation

- Yamada APDD Eng Handbk PDFDocument152 pagesYamada APDD Eng Handbk PDFAnas BENCHIKHPas encore d'évaluation

- A Very High Head PumpDocument11 pagesA Very High Head Pumphary100% (1)

- Actuadores Rotork IQ PDFDocument44 pagesActuadores Rotork IQ PDFAlexis YáñezPas encore d'évaluation

- Dawson Downie Lamont LTDDocument2 pagesDawson Downie Lamont LTDwarehouse cikalongPas encore d'évaluation

- OHH OHHL E00697 (Pump Zulzer)Document6 pagesOHH OHHL E00697 (Pump Zulzer)Jose Sosa CojPas encore d'évaluation

- 3.2 Atex GLRD enDocument19 pages3.2 Atex GLRD enatenciaj100% (1)

- Part Number PDFDocument6 pagesPart Number PDFana_mondekarPas encore d'évaluation

- High-performance YASKAWA A1000 HHP AC drive features compact designDocument32 pagesHigh-performance YASKAWA A1000 HHP AC drive features compact designJosé María Rodríguez Rivera100% (1)

- 10.piston CylinderDocument19 pages10.piston Cylinderprihartono_diasPas encore d'évaluation

- VS 6 - FlowserveDocument8 pagesVS 6 - FlowserveJung Jae YualPas encore d'évaluation

- Pw610 Pwi BBDocument2 pagesPw610 Pwi BBAbdulPas encore d'évaluation

- RuhrpumpenDocument4 pagesRuhrpumpenBenicio Joaquín Ferrero BrebesPas encore d'évaluation

- Sffeco Cps Ul Listed Horizontal Split Case and End Suction PDocument48 pagesSffeco Cps Ul Listed Horizontal Split Case and End Suction PAbdul Moeed Hasan100% (1)

- Ps 40 9 eDocument8 pagesPs 40 9 eManuel De LeonPas encore d'évaluation

- ITT Oil Gas Bulletin PDFDocument12 pagesITT Oil Gas Bulletin PDFsamix999Pas encore d'évaluation

- Heinkel Flyer Classifying Centrifuge v630 BK TiocentDocument2 pagesHeinkel Flyer Classifying Centrifuge v630 BK TiocentRaghPas encore d'évaluation

- Centrifuges For The Chemical IndustryDocument4 pagesCentrifuges For The Chemical IndustrypintaratPas encore d'évaluation

- Tutorial Motor Basics Lecture PDFDocument23 pagesTutorial Motor Basics Lecture PDFBenjaminas OrlovasPas encore d'évaluation

- Pressure Vessel HandBook Megyesy11th EdDocument247 pagesPressure Vessel HandBook Megyesy11th EdRaghPas encore d'évaluation

- Ro-Flo BrochureDocument4 pagesRo-Flo BrochureRaghPas encore d'évaluation

- Ro-Flo Packaging Guidelines ENG PDFDocument42 pagesRo-Flo Packaging Guidelines ENG PDFRaghPas encore d'évaluation

- Specs For Aluminum Geodesic Batten Domes 2012Document5 pagesSpecs For Aluminum Geodesic Batten Domes 2012RaghPas encore d'évaluation

- Methodology For RepairsDocument1 pageMethodology For RepairsRaghPas encore d'évaluation

- TycoDocument69 pagesTycog4goharPas encore d'évaluation

- Apt 60928 Evs TM 08 1Document108 pagesApt 60928 Evs TM 08 1Mohan JhaPas encore d'évaluation

- Hi-T Pigalert LiteratureDocument2 pagesHi-T Pigalert LiteratureRaghPas encore d'évaluation

- Methodology For RepairsDocument2 pagesMethodology For RepairsTaufik WhaePas encore d'évaluation

- Hi-T Pigalert IOM ManualDocument14 pagesHi-T Pigalert IOM ManualRaghPas encore d'évaluation

- Apt 60928 Evs TM 08 1Document108 pagesApt 60928 Evs TM 08 1Mohan JhaPas encore d'évaluation

- Sweco CatDocument21 pagesSweco CatArmandoZacariasAcostaPas encore d'évaluation

- Design of ring foundation for 18m diameter tankDocument6 pagesDesign of ring foundation for 18m diameter tankSher AfganPas encore d'évaluation

- Cara Perhitungan Air HeaterDocument1 pageCara Perhitungan Air HeaterfitratulqadriPas encore d'évaluation

- Power System Operation and Control Question BankDocument39 pagesPower System Operation and Control Question BankBenny MtmPas encore d'évaluation

- Time Table TybcsDocument2 pagesTime Table Tybcspratik wawarePas encore d'évaluation

- AMMJ Knowledge Centre Past Issue SummariesDocument4 pagesAMMJ Knowledge Centre Past Issue SummarieslisahunPas encore d'évaluation

- JESAUN - Volume 42 - Issue No 5 - Pages 1179-1192Document14 pagesJESAUN - Volume 42 - Issue No 5 - Pages 1179-1192Mohamed HassanPas encore d'évaluation

- Loyalist College Program Availability List For JAN - 2023 Intake 240522Document6 pagesLoyalist College Program Availability List For JAN - 2023 Intake 240522Jayrajsinh ParmarPas encore d'évaluation

- Noticias ABB Breakers y MedicionDocument68 pagesNoticias ABB Breakers y MedicionRonald Suriaga AuthemanPas encore d'évaluation

- New 3Document3 pagesNew 3Anonymous Ub9nEDlPas encore d'évaluation

- Progress Report 3: Department of Electrical Engineering College of EngineeringDocument15 pagesProgress Report 3: Department of Electrical Engineering College of EngineeringPunithan Ravichandran0% (1)

- Concrete Column and Footing Reinforcement DetailsDocument1 pageConcrete Column and Footing Reinforcement DetailsAmr HalabyPas encore d'évaluation

- 01 GCB History enDocument25 pages01 GCB History enInsan AzizPas encore d'évaluation

- Pricing List (E-Flex) 20190917 PDFDocument7 pagesPricing List (E-Flex) 20190917 PDFUserSMTPas encore d'évaluation

- Math156 Ie Feb 2019Document7 pagesMath156 Ie Feb 2019Josef CatiggayPas encore d'évaluation

- CE318-Final Exam F2012 - Practice Problems Set 2Document6 pagesCE318-Final Exam F2012 - Practice Problems Set 2mikePas encore d'évaluation

- Singapore Expansion Project: Bill of Material Sketch ListDocument1 pageSingapore Expansion Project: Bill of Material Sketch ListLocus Jhun MichaelPas encore d'évaluation

- BT NOTES For 2020Document3 pagesBT NOTES For 2020Ma. Bianca Isabelle S. GoPas encore d'évaluation

- 8th Semester CivilDocument10 pages8th Semester CivilsaadkhalisPas encore d'évaluation

- OHSAS Project Group Survey Results for OH&S Standards and CertificatesDocument79 pagesOHSAS Project Group Survey Results for OH&S Standards and CertificatesAntony LouisPas encore d'évaluation

- GFF - Flat Roof PDFDocument19 pagesGFF - Flat Roof PDFSêlva AvlêsPas encore d'évaluation